Piston ring automatic repairing machine tool

An automatic technology for piston rings, which is applied in the field of automatic piston ring repairing machine tools, can solve the problems of difficult machining accuracy, complex structure of the hydraulic push mechanism, and inability to control the progress of the push well, so as to achieve accurate machining accuracy, good control, and good The effect of driving progress

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

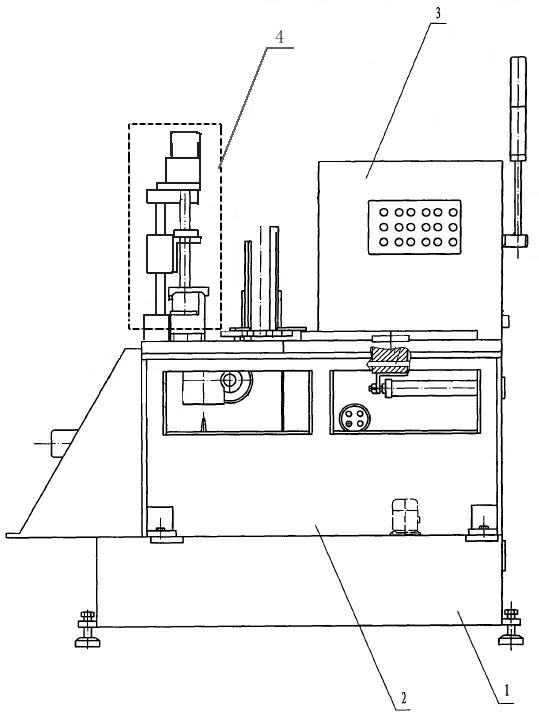

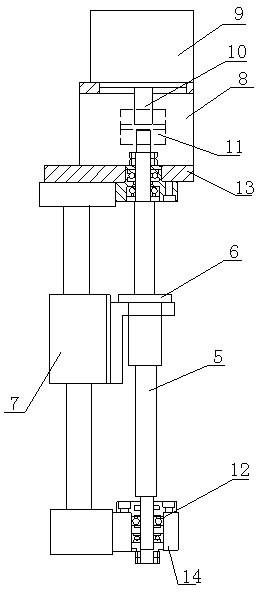

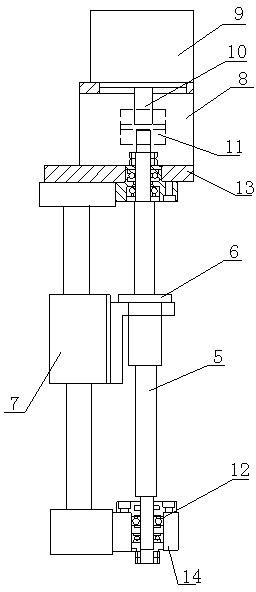

[0011] like figure 1 and 2 As shown, the automatic piston ring repairing machine tool of the present invention includes a base 1, a frame 2 fixed on the base 1, an electrical control box 3 fixed on the frame 2, and a pushing mechanism 4, and the pushing mechanism 4 includes a ball screw 5. Lead screw sleeve 6, lead screw bracket 7, transmission 8 and motor 9, motor 9 is connected with the motor connection shaft 10 in the transmission 8, and the motor connection shaft 10 is connected to the ball screw through the connection block 11 in the transmission 8 5, the upper end is connected, the upper end of the ball screw 5 is fixed on the transmission base 13 through the bearing 12, the screw cover 6 is sleeved on the ball screw 5, and the lower end of the ball screw 5 is fixed on the fixing seat 14 through the bearing 12, and the fixing seat 14 is connected with the bottom of the lead screw support 7, the middle part of the lead screw support 7 is connected with the lead screw cov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com