Forming method of iron core for movable iron unit

A molding method and iron core technology, applied in electrical components, sensors, etc., can solve the problems of difficult processing, high processing cost, and difficult to ensure processing accuracy, and achieve the effect of simple processing process, low processing cost, and guaranteed processing accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

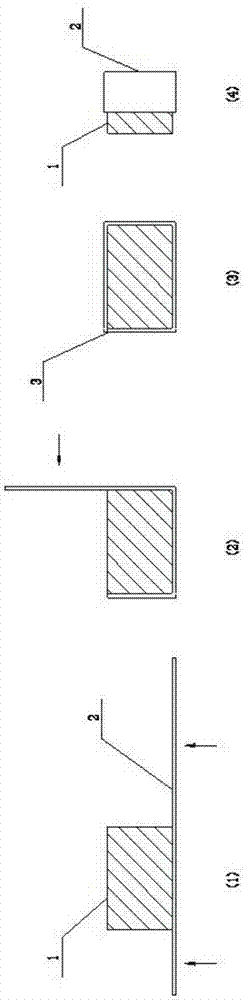

[0028] combine figure 1 As shown, the forming method of the iron core for the moving iron unit in the present embodiment may further comprise the steps:

[0029] (1) Prepare a piece of material 2 and a mold of kernels 1:

[0030] The length of the strip 2 is equal to the circumference and width of the outer ring of the iron core to be processed, and the width is equal to the axial length of the iron core to be processed, and the circumference of the outer ring of the mold core 1 is equal to the circumference and height of the inner ring of the iron core to be processed It is equal to the height of the inner ring of the iron core to be processed, and the axial length is at least equal to the axial length of the iron core to be processed;

[0031] (2) Punch the strip 2 through the punching equipment:

[0032] The mold core 1 is placed on the strip material 2, and the distance from it to one end of the strip material 2 is equal to the height of the mold core 1, and the strip ma...

Embodiment 2

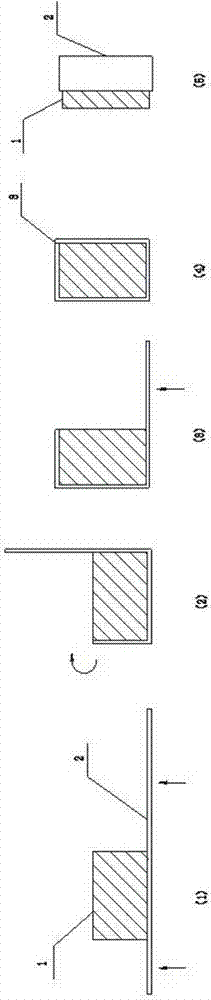

[0037] combine figure 2 As shown, the forming method of the iron core for the moving iron unit in this embodiment includes the same content as that of Embodiment 1, the difference lies in the included step 2), and this step 2) is: the mold core 1 is placed on the strip 2, the distance from one end of the strip 2 is equal to the height of the mold core 1, and the strip 2 is placed between the upper and lower molds of the punching equipment, such as figure 2 As indicated by the arrow, the two punching heads on the lower die punch the strip 2 along the mold core 1, and then turn the strip 2 and the mold core 1 by 90° through a turning device, and one punching head on the lower die continues Along the mold core 1 pair of strips 2 punching.

Embodiment 3

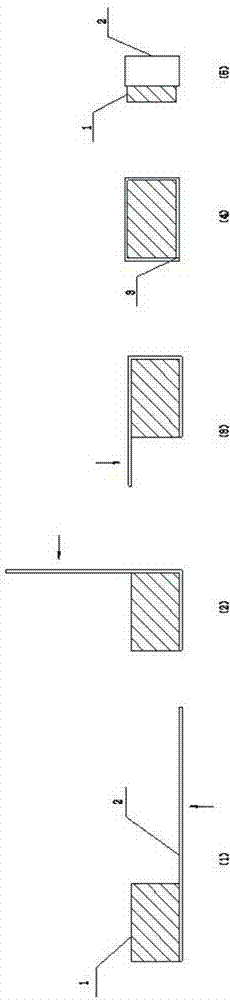

[0039] combine image 3 As shown, the forming method of the iron core for the moving iron unit in this embodiment includes the same content as that of Embodiment 1, the difference lies in the included step 2), and this step 2) is: the mold core 1 is placed on the strip 2, place the strip 2 between the upper and lower molds of the punching equipment, such as image 3 As indicated by the middle arrow, a punching head on a die in the lower die punches a pair of strips 2 along the core 1, and then places the strip 2 between a set of left and right dies perpendicular to the upper and lower dies , a punching head on the right die punches a pair of strips 2 along the mold core, and finally puts the strip 2 between the upper and lower dies, and a punching head on the upper die along the mold core 1 pair of strips Material 2 punching.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com