Novel crankshaft used for engine

An engine and crankshaft technology, applied in the field of crankshafts with a new structure, can solve the problems of large total length of the crankshaft, bending and torsional rigidity, etc., and achieve the effects of shortening the overall length, precise machining accuracy, and improving rigidity and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

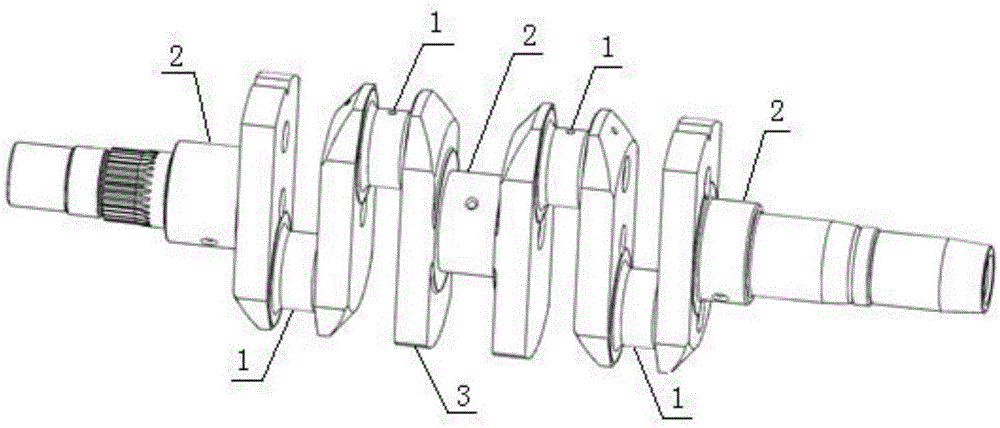

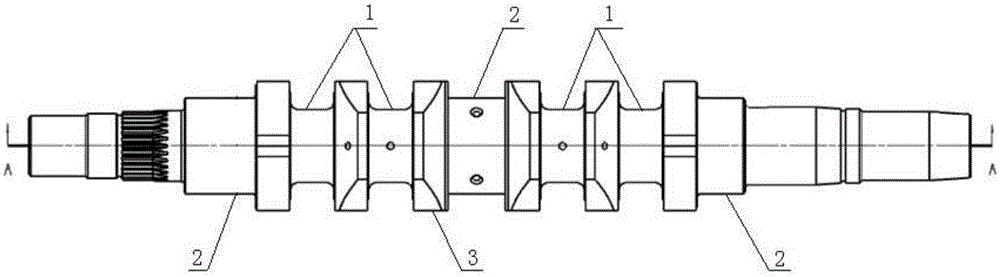

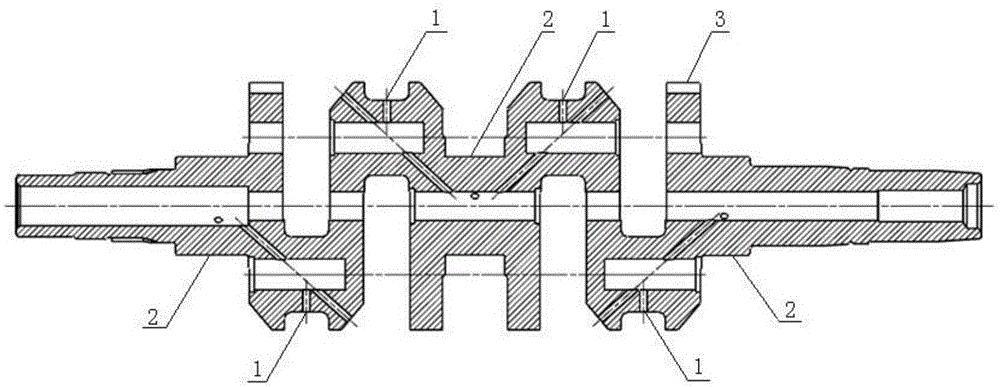

[0019] The present invention will be further described below in conjunction with the accompanying drawings.

[0020] as attached Figure 1-4 As shown, a new type of crankshaft for an engine includes front and rear main shaft supports 2 arranged at both ends of the crank shaft rod, and at least two bellcrank units connected by the main shaft supports 2 are arranged between the front and rear main shaft supports 2 , in this embodiment, there are two crank units; the crank unit includes three cranks 3 arranged in parallel, and the cranks 3 are made of an elliptical structure; cranks 1 are arranged between the cranks 3, that is, each Each bellcrank unit is provided with two bellcranks 1, and the centers of the two adjacent bellcranks 1 are respectively arranged at the upper and lower ends of the crank 3.

[0021] Wherein, the number ratio of crank throws and main shaft supports is n:n-1. In this embodiment, the crankshaft is provided with two crank throw units, the total number ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com