Patents

Literature

38results about How to "Accurate drilling positioning" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

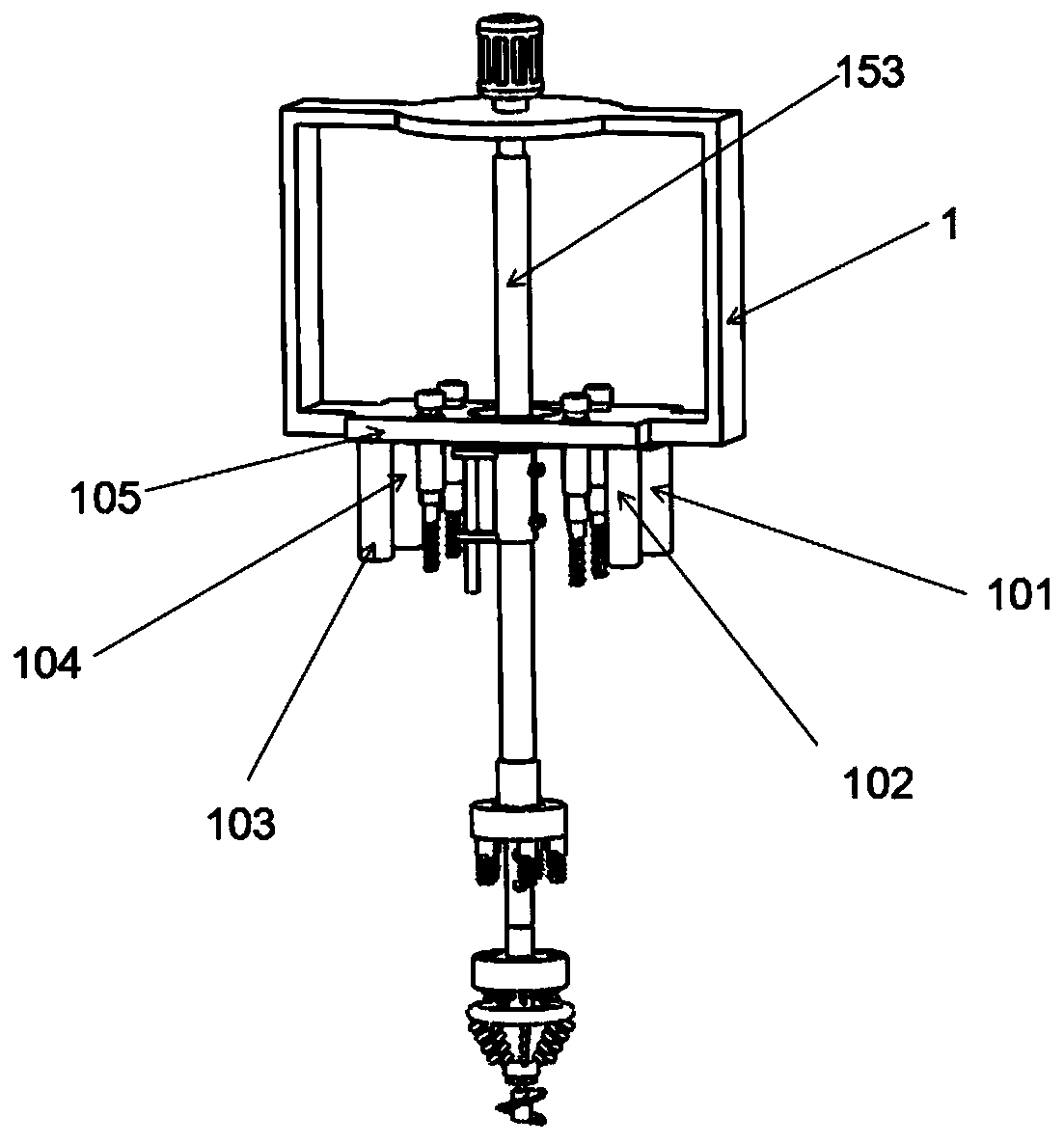

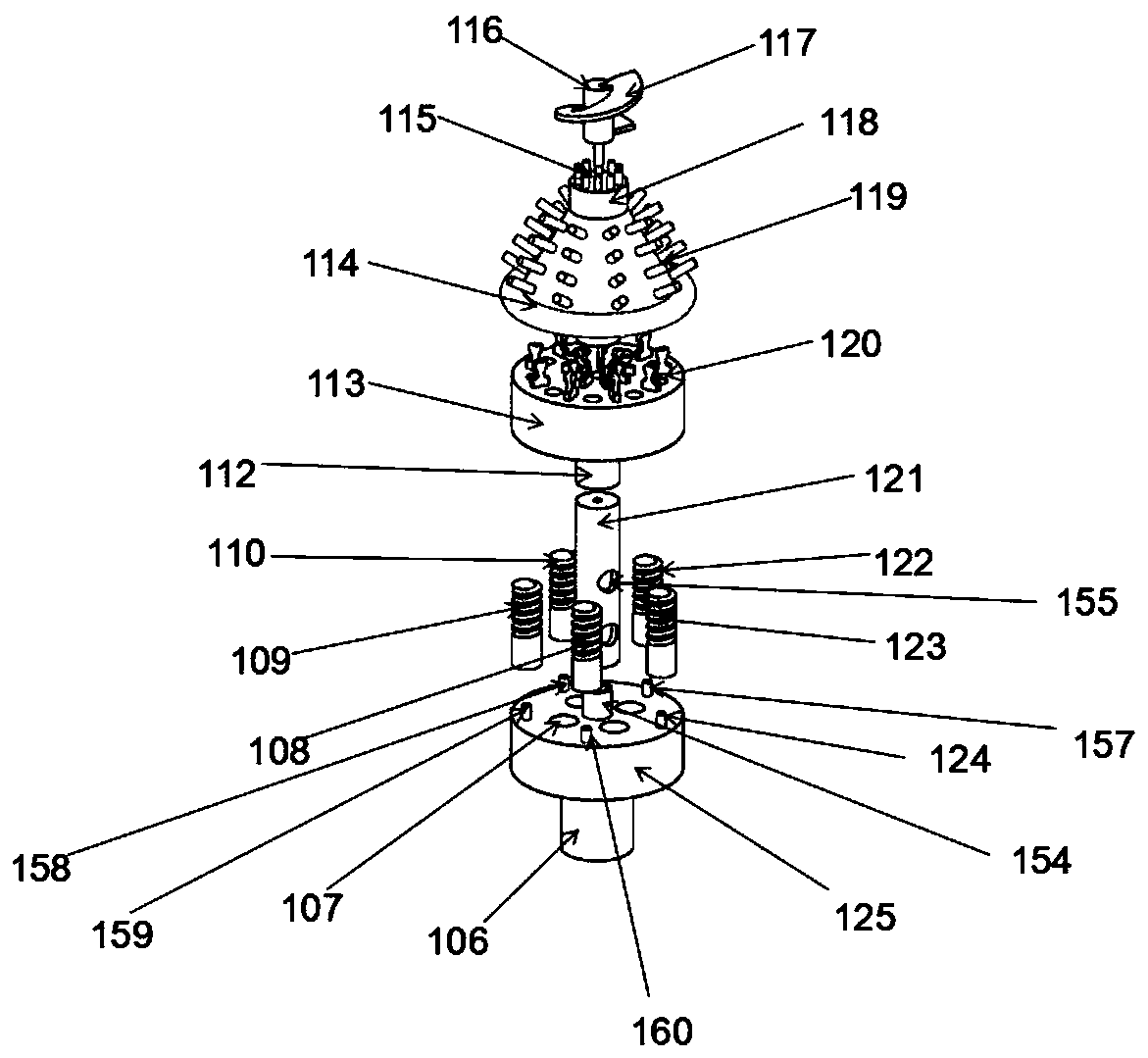

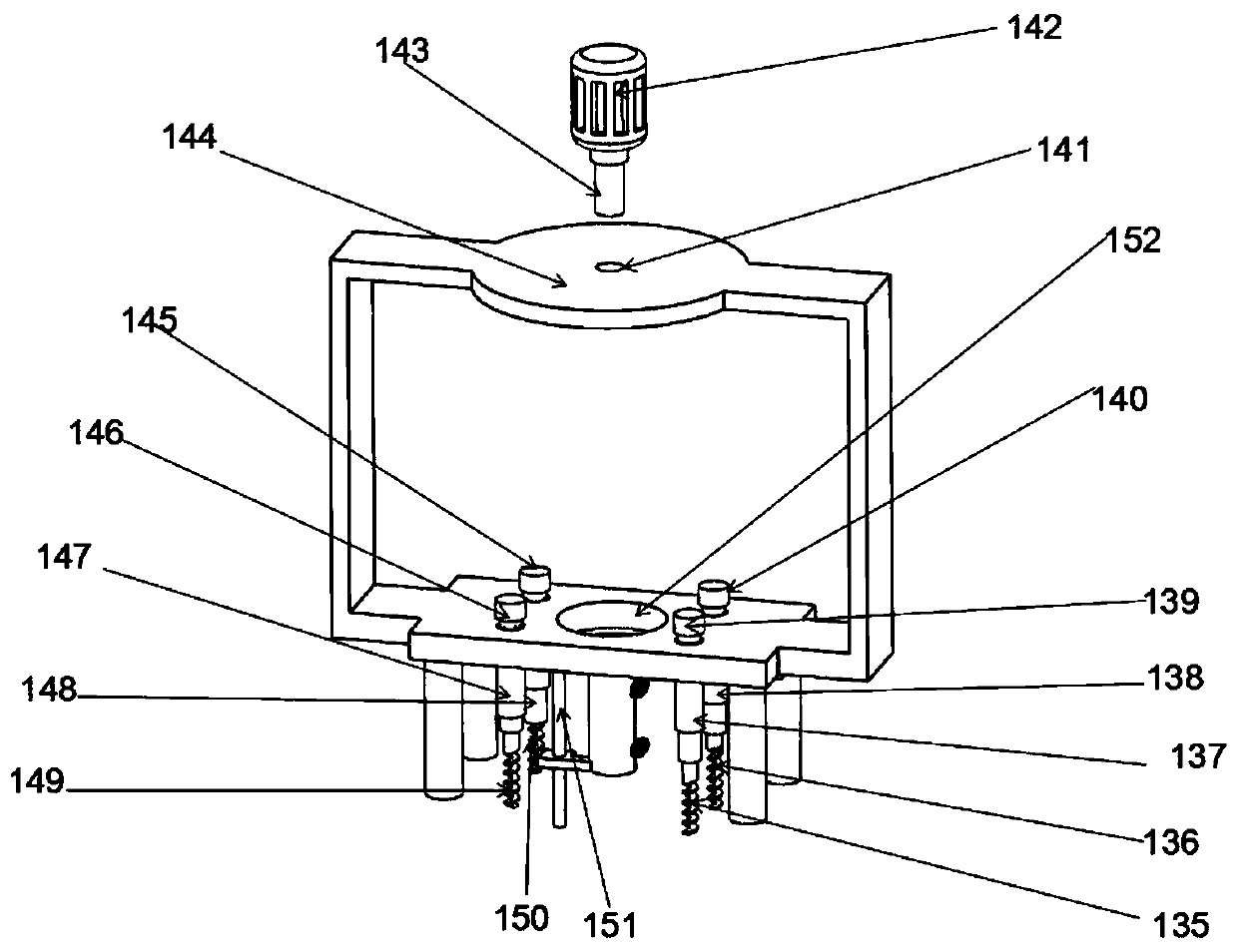

Multifunctional micropile drilling machine

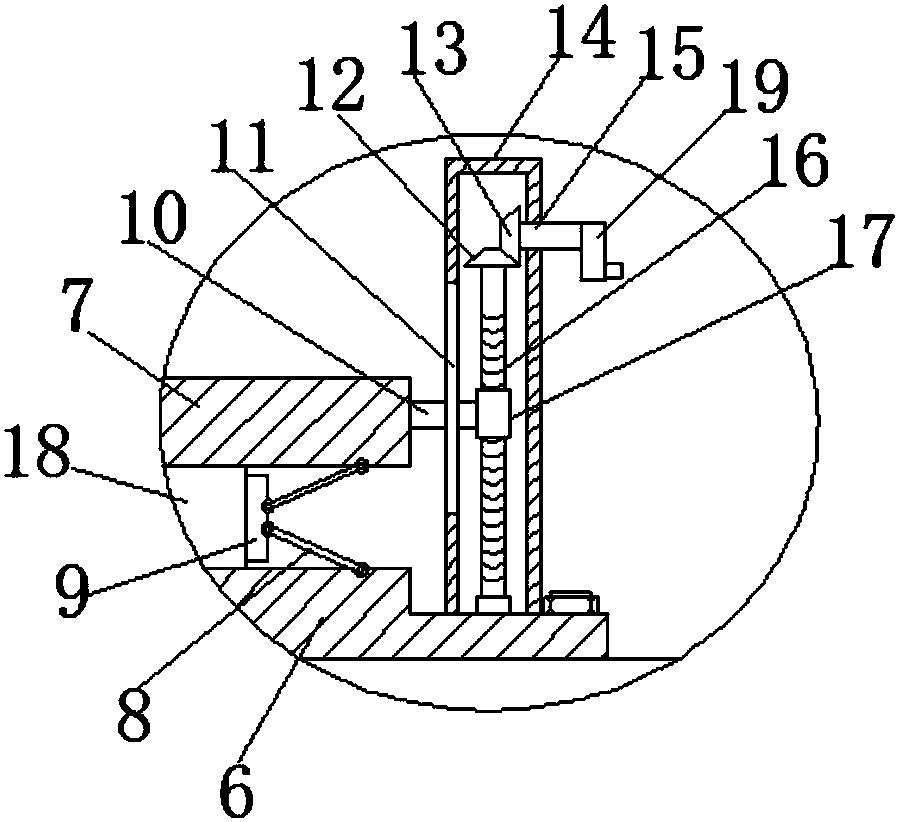

The invention discloses a multifunctional micropile drilling machine, comprising a base plate, a platform which is fixed on the base plate, a covering element and an amplitude variation mechanism which are arranged on the platform, and a drilling and lifting device which is connected with the amplitude variation mechanism, wherein a hydraulic system and a main control system are arranged in the covering element; the amplitude variation mechanism comprises a turning pair A and a turning pair B; the turning pair A drives the amplitude variation mechanism and the drilling and lifting device to rotate relatively to the platform by + / - 90 degrees; and the turning pair B drives the drilling and lifting device to rotate relatively to the amplitude variation mechanism by 360 degrees. The turning pair A of the multifunctional micropile drilling machine does not turn along with the platform and just drives the amplitude variation mechanism and the drilling and lifting device to turn, so that the turning moment is reduced and turning becomes quite steady; the turning pairs employed also are lower than the turning pair employed to drive the whole platform in power so that the cost is saved; the turning pair B is capable of rotating by 360 degrees; and in contrast with the similar drilling machine employing an oil cylinder for rotation, the multifunctional micropile drilling machine has the advantages that the rotation angle is large and positioning of drilling is also quite accurate.

Owner:湖南优钻工程科技有限公司

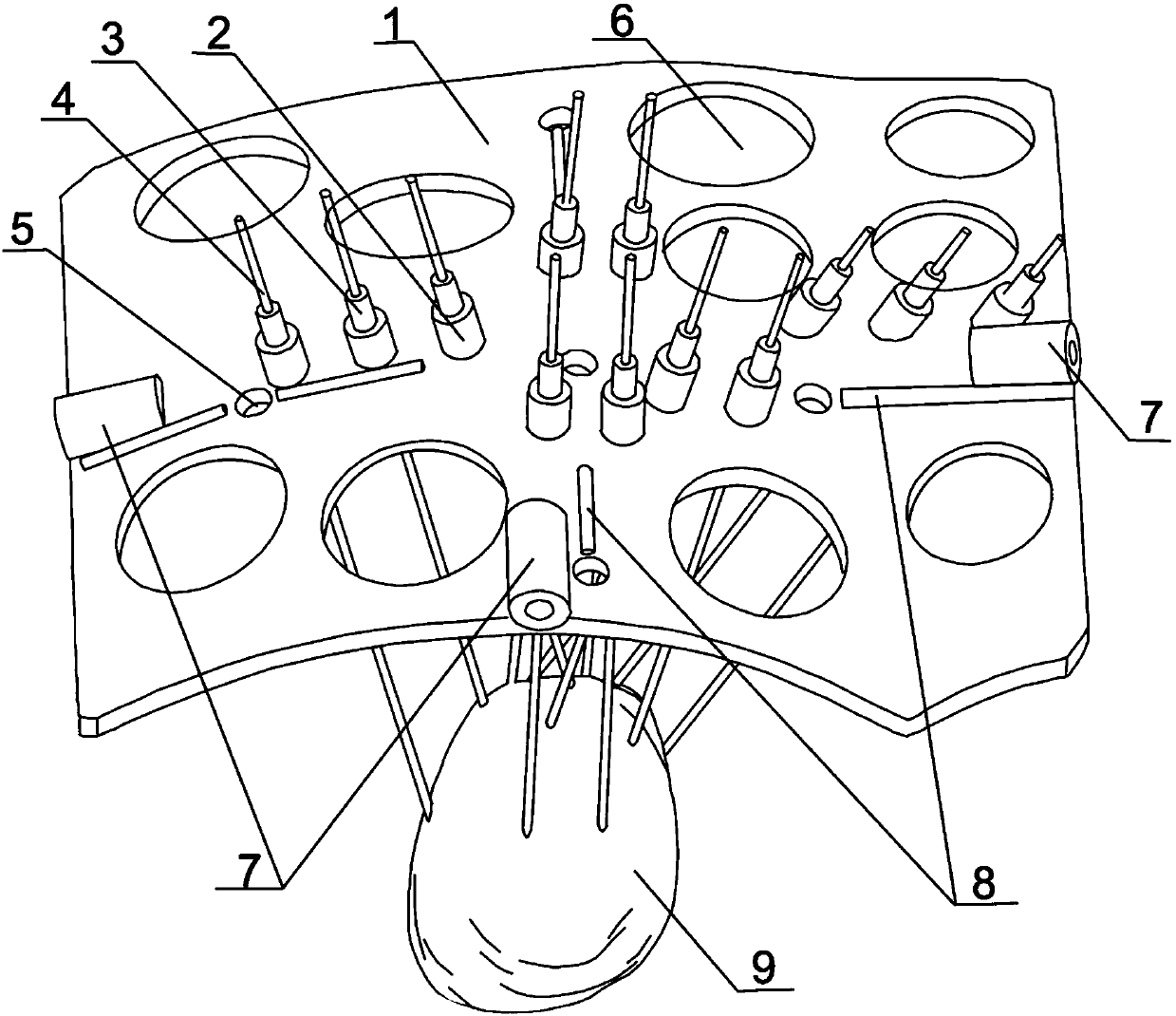

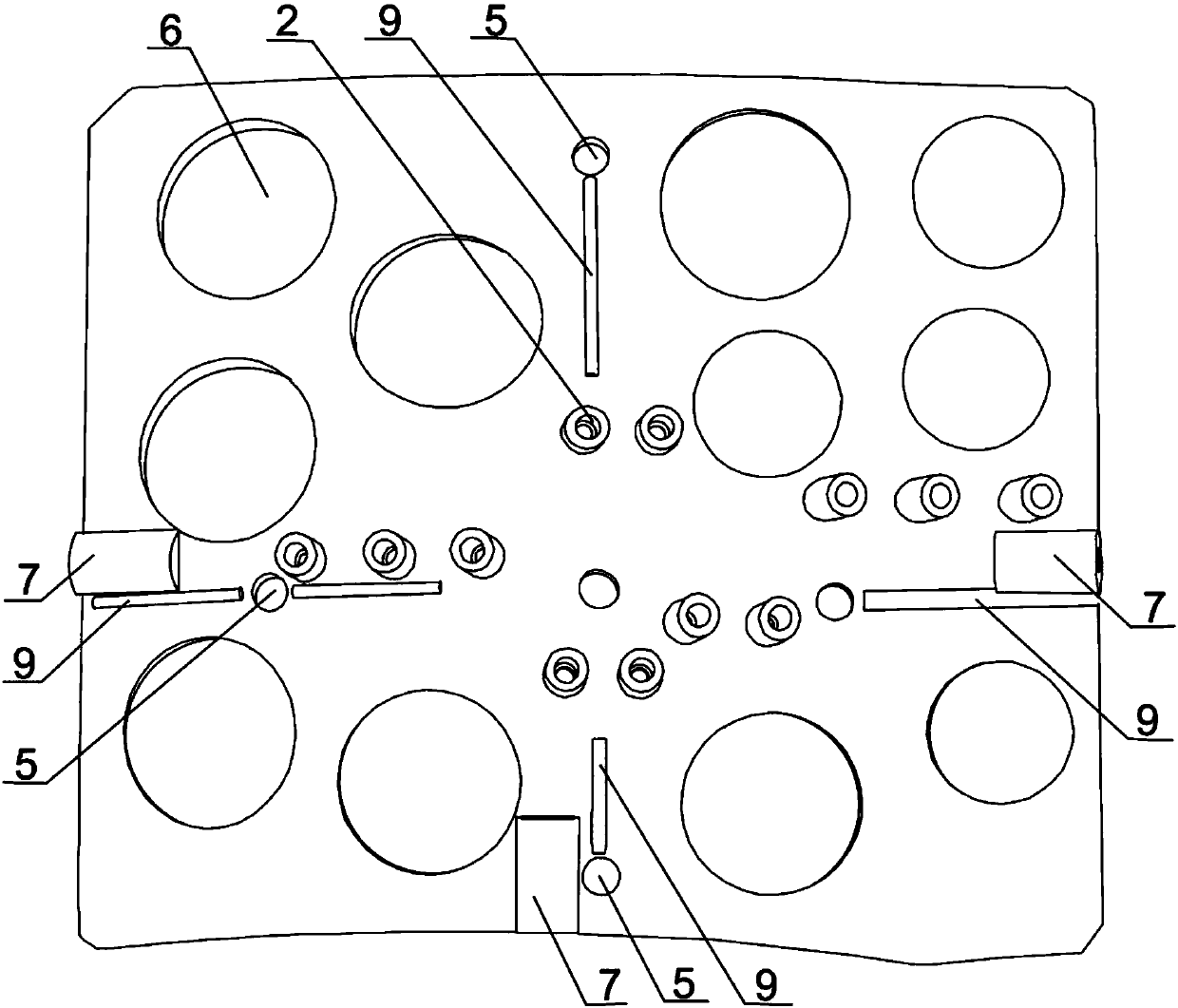

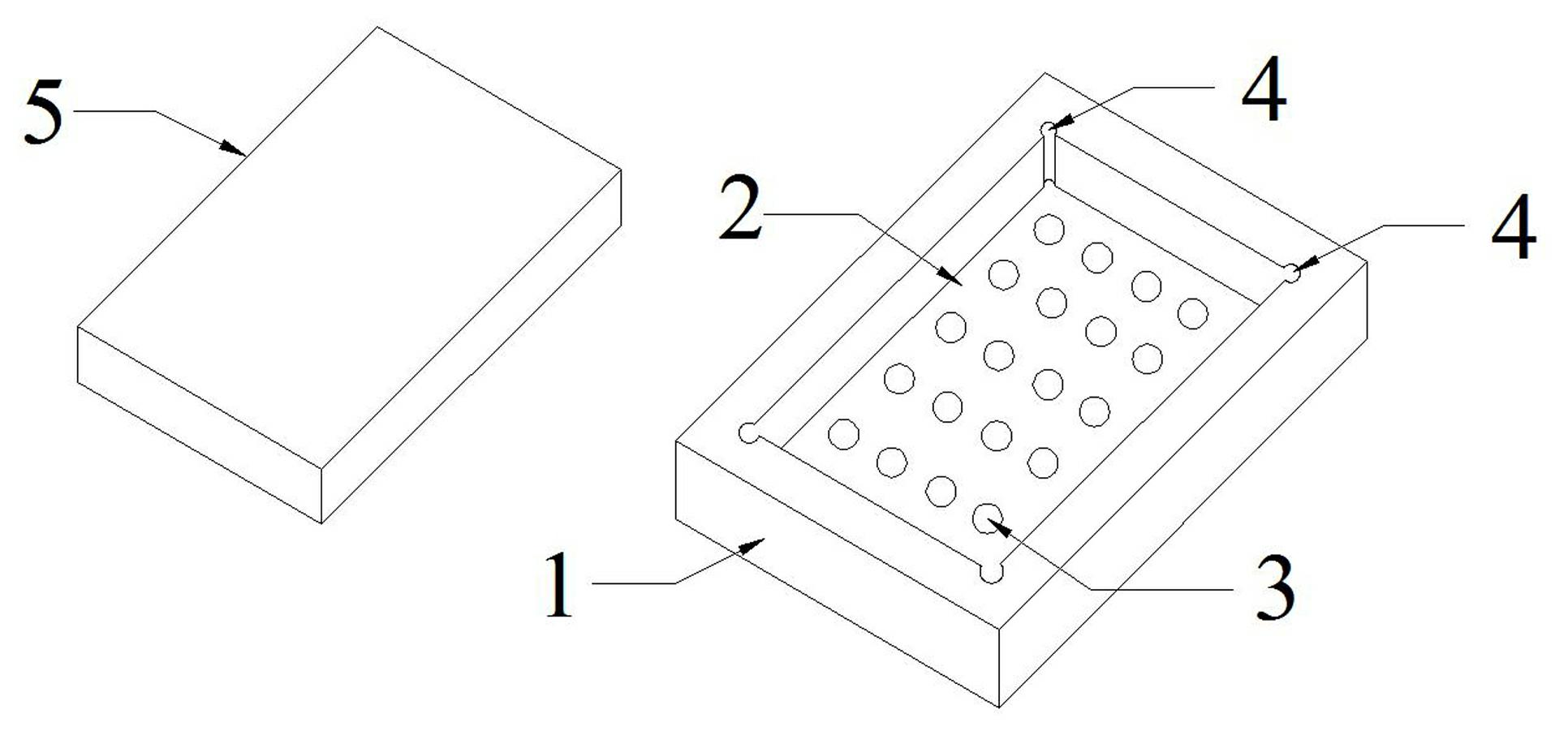

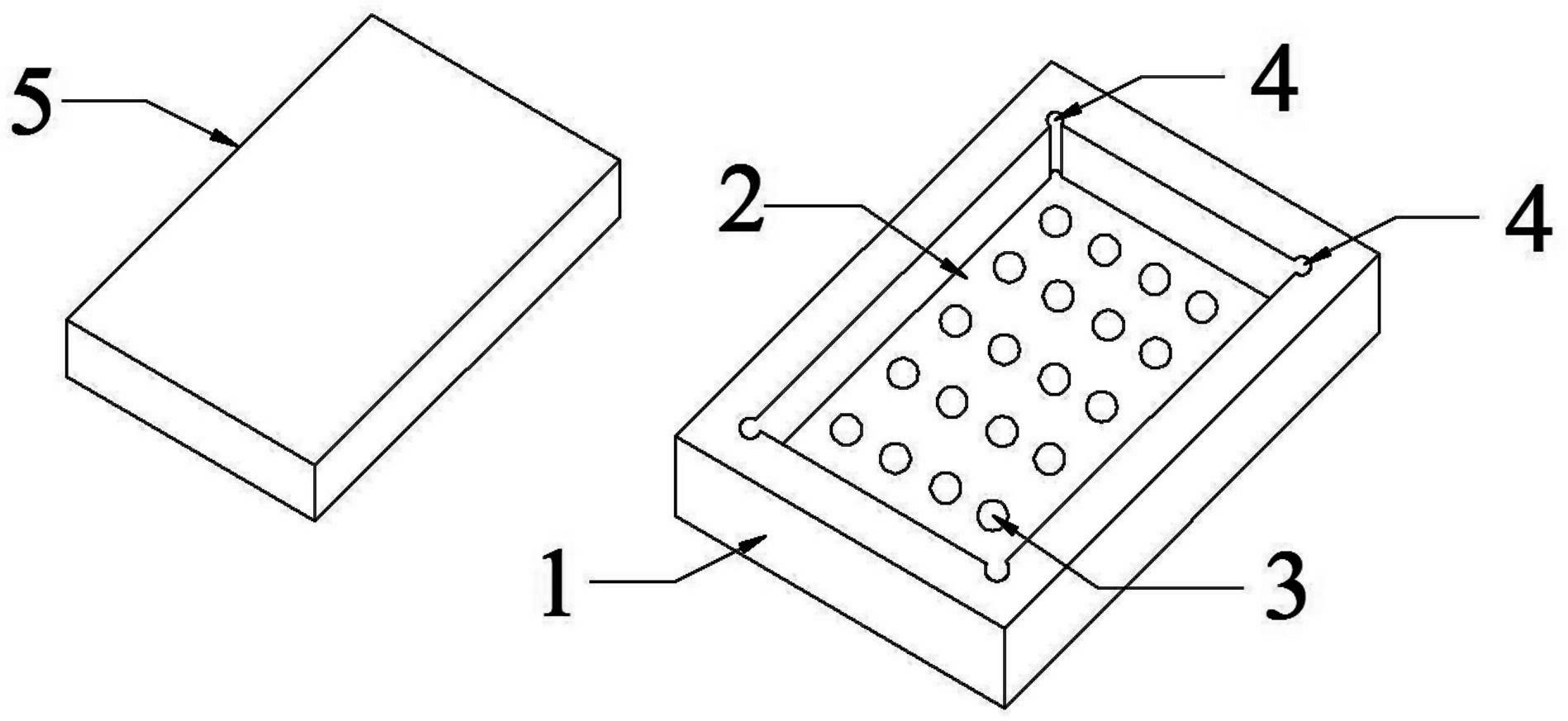

3D printing personalized plunger type puncture treatment template with fixing device

PendingCN107616838AReduce the burden onLow cost of design and productionAdditive manufacturing apparatusSurgical needlesResonanceTemplate based

The invention relates to a 3D printing personalized plunger type puncture treatment template with a fixing device. The treatment template comprises a template base plate, template guide holes, puncture needle guide columns, fine adjustment bracket insertion holes, positioning holes, lightweight through holes, laser alignment lines, puncture needle numbers, depth marks and the like. The template puncture needle guide columns can be taken down at any time, the diameter of the template guide holes is large and the length of the template guide holes is small after template puncture needle guide columns are taken down, so that local anesthesia points are accurate in positioning, local anesthesia is easy to implement, a bone drill with a large diameter can be conveniently used, and drilling andpositioning are precise. The three fine adjustment bracket insertion holes are formed and matched with a fine adjustment bracket in use so that the position of the template can be fine adjusted and fixed. The puncture needle numbers and the depth marks are arranged on the surface of the template base plate, and the situation that puncture needles are inserted by mistake because no depth marks arearranged is prevented. The template is customized, each puncture needle is precisely designed before operations according to CT, magnetic resonance and other medical images, precise minimally invasivesurgery is achieved, operation difficulty and operation risks are greatly reduced, the learning cycle of young doctors is shortened, services are quickly conducted, and then more patients are benefited.

Owner:于江平

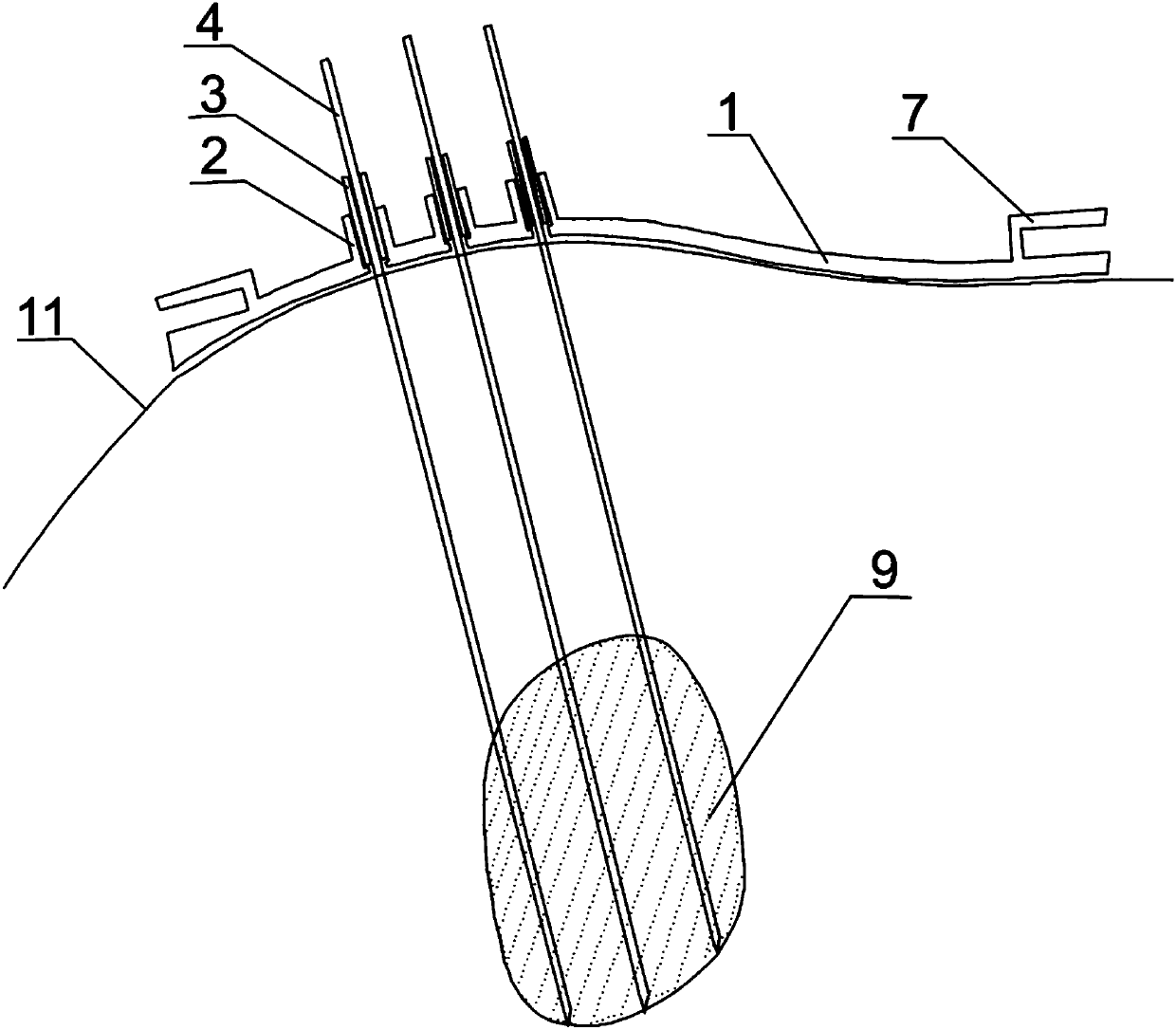

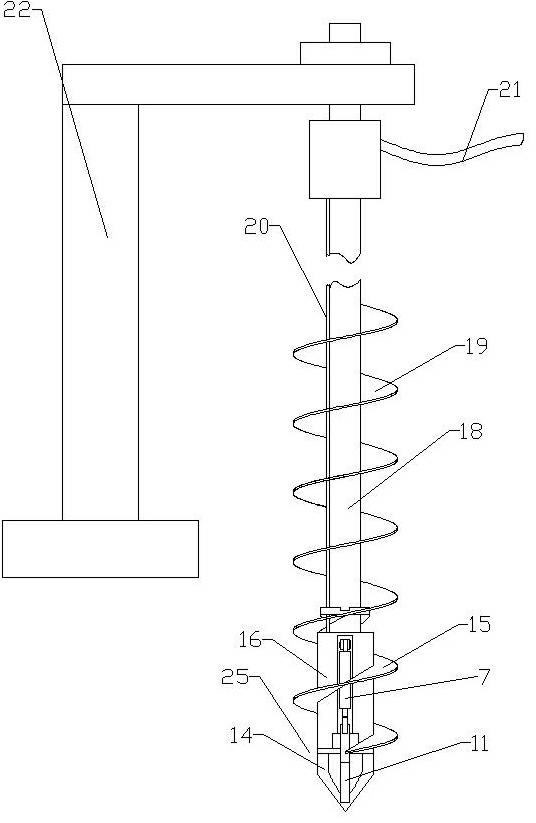

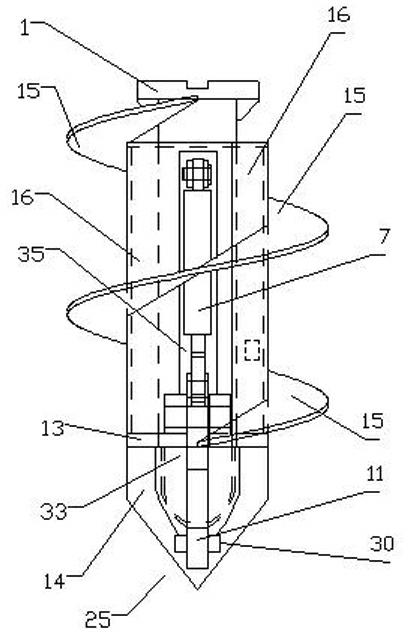

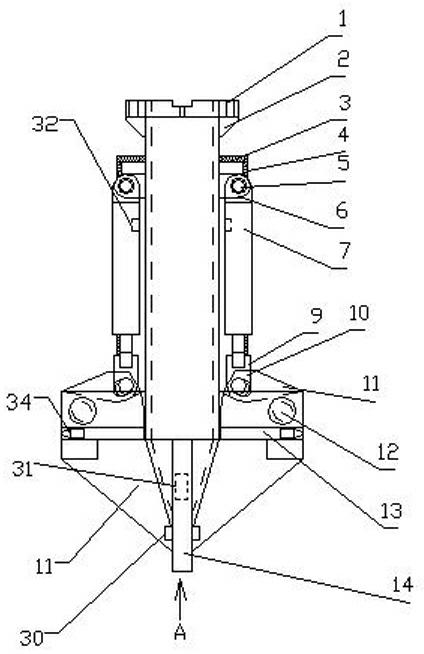

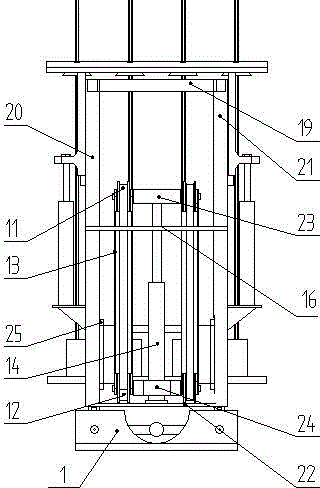

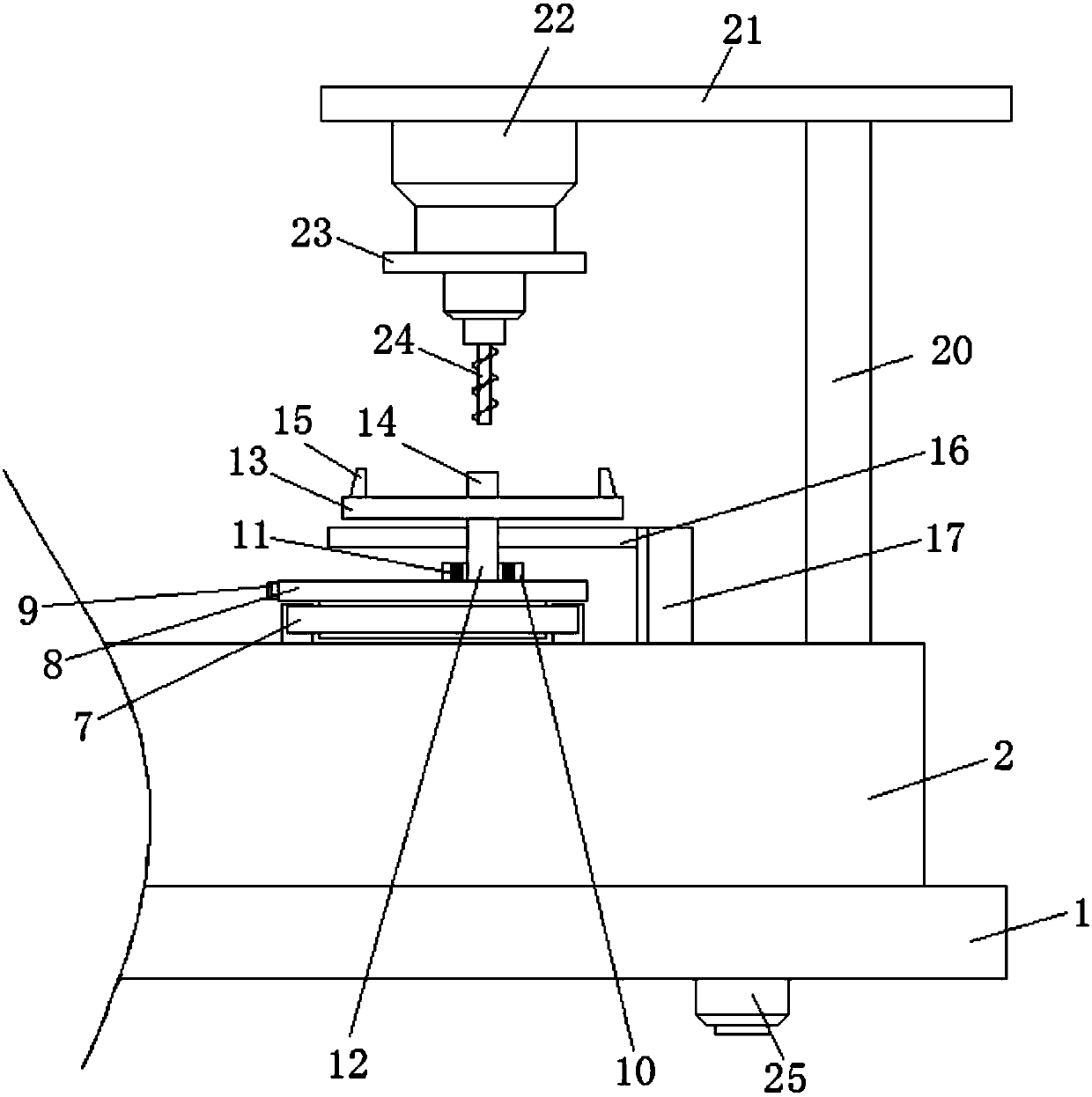

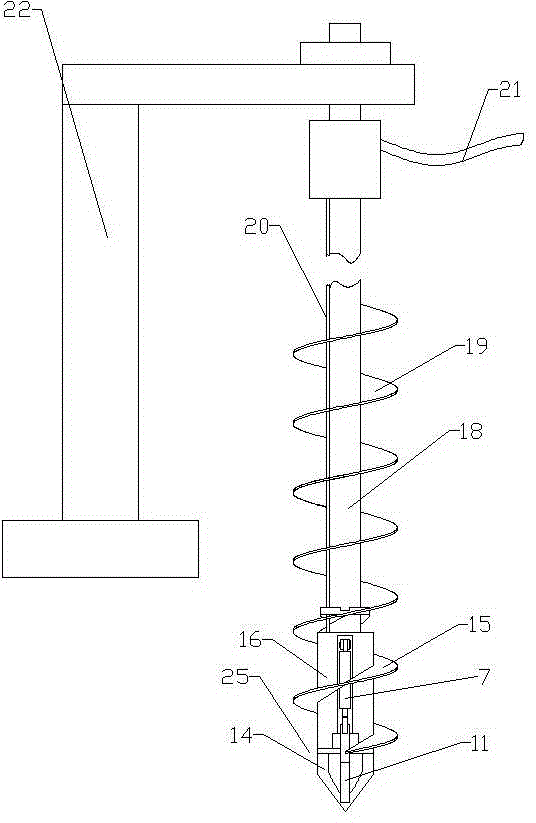

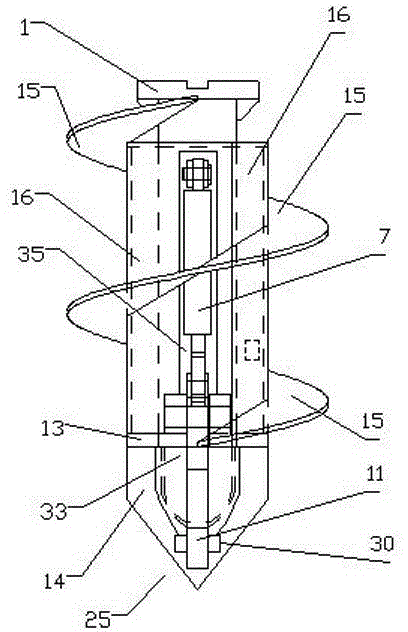

Concrete piling process and drilling machine special for same

InactiveCN102677666AAdjust in timePrecise positioningBulkheads/pilesHardnessUltimate tensile strength

The invention discloses a concrete piling process and a drilling machine special for the same. The concrete piling process is applicable to filled concrete and fluid such as cement, and can meet construction requirements of complicated geological conditions comprising high hardness or high collapsibility; by the concrete piling process, drilling, filling and broaching are completed at a time, and diameter-varied piles with high quality requirements can be molded; and transverse drilling can be realized at any position of pile holes accurately; the concrete piling process is convenient to construct and high in reliability; and the drilling machine special for the concrete piling process can meet requirements of a construction process, effectively shorten construction periods and accurately position the pile holes and determine the depths of the pile holes, and is reasonable in structure, high in strength and long in service life.

Owner:SHANDONG HONGTAI CONSTR GROUP

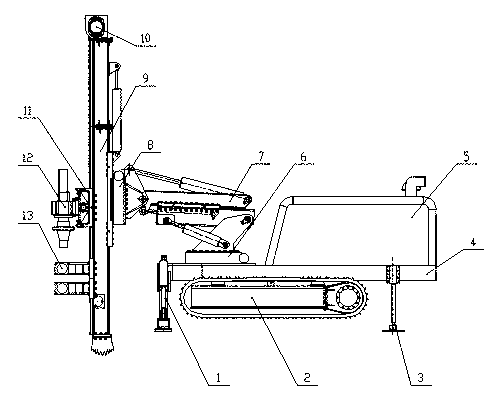

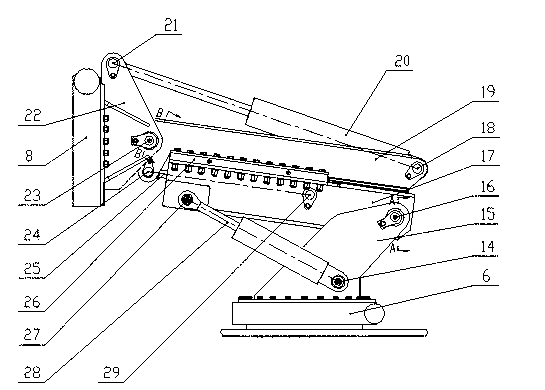

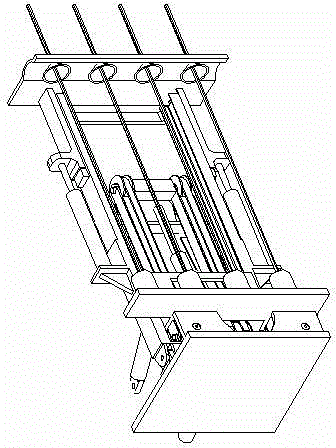

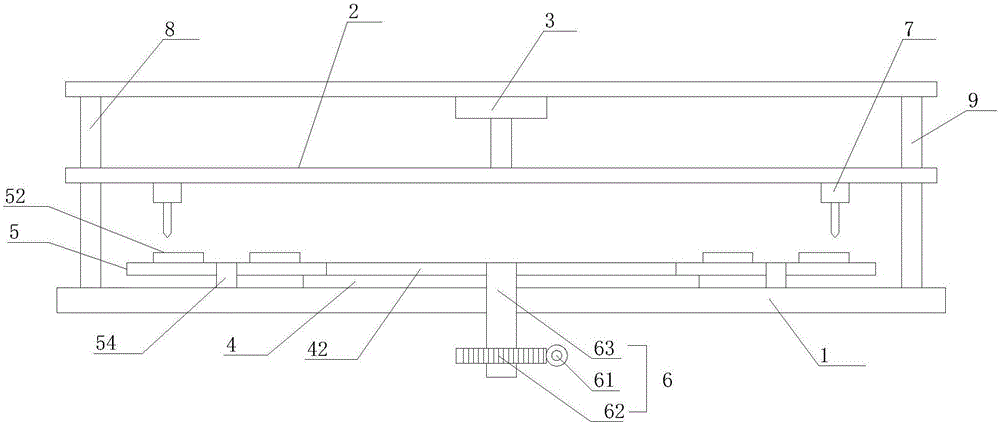

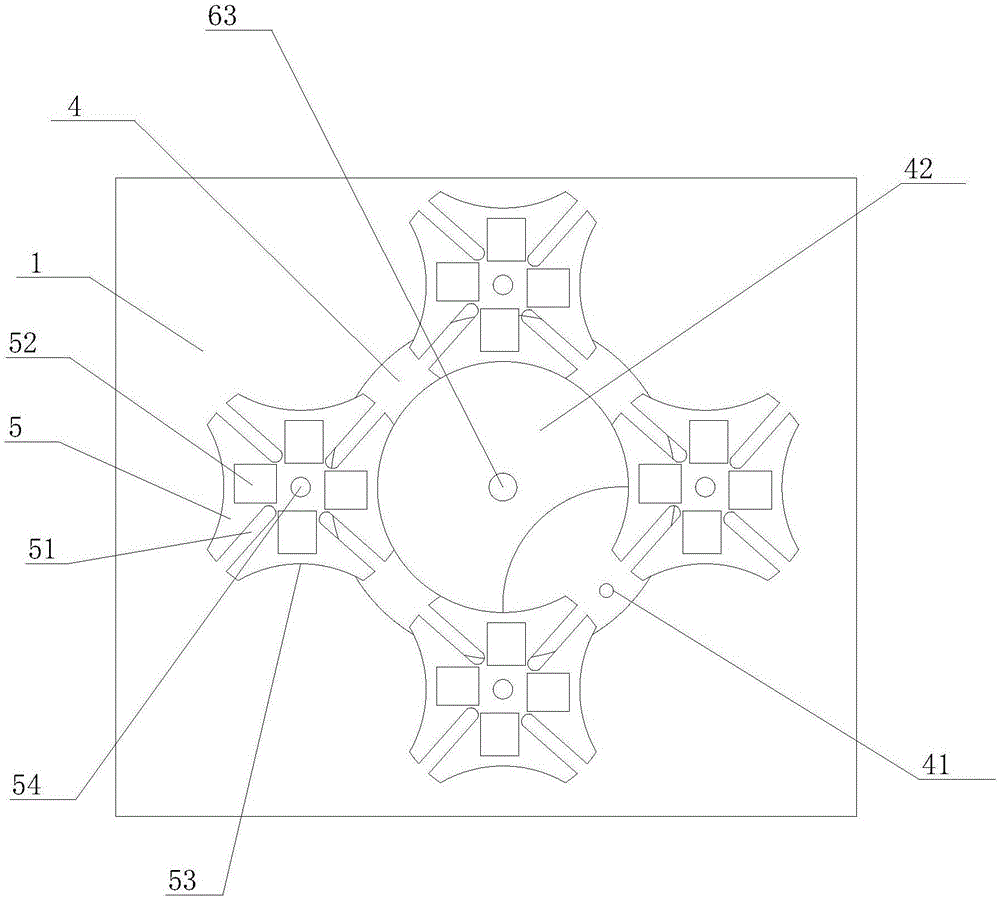

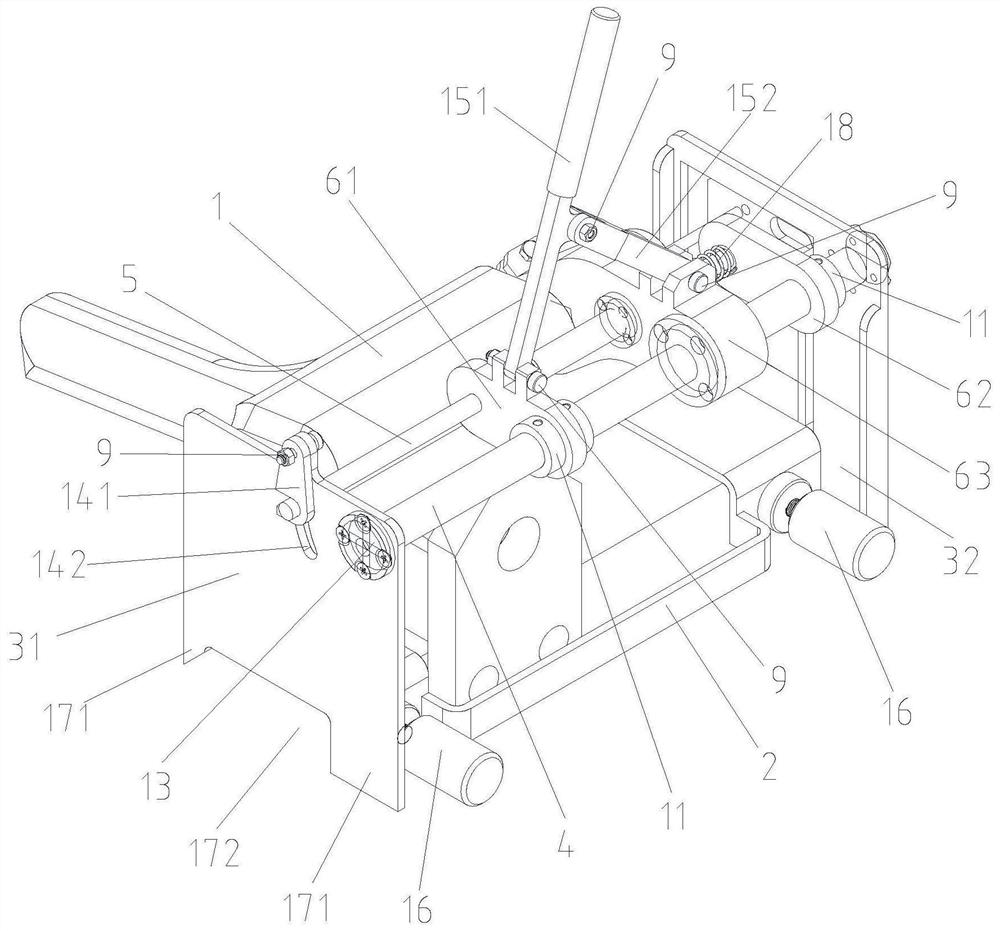

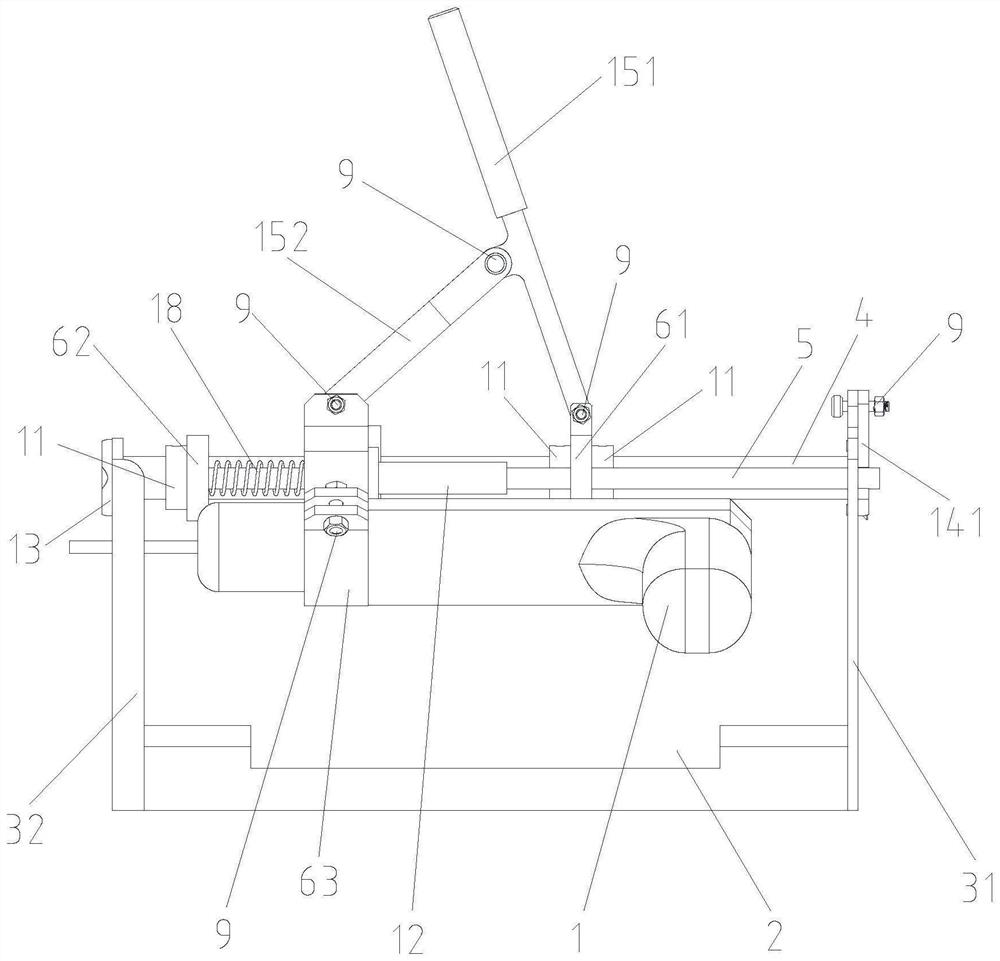

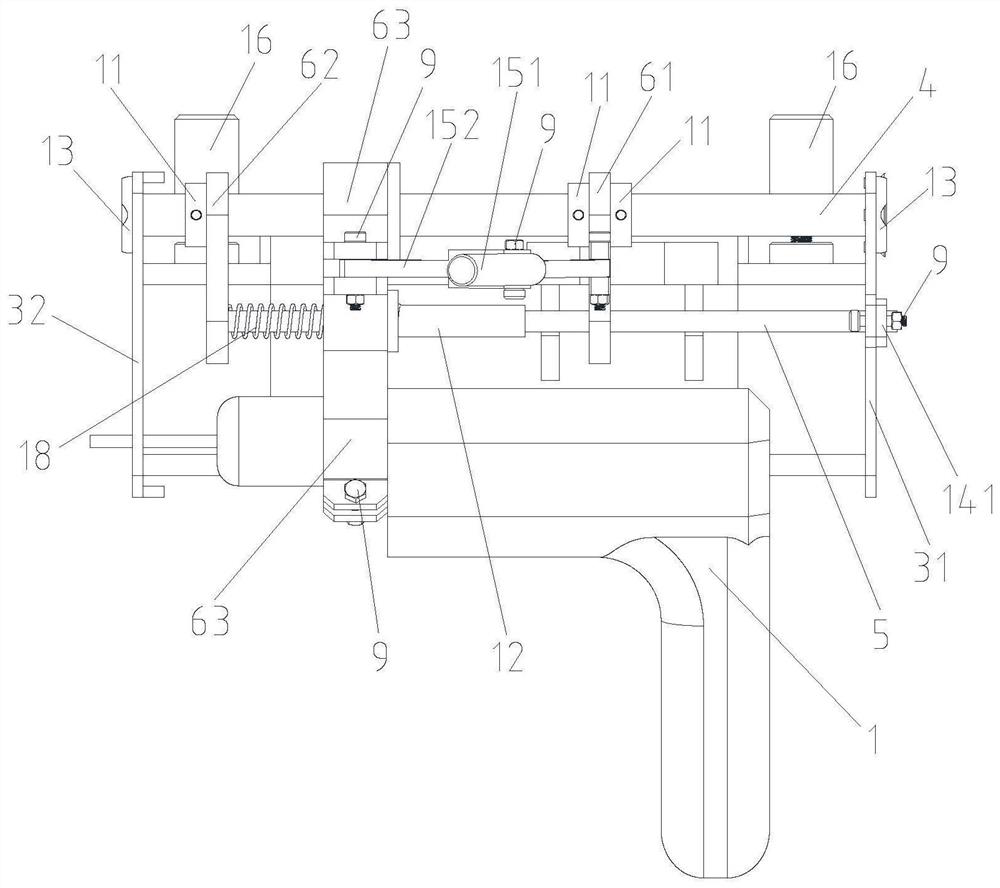

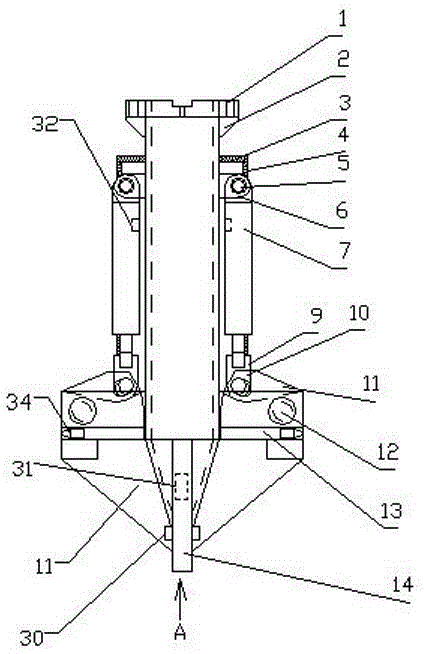

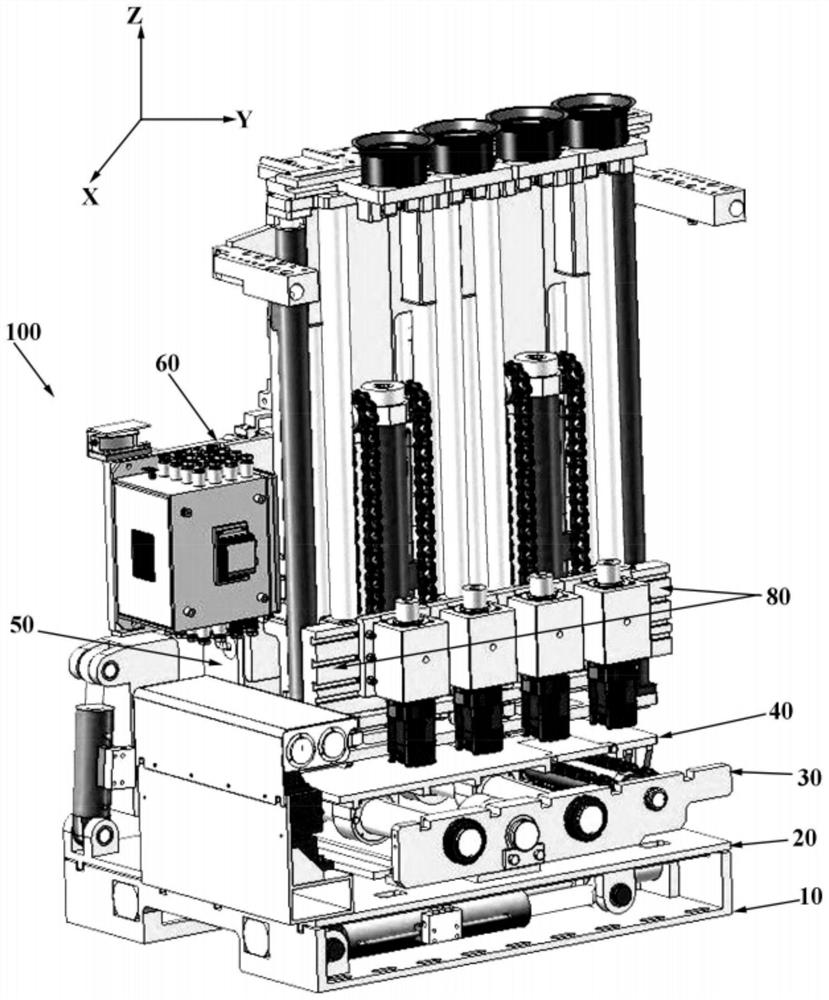

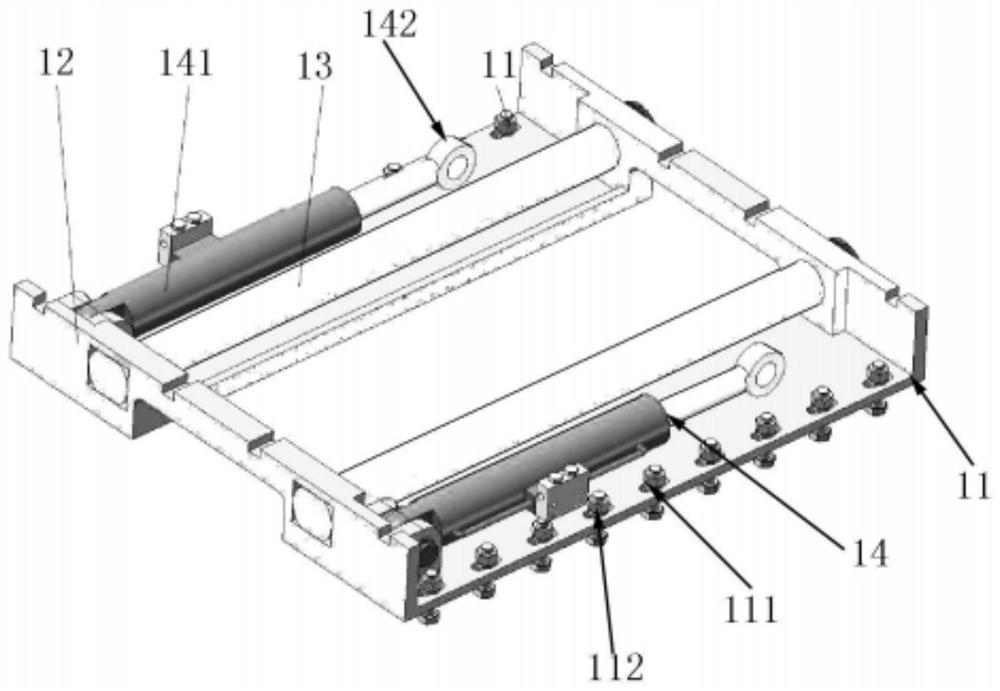

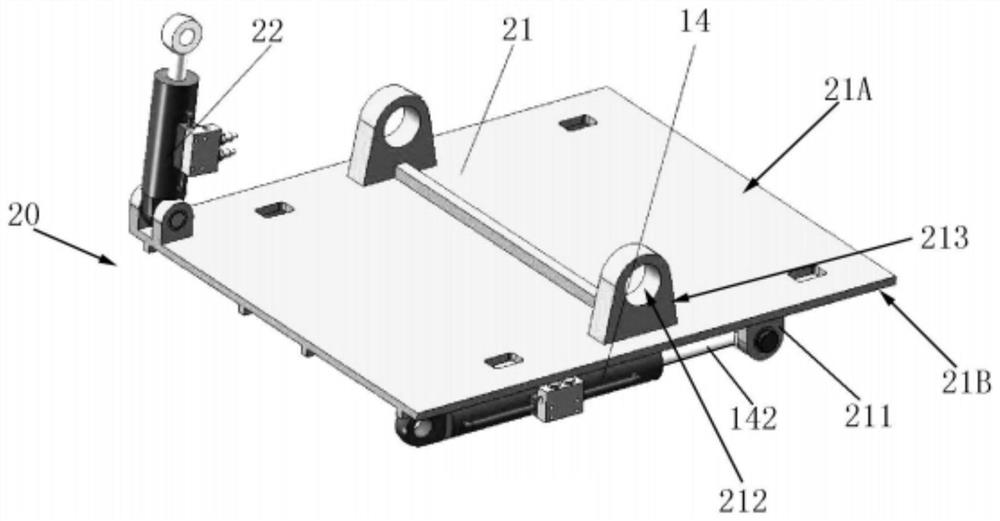

Hydraulic anchor rod group drilling machine

ActiveCN104131825AIncrease productivityAccurate drilling positioningDrilling rodsDerricks/mastsDrill holeRock bolt

The invention belongs to the field of drilling machines and particularly relates to a hydraulic anchor rod group drilling machine. The hydraulic anchor rod group drilling machine comprises a horizontal moving mechanism, a slope adjustment mechanism, a drilling rig portion and a drilling jig portion. The hydraulic anchor rod group drilling machine has the advantages that the number of holes drilled at the same time is large, the production efficiency is high, locating is timely and accurate during drilling, and manual carrying is not needed during daily use. By the adoption of the hydraulic anchor rod group drilling machine, the drilling efficiency can be improved by several times, after the two ends of a chain of the hydraulic anchor rod group drilling machine are fixed, a ring is formed, and the faults that the drilling machine get stuck and is difficult to retreat are effectively avoided during drilling.

Owner:山东浩民新材料科技有限公司

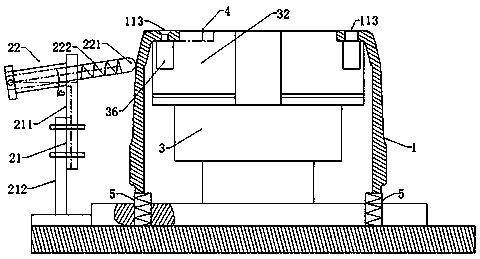

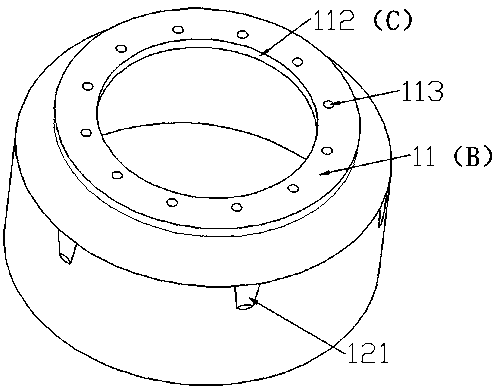

Drilling processing and fixing device and method for brake drum

InactiveCN108406352AEasy to fixAccurate drilling positioningChucksPositioning apparatusBiomedical engineering

The invention belongs to the field of automobile part processing and discloses a drilling processing and fixing device and method for a brake drum. The device comprises a chuck and a tool of an internal positioning device and comprises an upright post and an ejector rod of an external positioning device. The drilling processing and fixing device and method are accurate in positioning and drillingposition, high in dimensional accuracy, firm in fixing effect and wide in applicability.

Owner:JIANGXI JIUWANG AUTO PARTS MFG CO LTD

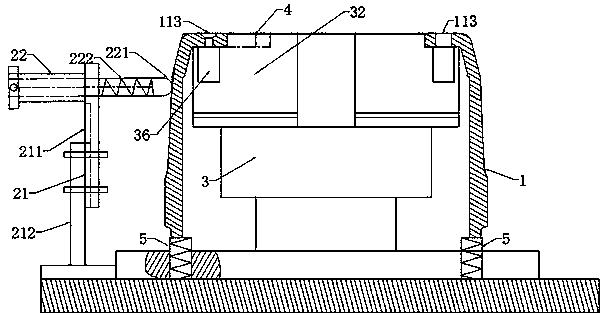

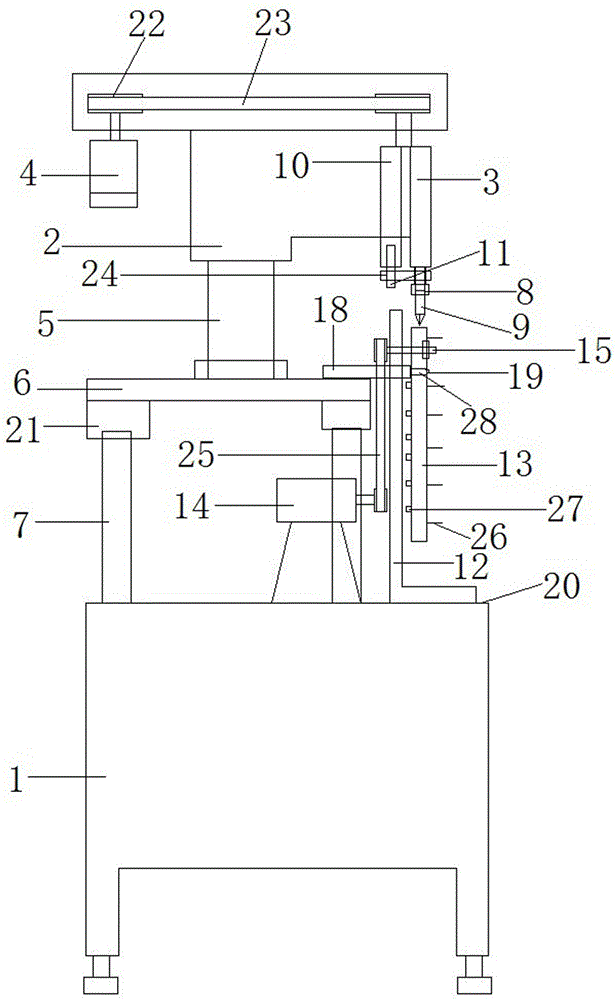

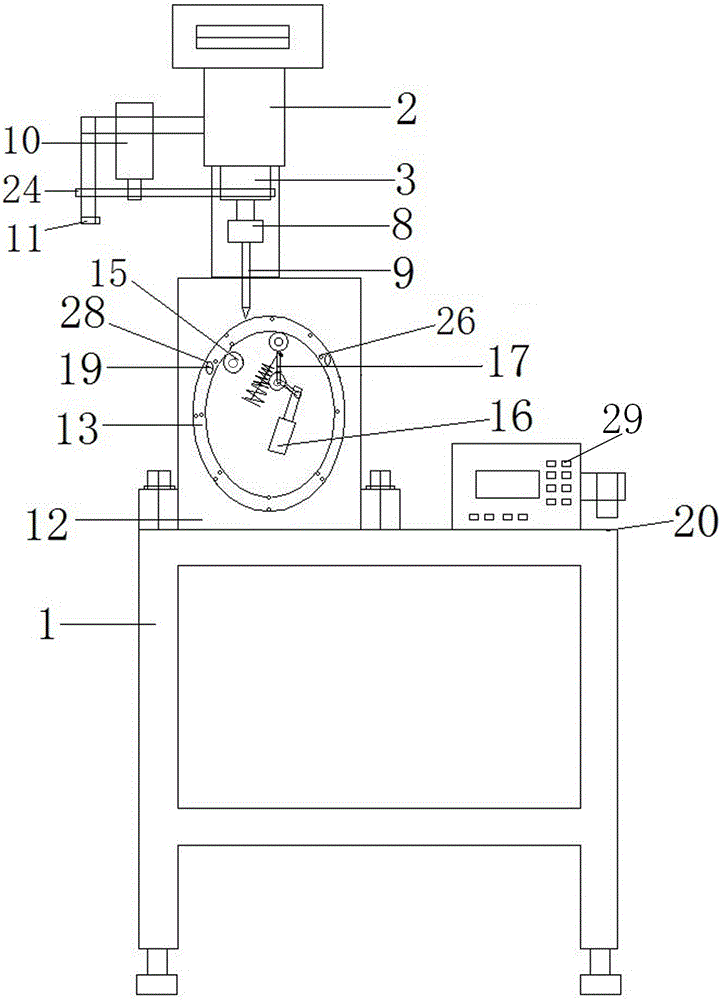

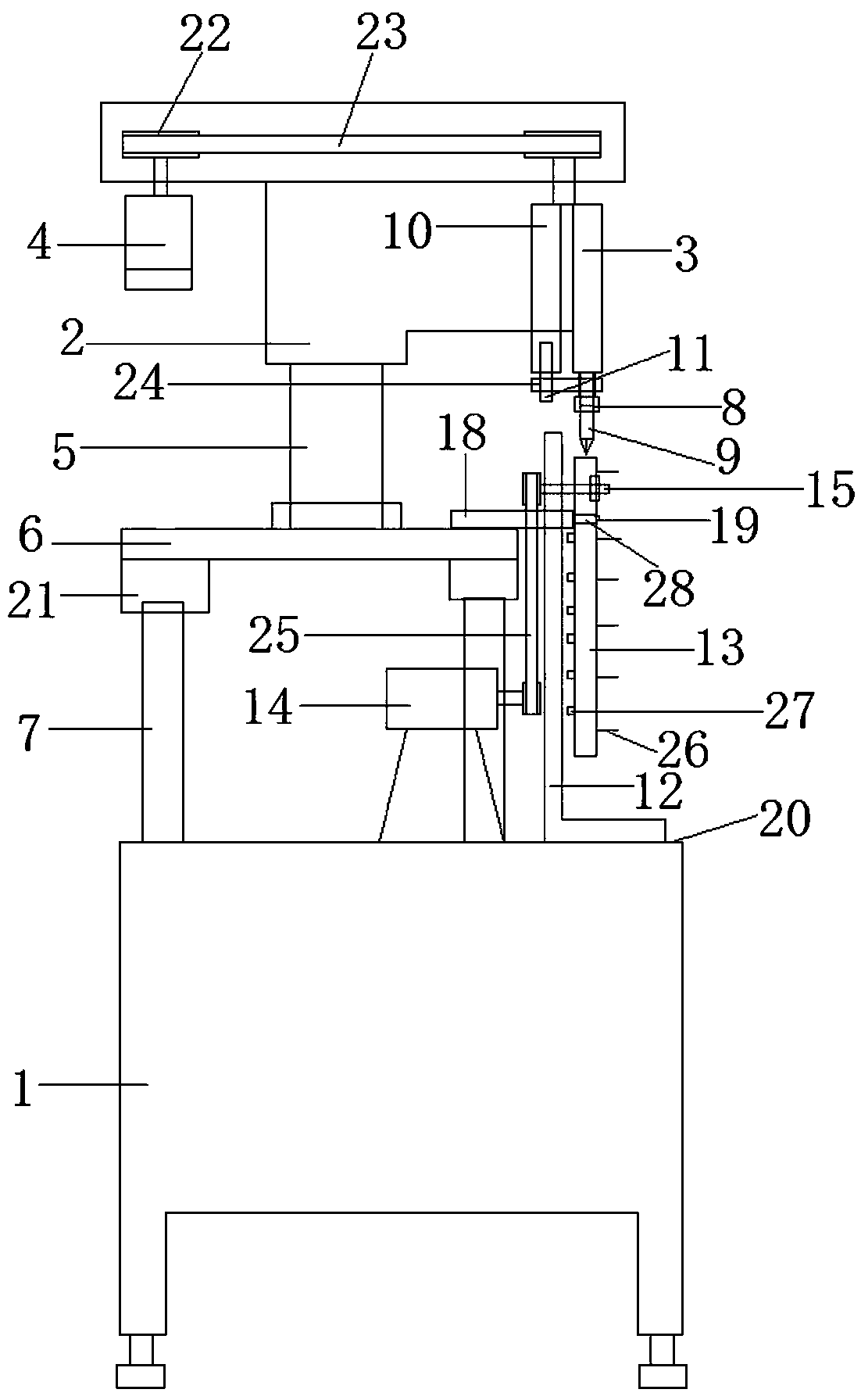

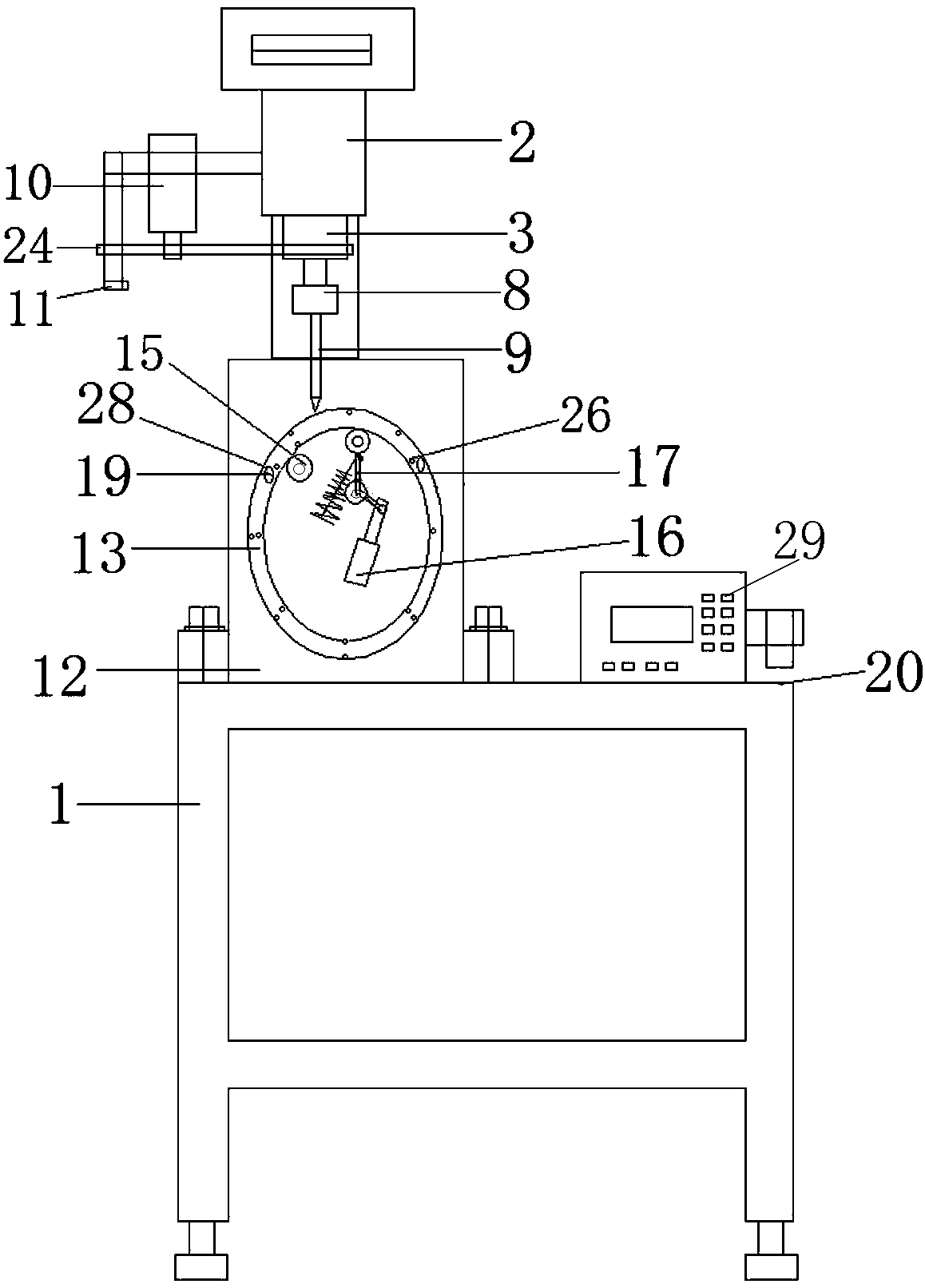

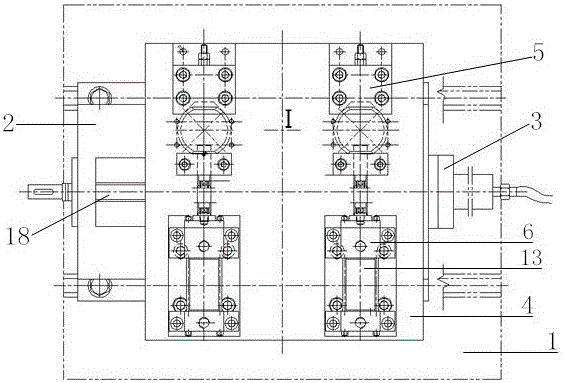

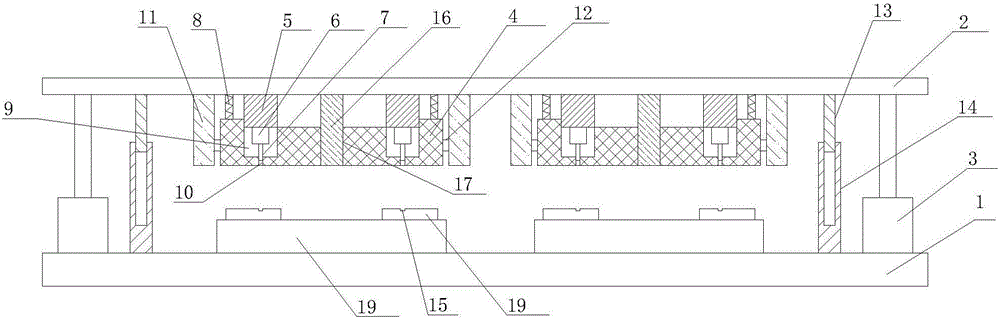

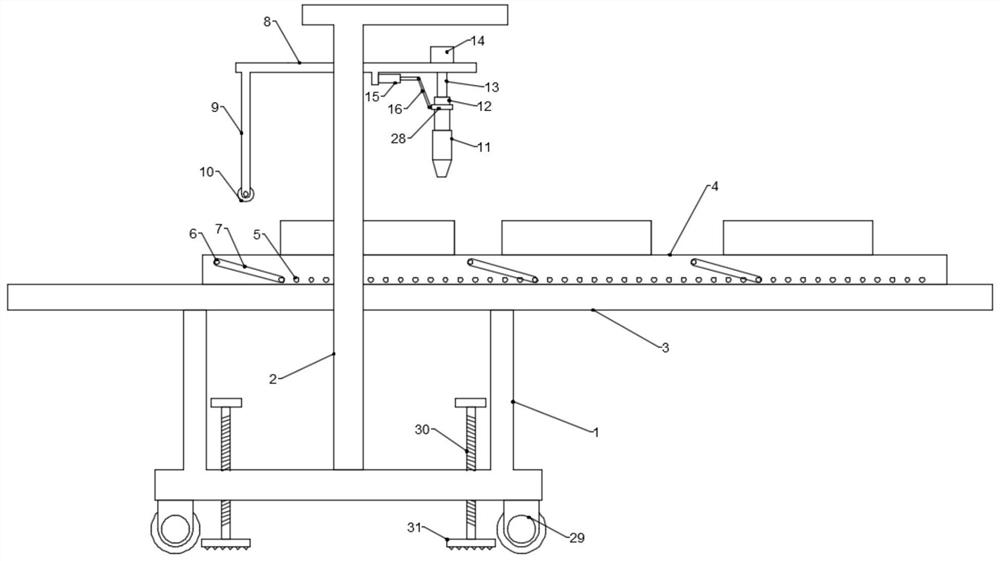

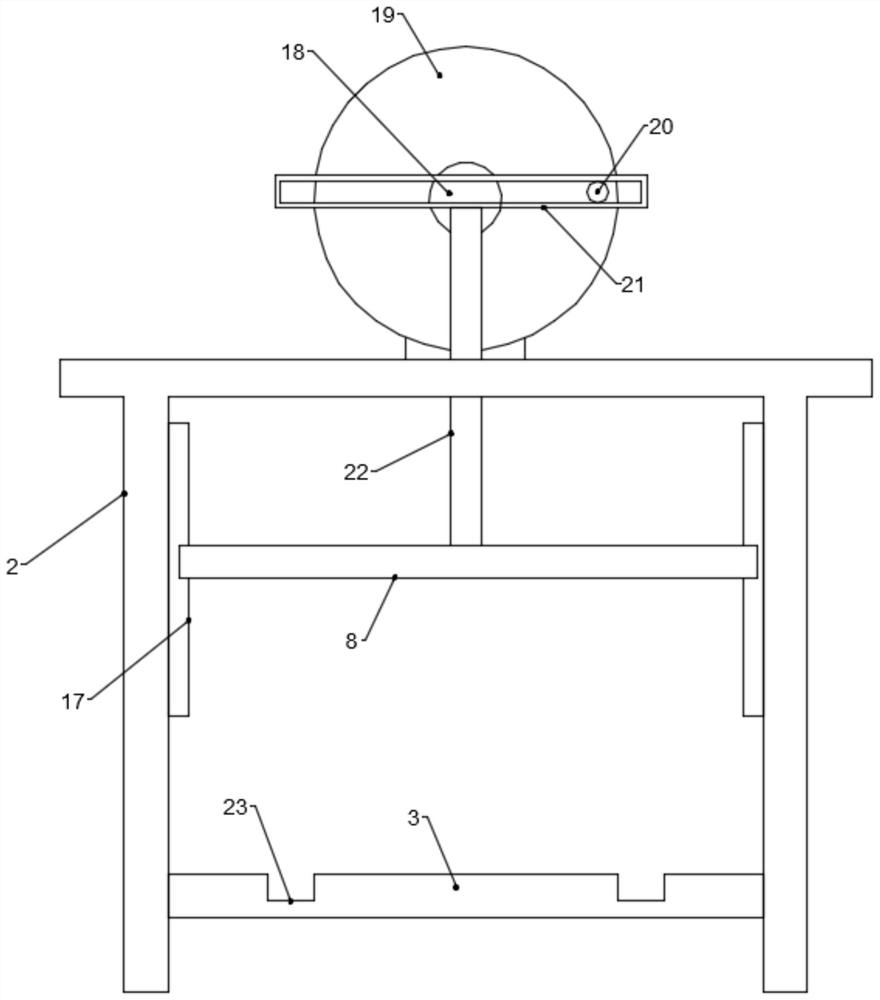

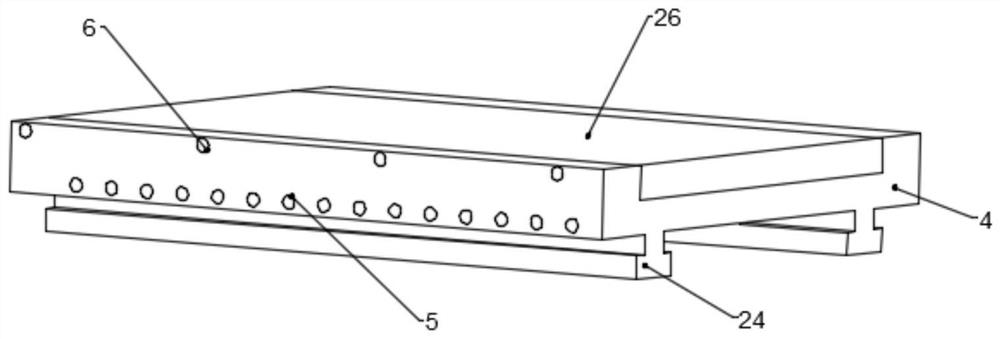

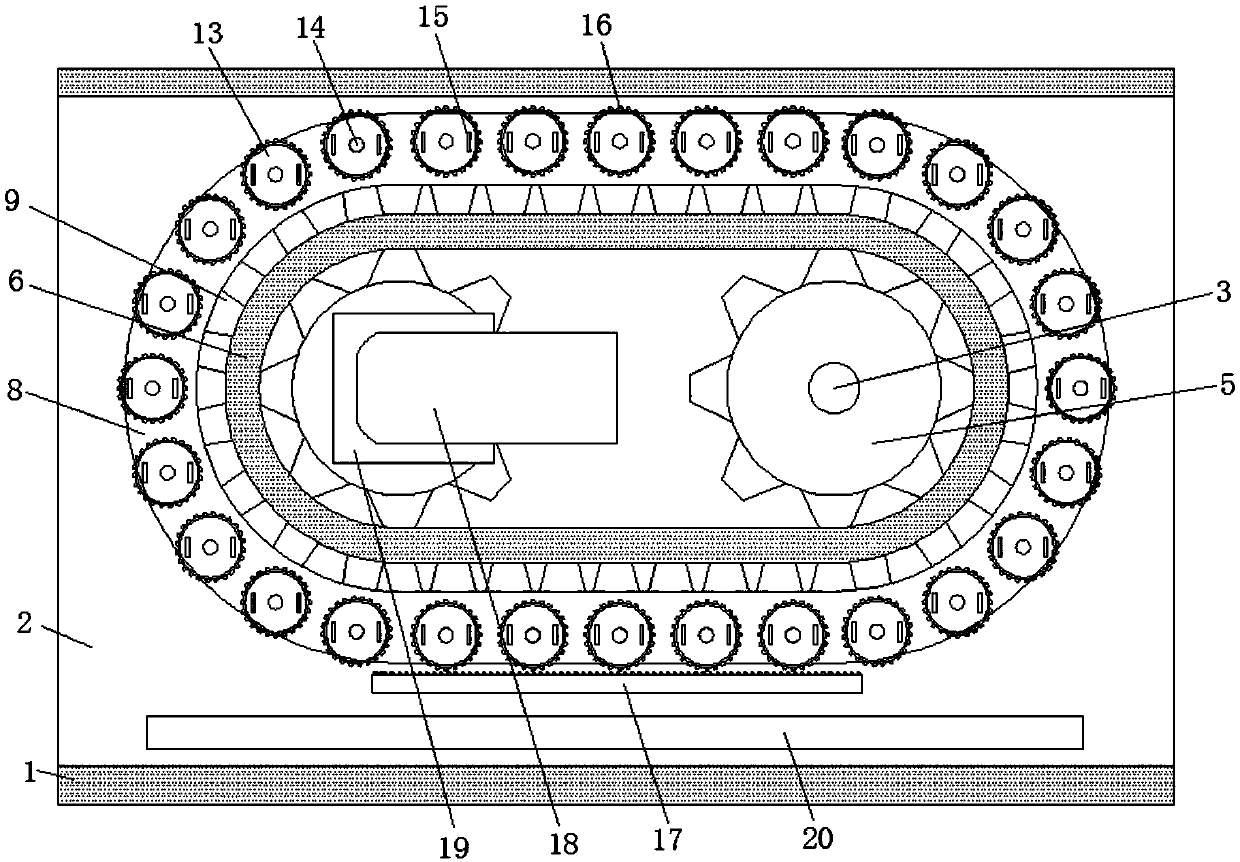

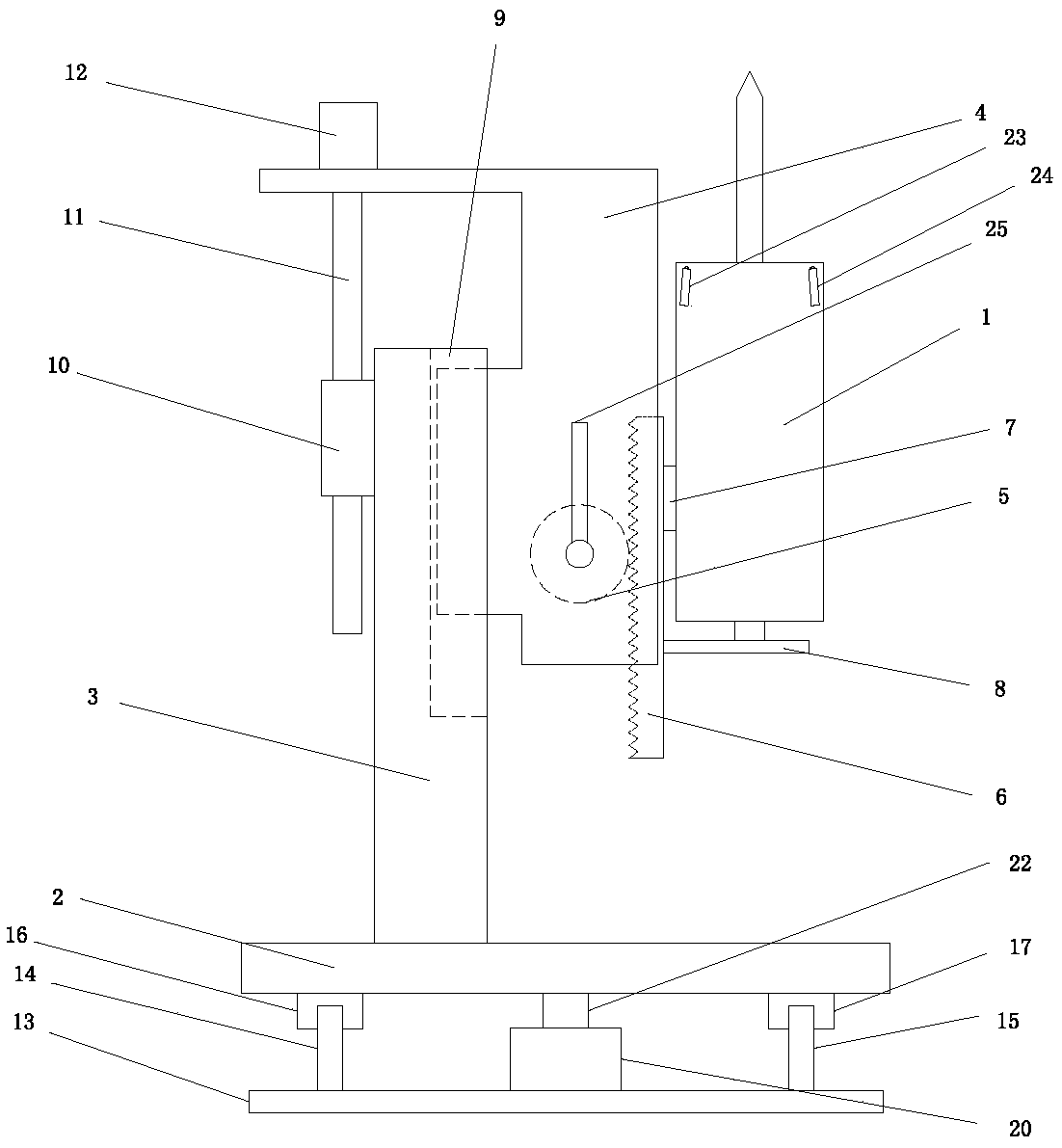

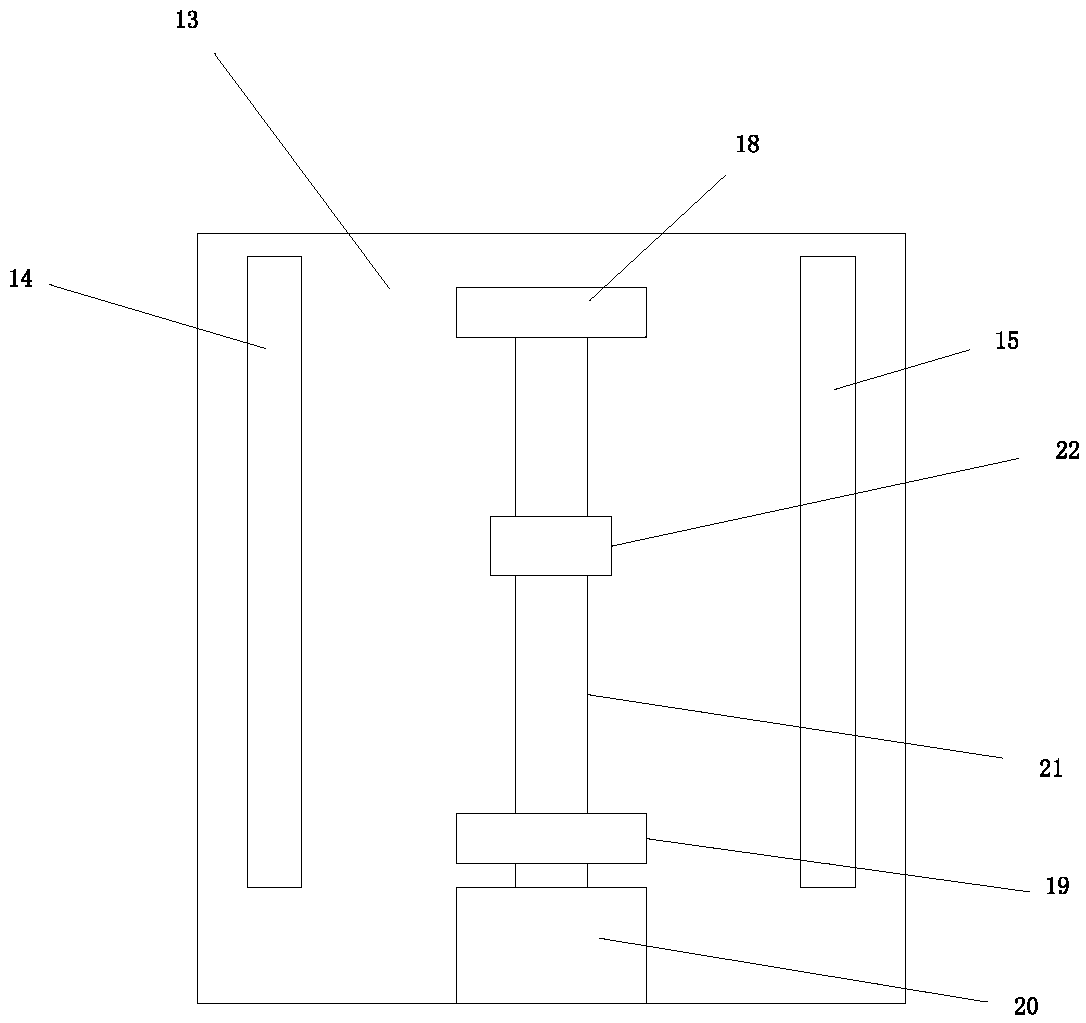

Full-automatic drilling machine for rackets

ActiveCN106735425AReasonable designCompact structureMetal working apparatusDrill jigsEngineeringTennis racket

The invention relates to a full-automatic drilling machine for rackets, and the automatic drilling machine is suitable for badminton racket frames and tennis racket frame net cable holes. The full-automatic drilling machine comprises a machine frame, a case, a spindle, a spindle transmission motor, a stand column, a stand column mounting plate, a supporting column, a drill chuck, a drill bit, a spindle lifting air cylinder, a lifting electromagnetic sensor, a horizontal positioning plate, a drilling die, a die transmission motor, a die transmission wheel, a die transposition pushing air cylinder, a steering connecting rod, a discharging air cylinder and an air pressure discharging rod. The spindle transmission motor is installed on one side of the case. The spindle is installed on the front portion of the case. The drill chuck is installed on the upper portion of the spindle. The drill bit is clamped by the drill chuck. The spindle lifting air cylinder is installed on the front side of the case. The front end of a piston rod of the spindle lifting air cylinder is connected with the lower end of the spindle through a connecting plate. The air cylinder lifting electromagnetic sensor is installed on the connecting plate and used for detecting the lifting position of the spindle in the drilling process. The horizontal positioning plate is installed on a workbench on the front side of the stand column mounting plate. The drill mold is installed on the outer side of the horizontal positioning plate and used for determining the installation position of a racket frame on the drilling mold.

Owner:宿迁圣力佳合体育用品有限公司

Simple positioning and drilling clamp

The invention discloses a simple positioning and drilling clamp which is characterized by comprising a die holder with a horizontal table top, a die cavity for clamping a work piece to be drilled, a guide hole formed in the die cavity and used for guiding a drilling tool to drill the work piece to be drilled, and a preformed groove recessed from the side wall of the die cavity towards the direction away from the center of the die cavity and used for conveniently taking the work piece to be drilled, wherein the axial direction of the guide hole is perpendicular to the plane where the die holder is positioned. The simple positioning and drilling clamp has the benefits that the drilling clamp has a simple structure and is convenient for fabrication and use, the labor intensity is reduced and the work efficiency is increased, the drilling positioned effect is accurate, the quality of products is improved, and the yield is increased.

Owner:苏州金牛精密机械有限公司

racket automatic drilling machine

ActiveCN106735425BReasonable designCompact structureMetal working apparatusDrill jigsTennis racketPiston rod

The invention relates to a full-automatic drilling machine for rackets, and the automatic drilling machine is suitable for badminton racket frames and tennis racket frame net cable holes. The full-automatic drilling machine comprises a machine frame, a case, a spindle, a spindle transmission motor, a stand column, a stand column mounting plate, a supporting column, a drill chuck, a drill bit, a spindle lifting air cylinder, a lifting electromagnetic sensor, a horizontal positioning plate, a drilling die, a die transmission motor, a die transmission wheel, a die transposition pushing air cylinder, a steering connecting rod, a discharging air cylinder and an air pressure discharging rod. The spindle transmission motor is installed on one side of the case. The spindle is installed on the front portion of the case. The drill chuck is installed on the upper portion of the spindle. The drill bit is clamped by the drill chuck. The spindle lifting air cylinder is installed on the front side of the case. The front end of a piston rod of the spindle lifting air cylinder is connected with the lower end of the spindle through a connecting plate. The air cylinder lifting electromagnetic sensor is installed on the connecting plate and used for detecting the lifting position of the spindle in the drilling process. The horizontal positioning plate is installed on a workbench on the front side of the stand column mounting plate. The drill mold is installed on the outer side of the horizontal positioning plate and used for determining the installation position of a racket frame on the drilling mold.

Owner:宿迁圣力佳合体育用品有限公司

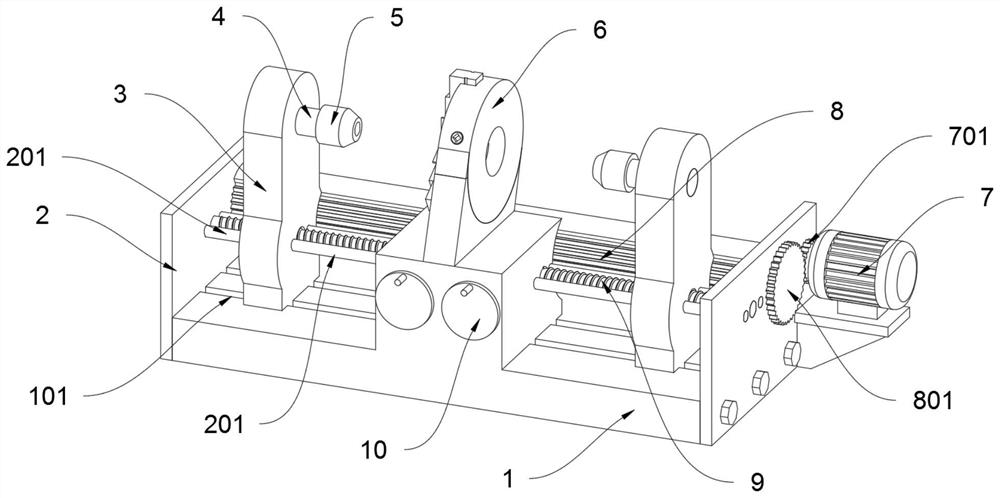

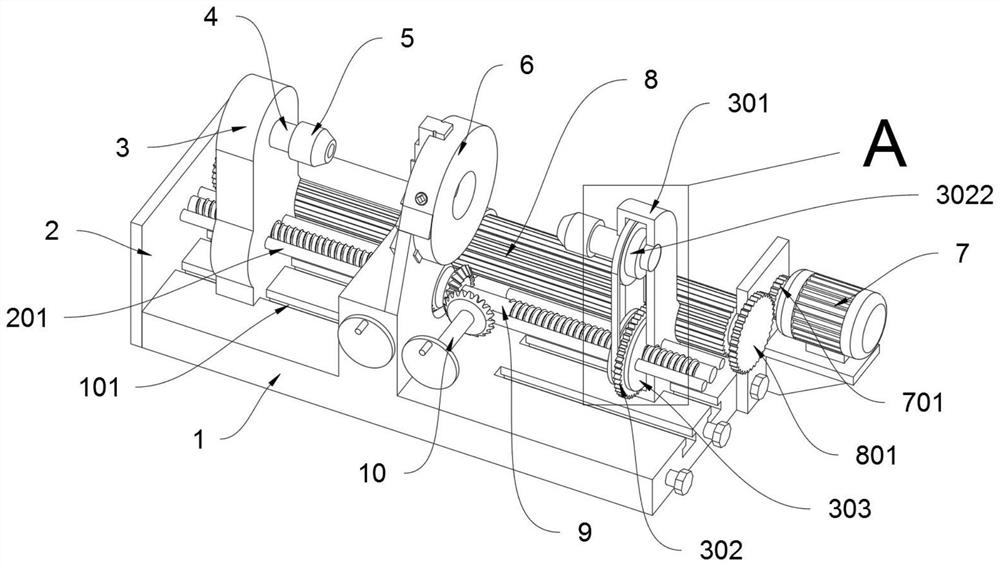

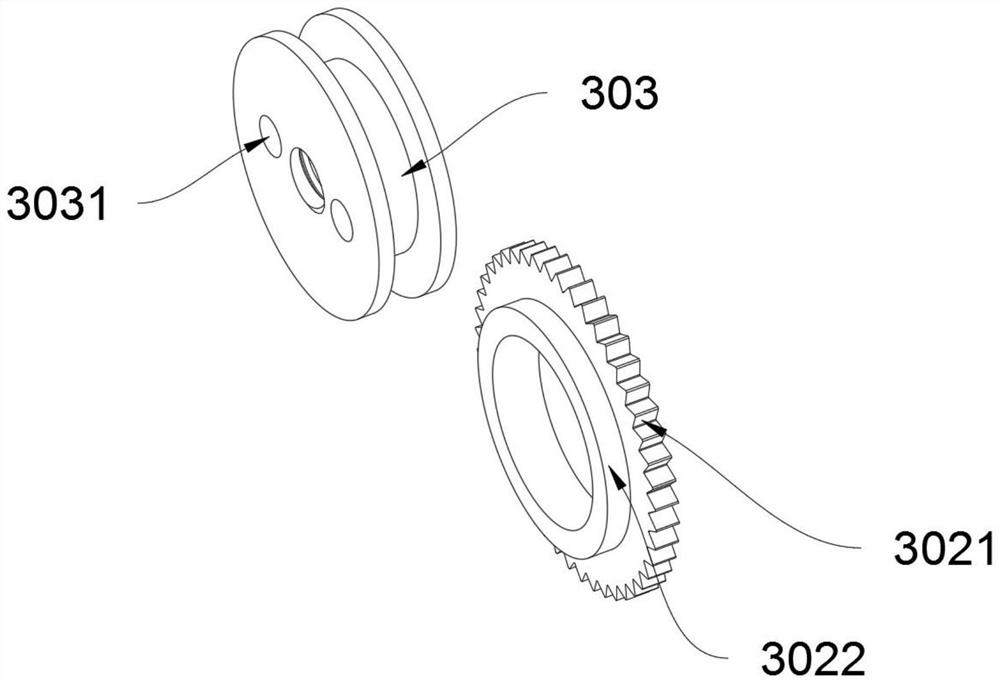

Double-head coaxial boring and milling machining device for machining

PendingCN112589151AAccurate drilling positioningFlexible and convenient operationBoring/drilling componentsBoring/drilling machinesMachine toolMachining

The invention discloses a double-head coaxial boring and milling machining device for machining, relates to the technical field of machining, and solves the problems that an existing machine tool canonly drill one end of a shaft part at a time, the other end of the shaft part can be drilled only by clamping the part again, the steps are tedious, hole sites at the two ends of the part are prone todeviation, and the production precision of parts is influenced. The double-head coaxial boring and milling machining device for machining comprises coaxial machining mechanisms, and the number of thecoaxial machining mechanisms is two. When the device is used for drilling the two ends of the shaft part, drill bits of two drill bit clamps can be coaxially driven to rotate through a transmission shaft, the two coaxial machining mechanisms can independently move, so that operation of drilling the two ends of the shaft part can be completed at the same time, one-time forming is achieved, the part does not need to be clamped again, drilling positioning is accurate, the operation is convenient and flexible, machining efficiency is high, and practicability and flexibility of the device are improved.

Owner:胡天娇

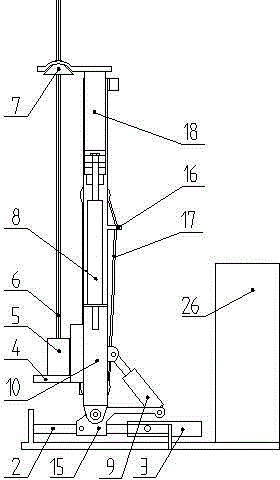

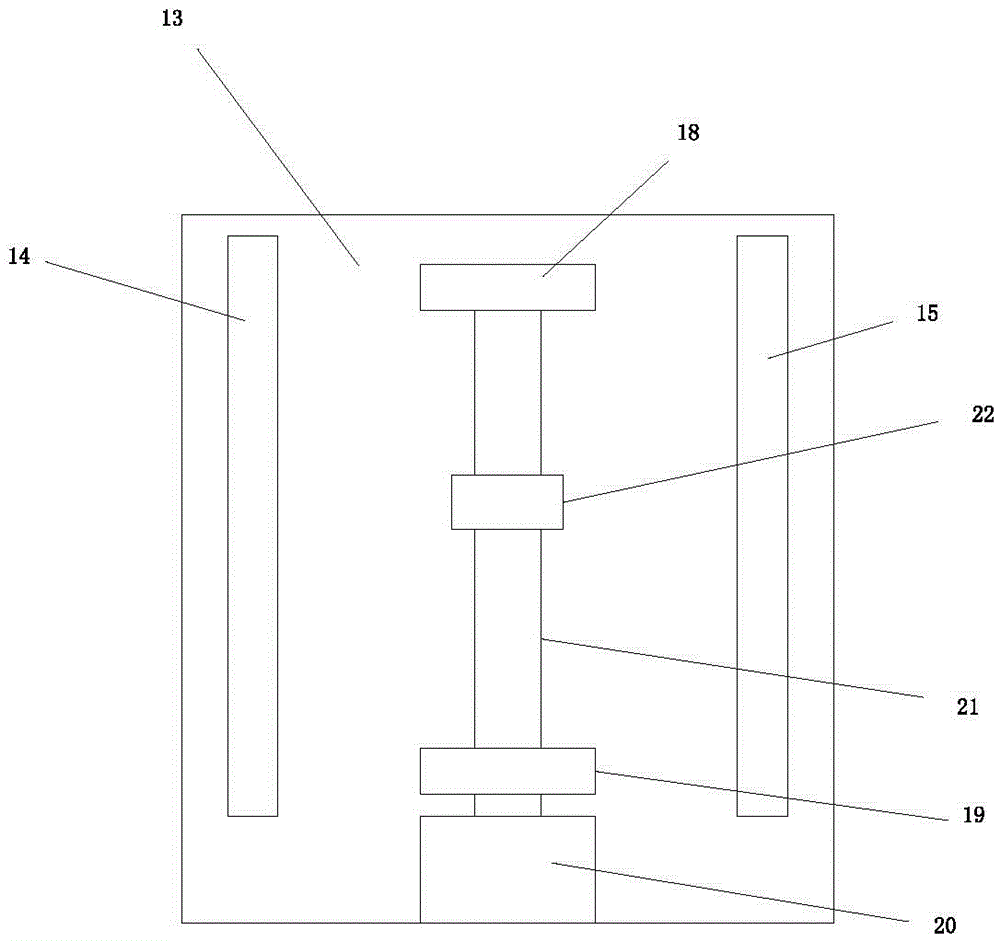

Perforating device for refrigerator van

ActiveCN106583791AEasy to operateSimple structureMeasurement/indication equipmentsFeeding apparatusRefrigerator carRefrigerated temperature

The invention discloses a perforating device for a refrigerator van. The perforating device comprises a perforating bracket, a perforating machine, a first lifting device and a second lifting device, wherein the first lifting device is connected with the perforating bracket; the second lifting device is connected with a driving end of the first lifting device; a steering seat is arranged at a driving end of the second lifting device; and the steering seat is connected with the perforating machine. The direction of a perforating end of the perforating machine is enabled to be upward through regulating the steering seat; the position of the second lifting device can be adjusted through the first lifting device; after the perforating machine on the second lifting device is adjusted to a working height, the perforating machine is started; afterwards, the perforating machine is enabled to move upwards through the second lifting device; the perforating work is completed; and the operation is simple.

Owner:GUANGZHOU BAIER COLD CHAIN POLYURETHANE TECH

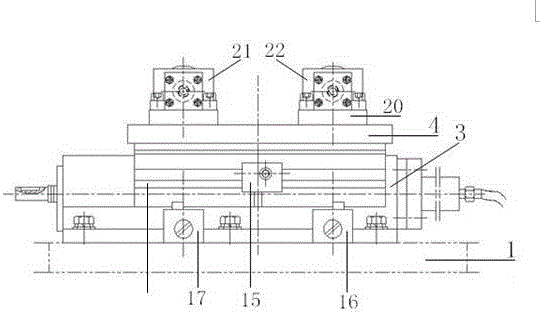

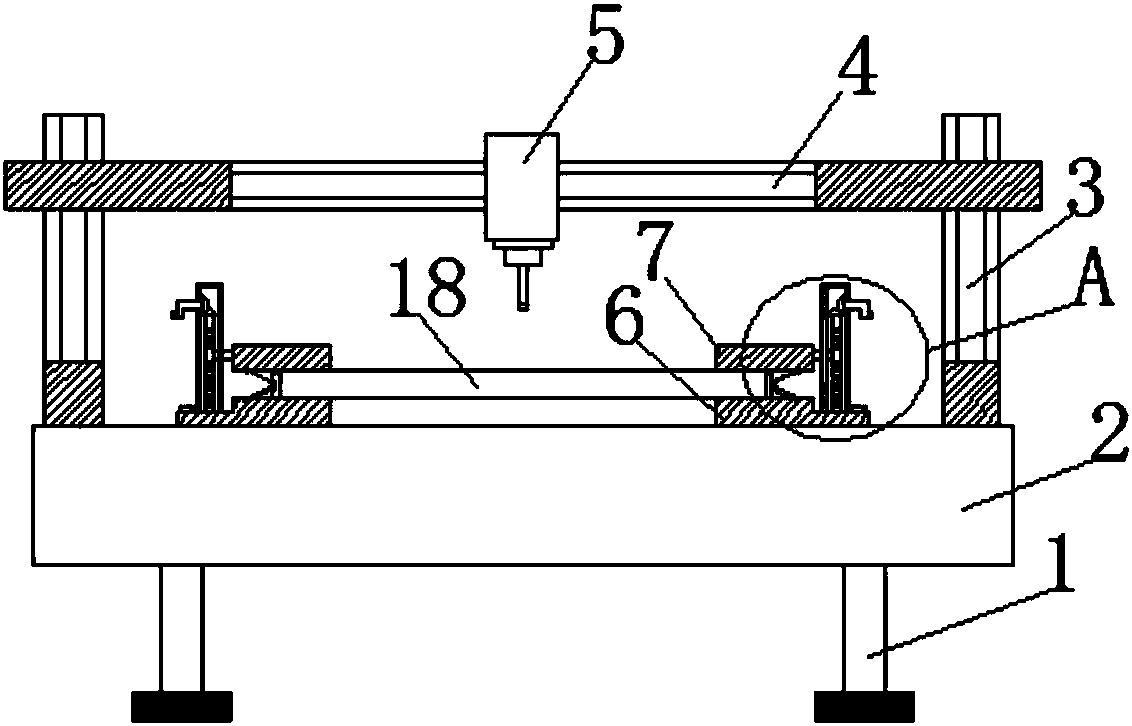

Drilling and locating device for hollow spheres of sphere-connected handrail

ActiveCN106736761AAccurate drilling positioningPrecise positioningFeeding apparatusPositioning apparatusMachine toolMachining

The invention discloses a drilling and locating device for hollow spheres of a sphere-connected handrail. The drilling and locating device comprises a machine tool working table, a guide rail, an oil pressure sliding table and a connection flat plate, wherein the guide rail is arranged on the machine tool working table; the oil pressure sliding table is arranged on the guide rail; a limiter is arranged on the oil pressure sliding table; two sensors are arranged on the machine tool working table; the connection flat plate is fixed on the oil pressure sliding table; two hollow sphere locating and fixing devices are arranged on the connection flat plate; the hollow sphere locating and fixing devices comprise locating parts and clamping parts; the locating parts comprise locating part bodies and floating locating taper pins; the floating locating taper pins consist of screw rods, nuts, cylindrical helical springs and locating taper pins; and the clamping parts comprise clamping part bodies and telescopic oil cylinders connected with the clamping parts. The drilling and locating device can accurately locate the hollow spheres on a machine tool and drill through the hollow spheres at one time, and can further realize continuous switching machining of two stations for hollow sphere drilling, so that the drilling efficiency for the hollow spheres is improved, and the manufacturing cost is greatly reduced.

Owner:ZIGONG DONGFANG STEEL STRUCTURE

Continuous type full-automatic drilling machining equipment for charger shell bodies

InactiveCN106735407AImprove processing efficiencyHigh precisionBoring/drilling machinesEngineeringMachining

The invention provides continuous type full-automatic drilling machining equipment for charger shell bodies. A driving mechanism drives a movable plate to intermittently move up and down in the vertical direction. M radial grooves are formed in the peripheries of driven groove wheels. A limiting platform used for fixing a to-be-machined workpiece is arranged in the position, between every two adjacent radial grooves, of the wheel surface. The disk surface edge of a driving poking disk is provided with a cylindrical pin and a convex locking arc for locking the driven groove wheels. A concave locking arc which is matched with the convex locking arc and can enable the corresponding driven groove wheel to be static is arranged between every two adjacent radial grooves. A transmission mechanism drives the driving poking disk to intermittently rotate. Drilling mechanisms conduct drilling machining on the to-be-machined workpieces fixed to the driven groove wheels. A controller is connected with the driving mechanism, the transmission mechanism, the N drilling mechanisms and a distance measuring sensor. According to the continuous type full-automatic drilling machining equipment for the charger shell bodies, the driving mechanism, the driving poking disk, the N driven groove wheels, the transmission mechanism, the N drilling mechanisms and the controller are matched with one another, and thus end surface drilling full-automatic continuous machining work of the multiple charger shell bodies can be completed at a time.

Owner:天长市优信电器设备有限公司

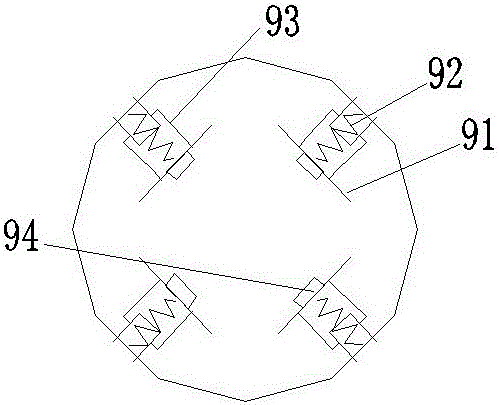

High-precision charger shell end face drilling machining device

InactiveCN106624033AAvoid shakingAvoid drilling deviationMeasurement/indication equipmentsLarge fixed membersEngineeringMachining

The invention provides a high-precision charger shell end face drilling machining device. The device comprises a workbench, an installing frame, a first driving mechanism, N drilling mechanisms, N fixing mechanisms and a controller; the installing frame is provided with a distance measuring sensor used for detecting a distance value between the installing frame and the workbench in real time; each drilling mechanism comprises M drilling components and prepressing sleeves, wherein the M drilling components are all installed on the installing frame and circumferentially distributed, drill bits of all the drilling components face the workbench, the prepressing sleeves are located under the installing frame, connected with the installing frame through multiple reset springs and provided with M guiding grooves, and a first guiding hole used for allowing the corresponding drill bit to penetrate through is formed in each guiding groove in the extending direction of the drill bit; M fixing platforms used for fixing a charger shell are arranged at the end, close to the installing frame, of a fixing base, and the controller is connected with the first driving mechanism and the distance measuring sensor. The high-precision charger shell end face drilling machining device is accurate in drilling and positioning performance, high in precision and drilling efficiency, good in machining effect and high in product quality.

Owner:天长市优信电器设备有限公司

Solar cell panel drilling device

InactiveCN108177258AReliable clampingAccurate drilling positioningFinal product manufactureWorking accessoriesSolar cellThreaded rod

The invention discloses a solar cell panel drilling device which comprises a fixed base. Two vertical electric guide rails are vertically and symmetrically arranged on the side wall of the upper sideof the fixed base, and sliding blocks in the two vertical electric guide rails are fixedly connected with a transverse electric guide rail which is transversely arranged. A sliding block in the transverse electric guide rail is fixedly connected with an electric drill which is vertically arranged. Two transversely-arranged base plates are symmetrically arranged on the side wall of the upper side of the fixed base. Mounting blocks are vertically arranged on the side walls of the upper sides of the base plates, and each mounting block is of a hollow structure. Threaded rods are arranged inside the corresponding mounting blocks. One sides of the threaded rods are connected with the inner walls of the mounting blocks in a rotating mode, and first bevel gears are arranged at the other sides ofthe threaded rods. The solar cell panel drilling device can fix and clamp solar cell panels, and clamping is firm; and meanwhile, the solar cell panels can be drilled and positioned accurately and theprecision of drilled holes is high.

Owner:CHANGZHOU SANLI JINGTU PHOTOELECTRIC

Perforating device for injection mold machining

The invention discloses a perforating device for injection mold machining. The perforating device comprises a lower supporting frame and an upper frame, wherein a drilling platform is arranged at the top end of the lower supporting frame, a mounting sliding table sliding on the drilling platform is arranged on the drilling platform, and a row of upper connecting holes and a row of lower connecting holes are formed in the side wall of the mounting sliding table; a plurality of pushing guide rod strips are further arranged at the side portion of the mounting sliding table, a driving transverse frame located above the mounting sliding table is arranged on the upper frame, a rotating rod shaft is installed on the driving transverse frame, a drill bit is arranged at the bottom end of the rotating rod shaft, and the two end sides of the driving transverse frame are connected with upper frame supporting columns in an up-down sliding manner through connecting guide rails; and a feeding mechanism is arranged at the top of the upper frame, and a pushing guide rod right opposite to the pushing guide rod strips is further arranged at the end, away from the drill bit, of the driving transverse frame. The perforating device is simple in structure, an injection mold is automatically pushed to move in the drill bit feeding process, the drilling distances are equal, drilling positioning is accurate, automatic perforating is achieved, and the efficiency is high.

Owner:余华

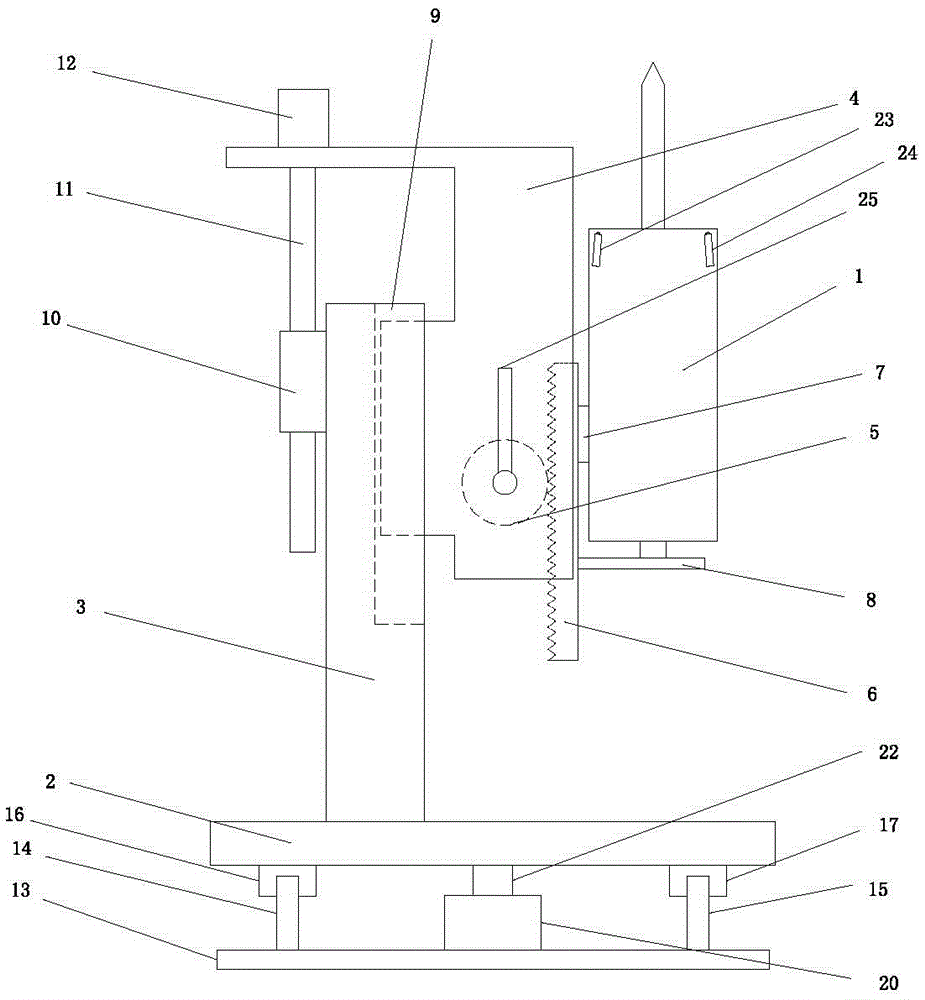

Drilling device

PendingCN111822752AEasy to operateAccurate drilling positioningWork benchesPortable drilling machinesClassical mechanicsStructural engineering

The invention discloses a drilling device. The drilling device comprises a drilling mechanism, a base, vertical plates located on the two sides of the base, a connecting rod connected with the two vertical plates and an operating assembly used for driving the drilling mechanism to move along the connecting rod. The operating assembly comprises a first locating block arranged on the connecting rod,a sliding block slidably arranged on the connecting rod, a handle rotatably arranged on the first locating block and a joint lever rotatably arranged on the sliding block. One end of the joint leveris rotatably arranged on the sliding block, and the other end of the joint lever is rotatably arranged on the handle. The drilling mechanism is slidably arranged on the connecting rod through the sliding block. The drilling device provided by the invention drives the joint lever to move through rotation of the handle and then pushes the sliding block to slide to enable the drilling mechanism connected to the sliding block to move, can move forwards to drill holes or retreat and is convenient to operate and accurate in drilling and locating.

Owner:SJEC CORP

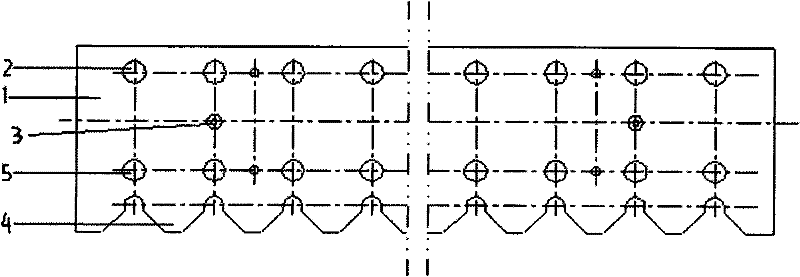

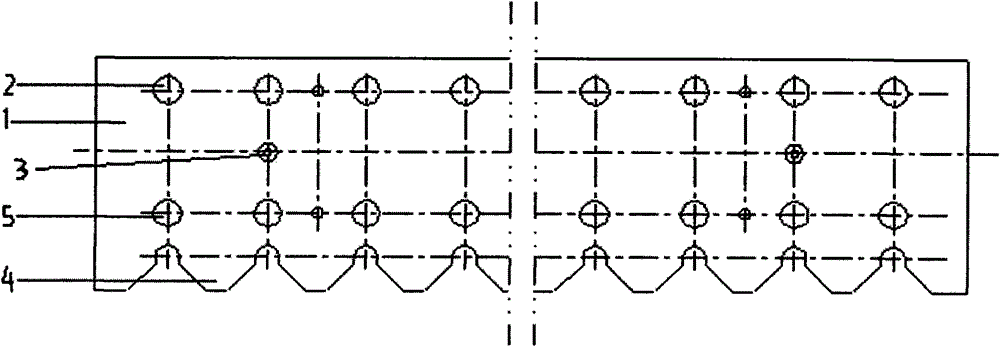

Flat buckle template

The invention discloses a flat buckle template, which is composed of a metal plate. One edge of the metal plate is saw-toothed. A first circular hole set and a second circular hole set are arranged on the metal plate. More than two first circular holes are arranged in the first circular hole set. The first circular holes are arranged in a direction parallel to the saw-toothed edge of the metal plate. Second circular holes, the number of which is the same to that of the first circular holes, are arranged in the second circular hole set. The second circular holes and the first circular holes form a rectangular array. The saw-toothed bottoms are semi-circles. Circle centres of the semi-circles are on longitudinal connection lines of circle centres of the first circular holes and circle centres of the second circular holes respectively. More than two locating pins or third circular holes are arranged on the metal plate. The locating pin or the third circular holes are arranged between thefirst circular hole set and the second circular hole set. All locating pins are vertical to the surface of the metal plate. Head faces of two conveying belts tightly press against the locating pins or the third circular holes from two sides of the locating pins or the third circular holes. The conveying belts are fixed through nails and then drilled through the first circular holes and the secondcircular holes by using a tool. The flat buckle template disclosed by the invention is precise to locate and simple and convenient to operate.

Owner:SHANGHAI GORO CONVEYOR EQUIP CO LTD

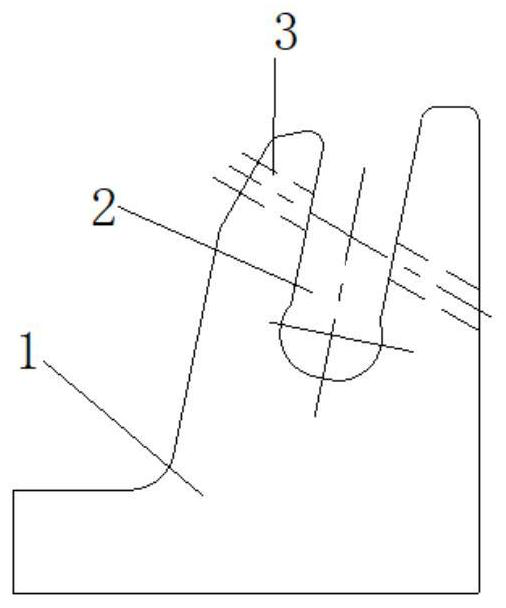

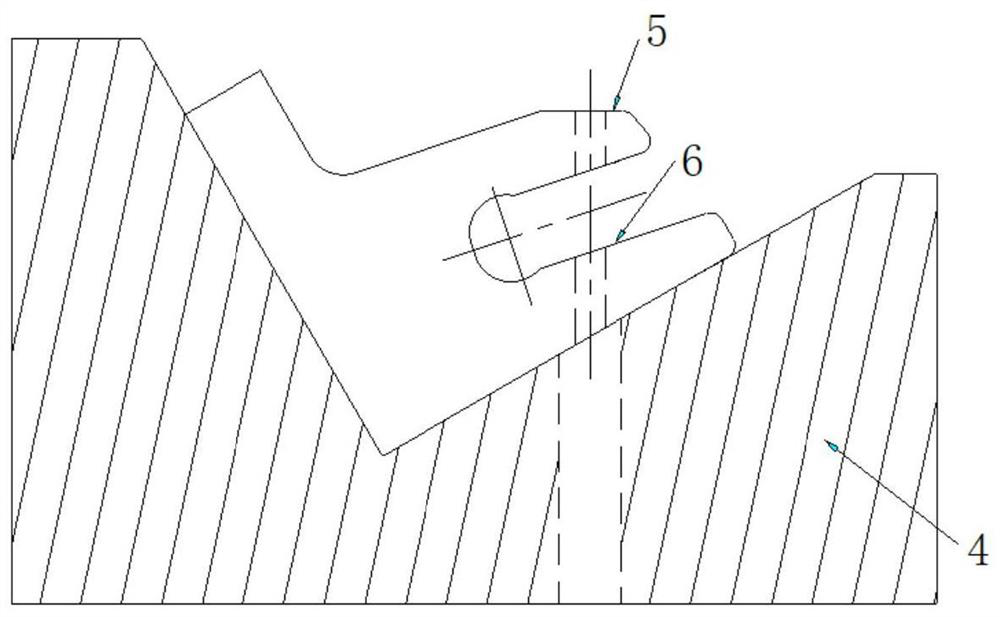

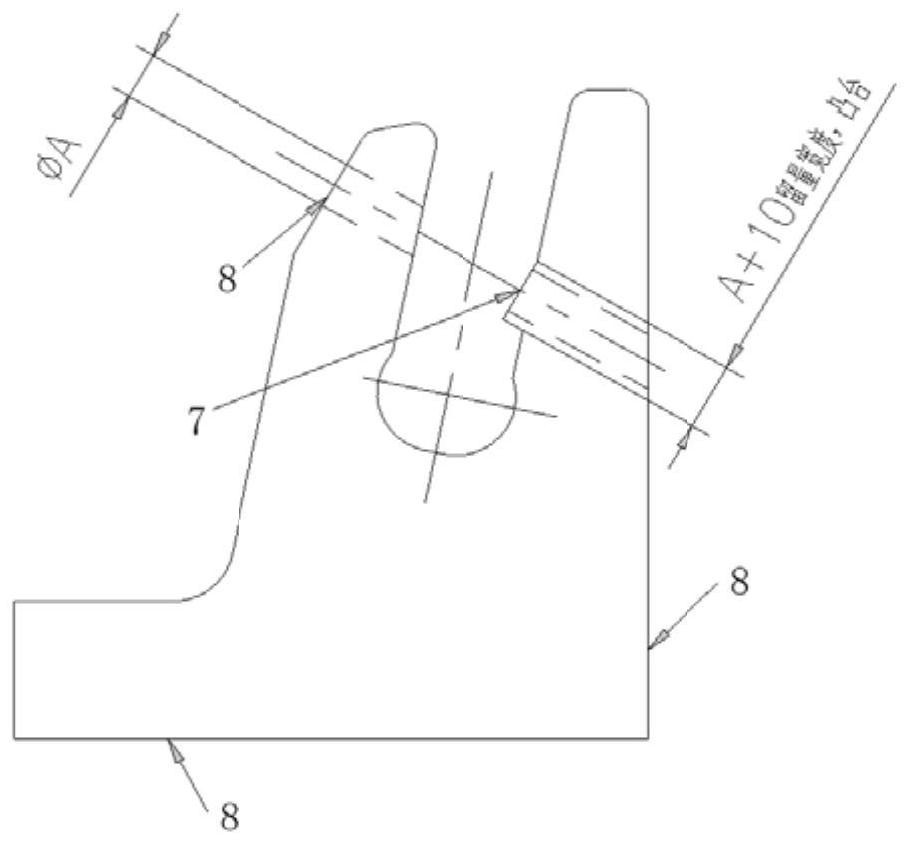

Processing method for push rod connecting base

InactiveCN112059228AAccurate drilling positioningImprove efficiencyPositioning apparatusMetal-working holdersDrill holeDrill bit

The invention discloses a processing method for a push rod connecting base. An inclined U-shaped groove and an inclined hinge pin hole are formed in the push rod connecting base, and the blank of thepush rod connecting base is arranged on a slope hole tool; it is ensured that the hinge pin hole to be machined is in the vertical direction, and drilled with a drill bit vertically; and a drill bit inlet of the hinge pin hole to be machined is processed into a plane; the drill bit is perpendicular to the plane; and a boss plane is reserved at the drill bit inlet of the inner wall of the U-shapedgroove, so that the drill bit is perpendicular to the boss plane. When the push rod connecting base is used for blanking and cutting, 3mm tool detection machining allowance is reserved on each of three cut surfaces, and the tool detection surfaces are used as reference surfaces for subsequent machining. Through regulation of the profile machining allowance of the connecting base, the plane for drilling the inclined hole is added, and it is ensured that an inclined location hole is a straight platform plane and is used in cooperation with an inclined hole machining tool; and it is ensured thatthe drilling location is accurate, and the machining drilling efficiency is effectively improved.

Owner:CHINA COAL BEIJING COAL MINING MACHINERY

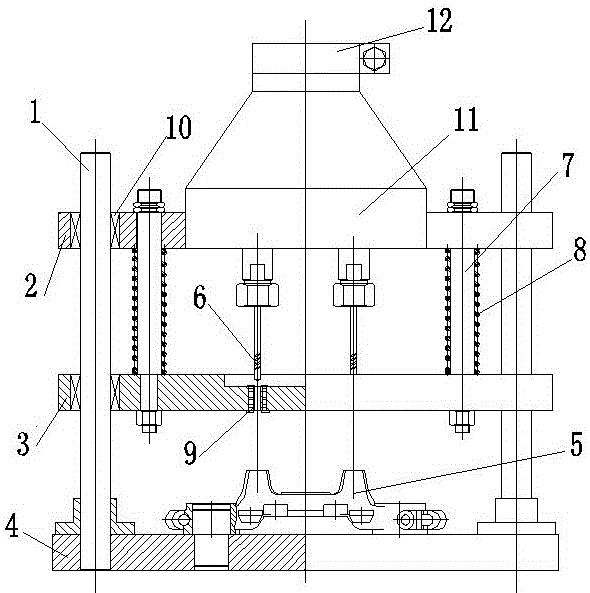

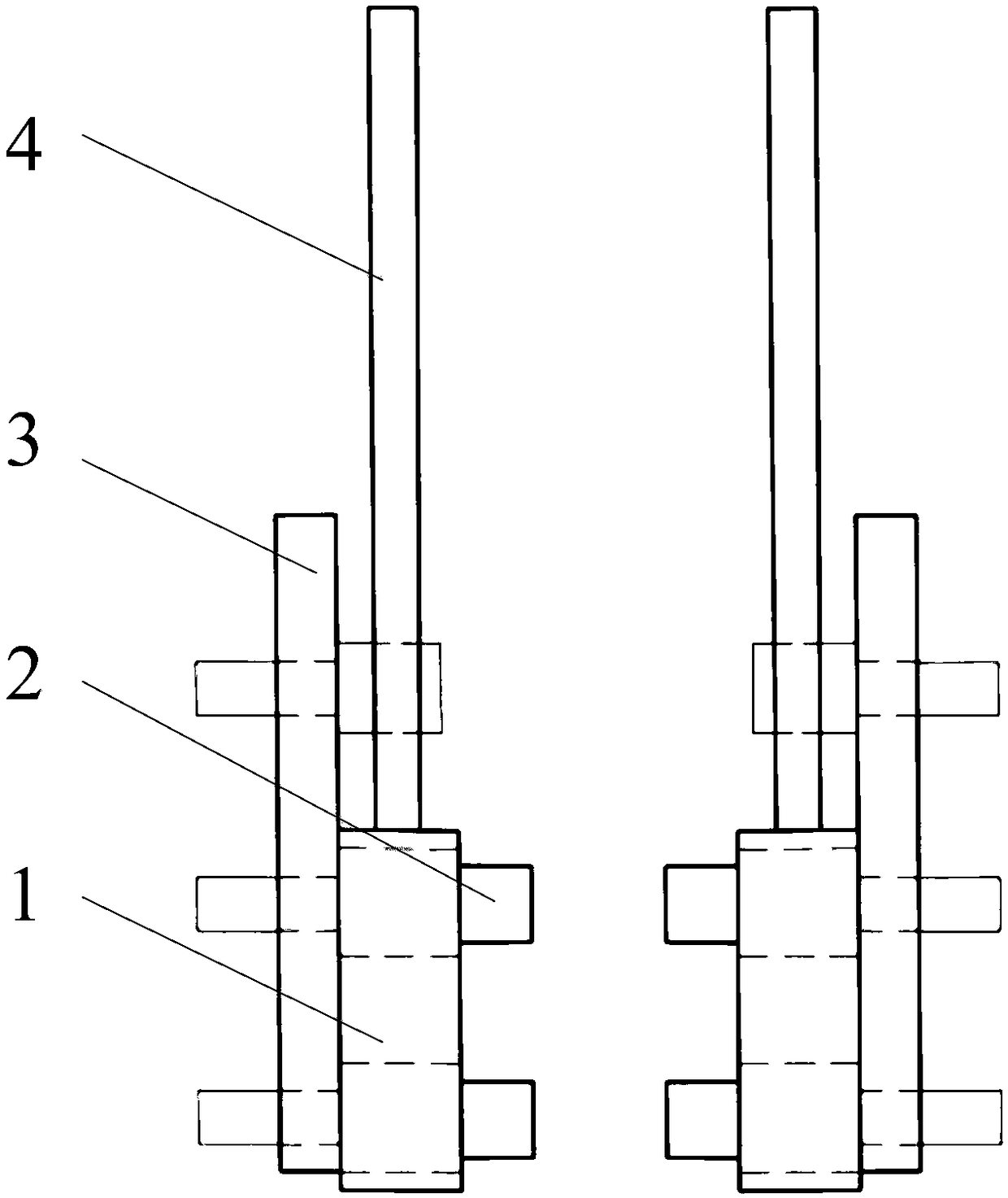

A drilling device with a drilling template that can float up and down

ActiveCN105935783BEasy to installAccurate drilling positioningDrilling/boring measurement devicesBoring/drilling machinesDrill bitGeotechnical engineering

The invention relates to a drilling device with a drill plate capable of floating up and down. The drilling device comprises guide columns. The guide columns are provided with a shaft plate and the drill plate. A clamp bottom plate fixedly arranged is arranged at the lower portion of the drill plate and provided with a positioning device fixing a workpiece. The shaft plate is connected with drill bits fixed to the lower surface of the shaft plate. The drill plate is provided with through holes for the drill bits to penetrate out of the drill plate. Guide rods penetrate the part between the shaft plate and the drill plate. The guide rods are sleeved with springs located between the shaft plate and the drill plate. The through holes are internally provided with drill sleeves guiding the drill bits. According to the structural form of the drill sleeves, each drill sleeve is formed by assembling a plurality of symmetrically-arranged guiding sleeves, the inner walls of the through holes and the guiding sleeves are connected through guiding springs, and telescopic casing pipes which can contain the guiding springs inside and can relatively slide are arranged between the inner walls of the through holes and the outer walls of the guiding sleeves. The drilling device with the drill plate capable of floating up and down is simple in structure and capable of conducting deviation correcting when the drill bits deviate.

Owner:JIANGSU XINGUANGHUA MACHINERY

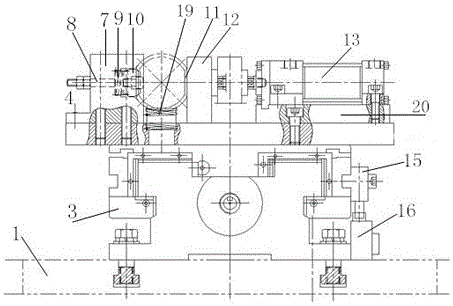

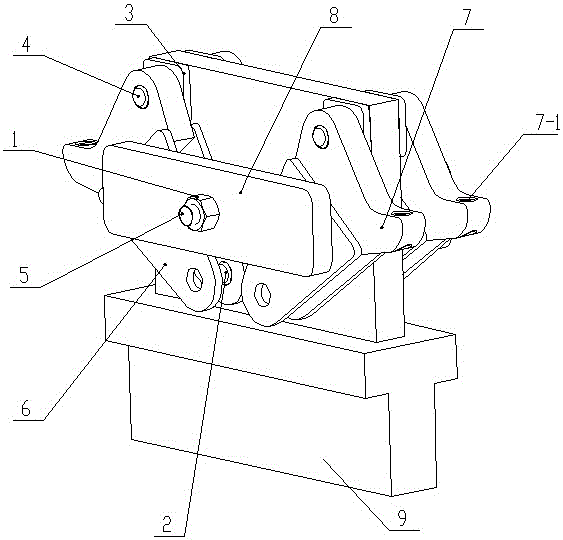

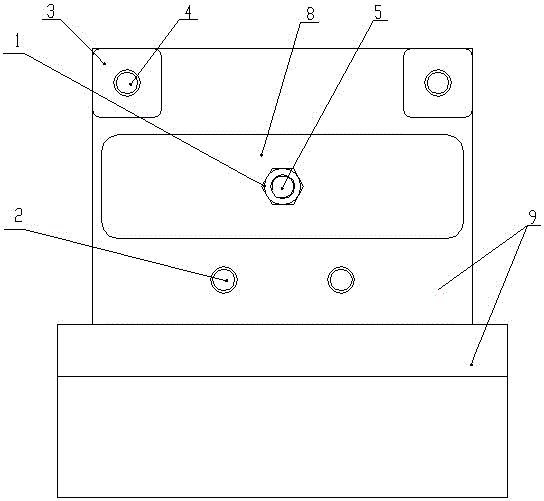

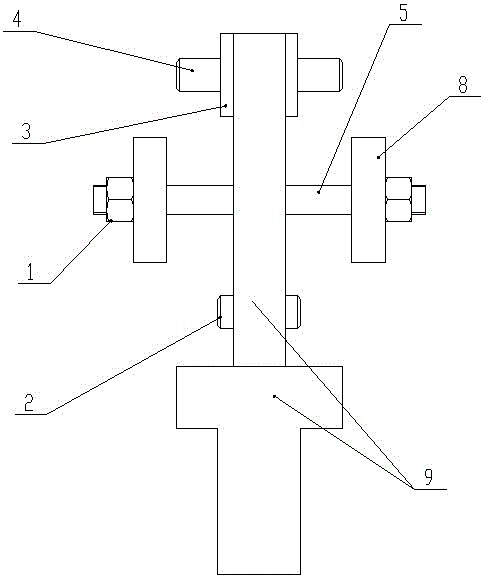

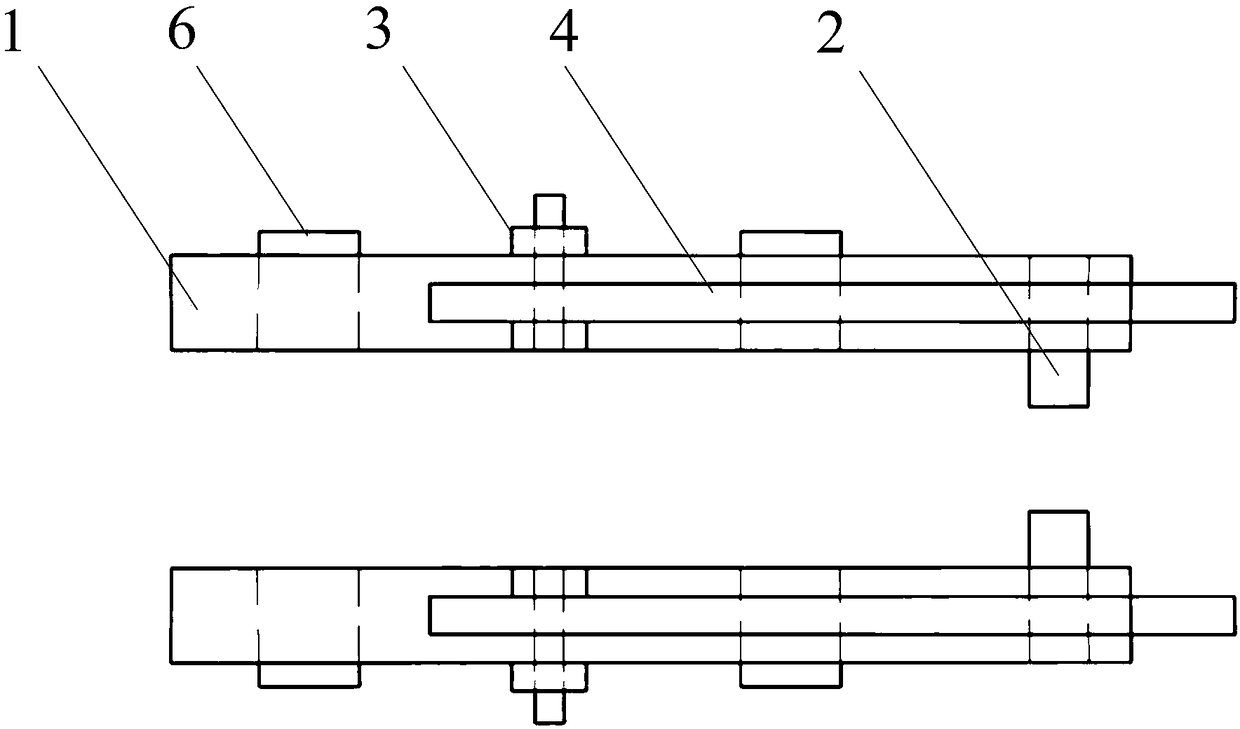

Drilling and positioning device for swinging part of four-claw material cover

ActiveCN103962857BPrecise positioningIncrease productivityWork clamping meansPositioning apparatusEngineeringInverted t

The invention provides a drilling positioning device of a four-claw material cover swing piece, and belongs to machining tools of bulk cement truck parts. The drilling positioning device of the four-claw material cover swing piece is characterized in that the drilling positioning device is mainly composed of a drilling seat plate, lower positioning pins, a pressing plate positioning pin, pressing plates, pressing nuts and upper positioning pins; the lower portion of the drilling seat plate is provided with an inverted T-shaped plate, a vertical face plate is arranged on the upper portion of the drilling seat plate, a main pin hole is formed in the center position of the vertical face plate, the pressing plate positioning pin is mounted at the center position of the vertical face plate, the front section and the rear section of the pressing plate positioning pin are respectively provided with one pressing plate in a sleeved mode, the front end and the rear end of the pressing plate positioning pin are respectively provided with an external thread and are respectively provided with one pressing nut in a screwing mode, a left lower pin hole I and a right lower pin hole I are formed in the lower portion of the vertical face plate, the upper end of the vertical face plate is provided with a left upper pin hole I and a right upper pin hole I respectively, and the left upper pin hole I and the right upper pin hole I are respectively provided with one upper positioning pin. In the using process, the front side face and the rear side face of the vertical face plate of the drilling seat plate are respectively provided with a left swing piece and a right swing piece, bolt holes are formed in the vertical direction of the machined swing pieces, positioning is accurate, and the production efficiency is high.

Owner:ANHUI XINGMA SPECIAL PURPOSE VEHICLE

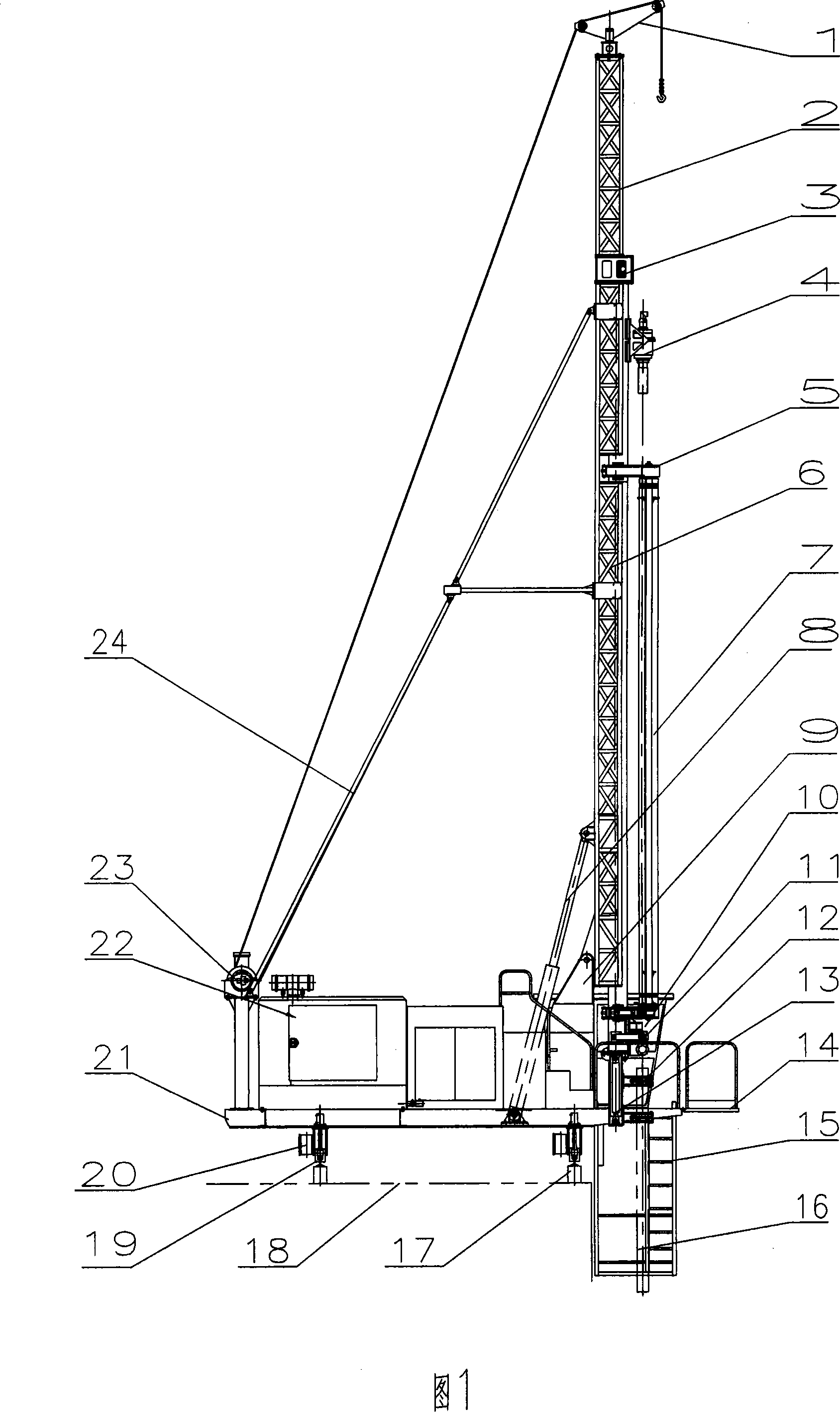

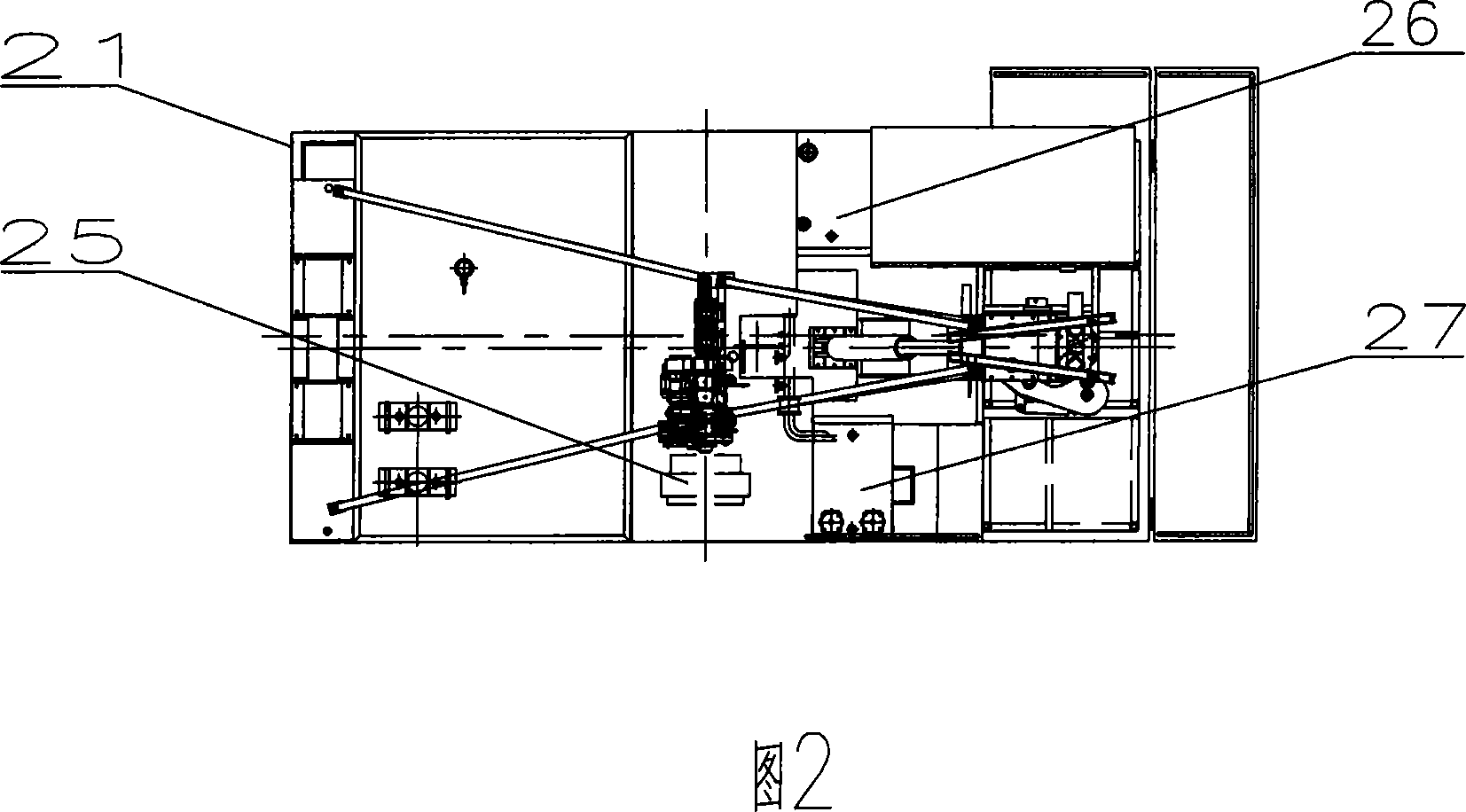

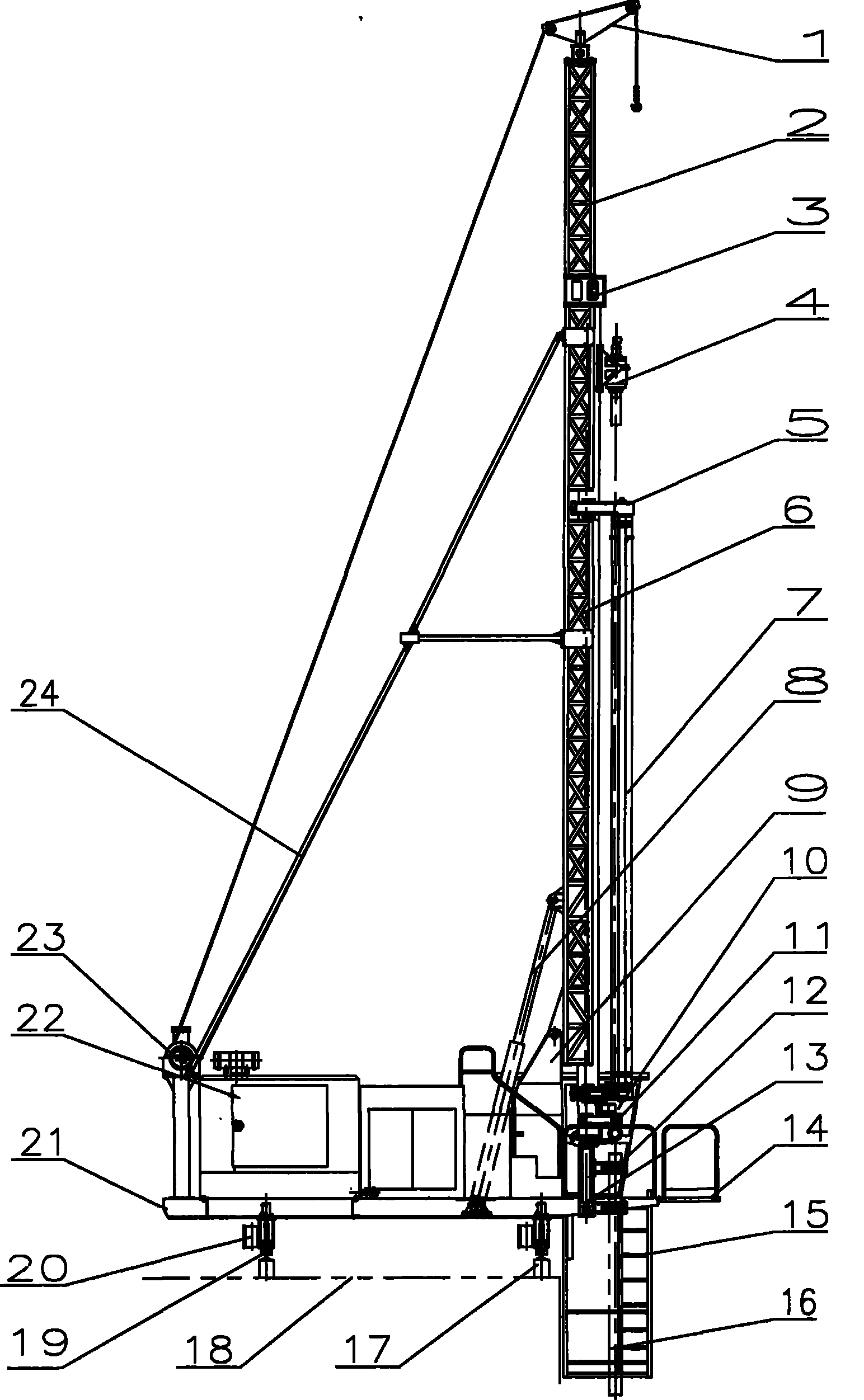

Sailing course drill

ActiveCN101122211BReduce labor intensityRapid, stable and reliable fixationDerricks/mastsUnderwater drillingHydraulic motorEngineering

Owner:CENT SOUTH UNIV +1

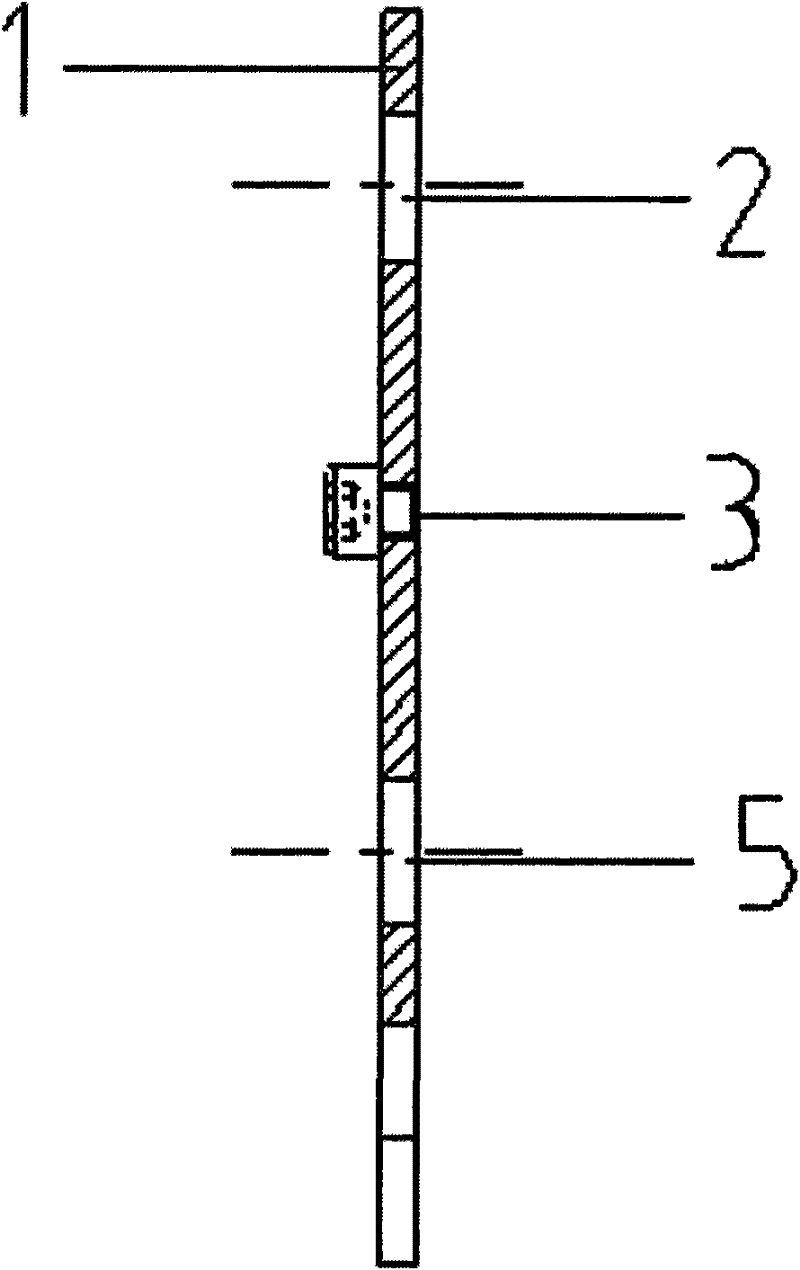

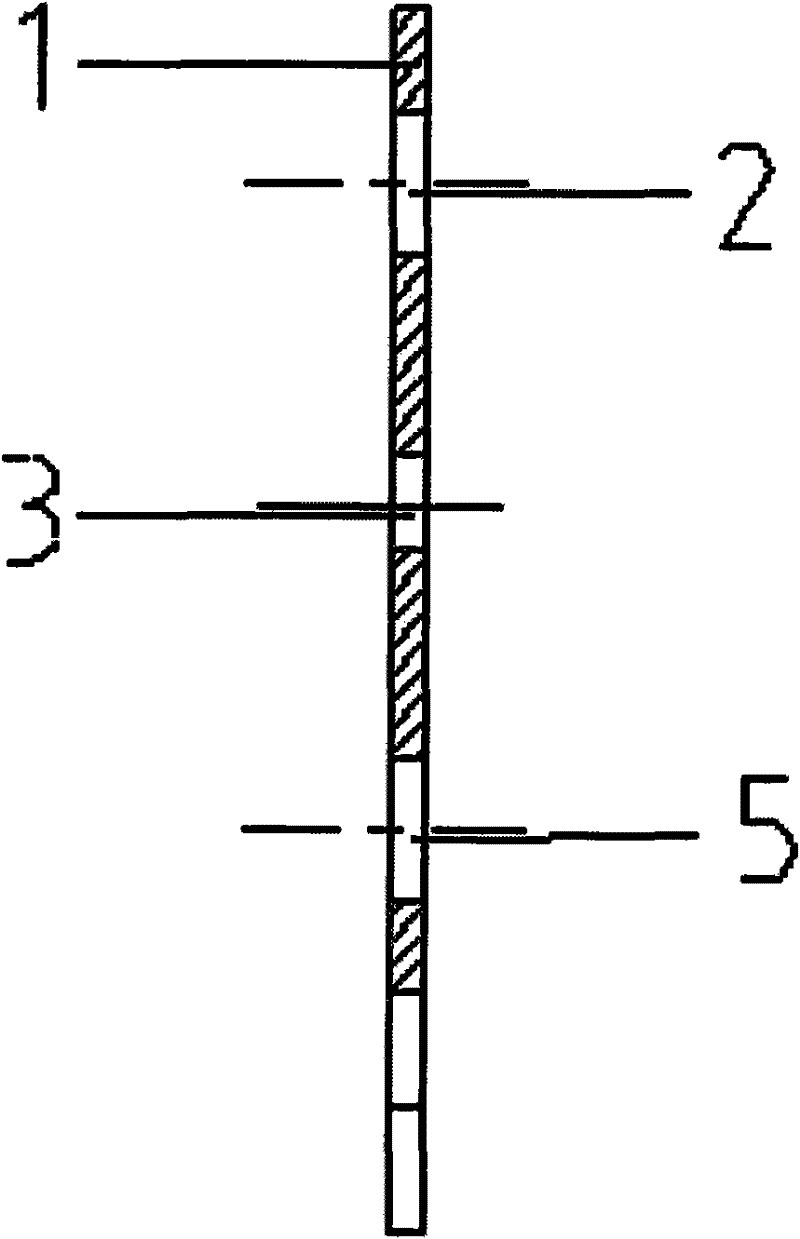

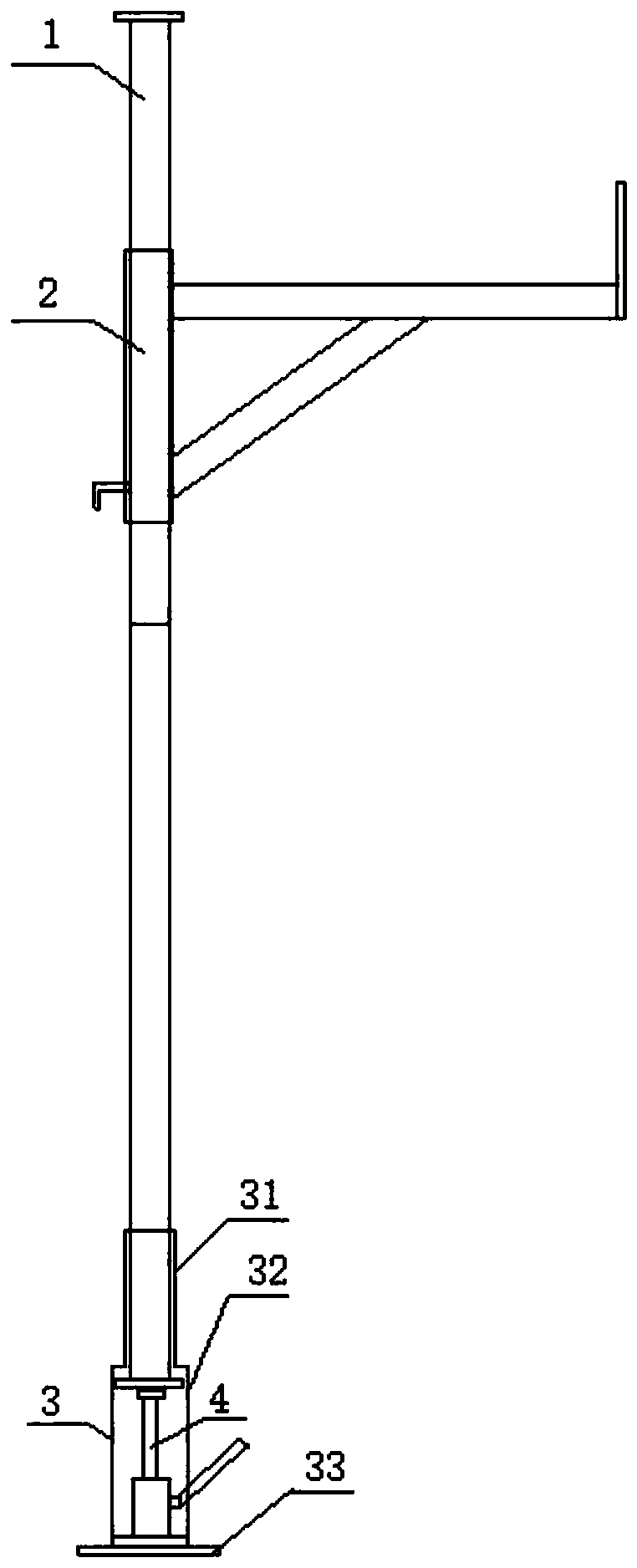

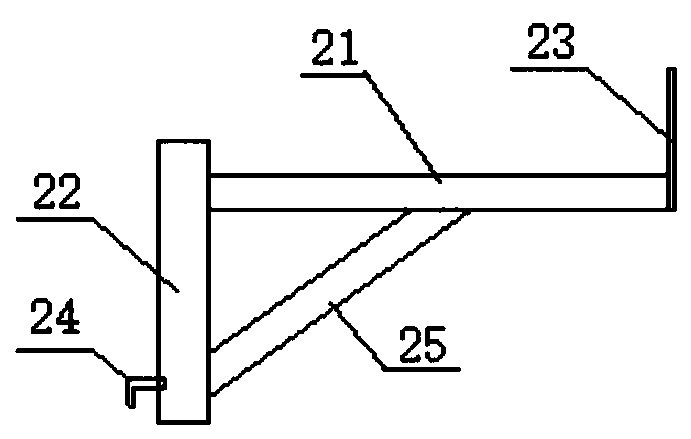

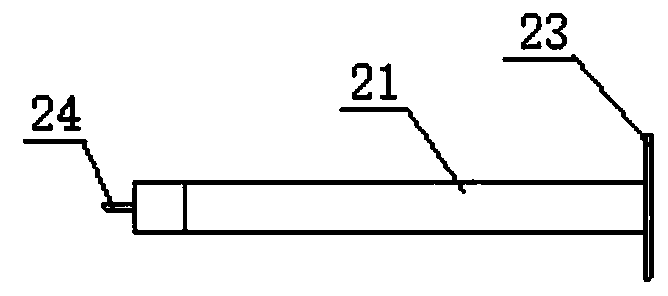

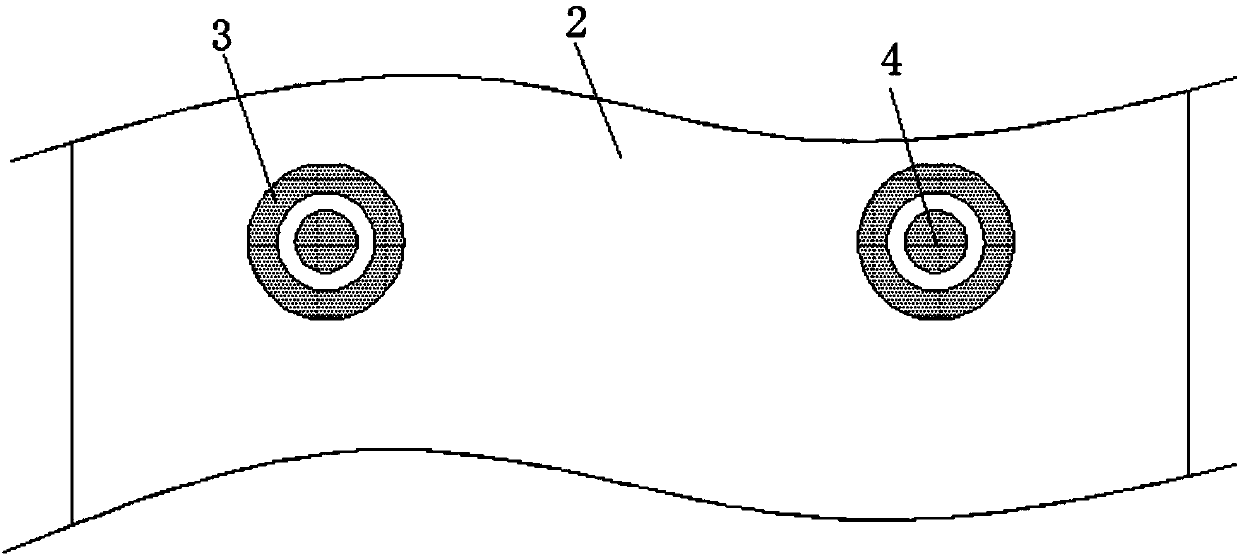

Fast-installing-and-dismantling support of water drilling machine and using method of fast-installing-and-dismantling support

The invention discloses a fast-installing-and-dismantling support for a water drilling machine. The fast-installing-and-dismantling support comprises a vertical rod, a water drilling machine bracket,a jack support and a jack; the water drilling machine bracket includes a transversal rod, a sliding sleeve, a water drilling machine fixing plate and a limiting screw; the two ends of the transversalrod are connected between the sliding sleeve and the water drilling machine fixing plate; the sliding sleeve is arranged on the vertical rod in a sleeving manner; a threaded through hole is formed inthe side wall of the sliding sleeve; the limiting screw is arranged in the threaded through hole; through holes are formed in the water drilling machine fixing plate; the jack support includes a connecting sleeve, a support shell and a bottom plate; the connecting sleeve is connected with the top part of the support shell; the bottom plate is connected with the bottom part of the support shell; the lower part of the vertical rod is arranged on the connecting sleeve in a sleeved manner; and the jack is arranged in the support shell. The invention further discloses a using method of the fast-installing-and-dismantling support. The fast-installing-and-dismantling support is suitable for drilling construction of different heights and various hole diameters, can be fast to install and dismantleand is accurate in drilling positioning.

Owner:CHINA MCC 2 GRP CO LTD

Aluminum alloy hub drilling production line

InactiveCN107790781ATo achieve streamlined processingAvoid distortionWheelsMetal working apparatusProduction lineMotor drive

The invention discloses an aluminum alloy wheel hub drilling production line, which comprises a base, the upper surface of the base is fixedly connected with a working platform, the upper surface of the working platform is clamped with a first bearing, the number of the first bearing is two, and the two The inner walls of the first bearings are fixedly connected with first rotating shafts, the surfaces of the two first rotating shafts are fixedly connected with first gears, and the two first gears are connected by crawler belt transmission, and the upper surface of the working platform is provided with transmission rollers. The invention drives the first rotating shaft to rotate through the stepping motor, thereby driving the crawler belt to rotate, and the crawler belt meshes with the first gear rail to drive the conveyor belt to rotate, so that the conveyor belt can transport the aluminum alloy wheel hub, thereby achieving streamlined processing. By setting the second The rotating shaft, the second gear and the second rack make the hub complete the rotation with the movement of the conveyor belt during the transportation of the conveyor belt to the hub, so that the hub is automatically transposed after one drilling, and the next drilling is accurate position.

Owner:蒋嘉文

Concrete piling process and drilling machine special for same

InactiveCN102677666BPrevent collapseStrong reliabilityBulkheads/pilesHardnessUltimate tensile strength

The invention discloses a concrete piling process and a drilling machine special for the same. The concrete piling process is applicable to filled concrete and fluid such as cement, and can meet construction requirements of complicated geological conditions comprising high hardness or high collapsibility; by the concrete piling process, drilling, filling and broaching are completed at a time, and diameter-varied piles with high quality requirements can be molded; and transverse drilling can be realized at any position of pile holes accurately; the concrete piling process is convenient to construct and high in reliability; and the drilling machine special for the concrete piling process can meet requirements of a construction process, effectively shorten construction periods and accurately position the pile holes and determine the depths of the pile holes, and is reasonable in structure, high in strength and long in service life.

Owner:SHANDONG HONGTAI CONSTR GROUP

Drilling device for refrigerated carriage

ActiveCN106583791BSimple structureEasy to operateMeasurement/indication equipmentsFeeding apparatusEngineeringRefrigerated temperature

The invention discloses a perforating device for a refrigerator van. The perforating device comprises a perforating bracket, a perforating machine, a first lifting device and a second lifting device, wherein the first lifting device is connected with the perforating bracket; the second lifting device is connected with a driving end of the first lifting device; a steering seat is arranged at a driving end of the second lifting device; and the steering seat is connected with the perforating machine. The direction of a perforating end of the perforating machine is enabled to be upward through regulating the steering seat; the position of the second lifting device can be adjusted through the first lifting device; after the perforating machine on the second lifting device is adjusted to a working height, the perforating machine is started; afterwards, the perforating machine is enabled to move upwards through the second lifting device; the perforating work is completed; and the operation is simple.

Owner:GUANGZHOU BAIER COLD CHAIN POLYURETHANE TECH

slot drilling machine

ActiveCN110094166BFlexible and fast angleAdjust angleDrilling rodsConstructionsClassical mechanicsStructural engineering

The invention relates to a joint-cutting hole drilling machine. The joint-cutting hole drilling machine is fixed to a hydraulic support, the hydraulic support is used for positioning and constructionof hole drilling. The joint-cutting hole drilling machine includes an installation base which is connected with the hydraulic support, a front-rear sliding seat which is installed on the installationbase and can be driven to move back and forth relative to the installation base, a front-rear swinging seat which is installed on the front-rear sliding seat and can be driven to swing back and forthrelative to the front-rear sliding seat, a left-right sliding seat which is installed on the front-rear swinging seat and can be driven to slide left and right relative to the front-rear swinging seat, a reversing seat which is installed on the left-right sliding seat and can be driven to deflect relative to the left-right sliding seat, and a left-right swinging seat which is installed on the reversing seat and can be driven to swing left and right relative to the reversing seat. One or more drill booms are installed on the left-right swinging seat, the drill booms are provided with drill bitsand drill pipes, and the drill pipes are hydraulically driven for hole drilling construction. According to the joint-cutting hole drilling machine, precise adjustment of the drilling direction and angle of the drill booms can be realized, and the construction requirements for an N00 construction method are met.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

Flat buckle template

Owner:SHANGHAI GORO CONVEYOR EQUIP CO LTD

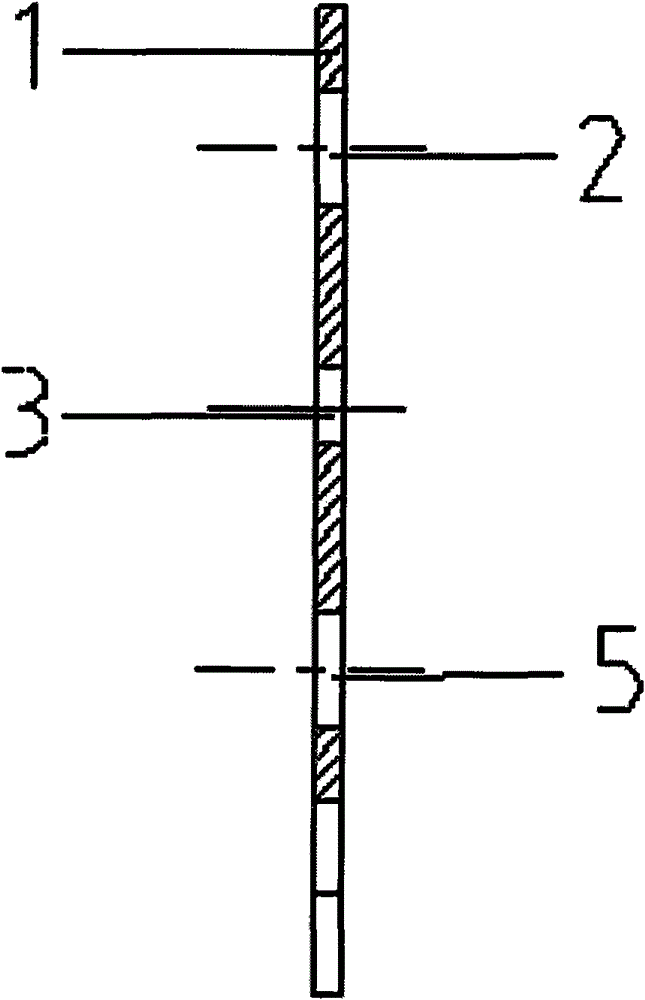

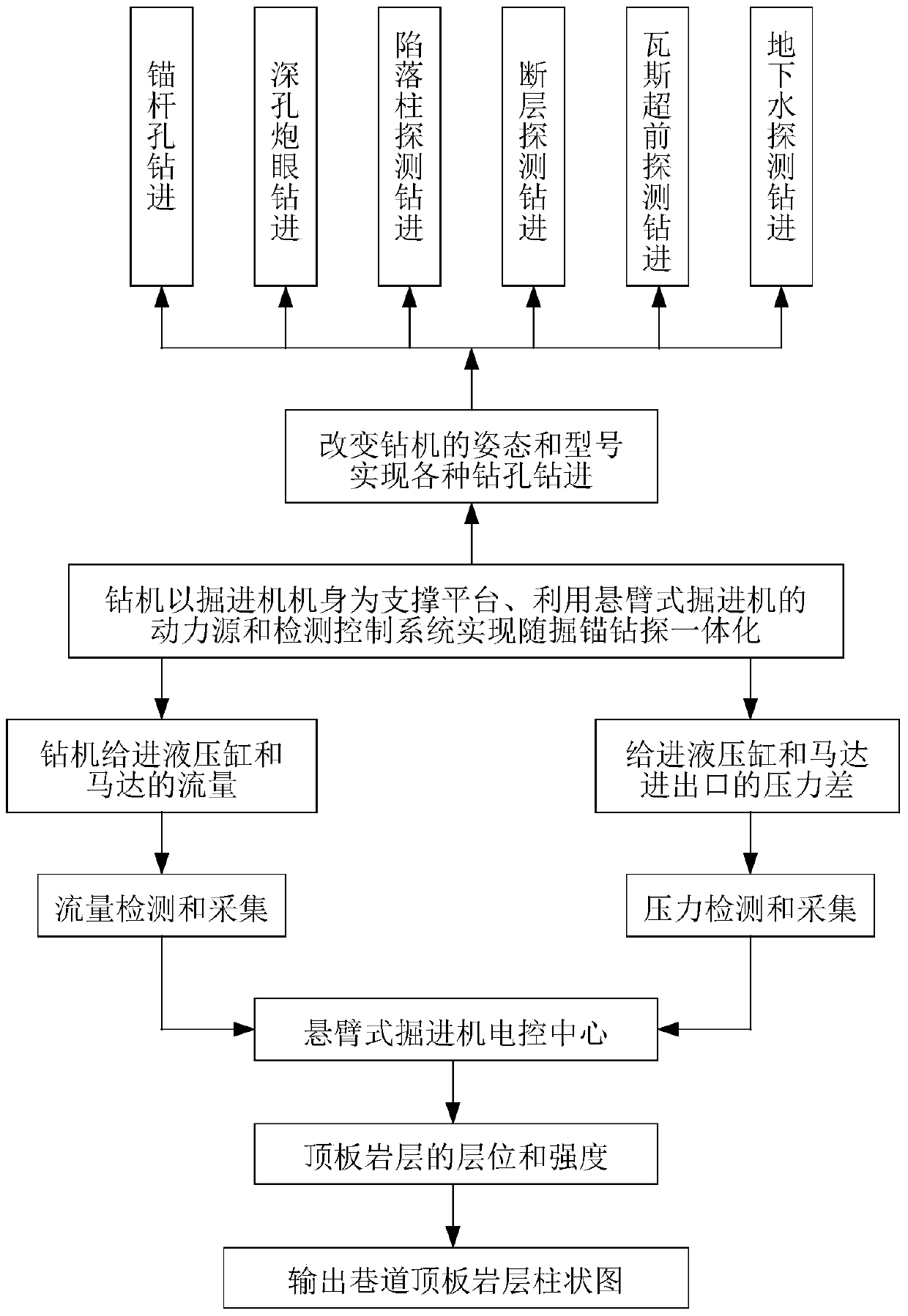

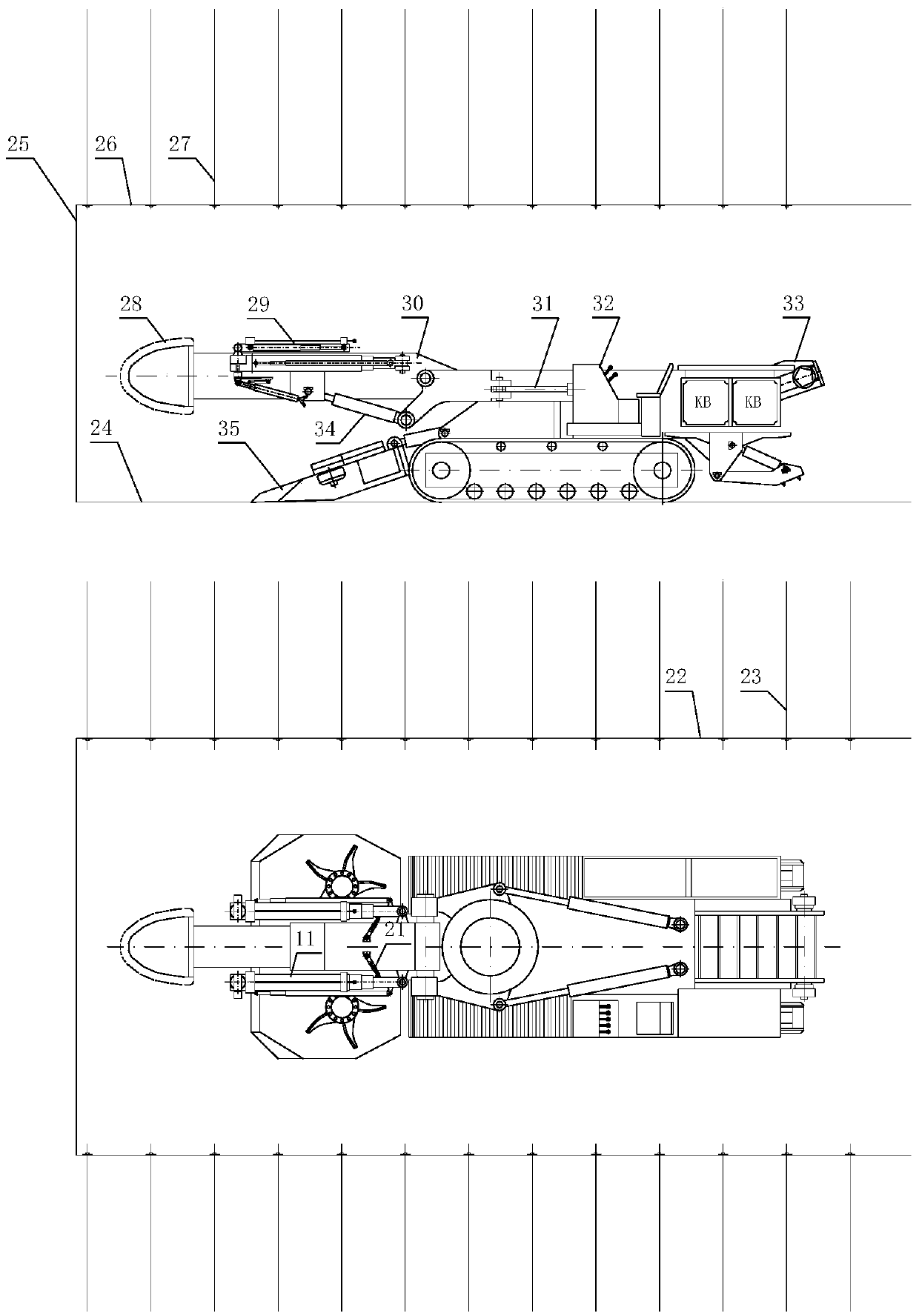

Integrated Drilling Rig for Bolt-while-Driving Drilling

The invention discloses a boom-type roadheader mounted tunneling anchor-along drilling integrated drilling machine which mainly consists of a steel plate structural piece and a hydraulic system, wherein the steel plate structural piece of the drilling machine comprises a main withdrawing and release arm, a drilling machine rack, a vertical rotary mechanism and a horizontal rotary mechanism; the hydraulic transmission system of the drilling machine comprises a drilling hole hydraulic motor, a drilling machine horizontal rotary hydraulic motor, a drilling machine vertical rotary hydraulic motor, a telescopic leg hydraulic cylinder, a drilling machine thrust hydraulic cylinder, a hydraulic control element and a hydraulic auxiliary element. The drilling machine is characterized in that the drilling machine and a tunneling machine are integrally combined and are distributed on two sides of a tunneling machine cantilever, and the walking of the drilling machine is achieved through a walking mechanism of the tunneling machine. Holes can be drilled in an all-direction and multifunction manner in a tunneled roadway, both anchor bolt support and top plate lithology detection can be achieved, and drilling of shotholes, drilling of gas sucking and discharge holes, geologic drilling and the like can be achieved, and facilities and methods are provided for safe, rapid and efficient roadway tunneling.

Owner:ANHUI UNIV OF SCI & TECH

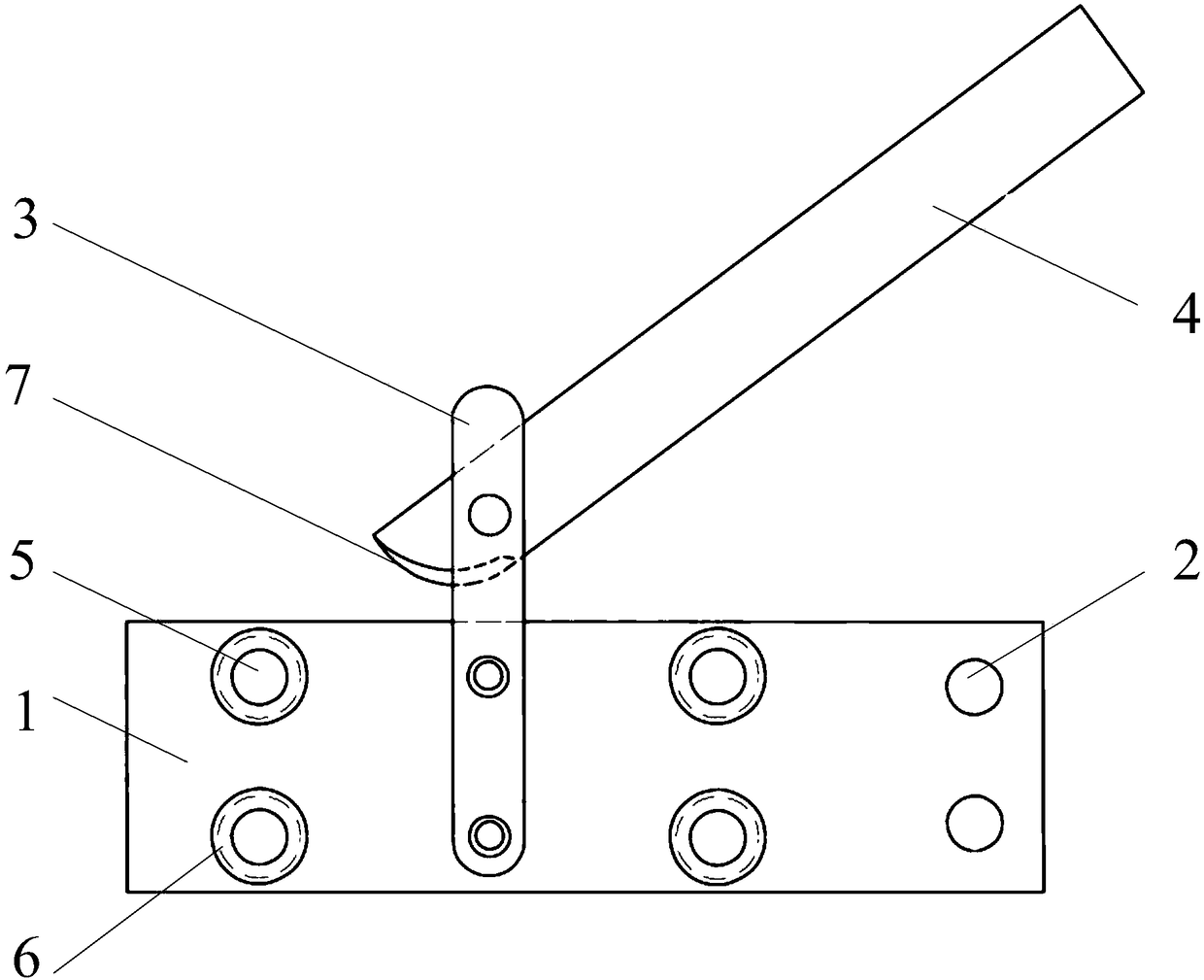

Rigid catenary busbar drilling mold

The embodiment of the invention discloses a rigid catenary busbar drilling mold which comprises two drilling mold parts, wherein the structures of the two drilling mold parts are mirror images of eachother; a plurality of drilling holes are as same as actual busbar and are arranged on a mold plate of each drilling mold part to serve as drilling positioning holes; and a positioning part is arranged inside each mold plate, so that the mold plate and the busbar are closely attached. The mold plates and the busbar are firmly fixed through a connecting strip and a connecting plate, so that the precise positioning of the drilling position of the busbar is achieved through the drilling holes on the mold plates. The drilling holes on the drilling mold parts are completely processed according to the hole position of the busbar. The rigid catenary busbar drilling mold has the advantages that the drilling positioning of the drilling mold parts on the busbar is accurate, the fixing operation is simple and can be completed by one person independently, the drilling precision is improved, the construction efficiency is improved and the construction cost is reduced.

Owner:中铁一局集团电务工程有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com