Perforating device for injection mold machining

A punching device and injection mold technology, applied in metal processing equipment, manufacturing tools, boring/drilling, etc., can solve problems such as low work efficiency, time-consuming and labor-intensive use, and inflexible use of drilling tools

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

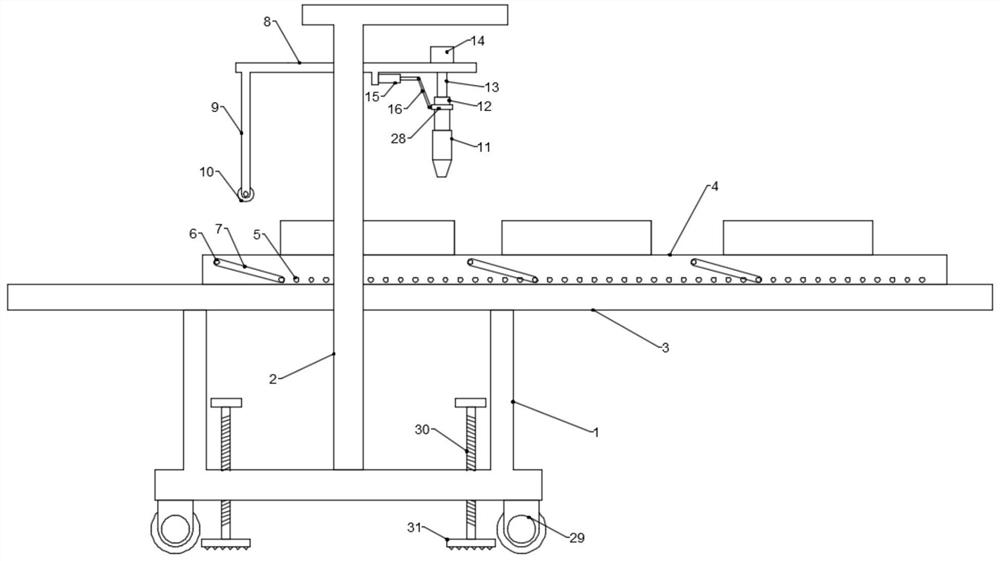

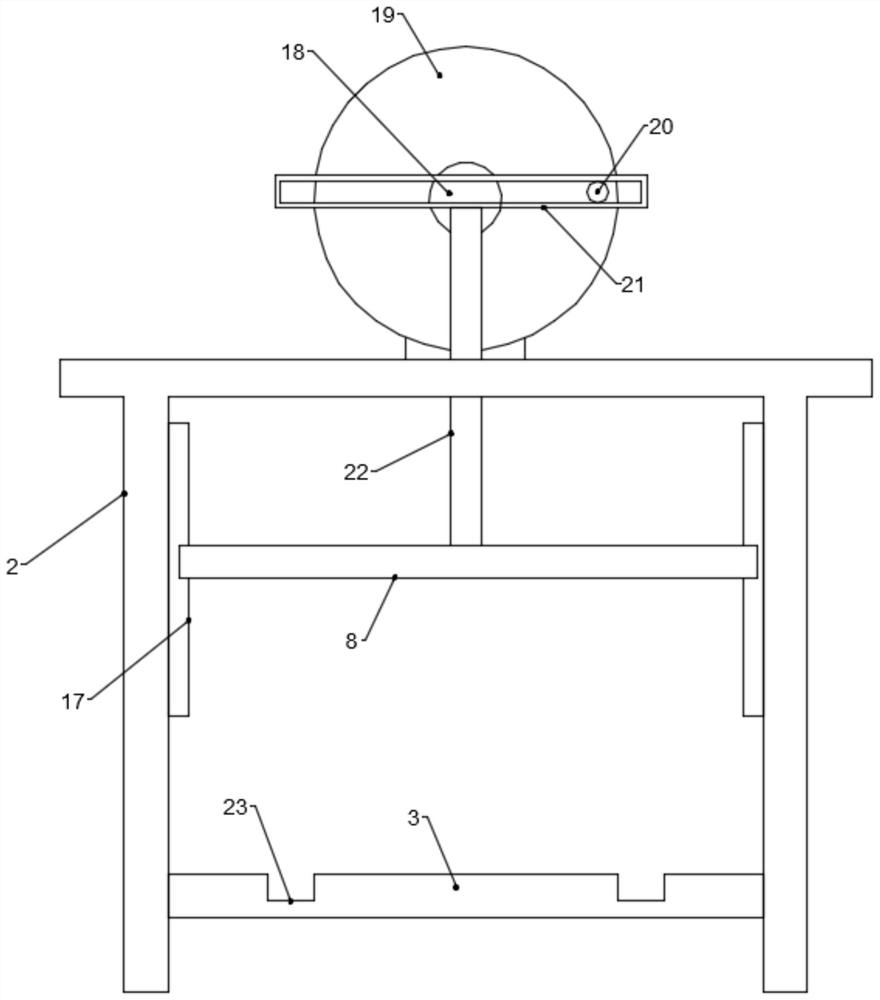

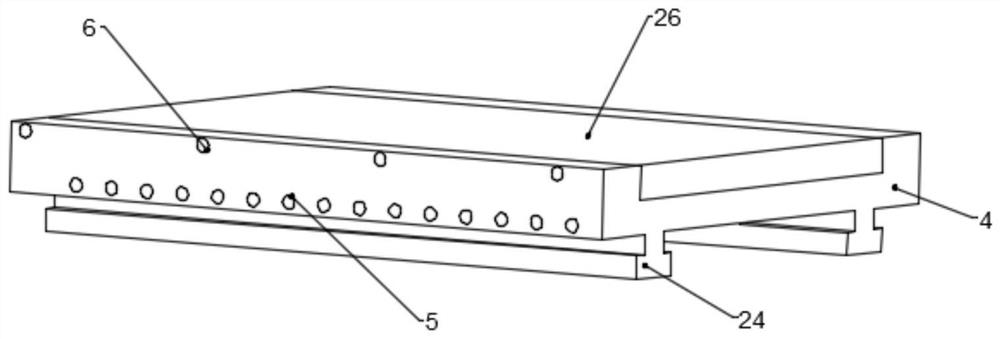

[0023] see Figure 1~4 , in an embodiment of the present invention, a punching device for injection mold processing includes a lower support frame 1 and an upper frame 2, the top end of the lower support frame 1 is provided with a drilling platform 3, and the drilling platform 3 is provided with a The sliding platform 4 is installed on it, and the side wall of the sliding platform 4 is provided with a row of upper connection holes 6 and a row of lower connection holes 5. The center position of the upper connection hole 6 is higher than the center position of the lower connection hole 5. The side of the installation slide table 4 is also provided with a plurality of push guide bars 7 and each end of each push guide bar 7 is provided with plugs inserted into the upper connection hole 6 and the lower connection hole 5 respectively. Column 25, the upper frame 2 is provided with a driving cross frame 8 located above the sliding table 4, the driving cross frame 8 is equipped with a ...

Embodiment 2

[0031] see figure 1The difference between this embodiment of the present invention and Embodiment 1 is that: the bottom of the lower support frame 1 is also provided with a universal moving wheel 29 and an adjustment screw 30, and the adjustment screw 30 spirally runs through the bottom of the lower support frame 1 and the bottom of the adjustment screw 30 A base plate 31 is provided, and the bottom surface of the base plate 31 is provided with a rubber protrusion. The setting of the universal moving wheel 29 facilitates the movement of the whole device, and the rotation adjustment screw 30 is used to adjust the height of the base plate 31. When the base plate 31 touches the ground and generates pressure with the ground The device is guaranteed.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com