Injection compression molding optical grade transparent product quality on-line inspection method

A technology of compression molding and detection methods, which is applied in sorting and other directions, can solve the problems of real-time detection of product molding quality and low recognition accuracy, and achieve the effects of reducing detection costs, improving inspection accuracy, and adjustable grid pitch

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

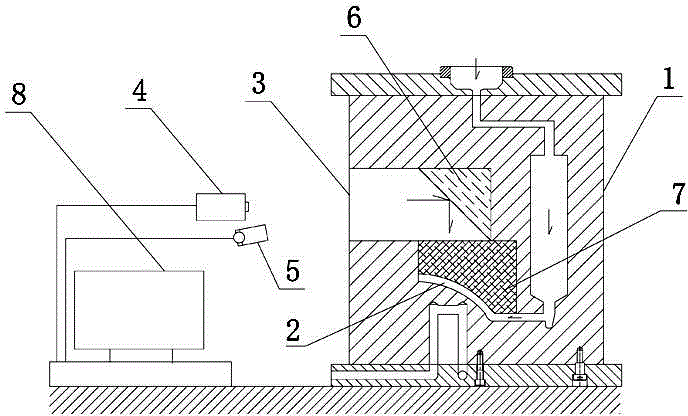

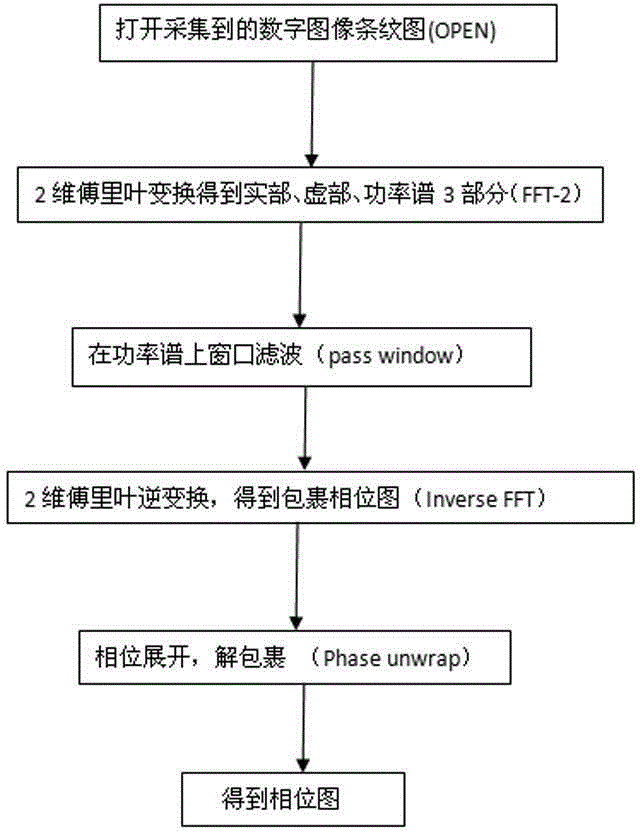

[0020] Such as figure 1 , 2 , 3, the injection compression molding optical-grade transparent product quality online detection method of the present invention is carried out according to the following steps:

[0021] The first step, a high-speed camera 4 and a projector 5 are set at the observation port 3 of the mold cavity 2 of the visualization mold 1; And the optical path of projector 5 is: observation port 3 → 45 ° reflecting prism 6 → quartz glass core 7 → cavity 2; Signal input and output connection;

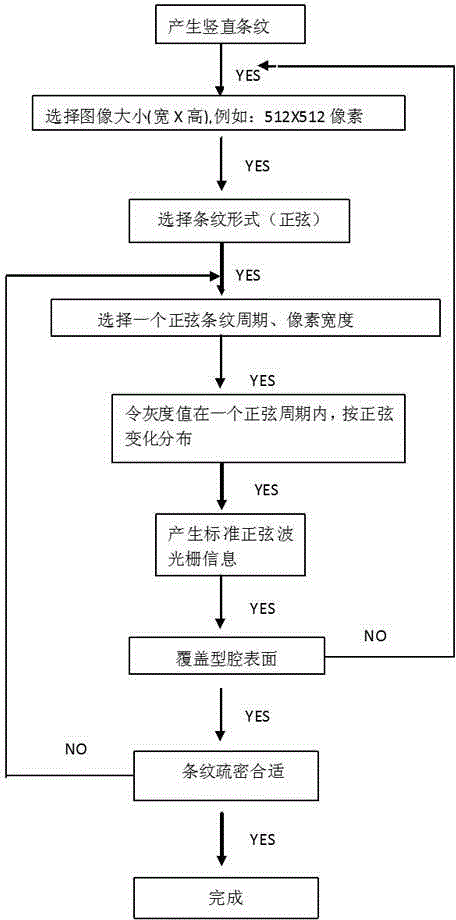

[0022] Second step, open computer 8, high-speed video camera 4, projector 5; Computer 8 generates standard sine wave grating signal output to projector 5 through internal software program, is projected to the mold cavity 2 surface of described visualization mold 1 through projector 5 , produce a standard sine wave grating with a grating width ≤ 1cm on the surface of the cavity 2; of course, a standard sine wave grating with a grating width ≤ 1cm can also be generated by...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com