Rigid catenary busbar drilling mold

A drilling mold and rigid contact technology, which is applied in the direction of drilling molds for workpieces, etc., can solve the problems of increasing manpower consumption, increasing deformation of the contact between drilling and template holes, time-consuming and labor-intensive problems, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] As stated in the background technology of this application, in the existing drilling positioning scheme, whether it is ruler measurement or the existing formwork measurement, it is time-consuming and laborious, the construction efficiency is low, and multiple people are required to assist in the operation, which increases the construction cost , increasing the construction time.

[0036] The embodiment of the present application provides a rigid catenary busbar drilling mold, which solves the problems of poor drilling accuracy, low construction efficiency, and high construction cost in the prior art.

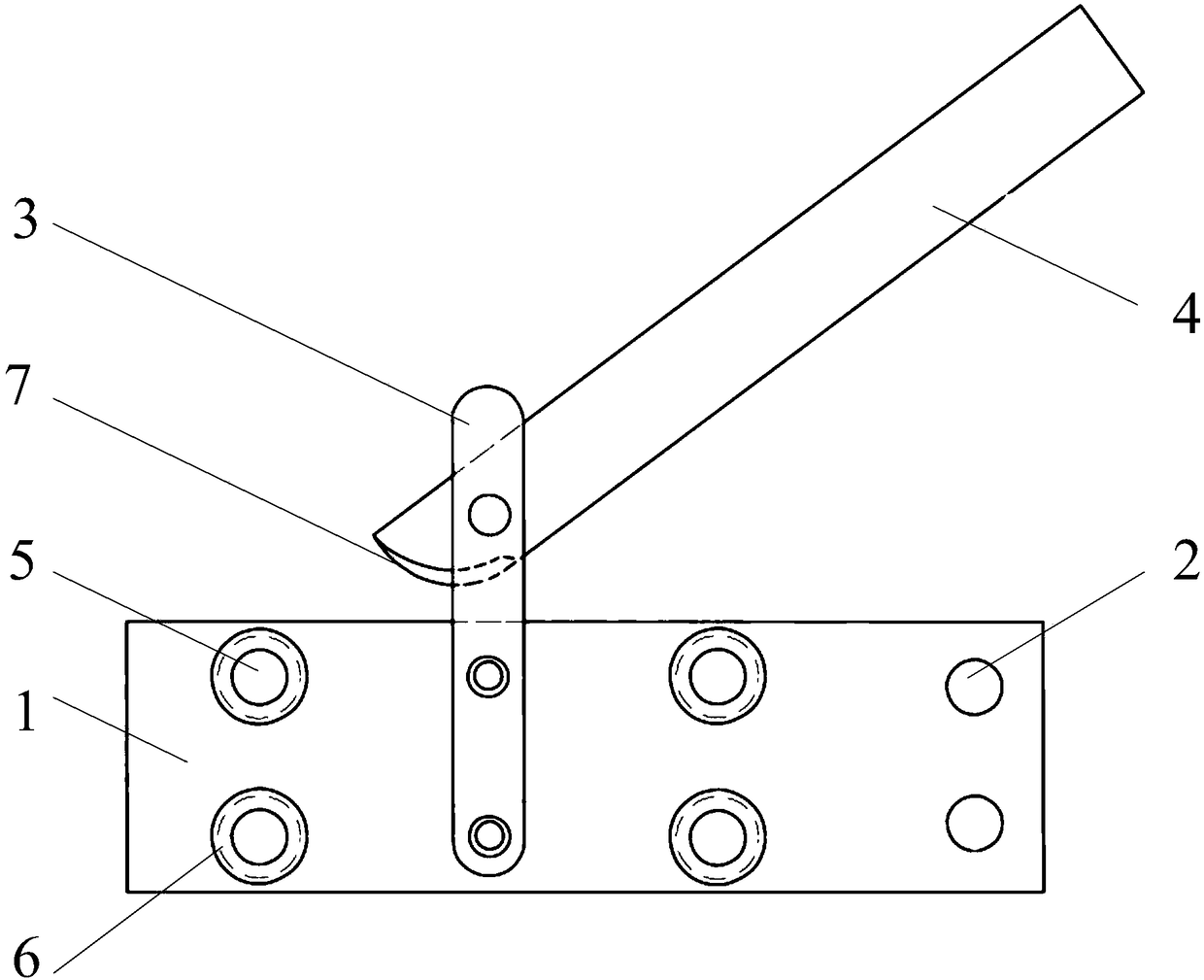

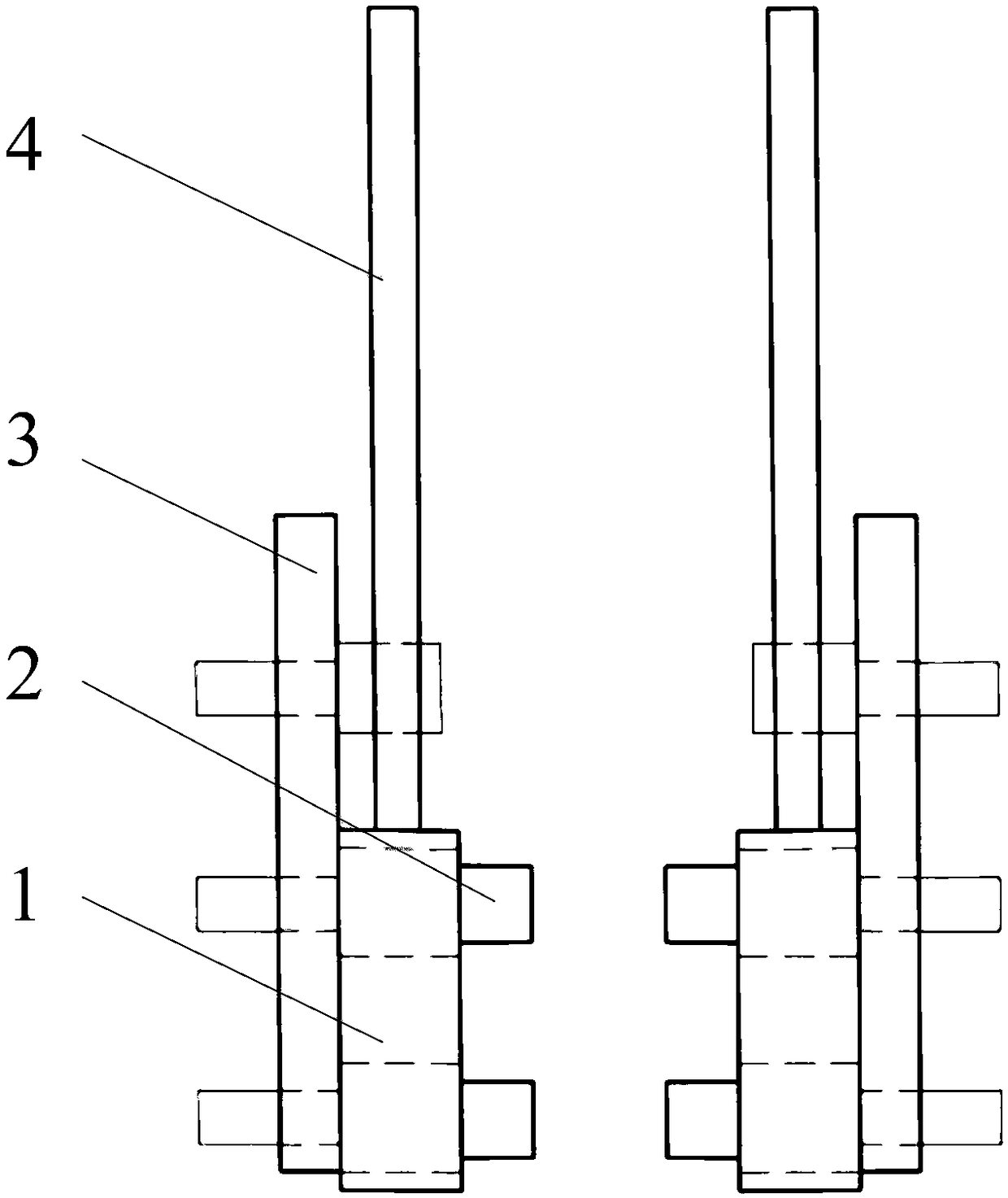

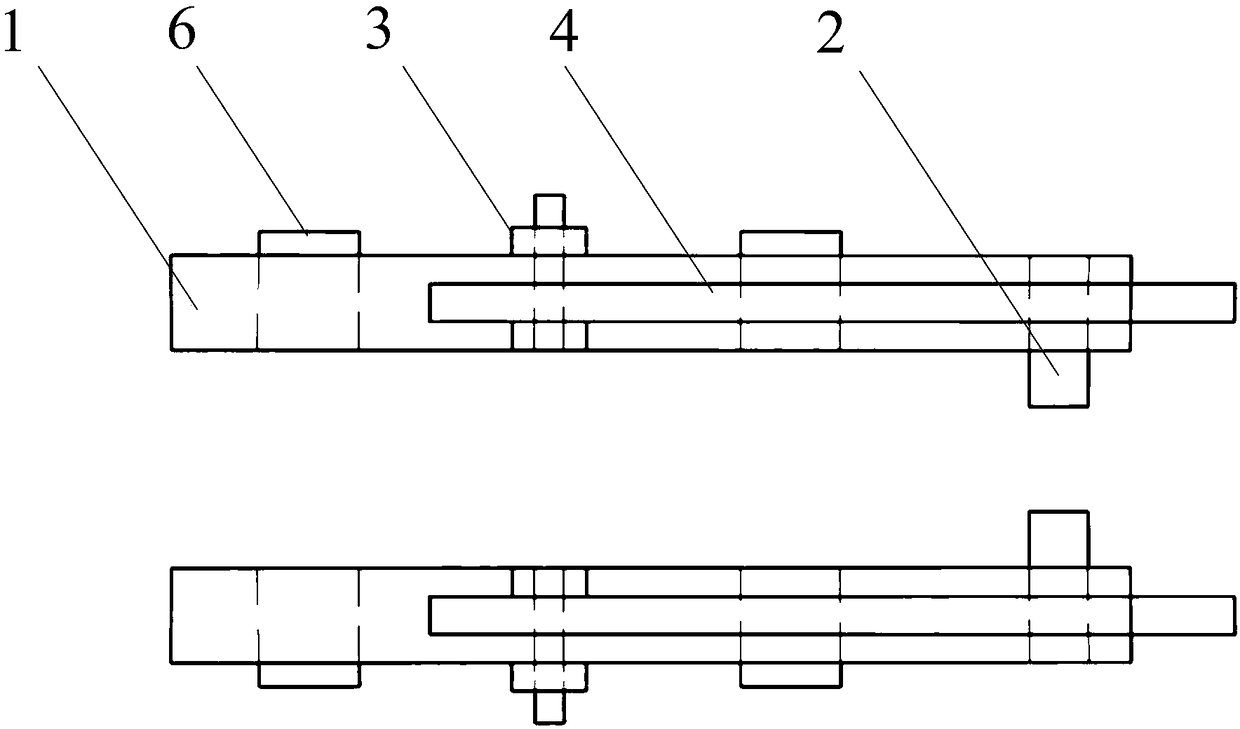

[0037] Such as figure 1 As shown, it is a schematic diagram of the overall structure of a rigid catenary busbar drilling die proposed in the embodiment of the present application. At the same time, in order to show the corresponding structural design more clearly, figure 2 and image 3 A side view and a top view of a rigid catenary busbar drilling mold proposed in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com