Simple positioning and drilling clamp

A drilling jig, a simple technology, applied in the direction of the drilling mold used for workpieces, etc., can solve the problems of inconvenient scribing and positioning one by one, insufficient drilling positioning accuracy, and high manual labor intensity, so as to achieve low manual labor intensity, Simple structure and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

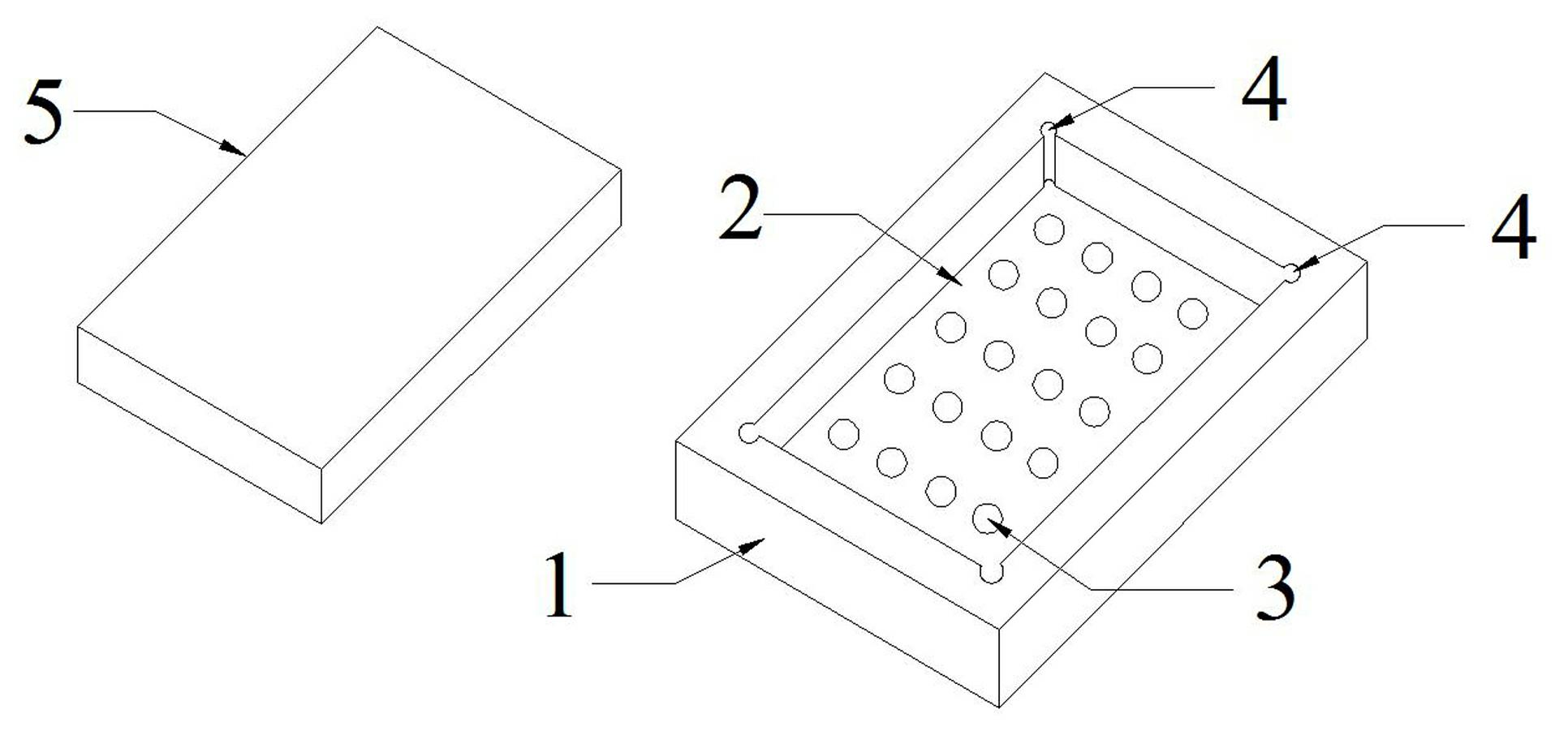

[0016] refer to figure 1 , the simple positioning drilling jig of the present invention includes: a mold base 1 with a horizontal platform, a cavity 2 for clamping a workpiece 5 to be drilled, formed in the cavity 2, and used to guide the drilling tool to be drilled. The workpiece 5 is drilled with a pilot hole 3, and the axial direction of the pilot hole 3 is perpendicular to the plane where the mold base 1 is located. The workpiece 5 to be drilled is placed in the cavity 2 on one side of the mold base 1, and the drilling tool is drilled from the other side of the mold base 1 through the guide hole 3 to the workpiece 5 to be drilled.

[0017] As a preferred solution, the mold cavity 2 is formed by the inward depression of the mold base 1 . In order to make the workpiece 5 to be drilled stably placed in the cavity 2, the bottom su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com