Integrated Drilling Rig for Bolt-while-Driving Drilling

A cantilever roadheader and roadheader technology, which is applied in cutting machinery, earthwork drilling and other directions, can solve the problems of excessive support strength, small drilling hole diameter and high labor intensity, and achieve stable and rapid movement and accurate drilling positioning. , The effect of flexible and labor-saving operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

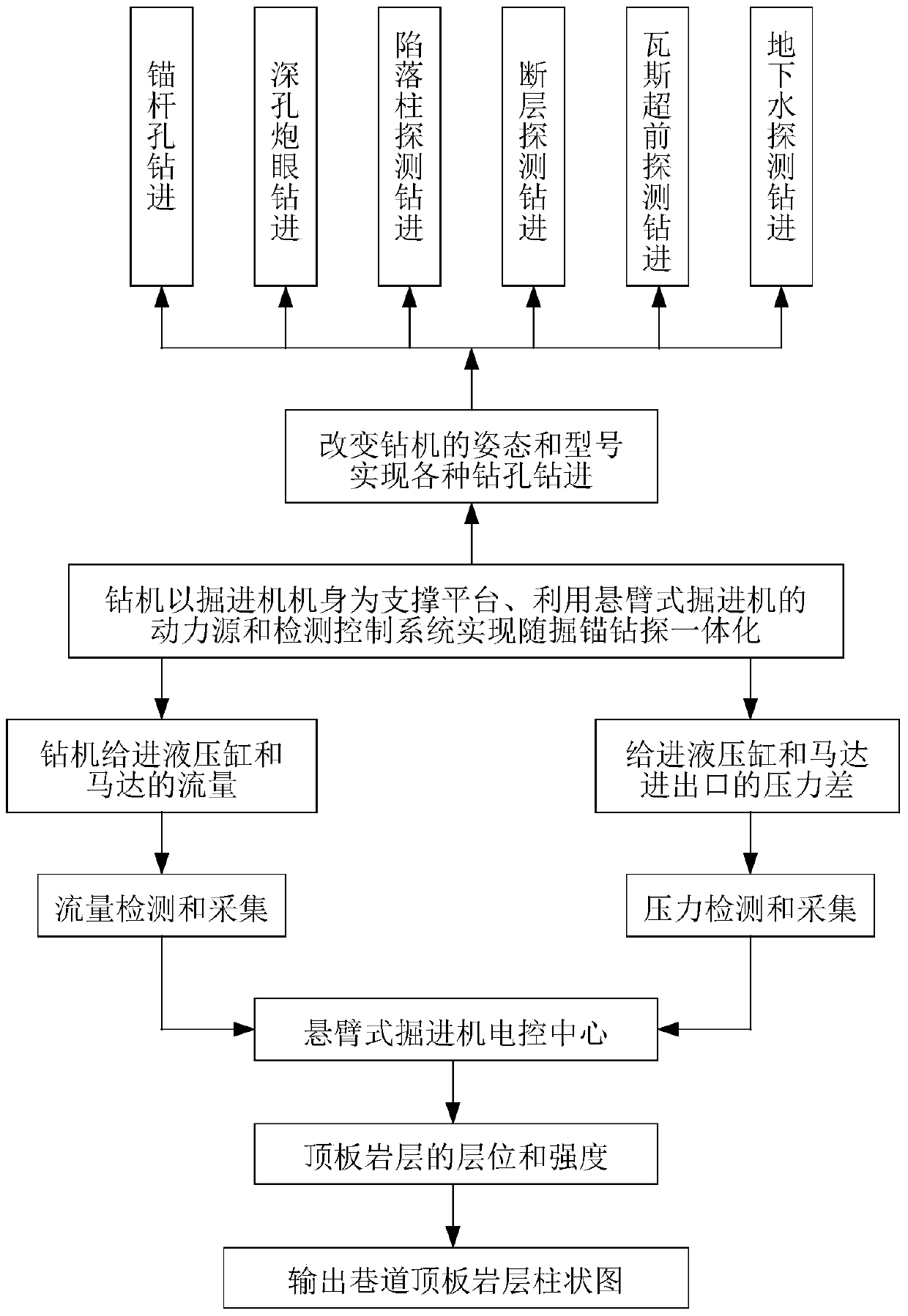

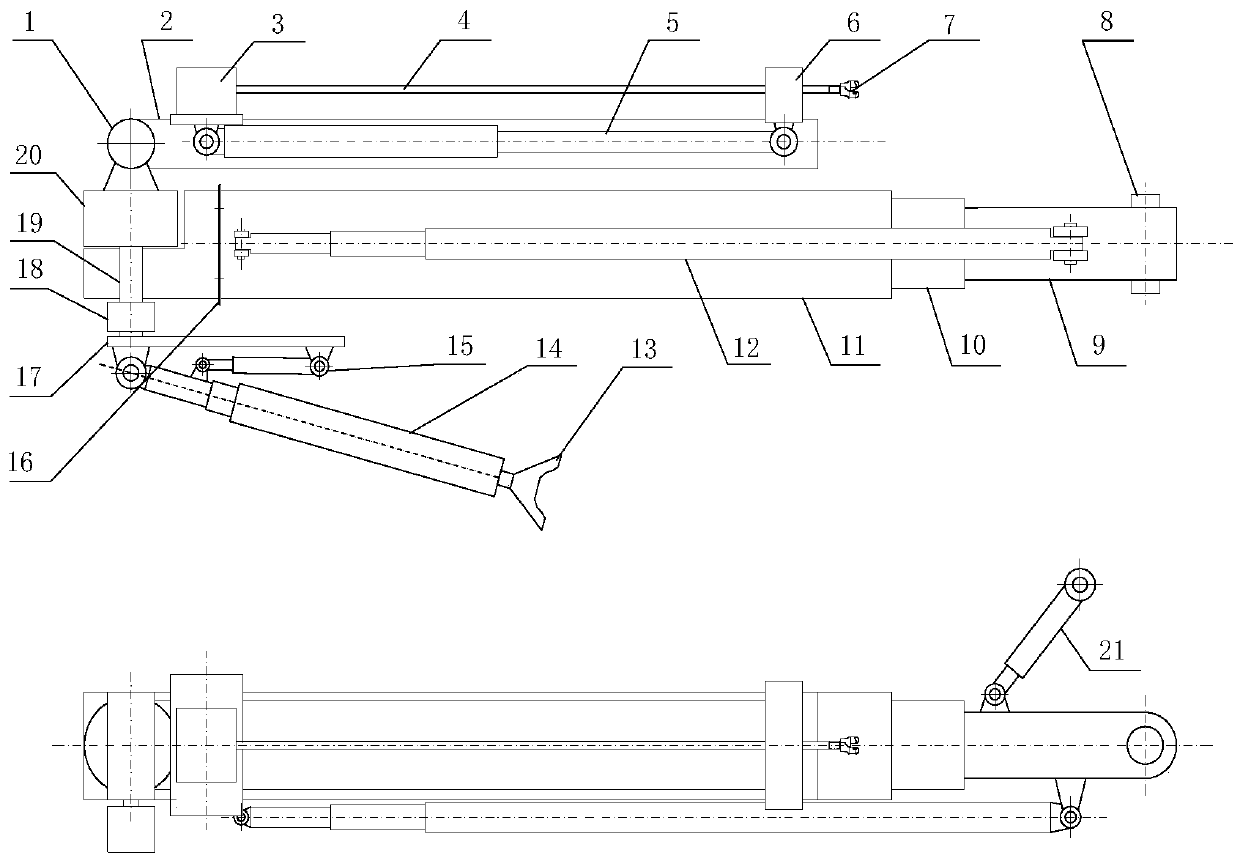

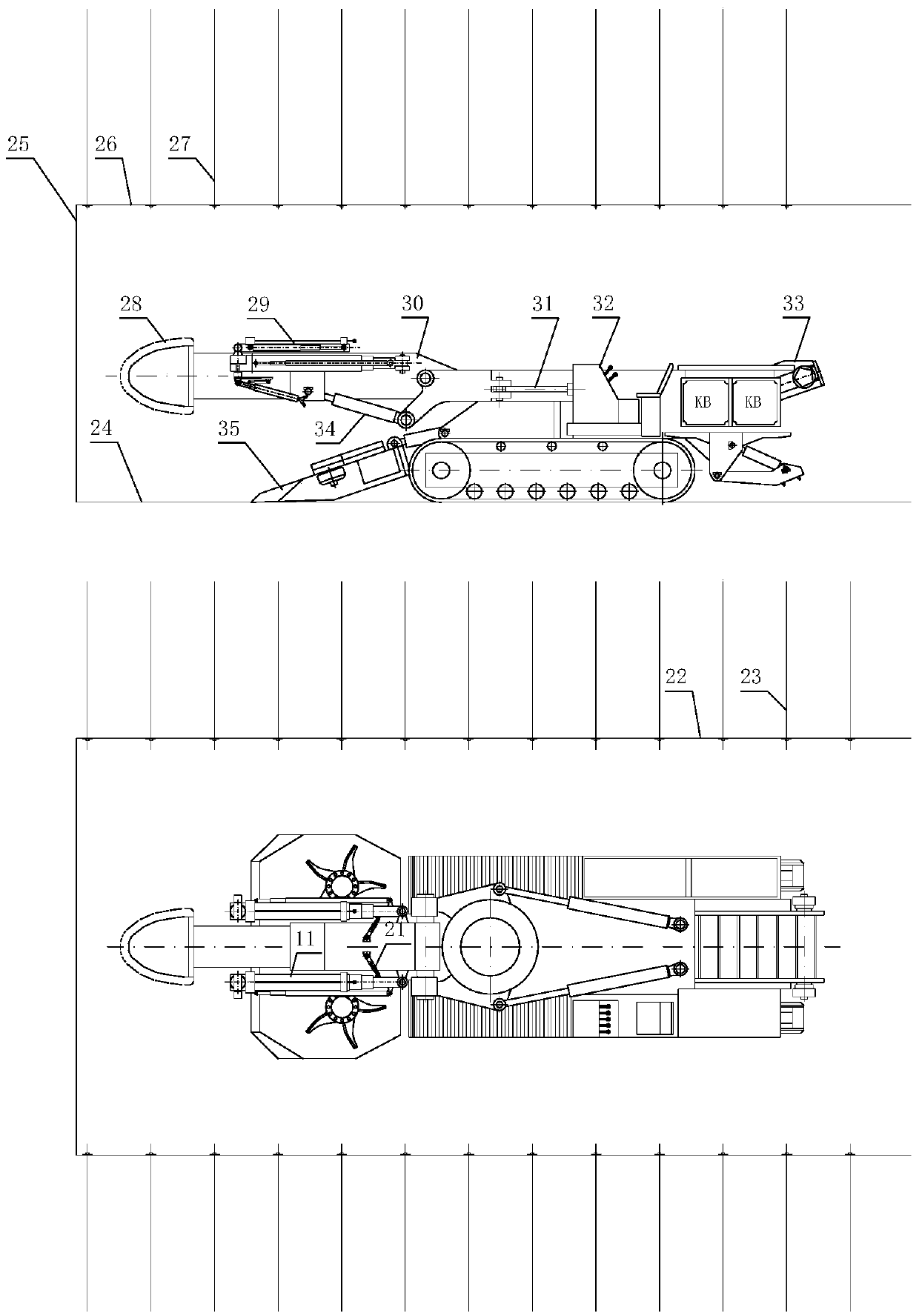

[0025] like figure 1 As shown, when the roadway adopts the bolt support method, the bolt hole must be drilled in each excavation cycle, and the roof lithology is detected while drilling, which is suitable for the characteristics of rapid excavation and rapid change of roof lithology. Combining the flow transmitter and pressure transmitter with the hydraulic rock bolter, the pressure and flow of the feed hydraulic cylinder of the hydraulic rocker drill, the pressure and flow of the hydraulic motor and other parameters are measured and transmitted to the electronic control of the roadheader. center. Through data processing, real-time analysis and judgment of the lithology at different positions of the roof during roadway excavation construction can provide reliable geological basis for real-time dynamic "quantitative" support design, and guide the support design and roof of the excavation face. Management, to ensure that the support can meet the needs of safety and production, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com