Sailing course drill

A technology for drilling rigs and waterways, which is applied to drilling equipment, underwater drilling, and earthwork drilling and production. It can solve the problems of reducing the working efficiency of drilling rigs, construction safety, troublesome movement of human-shaped ships, and difficulty in accurate positioning, so as to facilitate maintenance and conversion. Work site, improve work efficiency and construction safety, reduce the effect of auxiliary work time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

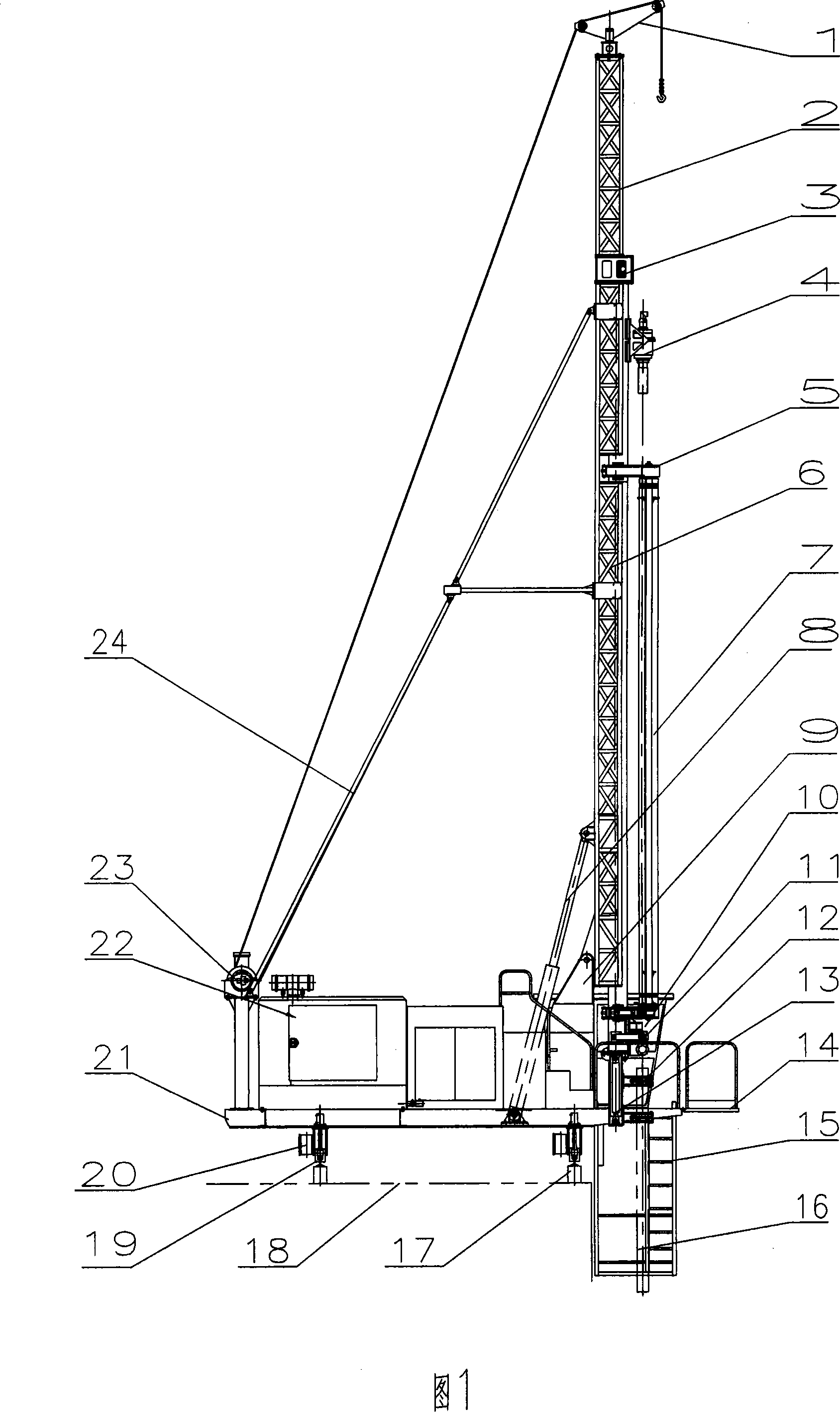

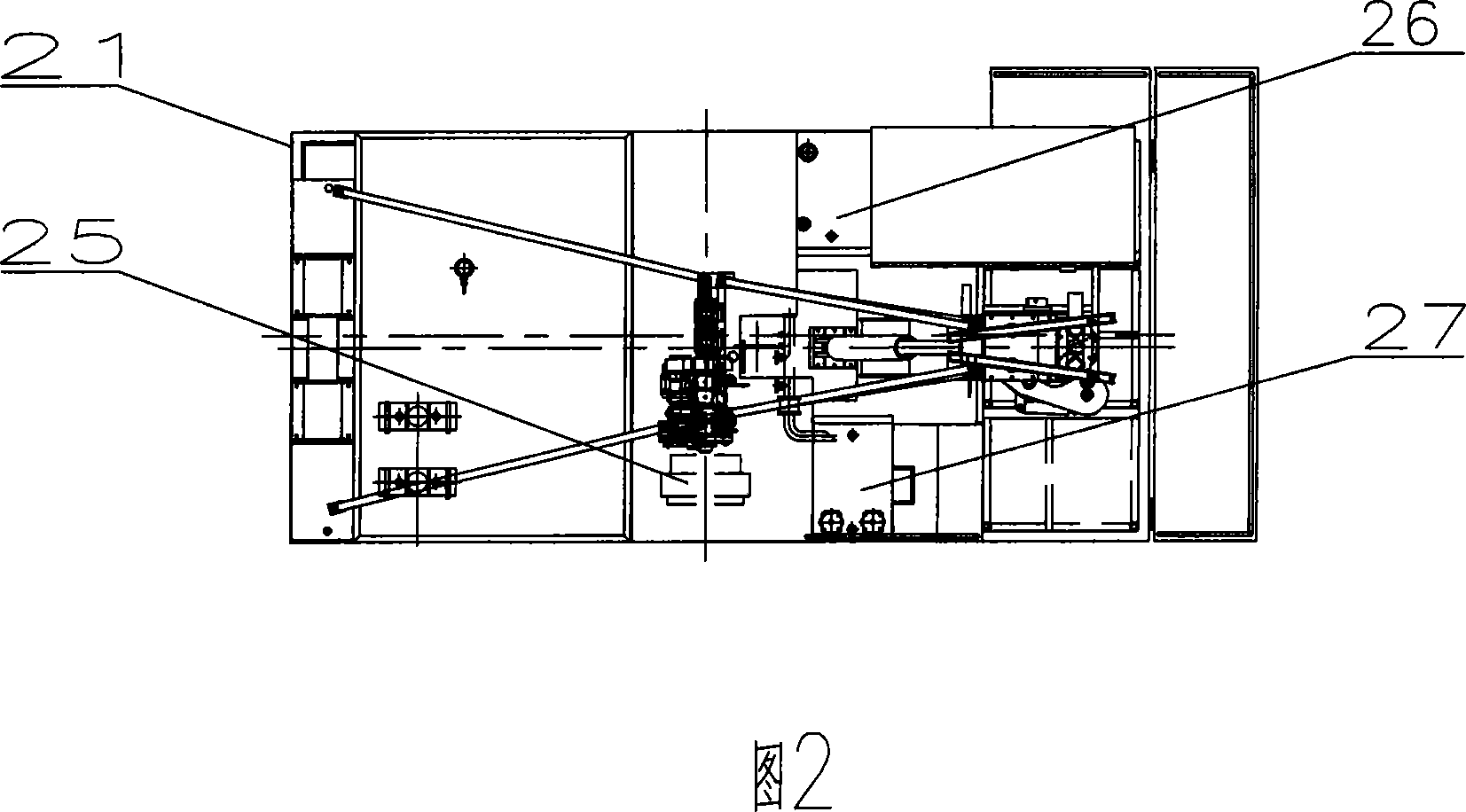

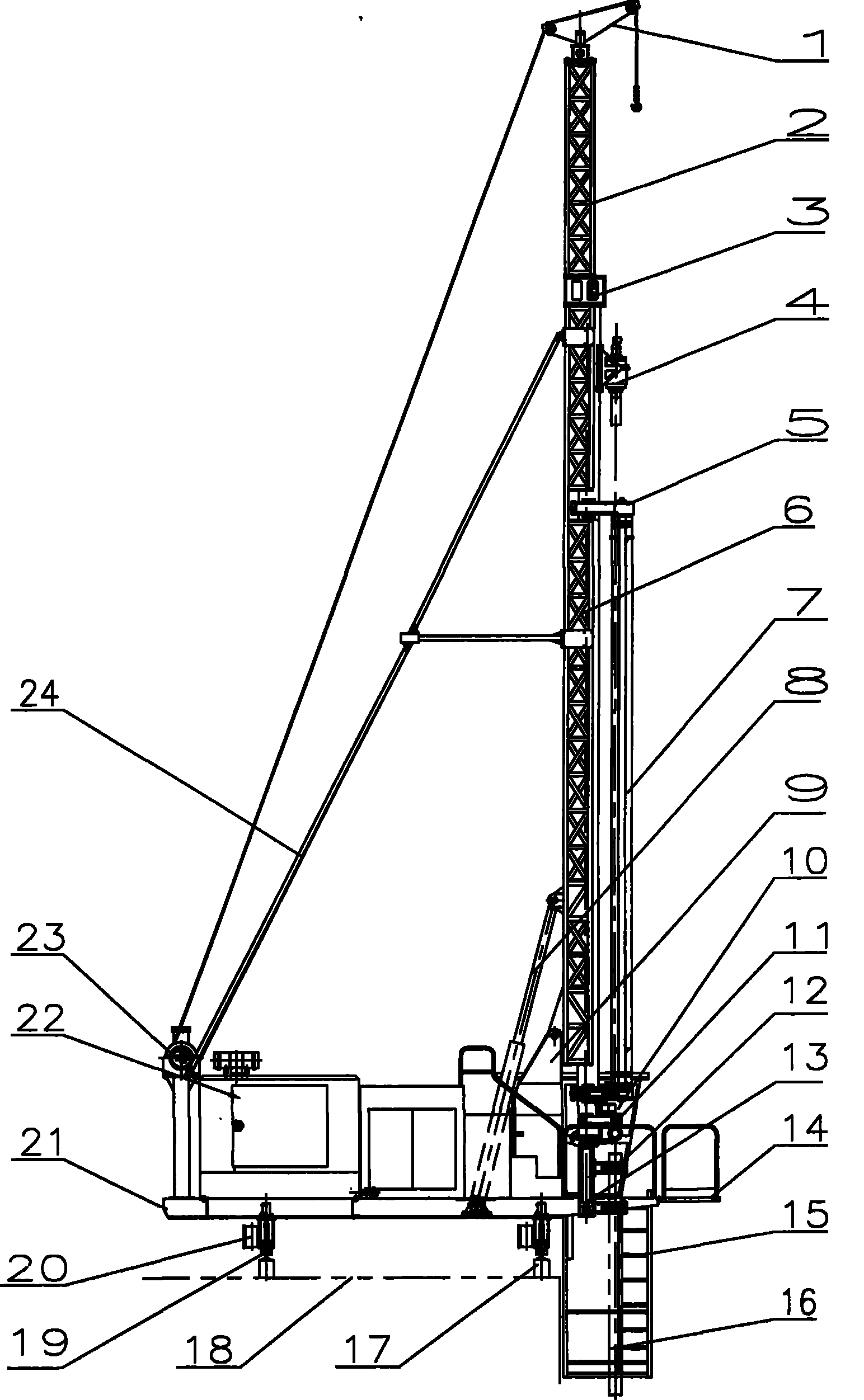

[0014] see figure 1 and figure 2 , the combined drill frame 6 is installed on the frame 21 through the drill frame support 9, the auxiliary drill frame 2 is installed on the combined drill frame 6, the boom 1 is installed on the auxiliary drill frame 2, and the There are hydraulic crane 23 and air compressor 22, engine pump group 25, diesel tank 26 and hydraulic oil tank 27, driver's cab 10, strut 24, front platform 14 and lower platform 15, and the combined drilling frame 6 is provided with a propulsion motor 3 , power head 4, drill pipe storehouse 5, drill pipe 7 and rod unloader 11, a lifting cylinder 8 is installed between the combined drill frame 6 and the frame 21, and a hydraulic motor traveling device 20 and The automatic hydraulic parking device 19 is provided with a track 17 corresponding to the hydraulic motor traveling device 20 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com