Drilling processing and fixing device and method for brake drum

A technology of a fixing device and a fixing method, which is applied in the field of brake drum drilling and fixing devices, and can solve problems such as difficulty in guaranteeing machining accuracy of a cylindrical drum body, inaccurate positioning of brake drum drilling, and easy jumping of brake drums, etc. Problems, to achieve dimensional accuracy, easy to control, prevent jumping, and withstand firm effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

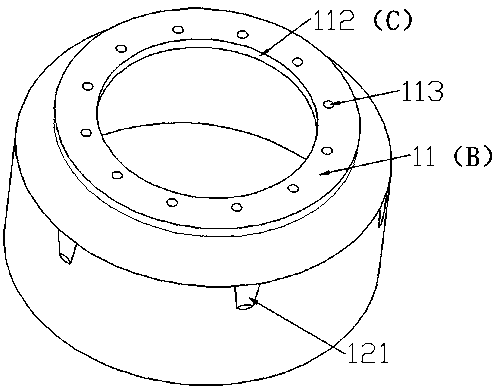

[0069] Such as image 3 , Figure 4 As shown, the brake drum is a drum-shaped structure, hollow, including the flange, that is, the drilling plane 11 (B), the braking surface circumference of the brake drum 12 (H), the bottom end surface of the braking surface circumference of the brake drum 13 (D); the flange process requires a flat surface structure, including the lower end surface 111 (E) of the flange, the upper end surface and the flange seam 112 (C) are all required to be a flat surface structure; the braking surface of the brake drum There is a groove 121 on the circumference 12 (H); a hole needs to be drilled on the drilling plane (B), which is the hole 113; the flange seam (C) is also required to be a perfect circular structure, and the peripheral surface is flat.

[0070] The brake drum application process has high requirements on the shape and dimensional accuracy of the flange seam (C), as well as the position and dimensional accuracy of the hole 113, and, for the...

Embodiment 2

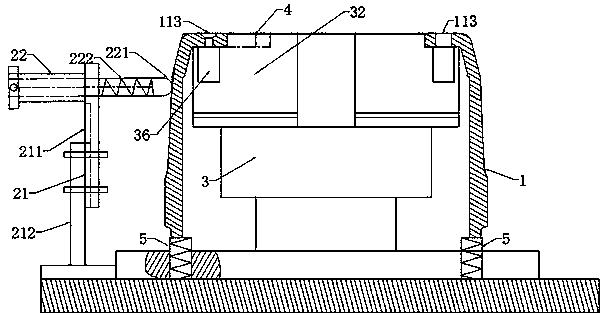

[0081] Such as figure 1 As shown, a brake drum drilling and fixing device includes an internal positioning device and an external positioning device; the internal positioning device includes a chuck 3 and a tooling 4, the chuck 3 is fixed on the table, and the chuck 3 is provided with claws 32 , the claw 32 is connected to the chuck 3 and supported by the chuck 3, the claw 32 is driven by the driving mechanism to extend outward, the claw 32 supports the brake drum flange (drilling plane) 11 (B) upward, and the tooling 4 is fixed and installed On the claw 32, the outside of the tooling 4 is a circular arc surface structure, and it withstands the stop of the brake drum flange (inner peripheral surface of the drilling plane) 112 (C); the external positioning device includes a column 21 and a push rod 22. The column 21 is vertically fixed on the table, the top of the column 21 is connected to the ejector rod 22, and the head 221 of the front end of the ejector rod is an arc-shaped...

Embodiment 3

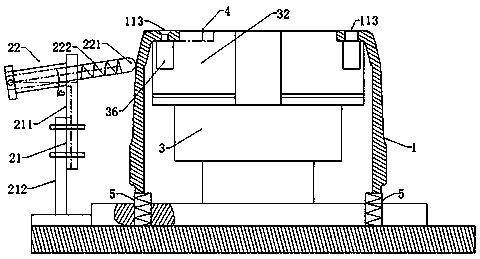

[0087] Such as figure 2 As shown, a brake drum drilling and fixing device includes an internal positioning device and an external positioning device; the internal positioning device includes a chuck 3 and a tooling 4, the chuck 3 is fixed on the table, and the chuck 3 is provided with claws 32 , the claw 32 is connected to the chuck 3 and supported by the chuck 3, the claw 32 is driven by the driving mechanism to extend outward, the claw 32 supports the brake drum flange (drilling plane) 11 (B) upward, and the tooling 4 is fixed and installed On the claw 32, the outside of the tooling 4 is a circular arc surface structure, and it withstands the stop of the brake drum flange (inner peripheral surface of the drilling plane) 112 (C); the external positioning device includes a column 21 and a push rod 22. The column 21 is vertically fixed on the table, the top of the column 21 is connected to the ejector rod 22, and the head 221 of the front end of the ejector rod is an arc-shape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com