Drilling and positioning device for swinging part of four-claw material cover

A technology of four-claw material cover and positioning device, which is applied in positioning device, clamping device, metal processing machine parts, etc., can solve the problems of complex movement mechanism of three-claw material cover, excessive height of bulk cement truck, and inability to perform normal production. , to achieve the effect of improving production efficiency and product quality, high production efficiency and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

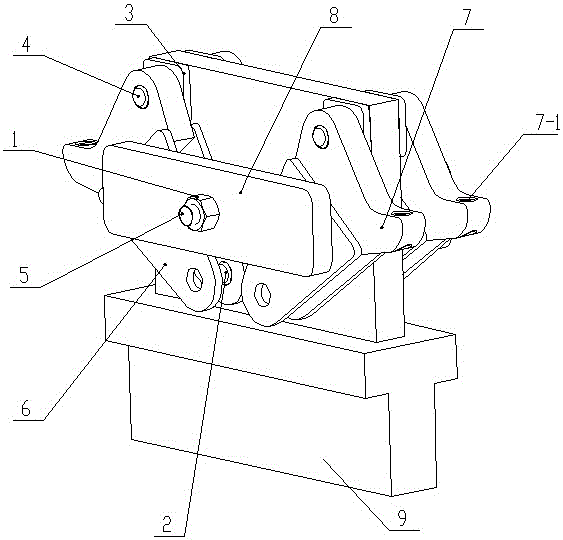

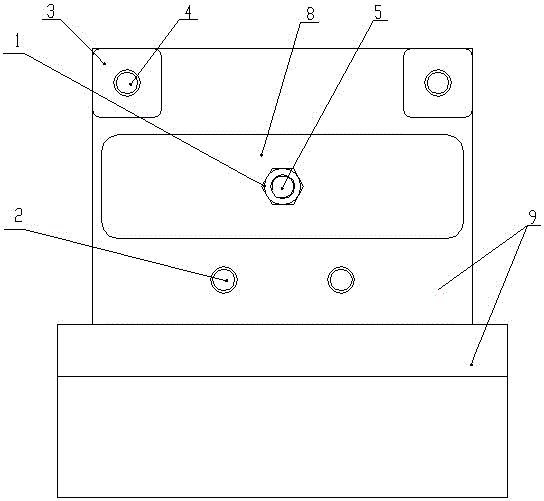

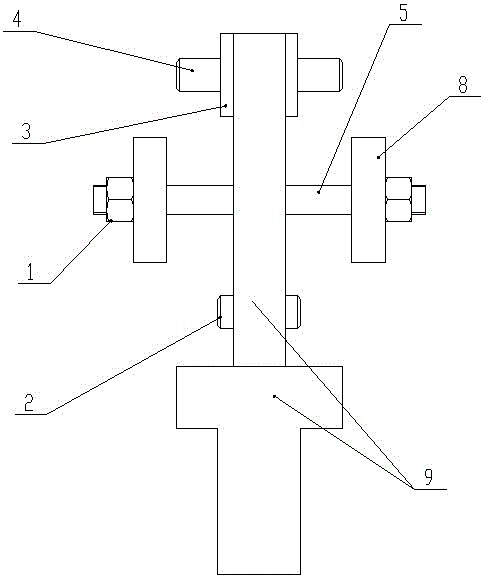

[0014] From Figure 1-Figure 3 It can be seen from the figure that a four-claw material cover swing member drilling and positioning device (referred to as the drilling positioning device) includes the processed swing member, which is composed of two front and rear connecting plates 6 and a pressing plate 7. The welded fork has lower pin holes symmetrically on the lower end sections of the front and rear connecting plates 6 of the ∩ shape of the swing piece, and has pinholes on the upper end section of the pressure block plate 7 of the swing piece. On the upper pin hole, a vertical bolt hole 7-1 is drilled on the flange of the briquetting block plate 7, and it is characterized in that: the drilling positioning device of the four-claw material cover swing member consists of a drilling seat plate 9, a lower positioning pin 2. The pressing plate positioning pin 5, the pressing plate 8, the compression nut 1 and the upper positioning pin 4 are composed. The lower part of the drilli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com