Double-head coaxial boring and milling machining device for machining

A boring and milling processing and mechanical processing technology, which is applied in the field of double-head coaxial boring and milling processing devices, can solve the problems of hole position deviation at both ends of parts, affect the production accuracy of parts, and have low practicability, so as to achieve high processing efficiency and improve Practicality, convenient operation and flexible effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

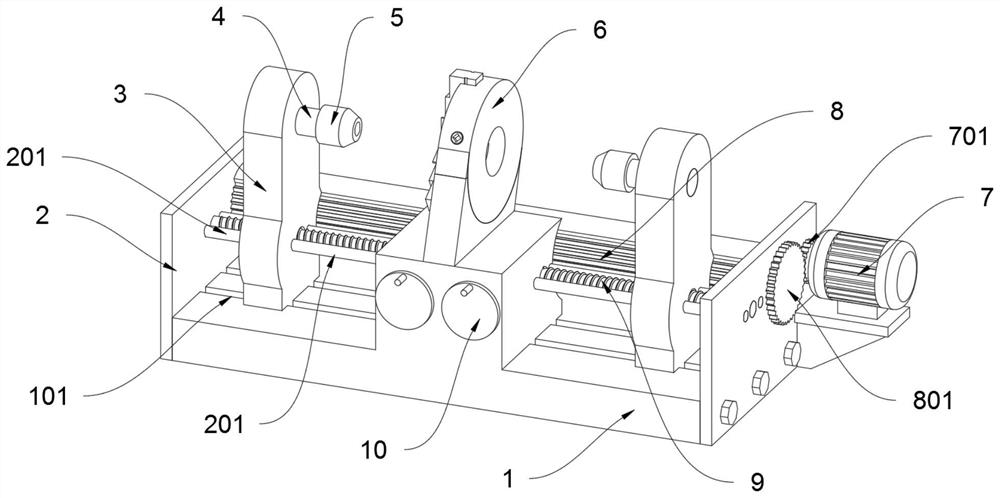

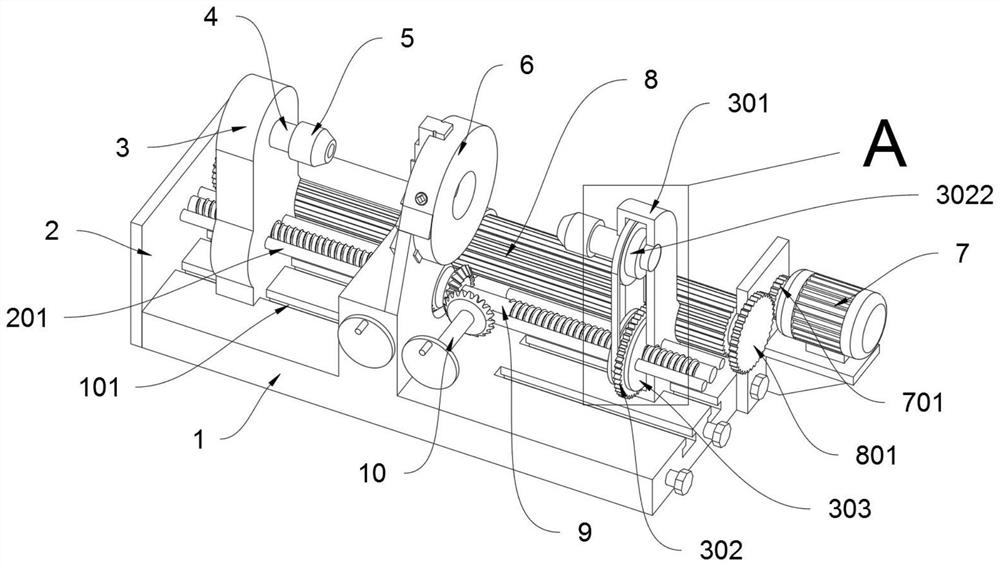

[0032] as attached figure 1 to attach Image 6 Shown:

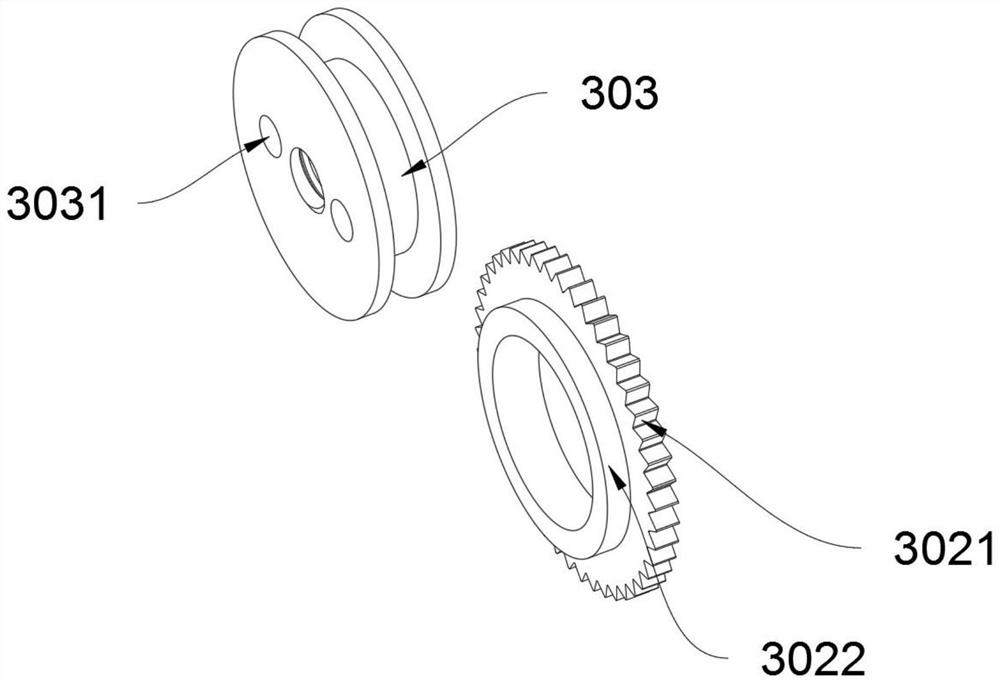

[0033]The present invention provides a double-headed coaxial boring and milling processing device for mechanical processing, which includes a machine base 1, a coaxial processing mechanism 3, a coaxial drill rod 4, a drill clamp 5, a three-axis centering chuck 6, and a drive Motor 7, drive shaft 8, linkage rod 9 and position control rod 10; the two sides on the left and right sides of machine base 1 are respectively screwed and fixed with supporting side plates 2; coaxial processing mechanism 3 is provided with two groups, and coaxial processing Mechanism 3 is installed symmetrically inside machine base 1; coaxial processing mechanism 3 is composed of mobile housing 301, composite transmission wheel 302 and positioning sleeve 303; mobile housing 301 is plugged inside the top surface of machine base 1; composite transmission wheel 302 rotates Connected to the outside of the positioning sleeve 303; the positioning sleeve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com