High-precision charger shell end face drilling machining device

A technology for processing devices and chargers, applied in positioning devices, boring/drilling, metal processing equipment, etc., can solve the problems of unguaranteed drilling position accuracy and low work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

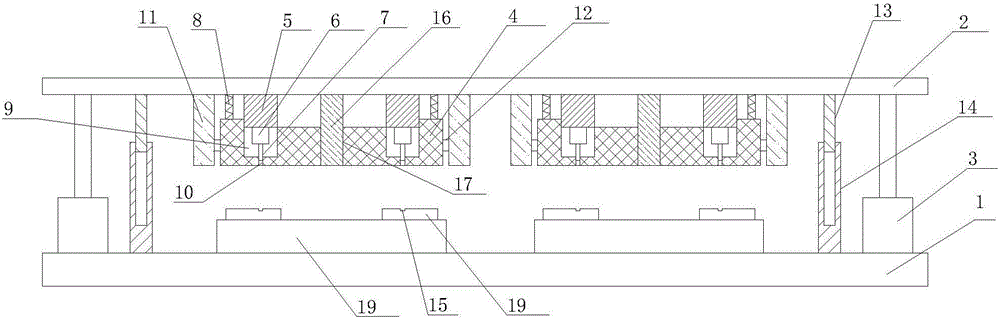

[0015] refer to figure 1 , the present invention proposes a high-precision charger shell end face drilling device, including a workbench 1, a mounting frame 2, a first driving mechanism 3, N drilling mechanisms, N fixing mechanisms and a controller, where N is a natural number And N≥1, where:

[0016] The workbench 1 is arranged horizontally, the installation frame 2 is located above the workbench 1 and parallel to the workbench 1, the side of the installation frame 2 close to the workbench 1 is provided with a plurality of first guide columns 13, and the side of the workbench 1 close to the installation frame 2 is arranged There are a plurality of guide sleeves 14, the number of the first guide posts 13 is consistent with the number of the guide sleeves 14 and the first guide posts 13 and the guide sleeves 14 are set in one-to-one correspondence, and the plurality of first guide posts 13 are respectively slidably matched with the plurality of guide sleeves 14 , The mounting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com