Auxiliary tool for accurate locating drilling

A precise positioning and mounting technology, applied in positioning devices, manufacturing tools, drill dies for workpieces, etc., can solve the problems of easy vibration of drill bits, deviation of inclination, difficulty in drilling, etc., and achieve simple structure and faster operation speed. , economical and practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

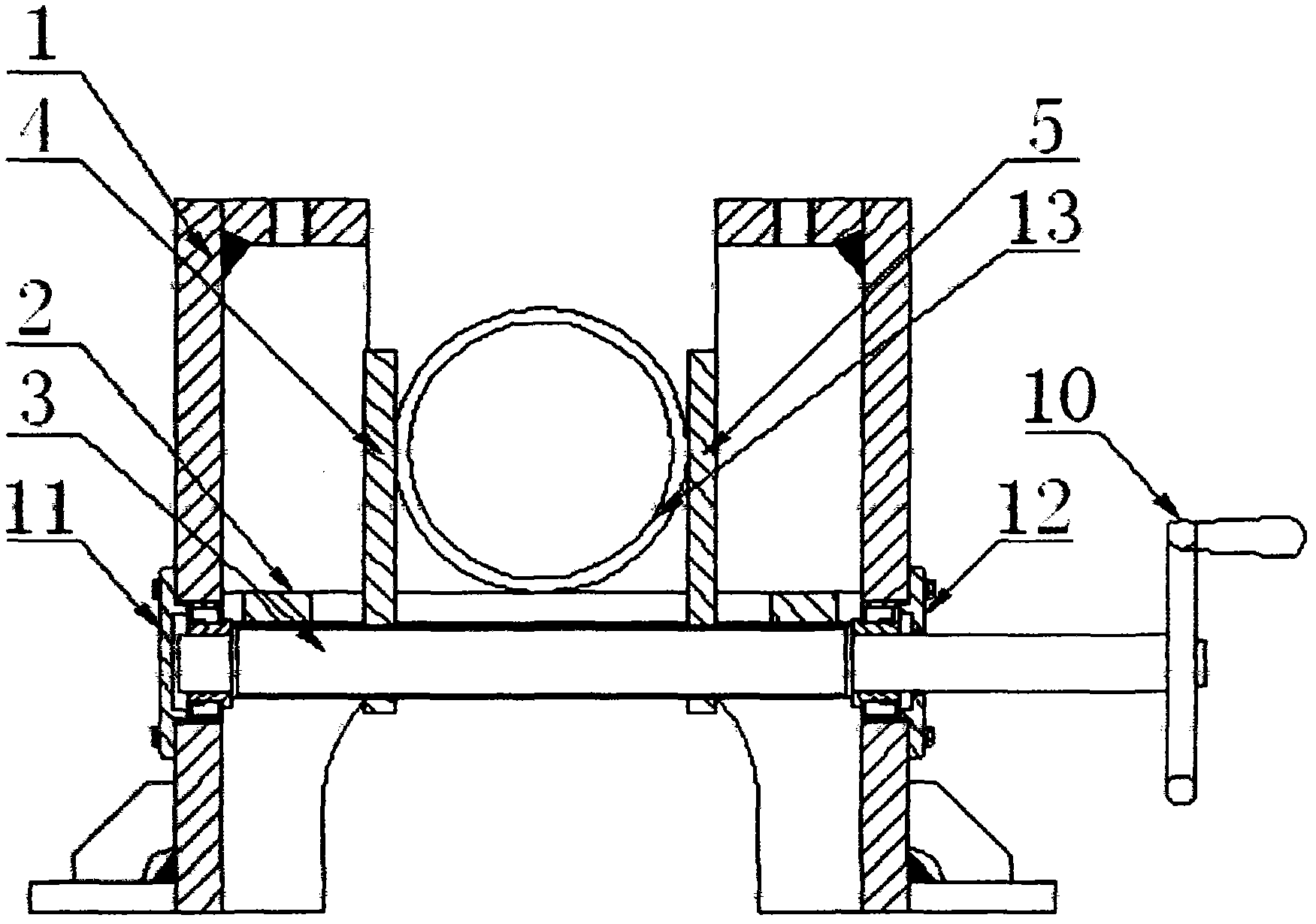

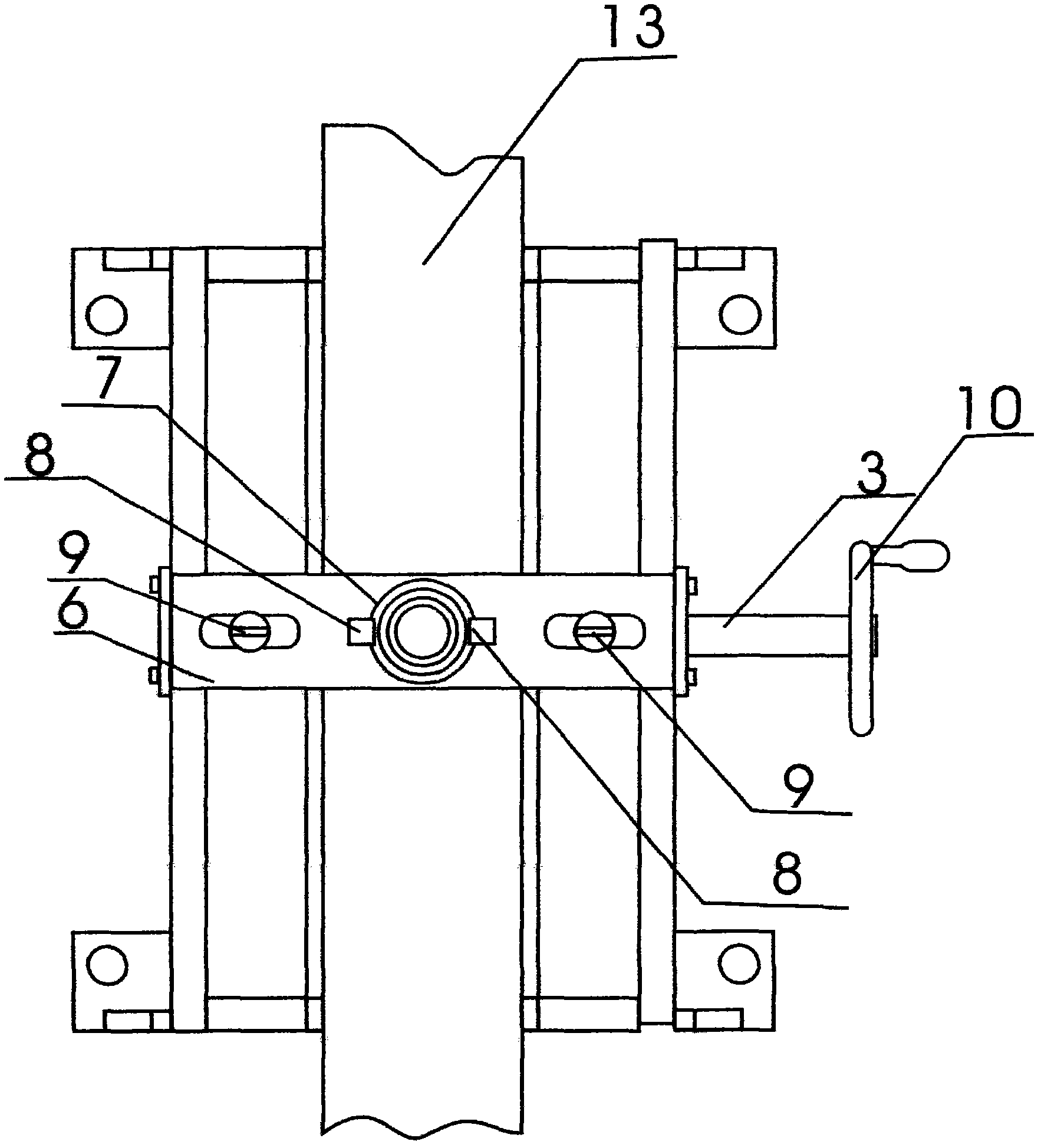

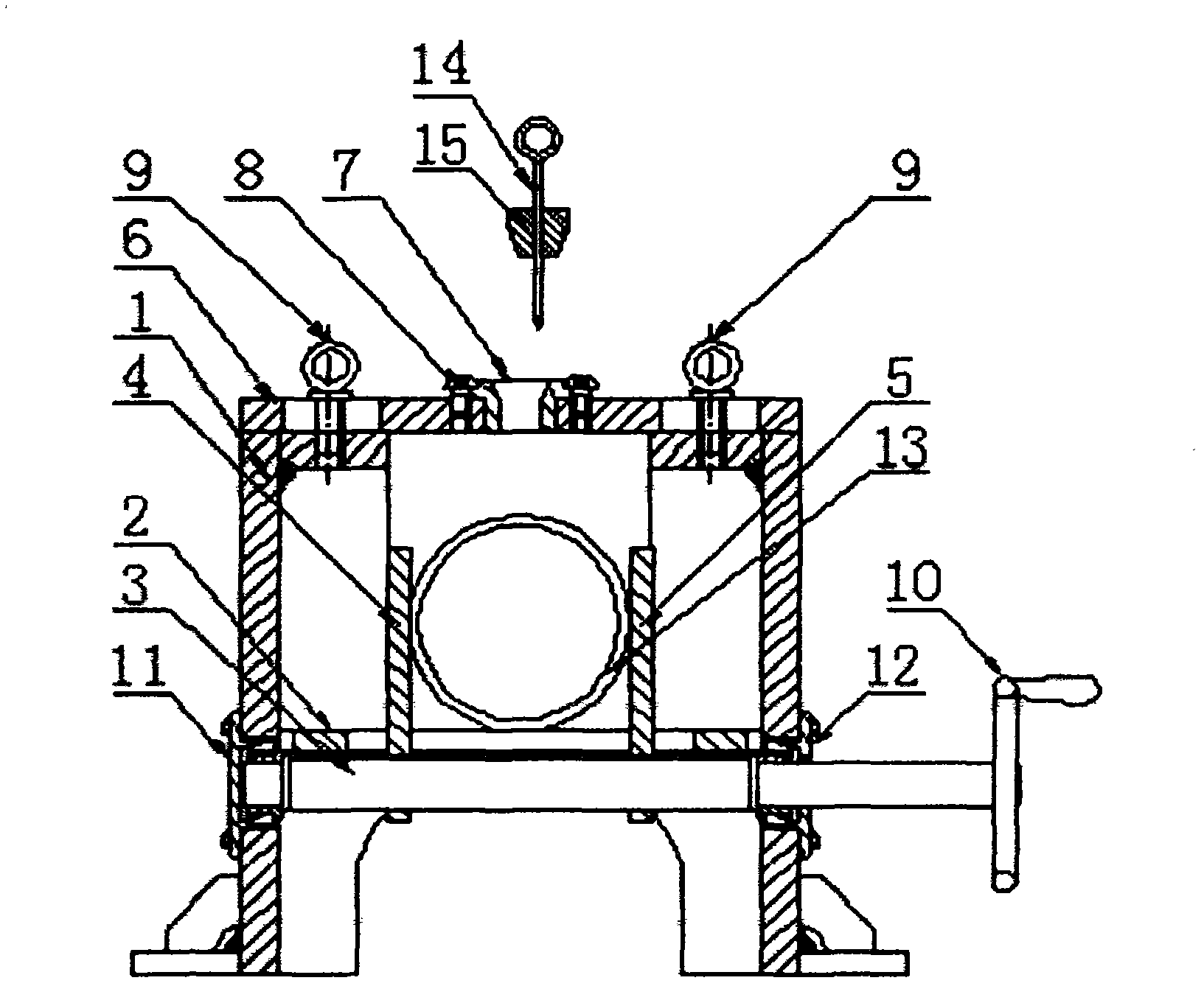

[0013] When this invention is installed, the box body (1) of the equipment and the drilling machine platform are first fixed by fasteners, and the slideway (2) inside the box body (1) is respectively provided with a left baffle plate (4) and a The right baffle (5), the left baffle (4) and the right baffle (5) can be screwed and fixedly connected with a rotating screw mandrel (3), and the rotating screw mandrel (3) is arranged on the box body through a bearing (1) on the left and right side walls; its left bearing gland (11) and right bearing gland (12) pass through the left and right side walls of the box body (1) and fix the rotating screw rod (3), the box body (1) There is a fixed drilling template (6) on the upper plane, and the fixed drilling template (6) is fixed on the box body (1) through the ring bolt (9), and can be moved left and right relative to the upper plane of the box body (1) and fixed , the middle of the fixed drilling template (6) is provided with a drilling...

Embodiment 2

[0015] When this invention is in use, the workpiece (13) to be processed is placed on the slideway (2) in the casing (1) and the support plate in the middle of the front and rear panels of the casing (1), and the workpiece (13) is adjusted. To add holes, make the center line perpendicular to the drilling machine platform and coincide with the longitudinal plane of the rotating screw mandrel (3), and then drive the rotating screw mandrel (3) to rotate by shaking the handwheel (10), so that the left baffle (4) and The right baffle (5) moves toward the workpiece (13) along the slideway (2) and clamps the workpiece (13) in the box (1), and then places the fixed drilling template (6) of the inherent drilling template (7) On the upper plane of the box body (1), place the positioning pin sleeve (15) with the positioning pin (14) in the drilling mold (7), so that the positioning pin (14) and the workpiece (13) to be processed The centers of the holes are coincident, and then the fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com