A cooling device for bearing forgings

A technology of cooling device and water cooling device, which is applied in the field of bearing processing, can solve the problems of reducing the air cooling effect and good ventilation of bearing forgings, and achieve the effect of maintaining the air cooling effect, reducing labor intensity and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

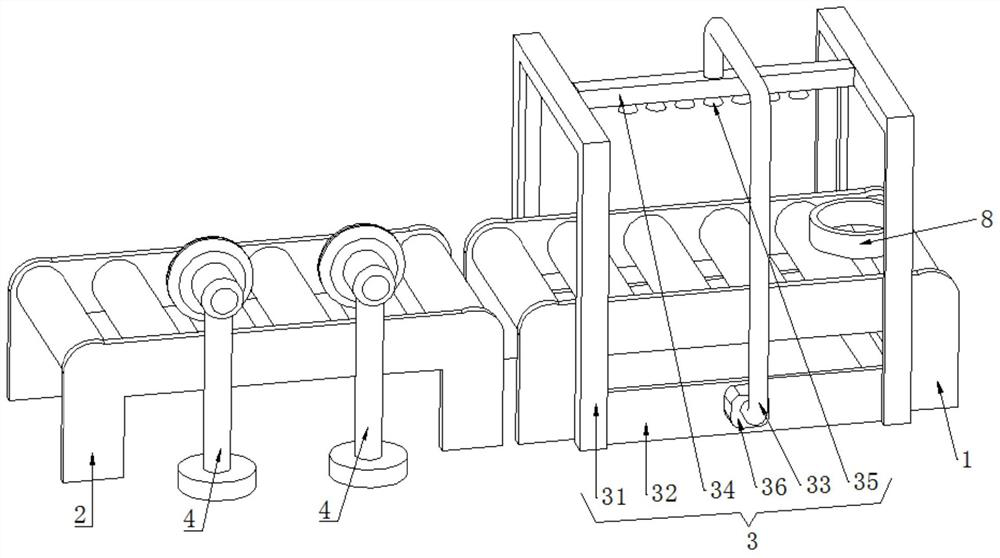

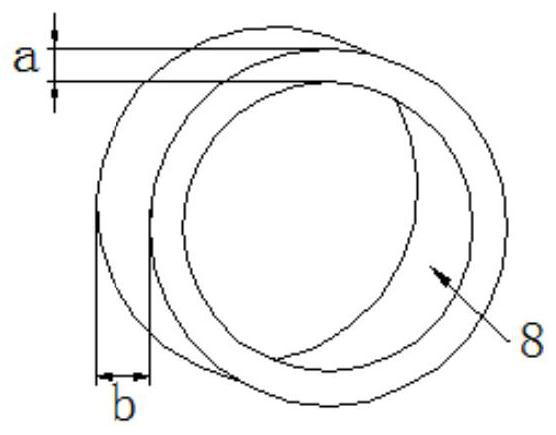

[0047] like Figure 2-6 As shown, a cooling device for a bearing forging includes a water-cooled conveyor 1 , an air-cooled conveyor 2 , a water-cooled device 3 , an air-cooled device 4 , and a turning mechanism 5 .

[0048] Both the water-cooled conveyor 1 and the air-cooled conveyor 2 can use a chain conveyor or a roller conveyor. The water-cooled conveyor 1 and the air-cooled conveyor 2 are placed on the ground in turn.

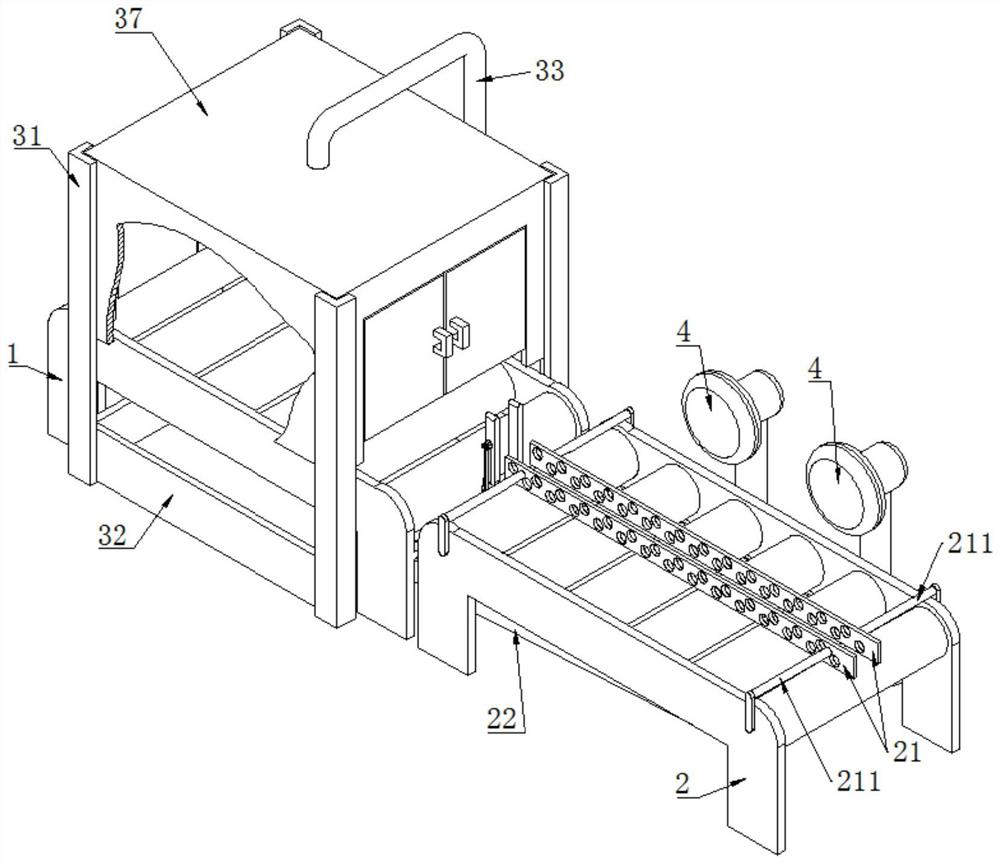

[0049] The water cooling device 3 includes a water cooling frame 31 , a protective box 37 , a collection tank 32 , a water supply pipe 33 , a water distribution pipe 34 , a spray head 35 , and a water pump 36 . The upper end of the water cooling rack 31 is welded with a protective box 37 , and the lower end of the water cooling rack 31 is welded with a collecting tank 32 . One end of the water supply pipe 33 is welded and fixed to the groove wall of the collection tank 32, the water supply pipe 33 is communicated with the inner cavity of the collection t...

Embodiment 2

[0062] like Figure 7-8 As shown, this Embodiment 2 makes further improvements on the basis of Embodiment 1.

[0063] In a cooling device for a bearing forging in the second embodiment, an auxiliary spray mechanism 6 is also included.

[0064] The auxiliary spray mechanism 6 includes an auxiliary telescopic rod 61, an auxiliary vertical rod 62, an auxiliary horizontal rod 63, a first spray seat 64, a second spray seat 65, a first auxiliary spray head 66, a second auxiliary spray head 67, and a connecting hose 68. Auxiliary hose 69.

[0065] The auxiliary telescopic rod 61 also adopts an electric push rod. The auxiliary telescopic rod 61 is arranged outside the protective box 37 , and the lower end of the auxiliary telescopic rod 61 is welded and fixed to the protective box 37 .

[0066] The upper end of the protective box 37 is provided with an installation hole 371 , and the upper end of the auxiliary vertical rod 62 passes through the installation hole 371 .

[0067] The ...

Embodiment 3

[0074] like Figure 9-10 As shown, this embodiment 3 makes further improvements on the basis of embodiment 2:

[0075] In a bearing forging cooling device of the third embodiment, the auxiliary spray mechanism 6 further includes a radial adjustment component 7 .

[0076] The radial adjustment assembly 7 is arranged in the protective box 37 , and the radial adjustment assembly 7 includes an adjustment sliding cylinder 71 , an adjustment telescopic rod 72 , an adjustment rod 73 , and an adjustment connecting rod 74 .

[0077] The adjusting slide cylinder 71 is sleeved on the auxiliary vertical rod 62 , and the adjusting slide cylinder 71 can slide up and down along the auxiliary vertical rod 62 .

[0078] The adjusting telescopic rod 72 also adopts an electric push rod. The upper end of the adjusting telescopic rod 72 is welded and fixed to the auxiliary vertical rod 62 , and the lower end of the adjusting telescopic rod 72 is welded and fixed to the adjusting sliding cylinder ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com