Environment friendly thermoplastic elastomer used as fire-retardant sealing strip and preparation method thereof

A thermoplastic elastomer and environmentally friendly technology, applied in the field of sealing strips, can solve the problems of resource waste, time consumption, energy consumption, etc., and achieve the effects of improving production efficiency, reducing costs, and saving resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

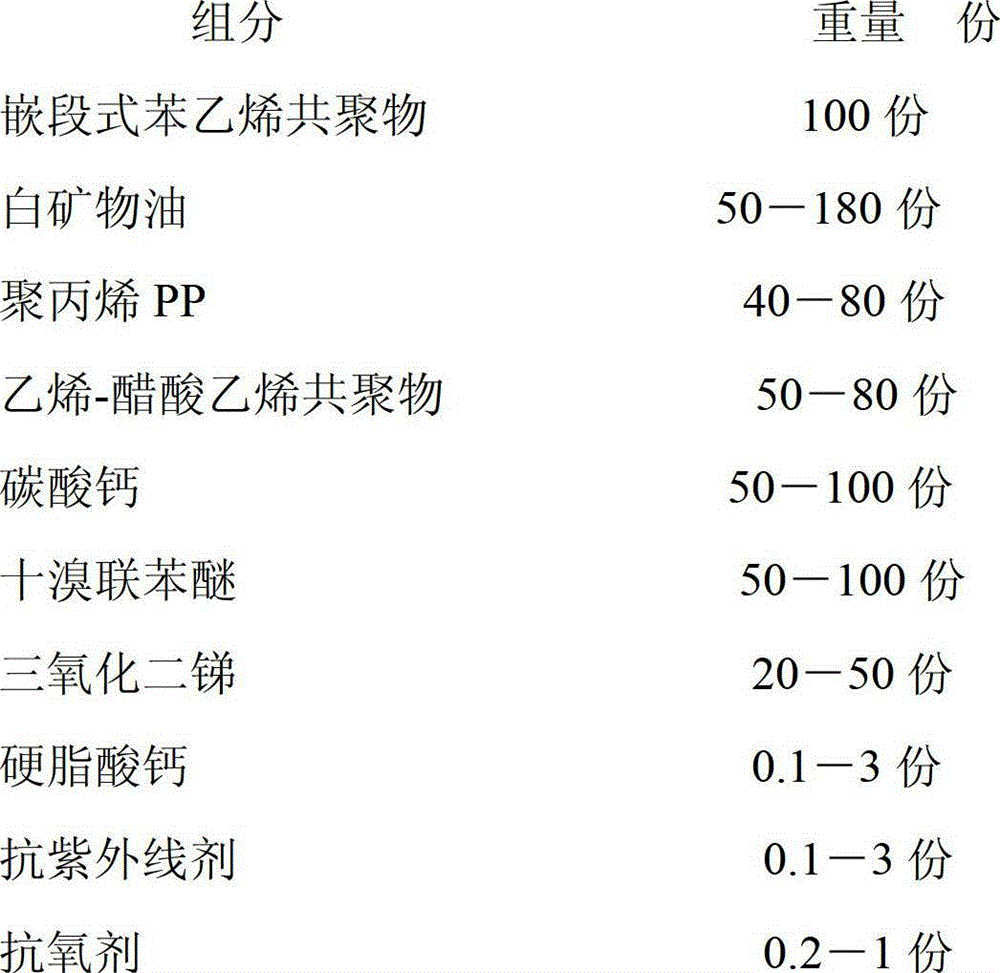

Method used

Image

Examples

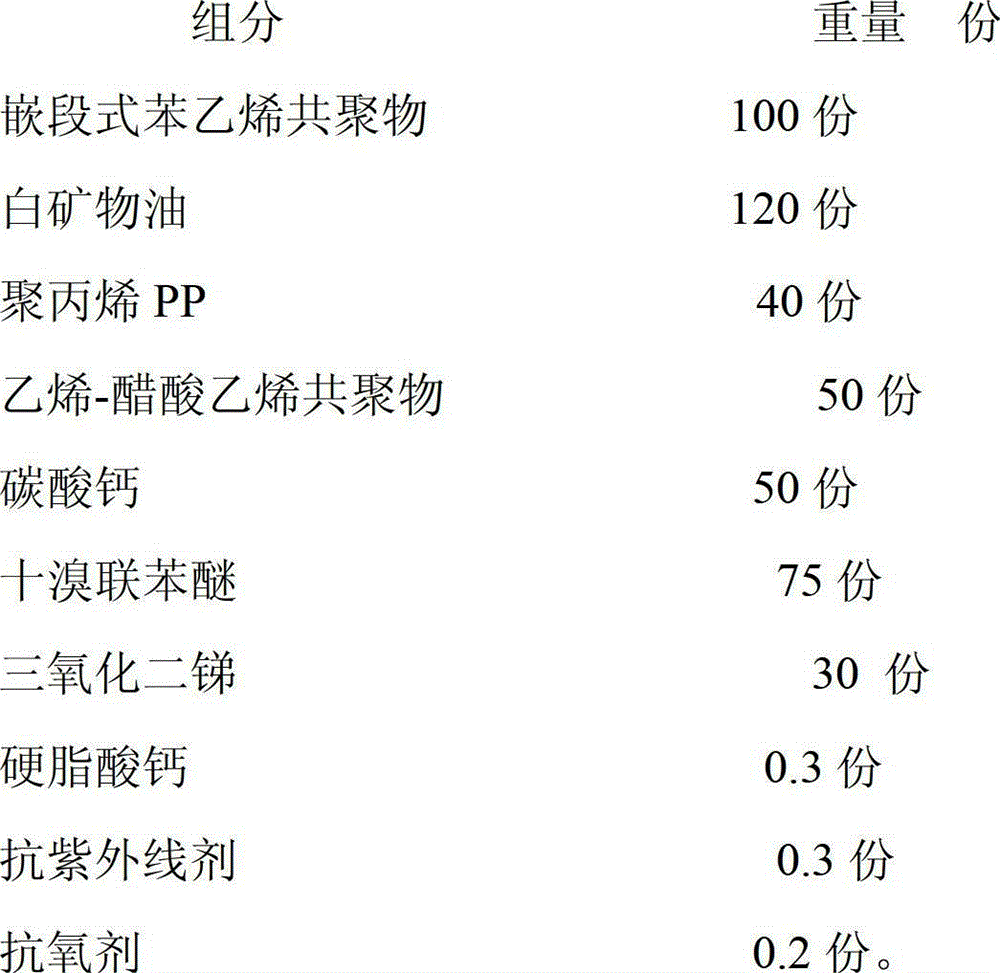

Embodiment 1

[0039] Embodiment one, 1, raw material preparation: each composition by following weight ratio:

[0040] SEBS 100 copies

[0041] 120 parts white mineral oil

[0042] Polypropylene PP 40 parts

[0043] EVA 50 parts

[0044] Calcium carbonate 50 parts

[0045] Decabromodiphenylethane 75 parts

[0046] Antimony trioxide 30 parts

[0047] Calcium stearate 0.3 parts

[0048] Anti-ultraviolet agent 0.3 parts

[0049] Antioxidant 0.2 parts.

[0050] 2. Preparation equipment: twin-screw extrusion granulator, extruder, and prefabricated molds for manufacturing passenger car sealing strips.

[0051] 3. Preparation steps:

[0052] b. Pour SEBS into the mixer first;

[0053] c. Put the white mineral oil into the blender and stir for 3 minutes;

[0054] d. Put other raw materials into the mixer together, and stir for another 3 minutes to fully mix;

[0055] e. Put the mixed material into a twin-screw granulator to extrude and granulate at 200°C;

[0056] f. Put the finished p...

Embodiment 2

[0070] 1. Raw material preparation: each ingredient according to the following weight ratio:

[0071] SEBS 100 copies

[0072] 180 parts white mineral oil

[0073] Polypropylene PP 80 parts

[0074] EVA 80 parts

[0075] Calcium carbonate 100 parts

[0076] Decabromodiphenyl ether 100 parts

[0077] Antimony trioxide 50 parts

[0078] 3 parts calcium stearate

[0079] Anti-ultraviolet agent 0.3 parts

[0080] Antioxidant 1 part.

[0081] 2. Preparation equipment: twin-screw extrusion granulator, extruder, and prefabricated molds for manufacturing passenger car sealing strips.

[0082] 3. Preparation steps:

[0083] b. Pour SEBS into the mixer first;

[0084] c. Put the white mineral oil into the blender and stir for 3 minutes;

[0085] d. Put other raw materials together and stir for another 3 minutes to fully mix;

[0086] e. Put the mixed material into a twin-screw granulator to extrude and granulate at 200°C;

[0087] f. Put the finished pellets into a single-s...

Embodiment 3

[0101] 1. Raw material preparation: each ingredient according to the following weight ratio:

[0102] SEBS 100 copies

[0103] 50 parts white mineral oil

[0104] Polypropylene PP 40 parts

[0105] EVA 50 parts

[0106] Calcium carbonate 50 parts

[0107] Decabromodiphenyl ether 50 parts

[0108] Antimony trioxide 20 parts

[0109] Calcium stearate 0.1 parts

[0110] Anti-ultraviolet agent 0.1 parts

[0111] Antioxidant 0.2 parts.

[0112] 2. Preparation equipment: twin-screw extrusion granulator, extruder, and prefabricated molds for manufacturing passenger car sealing strips.

[0113] 3. Preparation steps:

[0114] b. Pour SEBS into the mixer first;

[0115] c. Put the white mineral oil into the blender and stir for 3 minutes;

[0116] d. Put other raw materials together and stir for another 3 minutes to fully mix;

[0117] e. Put the mixed material into a twin-screw granulator to extrude and granulate at 200°C;

[0118] f. Put the finished pellets into a single...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com