Special rotating shaft

A technology of a rotating shaft and a rotating joint, applied in the field of air conditioning unit structure, can solve the problems of increasing the power consumption of the air conditioning unit, being unable to change the air conditioning unit, not conforming to the design concept, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

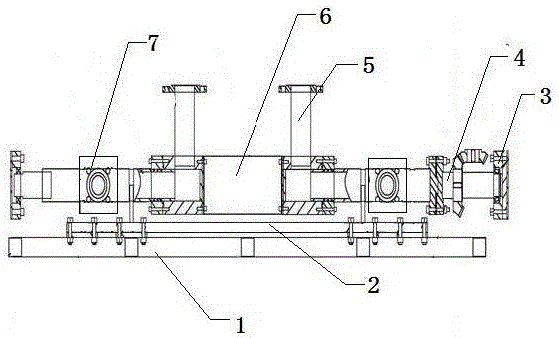

[0013] This embodiment provides a special rotating shaft, which is characterized in that: the special rotating shaft includes installation support (1), conversion frame (2), bearing seat (3), shaft welding parts (4), rotary joint welding piece (5), joint fixing seat (6), liquid medium static interface (7);

[0014] Wherein: the shaft weldment (4) is disconnected from the middle and is connected with the conversion frame (2), the middle is suspended in the air, and a connection port is provided at the upper and lower ends respectively, and the swivel joint weldment (5) is fluid The dynamic and static conversion seal of the medium is mated with one of the connection ports of the shaft weldment (4), the other connection port of the shaft weldment (4) is provided with a bearing seat (3), and the rotary joint weldment (5) is A rotary joint fixing seat (6) is also provided.

[0015] The installation support (1), rotary joint welding piece (5), joint fixing seat (6), bearing seat (3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com