Moth grinding sample preparation system for detecting silkworm female moth corpuscule pathogeny spore

A technology of pathogenic spores and microparticles, which is applied in the field of moth grinding sample preparation system, can solve the problems of waste, labor and effort, and retention

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

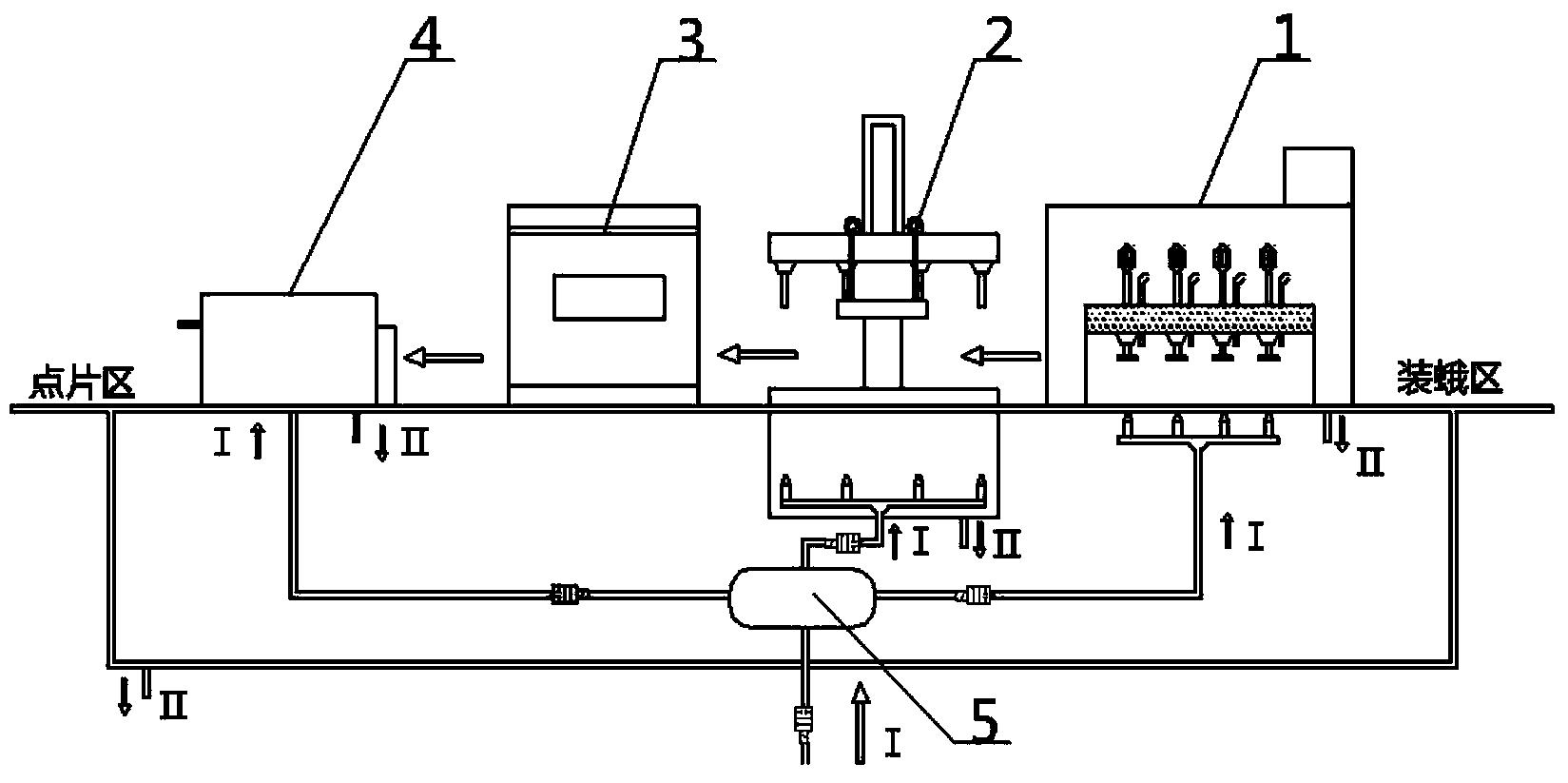

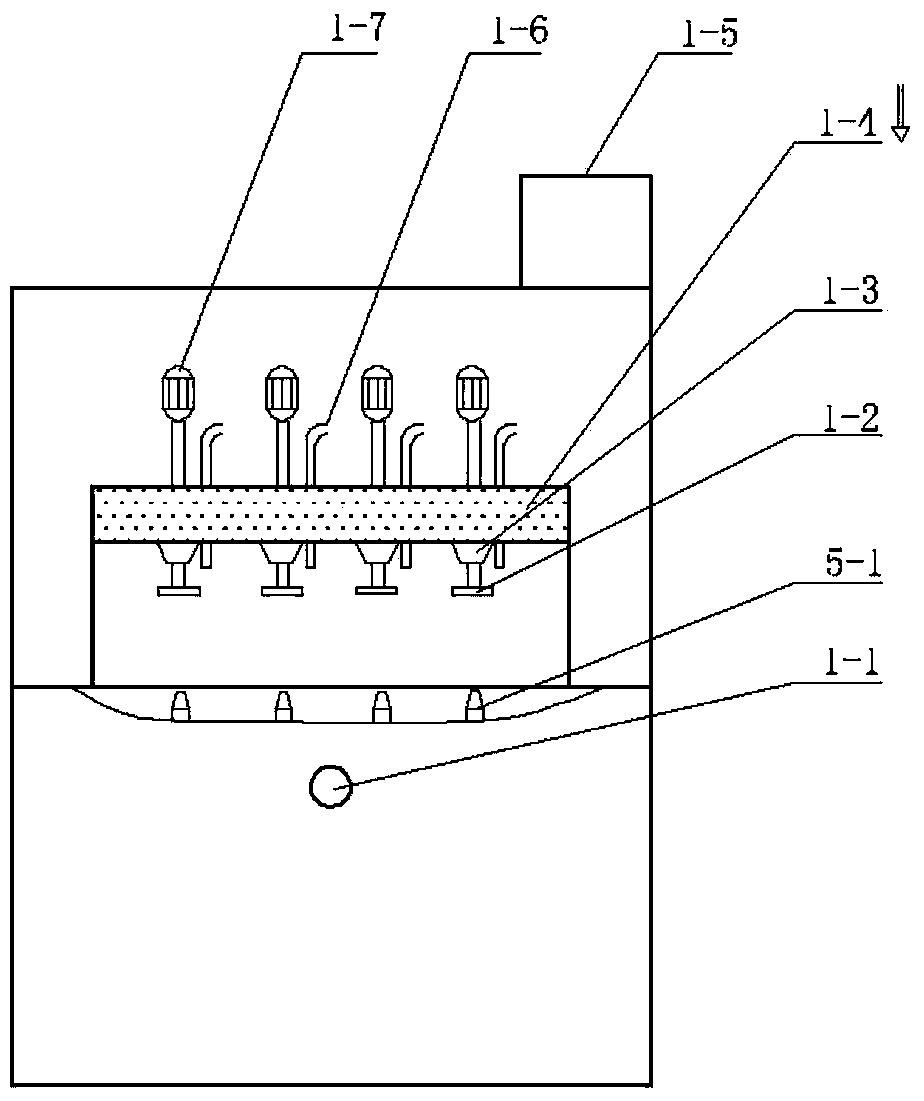

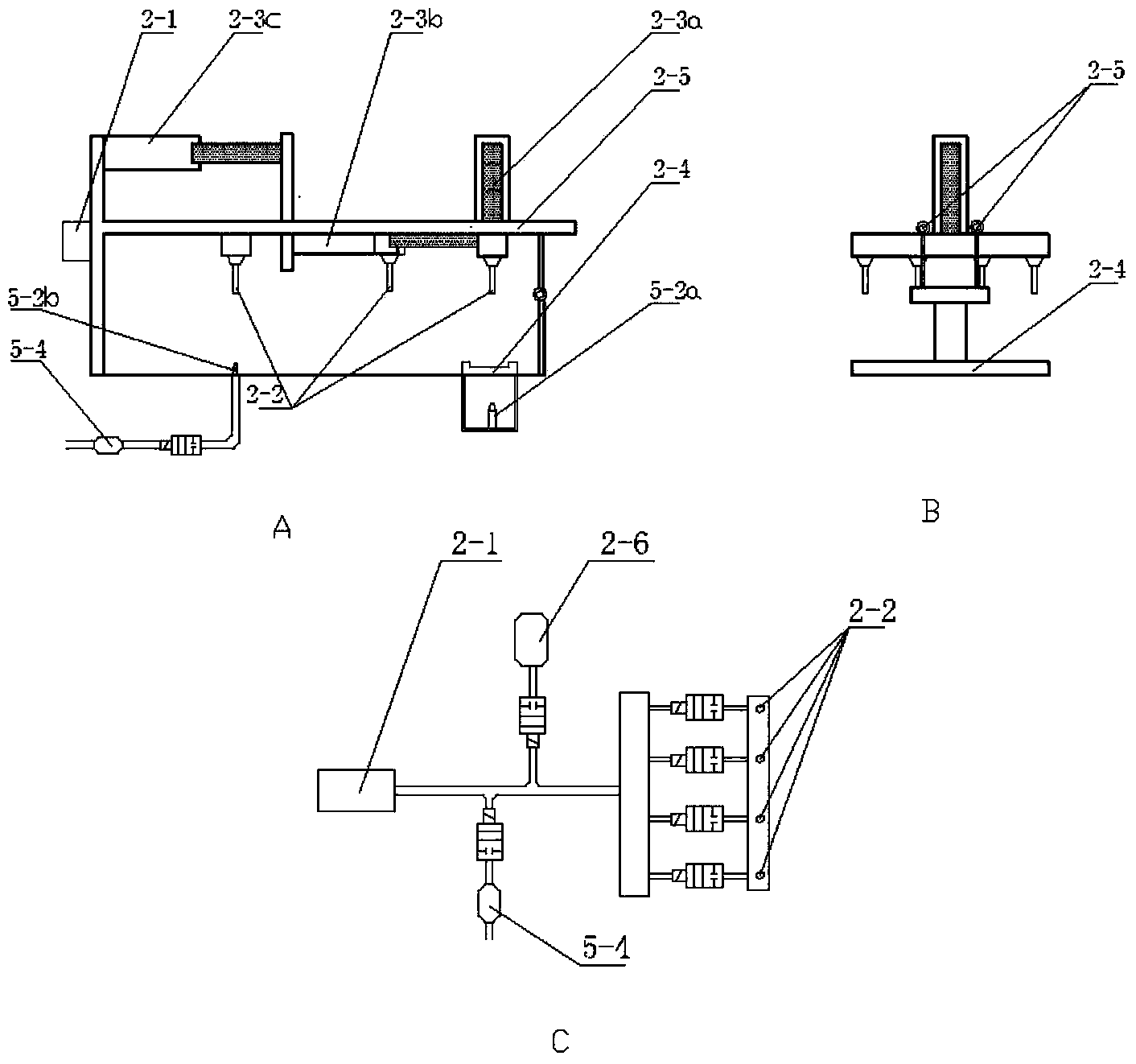

[0027] Such as figure 1 As shown, moth grinding system 1, automatic pipetting system 2, centrifuge enrichment device 3, centrifuge tube washing device 4 and automatic cleaning system 5 are integrated into one worktable; Moth area, followed by moth grinding system 1, automatic pipetting system 2, centrifugal enrichment device 3, centrifuge tube washing device 4 and automatic cleaning system 5, the leftmost is the spot area; under the table is the pipeline of automatic cleaning system 5 , water pumps and nozzles, etc.;

[0028] The working process of each component of the moth grinding sample preparation system is as follows. In the moth loading area, put the female moth of silkworm into the material cup, and then move the material cup to the moth grinding system 1; after the moth grinding is completed, move the material cup to the automatic pipetting system 2 , transfer the sample to the centrifuge tube, and then rotate the electromagnetic flap to clean the material cup, and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com