Clamp mechanism for cutting and splicing car body pieces

A technology of body parts and fixtures, applied in welding/cutting auxiliary equipment, clamping, manufacturing tools, etc., can solve the problems of not having fixtures, cutting and splicing quality dependencies, etc., to improve quality, save production costs, and reduce processing cycles Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The jig mechanism for cutting and splicing body parts according to the present invention will be further explained and described in conjunction with the accompanying drawings and specific embodiments. However, the explanation and description do not constitute an improper limitation on the technical solution of the present invention.

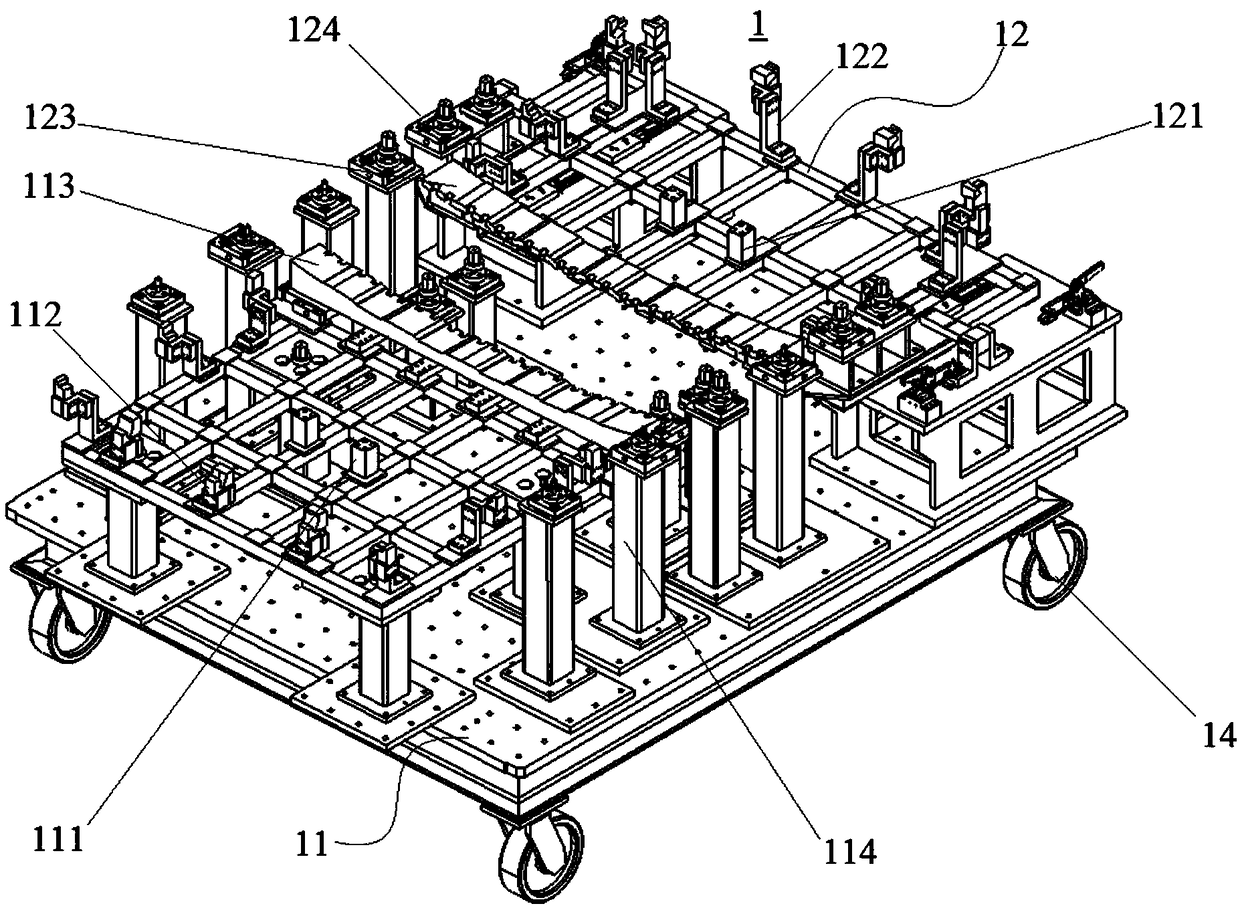

[0035] figure 1 It is a structural schematic diagram of some implementations of the jig mechanism for cutting and splicing body parts according to the present invention.

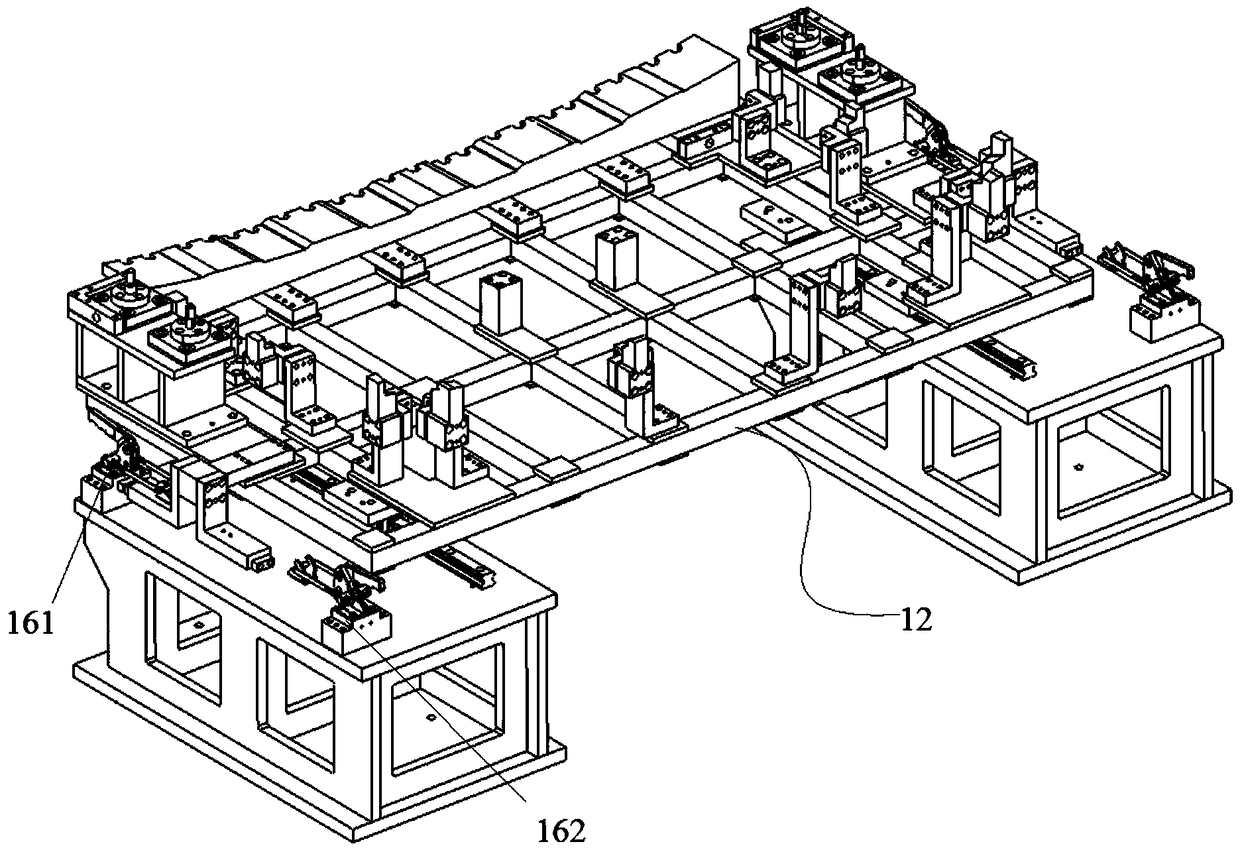

[0036] like figure 1 As shown, in some embodiments, the jig mechanism 1 for cutting and splicing body parts includes a base 11, a slide table 12 arranged on the base, and a roller 14 provided at the bottom of the base 11, wherein the slide table 12 can be The base 11 slides in the lengthwise direction.

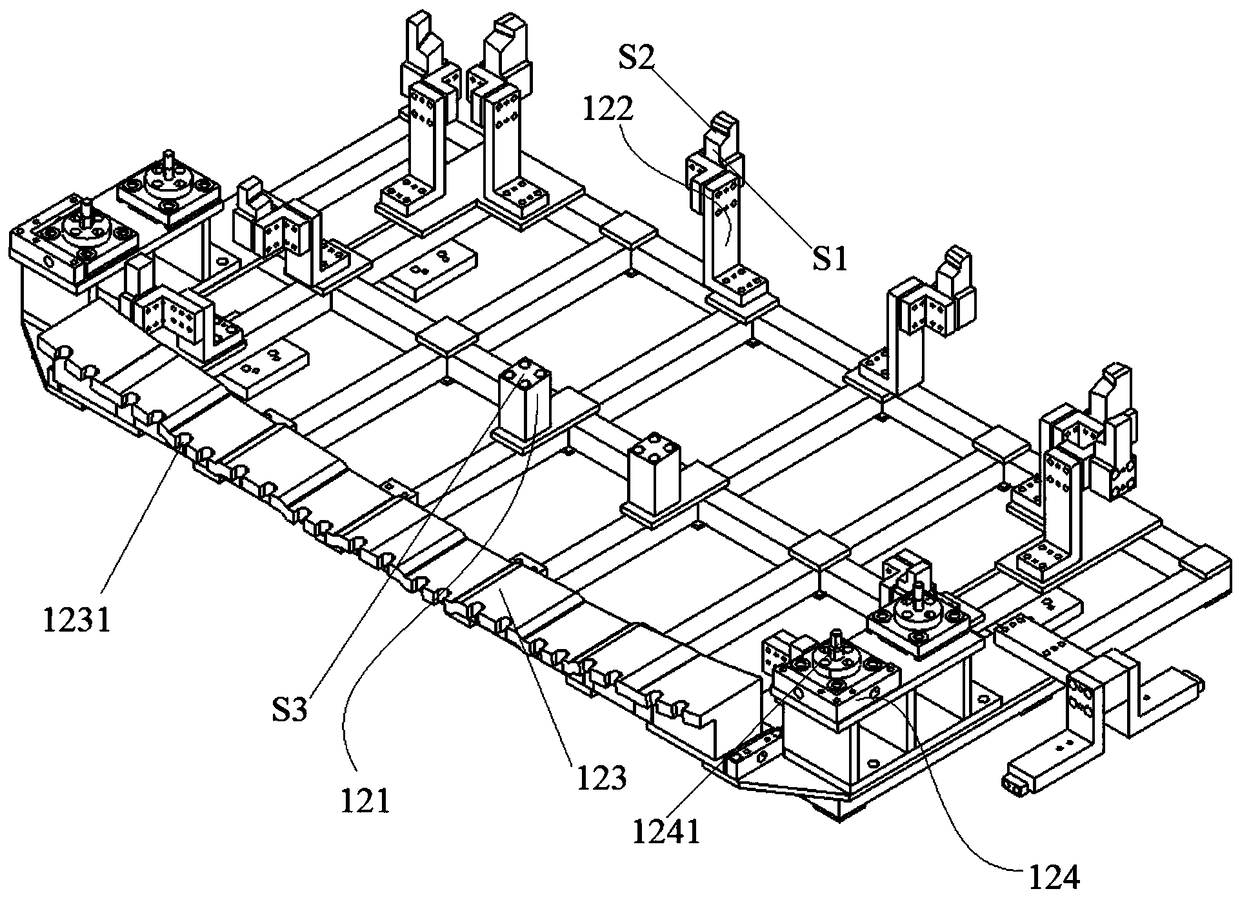

[0037] In order to provide support for the bottom of the body part, a first support block 111 and a second support block 121 are respectively provided on the base 11 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com