Highlight injection mould heating and cooling device and heating and cooling method thereof

A cooling device and injection mold technology, applied in the field of heating and cooling devices for high-gloss injection molds, can solve the problems of complex mold production, high energy consumption, and low safety, and achieve shortened injection molding cycle, high gloss, and heat transfer rate. high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

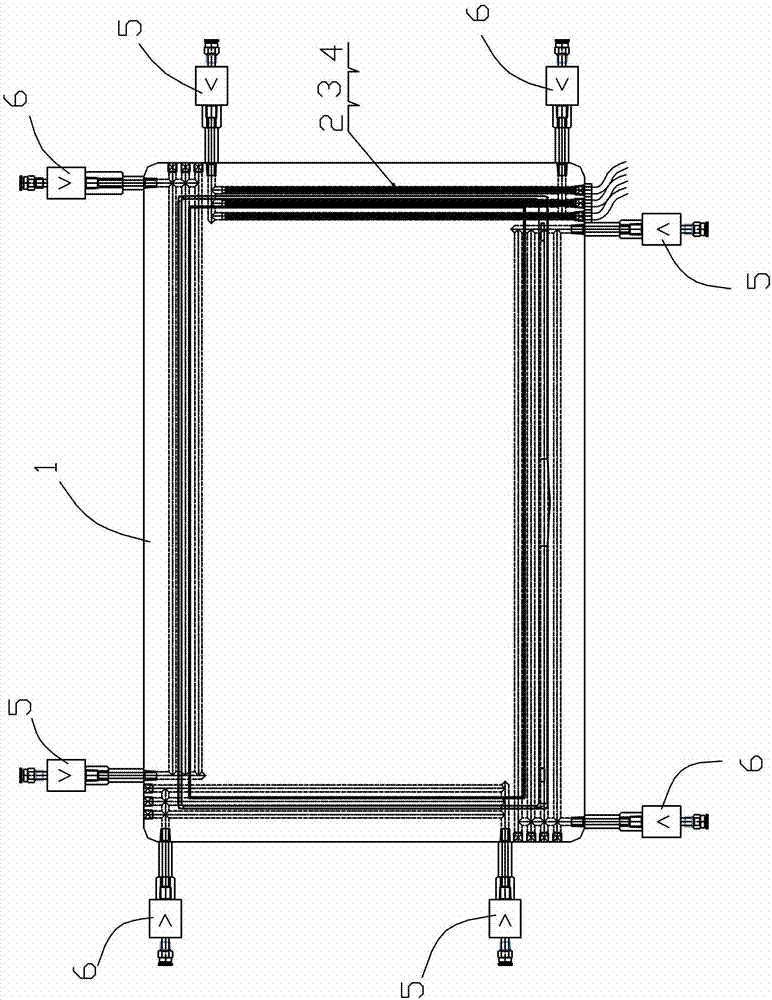

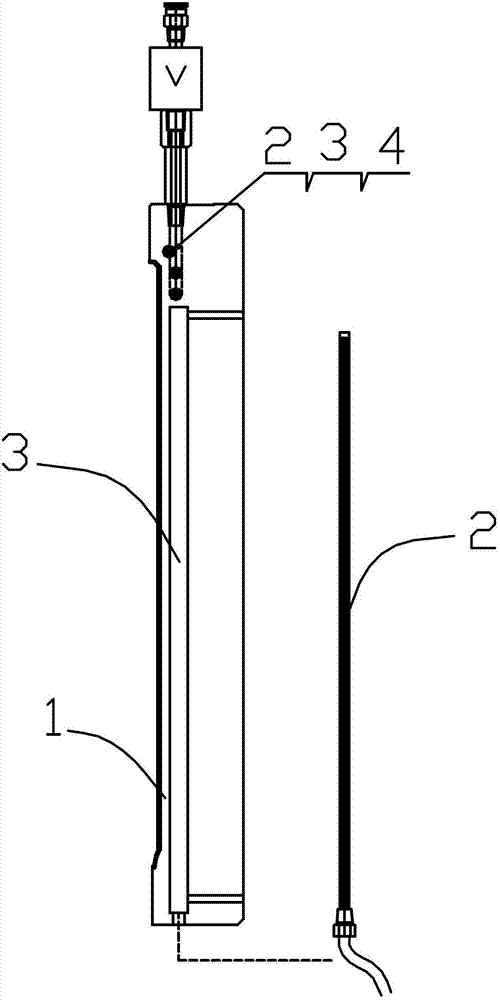

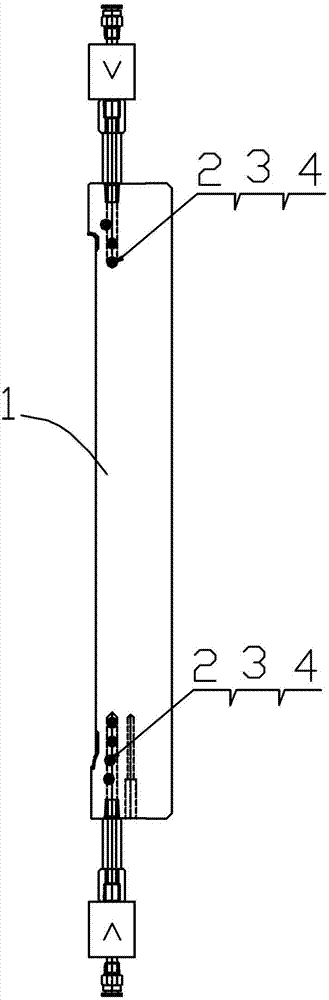

[0026] combine Figure 1 to Figure 4 , a high-gloss injection mold heating and cooling device, including a mold cavity 1, an electric heating rod 2, a pump, a heat exchange medium storage container and a controller. A pipe 3 is arranged on the mold cavity, and the electric heating rod is arranged in the pipe. There is a gap 4 for heating or cooling the heat exchange medium between the electric heating rod and the inner wall of the pipe. One end of the pipe is the heat exchange medium. At the inflow end, a No. 1 control valve 5 is set at the inflow end. The other end of the pipeline is the outflow end of the heat exchange medium, and a No. 2 control valve 6 is set at the outflow end. A temperature sensor is arranged on the mold cavity, and a pressure sensor is arranged in the pipeline. The above-mentioned temperature sensor and pressure sensor are connected to the controller, and the above-mentioned pump, No. 1 control valve, No. 2 control valve, and electric heating rod are a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com