Mold clamping mechanism of two-plate injection molding machine

A mold clamping mechanism and injection molding machine technology, applied in the field of injection molding machines, can solve the problems of large mold clamping cylinder, lower production efficiency, increase injection time, etc., achieve the effect of shortening injection molding cycle, improving production efficiency, and high degree of linkage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

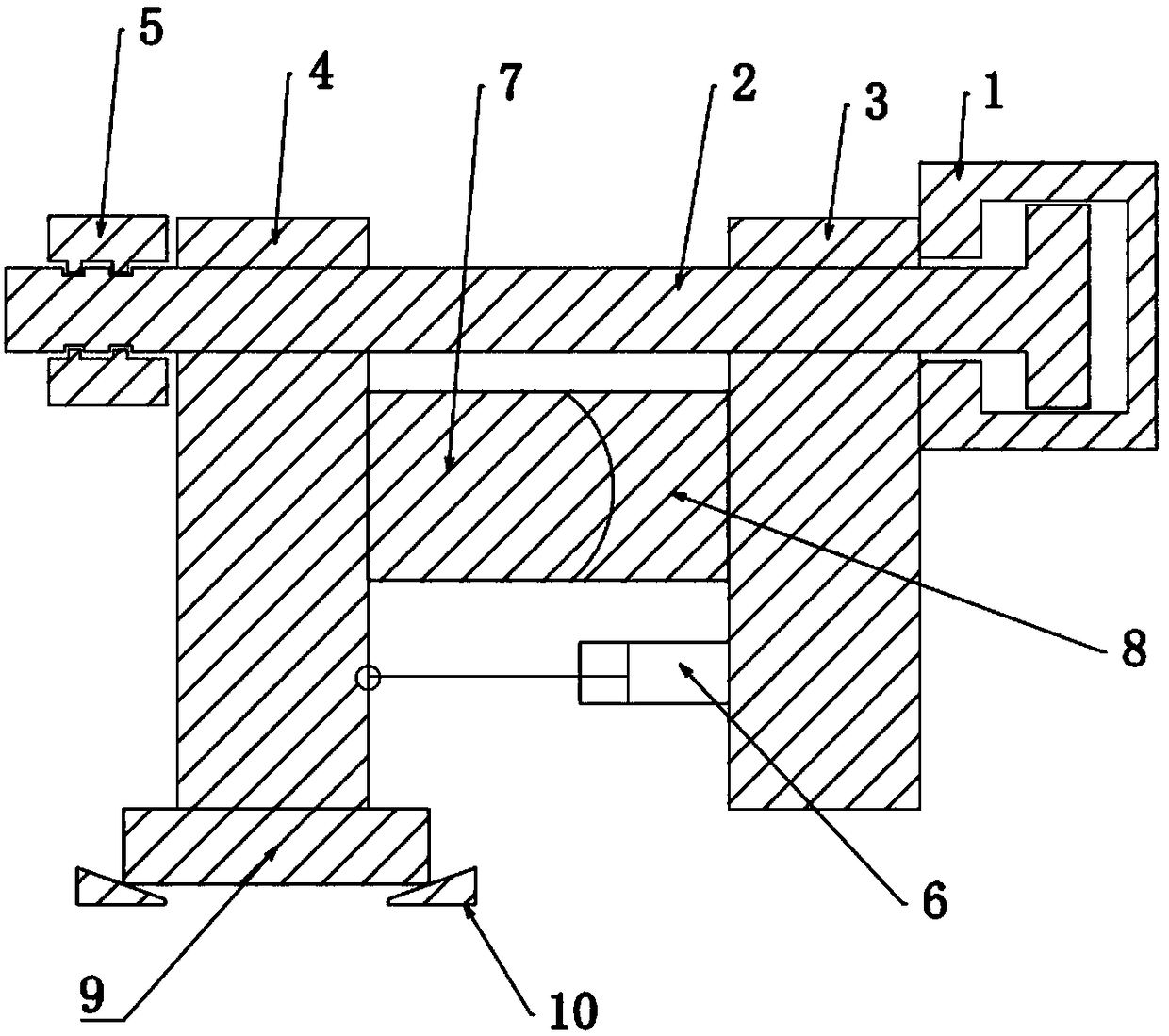

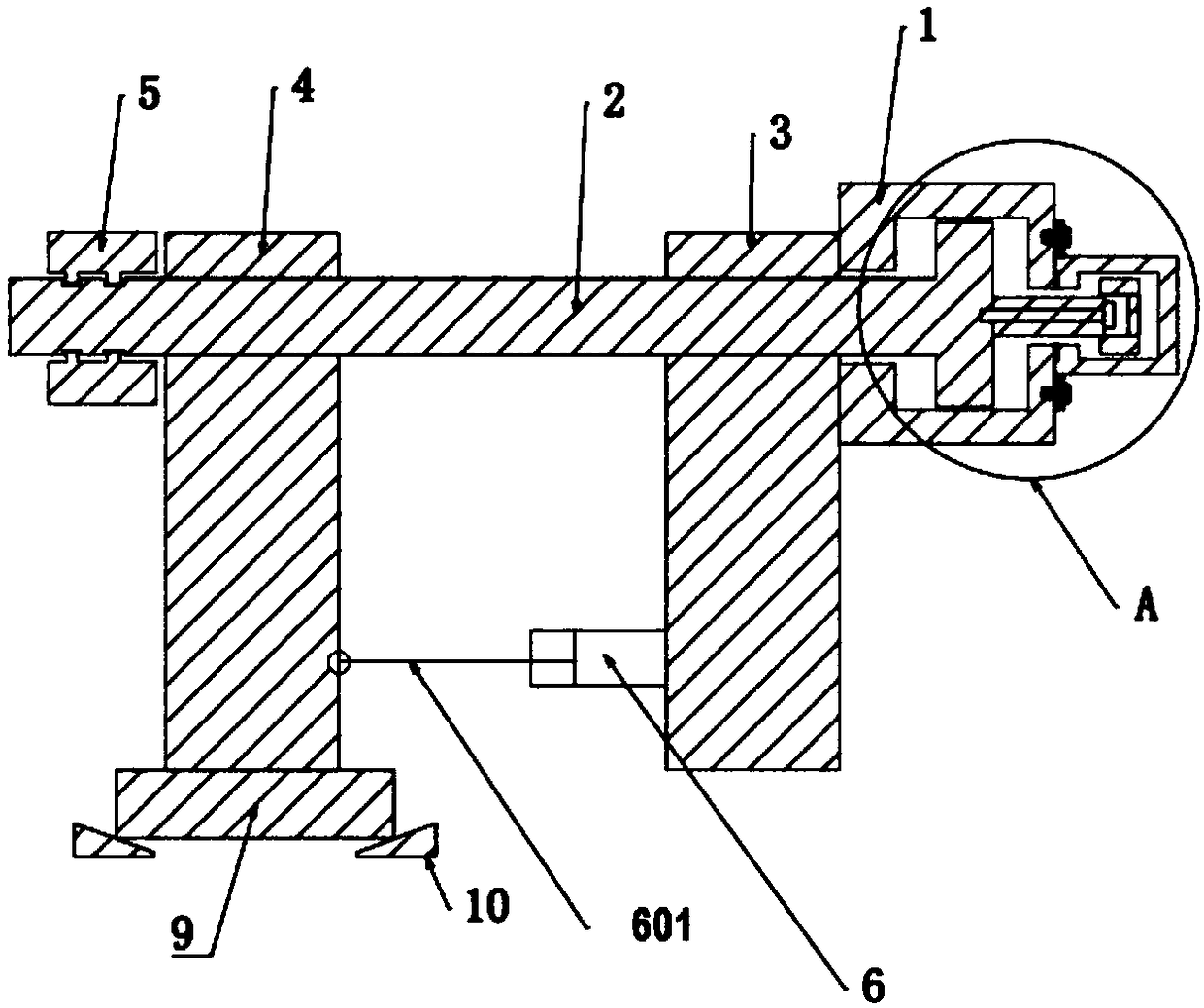

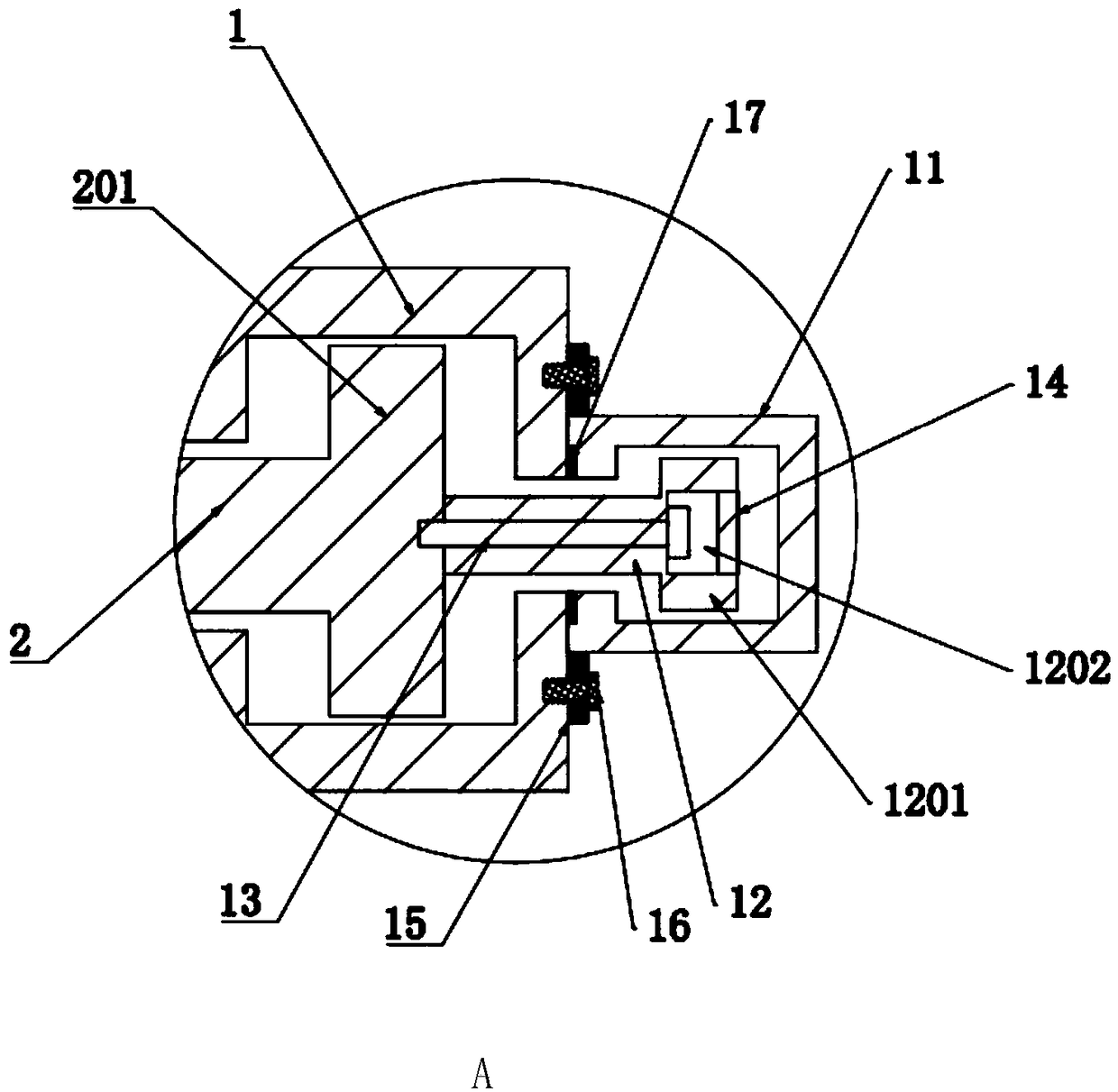

[0031] The clamping mechanism of the two-platen injection molding machine of prior art is as figure 1 As shown, it generally includes a fixed template 3, a movable template 4, a clamping cylinder 1, a pull rod, half lock nuts 5, a mold transfer cylinder 6, a supporting sliding foot 9, and an adjustment slant iron 10. The fixed template 3 and the movable template 4 are arranged in parallel at intervals, the mold-moving cylinder 6 is fixed on the fixed template 3, the mold-moving cylinder 6 is provided with a mold-moving piston rod 601, and the end of the mold-moving piston rod 601 is connected with the movable template 4 to realize For mold clamping and mold opening operations, the clamping cylinder 1 is set at the end of the fixed platen 3 away from the movable platen 4, the end of the clamping piston rod 2 far away from the fixed platen 3 is connected with a tie rod, and the pull rod and piston rod pass through the fixed platen 3 and the movable platen in turn. The template 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com