Rotating laminated type injection mould and injection method using same

An injection mold and lamination technology, which is applied to the rotary laminated injection mold and the injection molding field using the mold, achieves the effects of being beneficial to mass production, avoiding air bubbles, and being convenient for injection molding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention is described further below with embodiment, is not to limit the scope of implementation of the present invention hereto.

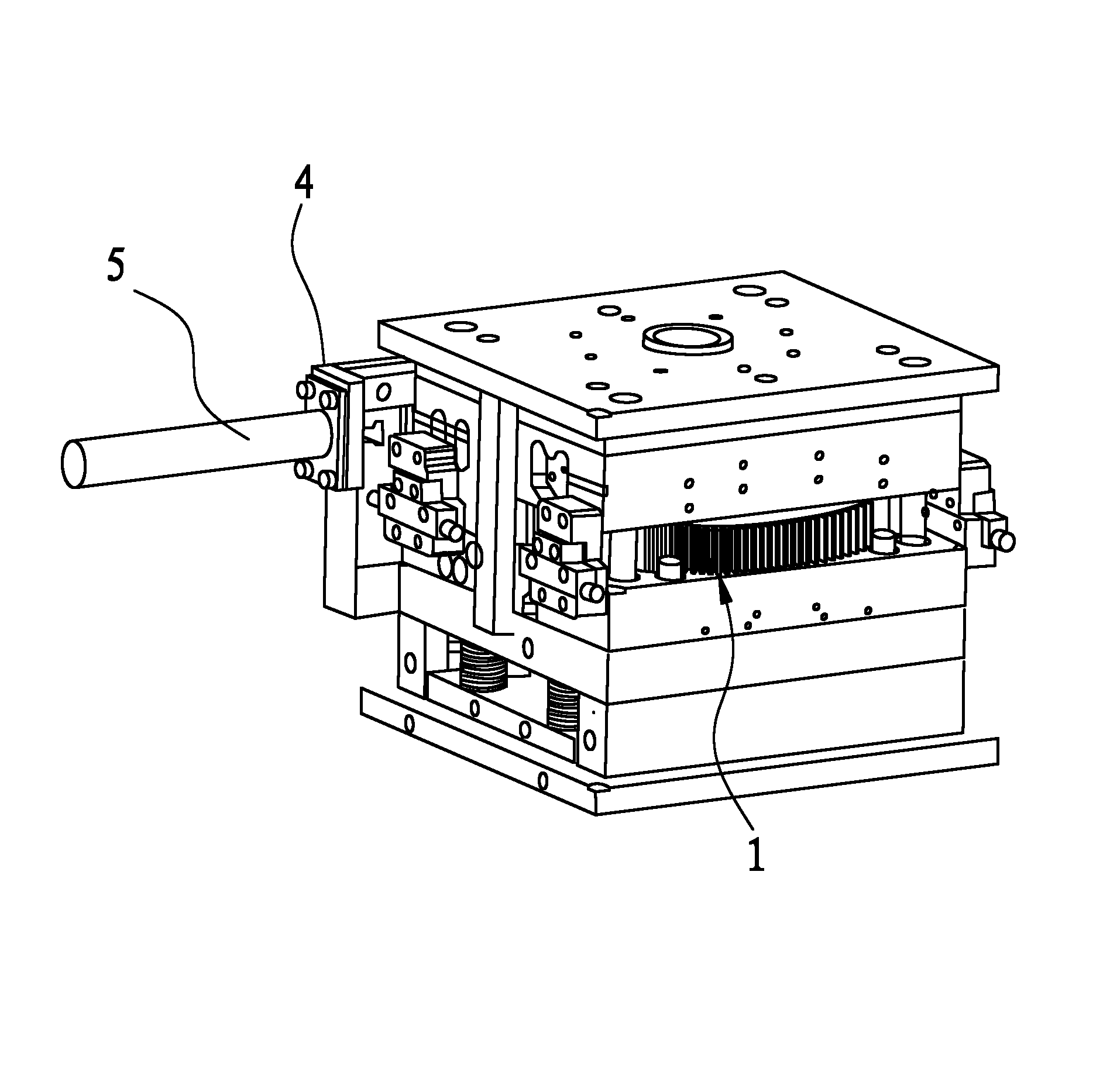

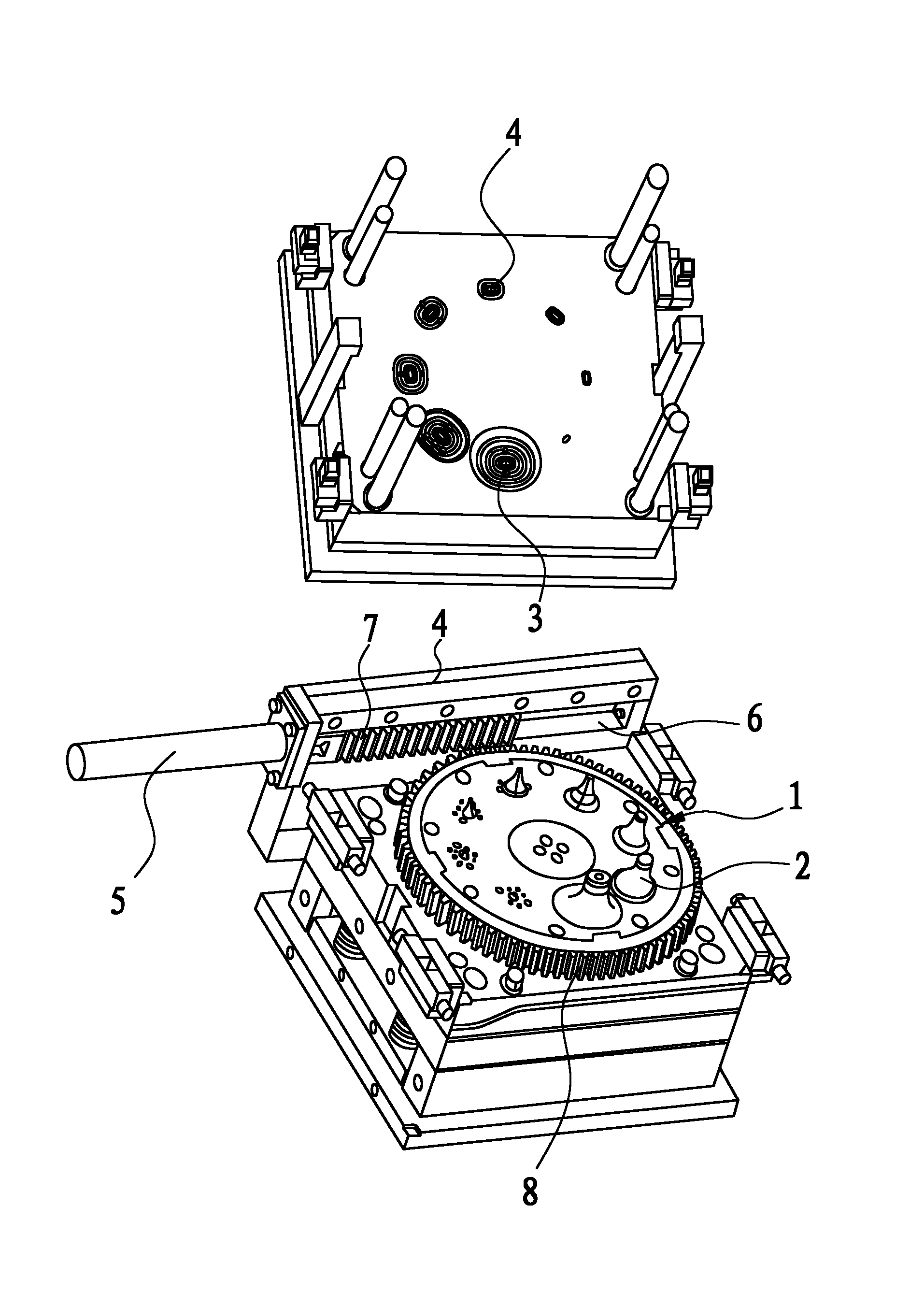

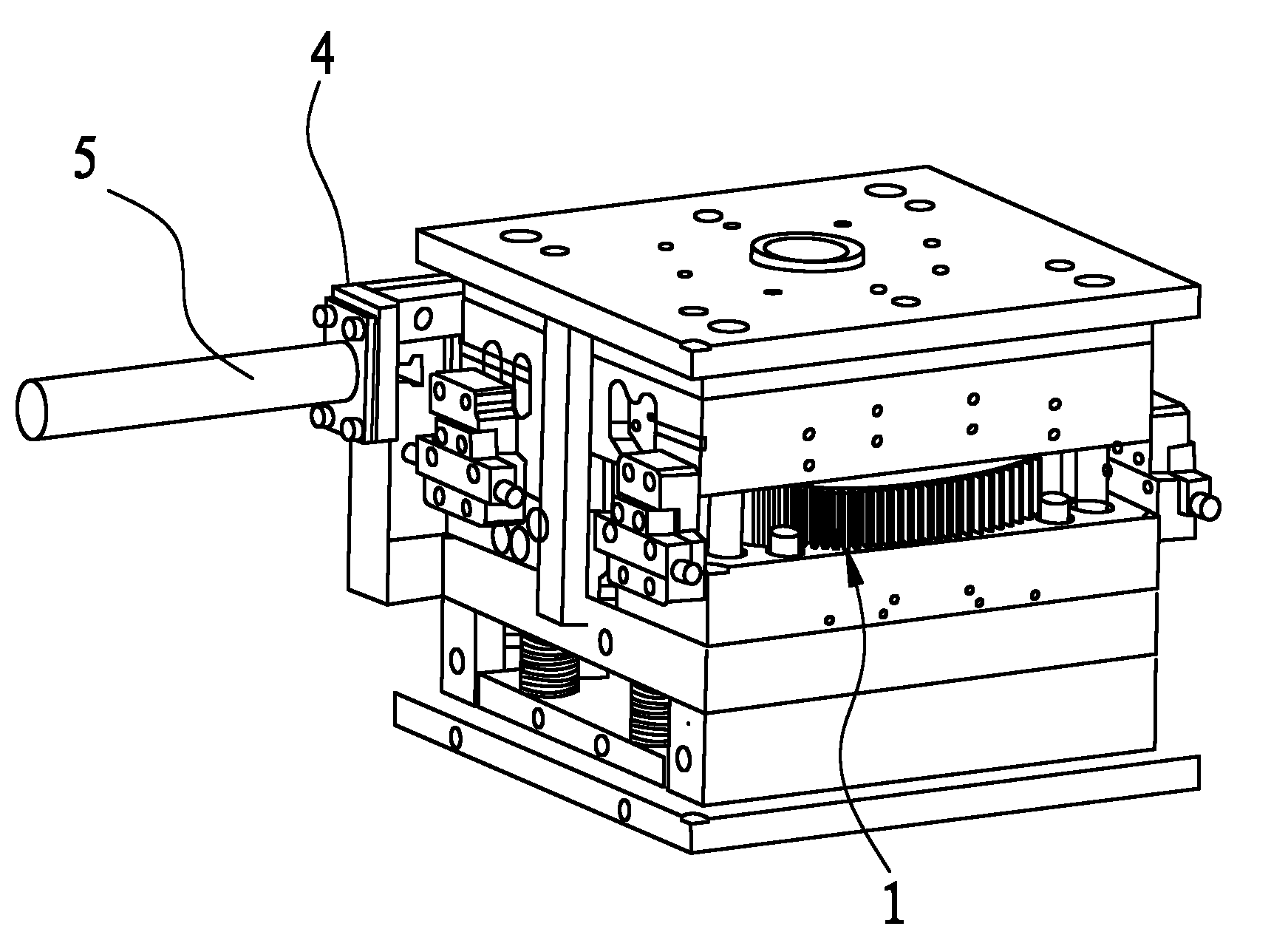

[0036] A rotary laminated injection mold, comprising a fixed mold overall and a movable mold overall, the fixed mold overall includes a fixed template and a fixed mold cavity, the movable mold overall includes a movable template, an ejection mechanism and a movable mold cavity, the The movable mold cavity is connected with a rotating disk 1, which rotates around the axis of the mold cavity, and a driving device for driving the rotating disk 1 is provided on one side of the mold. The ring of the rotating disk 1 is provided with at least two Set of inserts2. According to the specific thickness of the transparent product, it is divided into multiple equal parts, and each equal part is provided with an insert 2. Of course, the equal parts of the transparent product and the number of inserts 2 can be flexibly divided according to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com