Patents

Literature

55results about How to "Easy to powder" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Glittery metallic powder coating and preparation method thereof

ActiveCN101955720AImprove flatnessIntense metallic glitter effectPowdery paintsEpoxy resin coatingsWaxDefoaming Agents

The invention provides a glittery metallic powder coating and a preparation method thereof, which can solve the problems that the metallic glittery effect is undesirable, and the coat is easy to wear away and distributed unevenly existing in the prior art. The glittery metallic powder coating comprises the following components in percentage by weight: 50 to 70 percent of transparent powder, 25 to 45 percent of dark and light covering power, 2.0 to 5.0 percent of coarse aluminum silver powder, 0.05 to 0.5 percent of fine aluminum silver powder, 0.1 to 1 percent of wax powder, 0.1 to 1 percent of defoaming agent, and 0.05 to 0.5 percent of fluidity improver. The invention also provides a method for preparing the glittery metallic powder coating. The glittery metallic powder coating of the invention has the advantages that: the leveling can be improved; the surface of the coat has a strong metallic glittery effect, and the coat is easy to wear away and uniform in color so as to give people a fashionable and beautiful feeling and show a high-grade decoration effect, therefore, the glittery metallic powder coating is very suitable for high-grade decoration field; and meanwhile, the production cost of the glittery metallic powder coating is not high.

Owner:HAIER GRP CORP +1

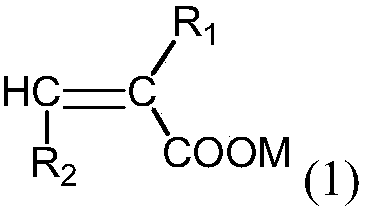

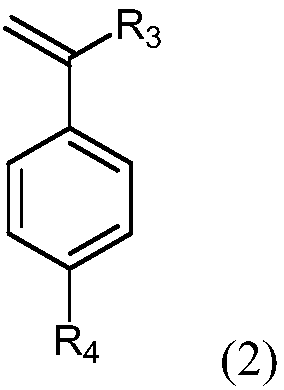

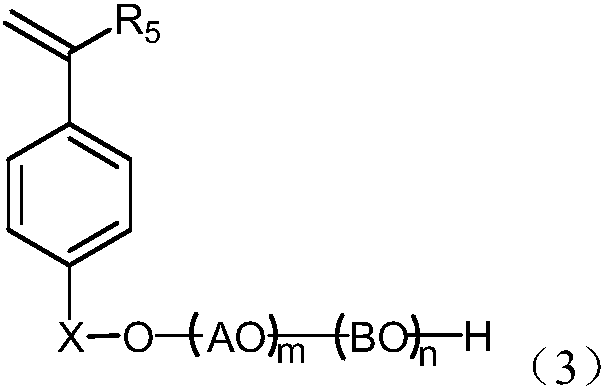

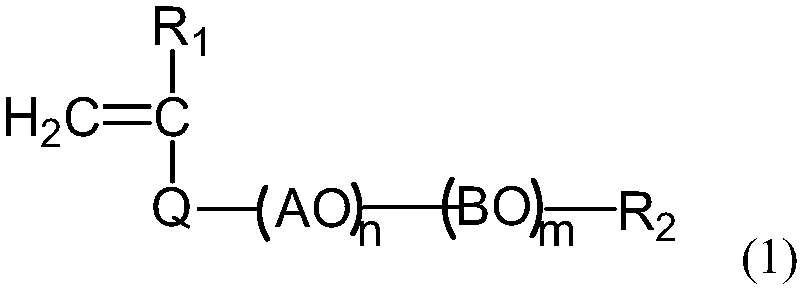

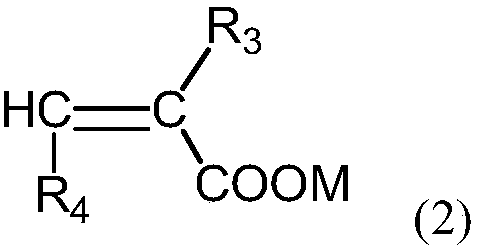

Preparation method and application of powdery polycarboxylic acid water-reducing agent

The invention discloses a preparation method and application of a powdery polycarboxylic acid water-reducing agent. The preparation method comprises the following steps: preparing from a carboxylic acid monomer a, a benzene ring-containing small monomer b and a benzene ring-containing polyether monomer c in an aqueous medium through free radical copolymerization to obtain polycarboxylic acid water-reducing agent mother liquor; and directly forming the polycarboxylic acid water-reducing agent mother liquor into fog drops through a centrifugal atomizer for a sprayer without adding an isolation agent, controlling the average particle size of powder to be 50-150 [mu]m, drying into powder after the fog drops enter a drying room, leading a material to a discharge port through an induced draft fan, and packaging and discharging by adopting a bagged packaging machine to obtain the powdery polycarboxylic acid water-reducing agent. The preparation method disclosed by the invention has the benefits that not only is the effective content of polymers in the powder improved, but also the production technical process is reduced, and the production cost is reduced; and the prepared powdery polycarboxylic acid water-reducing agent is optimal in fluidity, incapable of caking, high in storage stability, low in long-distance transportation cost, excellent in water-reducing property and suitable for various dry mortar.

Owner:JIANGSU SOBUTE NEW MATERIALS +1

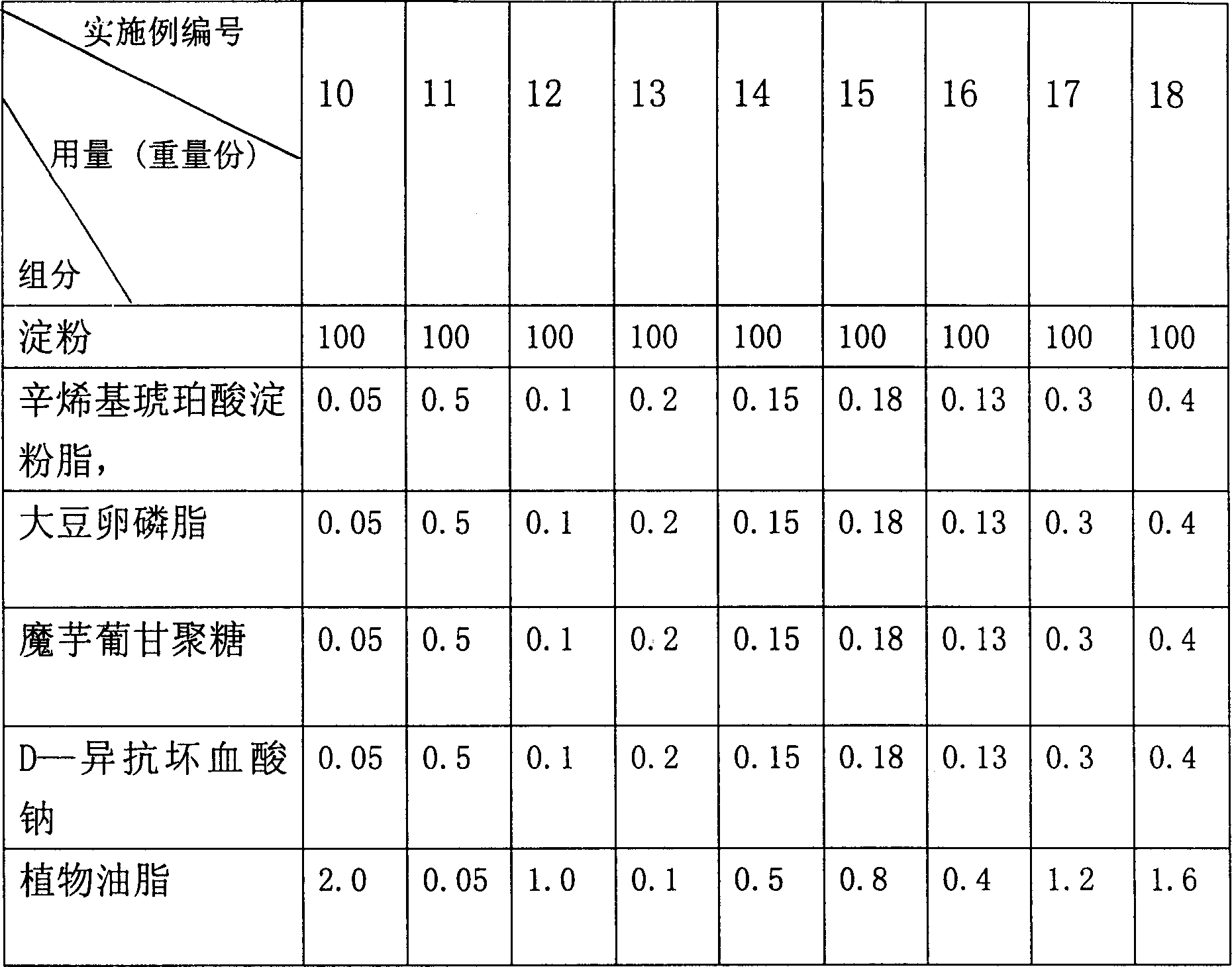

Process for making vermicelli without alums

A method for preparing to long-thread vermicelli (or sheet jelly) includes such steps as proportionally mixing starch, starch ester of octenyl succinate, soya bean lecithin, konjak glucomannan, D-sodium isoascorbate, edible vegetative oil and water, stirring, and heating while shaping. It features no use of alum.

Owner:SICHUAN GUANGYOU SWEET POTATO & FOOD PROD CO LTD

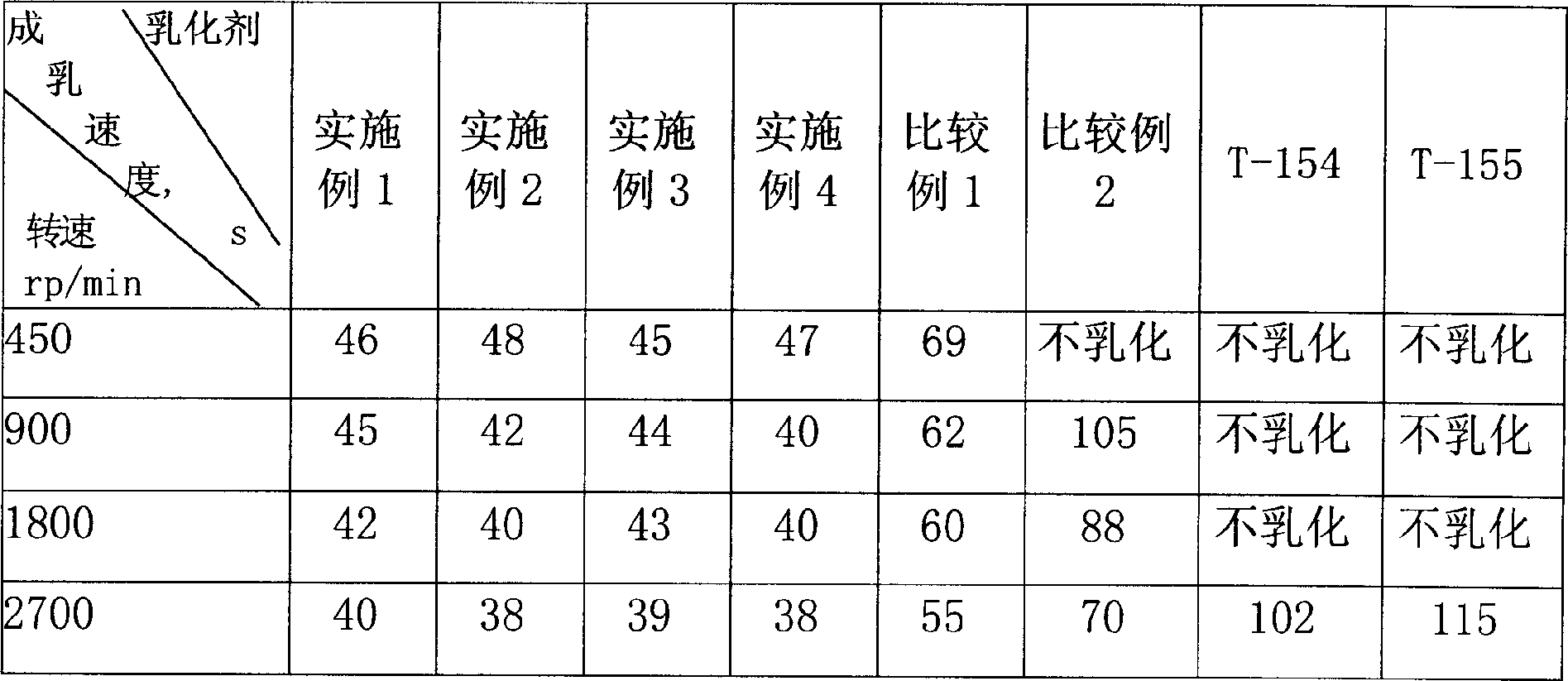

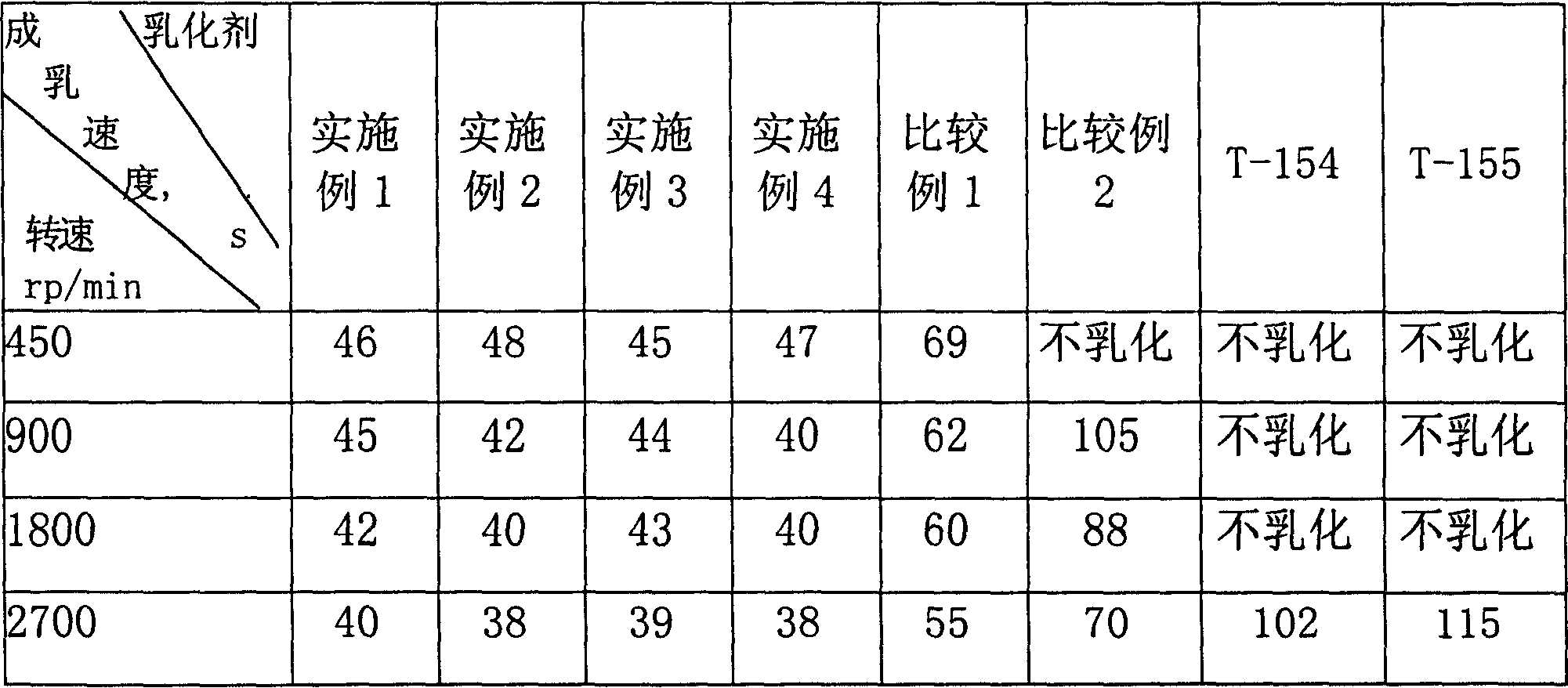

Emulsifier for powdered emulsified explosive and its prepn process

ActiveCN1609079AImprove stabilityGood storage stabilityNon-explosive/non-thermic compositionsPolymer scienceAlcohol

The present invention provides the preparation process of one kind of emulsifier for powdered emulsified explosive. The polymer emulsifier with excellent emulsifying performance and high emulsifying stability is prepared through the reaction between alkyl carboxylic acid or carboxylic anhydride and the mixture of several kinds of alcohol amine compounds. The powdered emulsified explosive prepared with the emulsifier has high explosion performance, high stability and long storing period.

Owner:CHINA PETROLEUM & CHEM CORP +1

Preparation method of powdered acrylonitrile-butadiene rubber with high performance

A preparation method of a powdered acrylonitrile-butadiene rubber with high performance comprises steps of: dispersing of carbon nanotubes: adding carbon nanotubes and water in a high-speed disperser, and stirring to evenly disperse the carbon nanotubes; preparation of a rapid polymerization latex: adding water, acrylonitrile and an emulsifier into a polymerization kettle, after confirmation of no leakage, adding butadiene, a crosslinking agent, an initiator and a molecular weight regulator for polymerization; and when the conversion rate reaches a certain level, adding a terminator to obtain a fast polymerization acrylonitrile-butadiene latex; and condensation into a powder: adding the acrylonitrile-butadiene latex, water, carbon nanotubes, a separant, a flocculant and a coagulant into a coagulation tank; curing, washing, dehydrating and drying to obtain the powdered acrylonitrile-butadiene rubber. The prepared acrylonitrile-butadiene rubber slurry has the following properties: pH of 7-10, Mooney viscosity of ML (1+4) 100 DEG C 60-110, structure gel of 75%-85%, and acrylonitrile-butadiene rubber mechanical stability of less than 1.0%; and the powdered acrylonitrile-butadiene rubber has the following properties: powder particle size of 0.6-1.0 mm, acrylonitrile content of 40%-55%, ash content no more than 1.0, volatile matter no more than 1.0, and powdered ratio no less than 95%.

Owner:PETROCHINA CO LTD

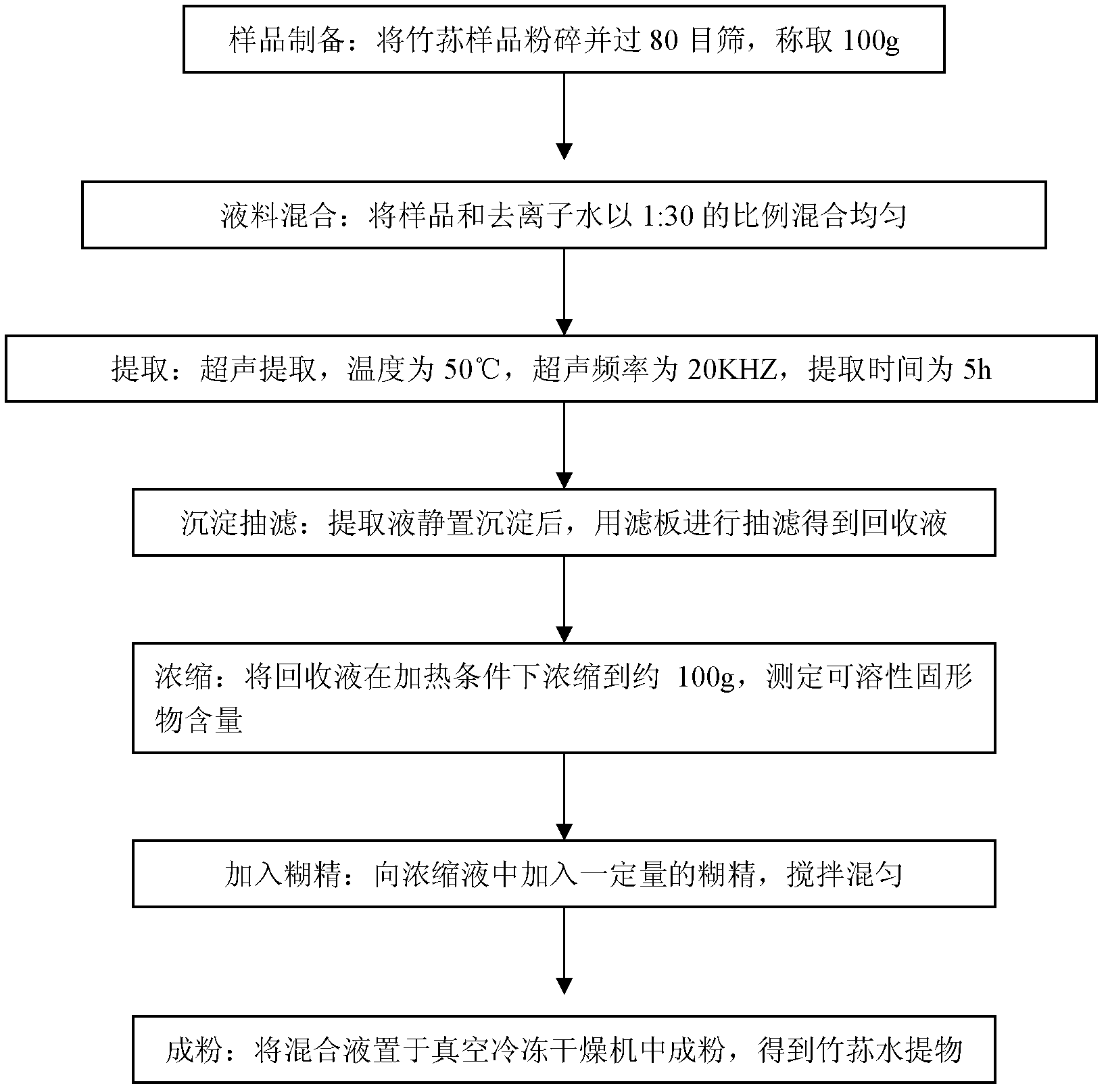

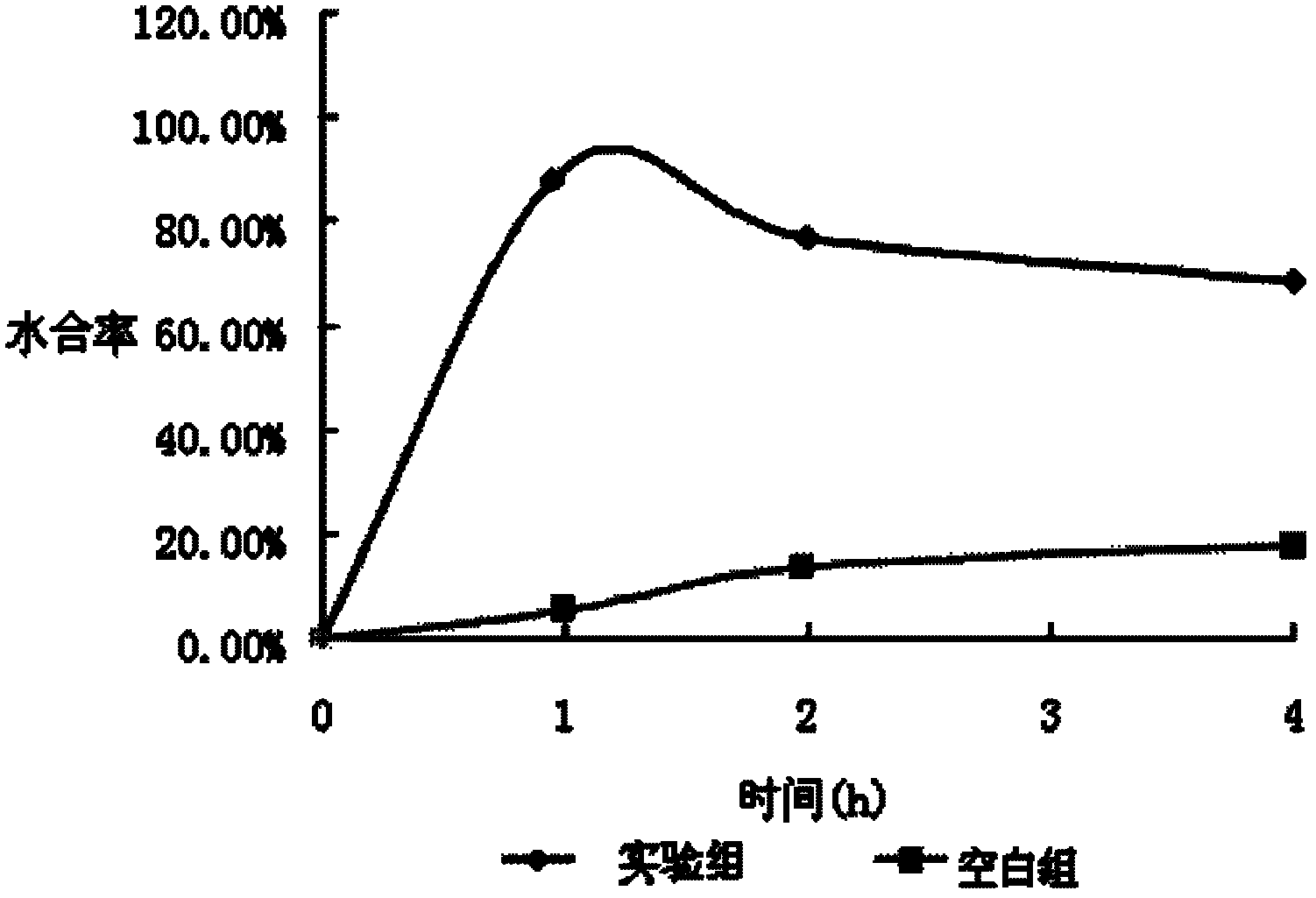

Dictyophora indusiata water extract and preparation method and application thereof

ActiveCN102512353AEasy to operateReduce manufacturing costCosmetic preparationsToilet preparationsChemistryFreeze dry

The invention discloses a Dictyophora indusiata water extract and a preparation method and application thereof. The preparation method comprises the following steps of: (1) mixing Dictyophora indusiata powder and deionized water, and performing ultrasonic extraction to obtain an extracting solution; (2) standing and precipitating the extracting solution, and filtering to obtain a recovered solution; (3) concentrating the recovered solution to obtain a concentrated solution; and (4) adding dextrin into the concentrated solution, stirring uniformly, and freeze-drying to obtain a product. The preparation method is easy to operate and is low in production cost; the obtained Dictyophora indusiata water extract is high in purity and high in yield; the Dictyophora indusiata water extract can be powdered easily, and is light yellow or yellow; and a cosmetic product prepared by using the Dictyophora indusiata water extract has a remarkable anti-aging effect and a more remarkable moisturizing effect.

Owner:BEIJING TECHNOLOGY AND BUSINESS UNIVERSITY

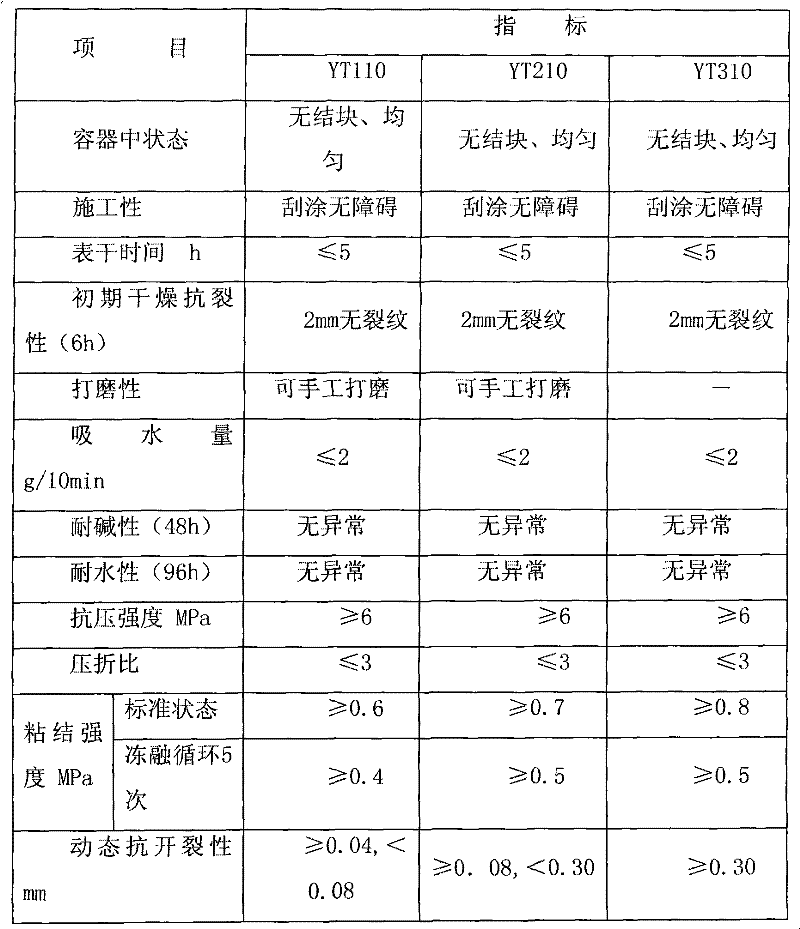

Inorganic high-strength filler for coating

InactiveCN102173679ARealize one-time coatingCrack resistantSolid waste managementFilling pastesCelluloseCoating system

The invention discloses an inorganic high-strength filler for a coating. The inorganic high-strength filler is prepared by fully mixing 220 to 300 weight parts of white portland cement used as a gelled material, 350 to 550 weight parts of white quartz sand and 150 to 250 weight parts of quartz powder which are used as aggregate, 50 to 100 weight parts of wollastonite powder, and 0.3 to 1.5 weightparts of polypropylene fiber anti-cracking material, and a dry powder material which is prepared by mixing 2 to 8 weight parts of cellulose ether and 10 to 30 weight parts of gelatine powder uniformly by a stirring machine, and packaging. The inorganic high-strength filler can be conveniently coated on a dry wall, is easy and convenient to construct, and is easy to level and polish; and when the inorganic high-strength filler is used as a penetration base layer of an inorganic penetration coating, first coat can be saved during coating construction of an inorganic coating, and the coating system can save materials and labor, is economic and reliable and save energy and is environment-friendly.

Owner:XIAMEN QIANRUI BUILDING MATERIALS TECH

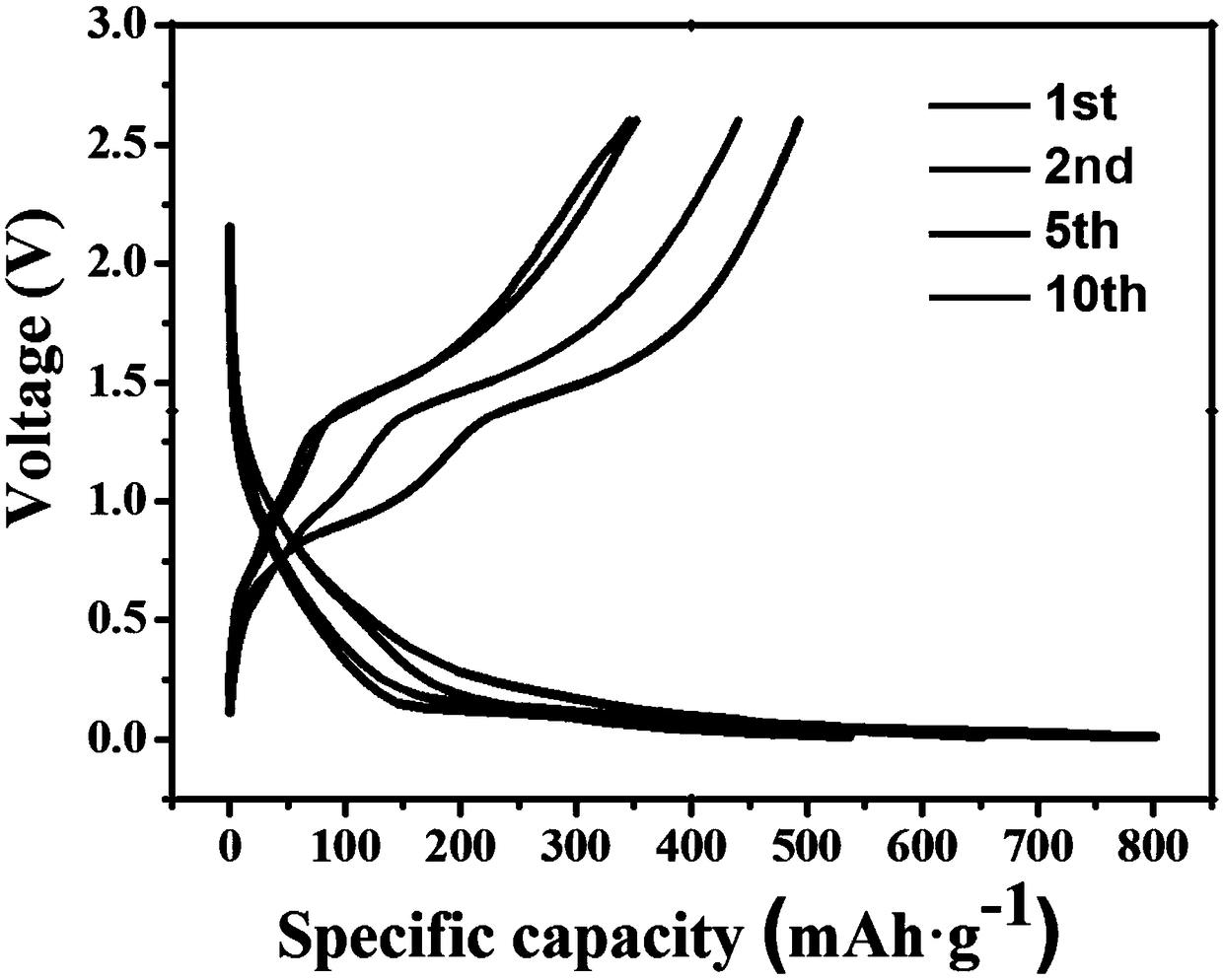

Preparation method and application of stainless steel net-loaded SnO2/SnS2 nanosheet potassium ion battery negative electrode composite material

InactiveCN108878812AUniform cycle performanceCyclic performance impactFinal product manufactureElectrode carriers/collectorsTest performanceSodium hydroxide

The invention relates to preparation method and application of a stainless steel net-loaded SnO2 / SnS2 nanosheet potassium ion battery negative electrode composite material. The preparation method comprises the steps of dissolving sodium hydroxide in certain mass into deionized water to obtain a solution A; adding tin chloride into the solution A to obtain a solution or emulsion B under stirring ofa magnetic force; transferring the solution B to a hydrothermal reaction kettle, placing a stainless steel net which is cleaned in advance in the solution B, performing hydrothermal reaction, performing cooling after reaction is ended, and cleaning the stainless steel net with the deionized water and ethyl alcohol to obtain a stainless steel net-loaded tin oxide nanometer-structure precursor; andplacing the stainless steel net-loaded tin oxide nanometer-structure precursor in a solution containing a sulfur source, performing reaction for certain time under a certain temperature, cleaning with the deionized water and the ethyl alcohol, and drying under the certain temperature to obtain the stainless steel net-loaded SnO2 / SnS2 nanosheet-shaped structure. By the preparation, the conductivity of a potassium ion battery is improved, meanwhile, the error of paste mixing and coating processes is omitted, and the situation that the test performance of the battery is affected by application of a binding agent is prevented.

Owner:SHAANXI UNIV OF SCI & TECH

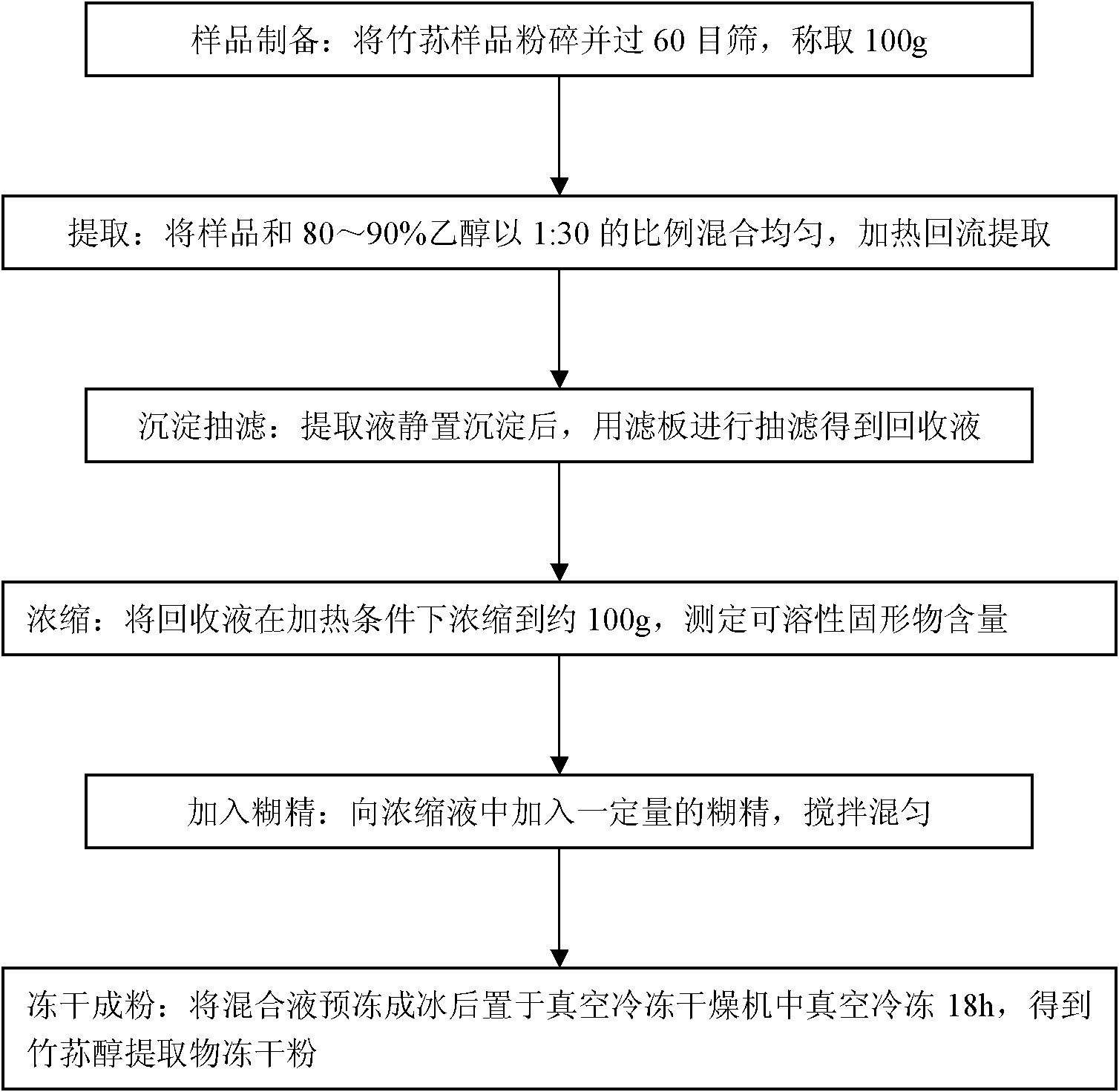

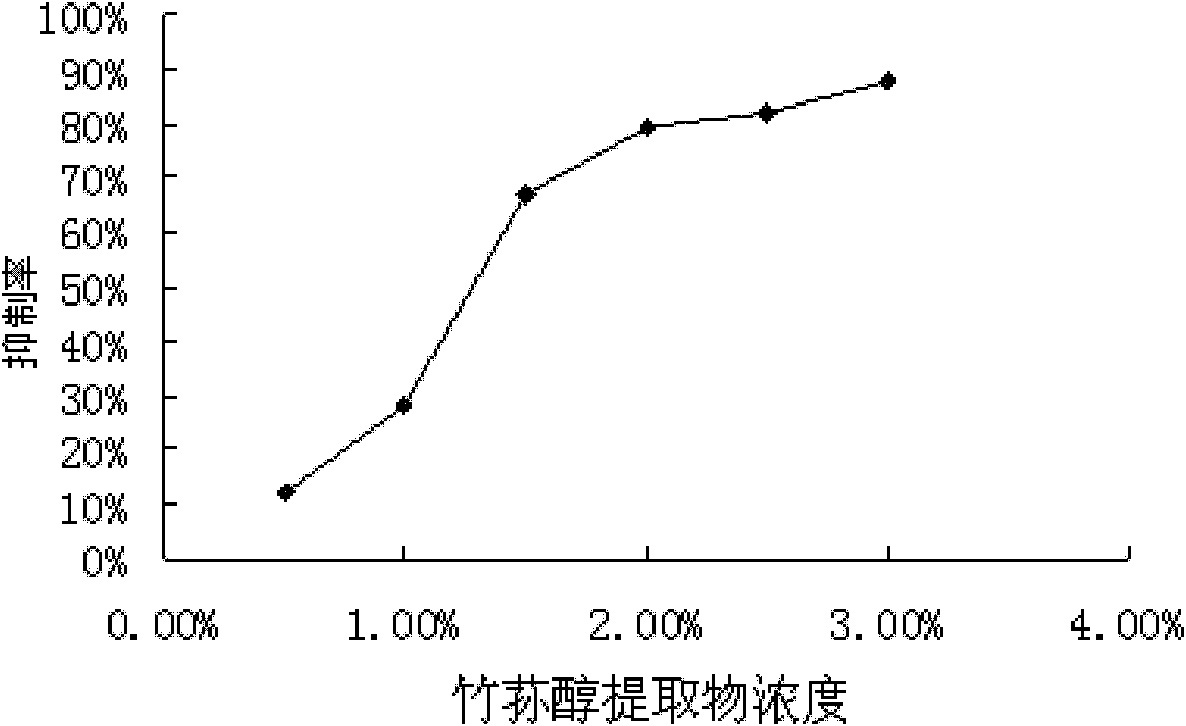

Bamboo fungus alcohol extract and preparation method and application thereof

ActiveCN102512354AEasy to operateReduce manufacturing costCosmetic preparationsToilet preparationsChemistryAqueous solution

The invention discloses a bamboo fungus alcohol extract, and a preparation method and an application thereof. The preparation method comprises the following steps of: (1) mixing bamboo fungus powder and ethanol water and then heating and extracting to obtain an extracting solution; (2) filtering the extracting solution after standing and depositing to obtain a recovered solution; (3) concentrating the recovered solution to obtain a concentrated solution; (4) and adding dextrin into the concentrated solution, uniformly stirring and then sequentially pre-freezing into ice and freezing and drying to obtain a product. The method has simple operation and low production cost, and the prepared product has higher purity and high active ingredient yield. The bamboo fungus alcohol extract prepared according to the method is easy to become powder, the color is light yellow or yellow, and the bamboo fungus alcohol extract is easily added into cosmetic formulas. Cosmetics prepared by the extract have an obvious anti-aging effect, and whitening and cosmetic effects are more significant.

Owner:BEIJING TECHNOLOGY AND BUSINESS UNIVERSITY

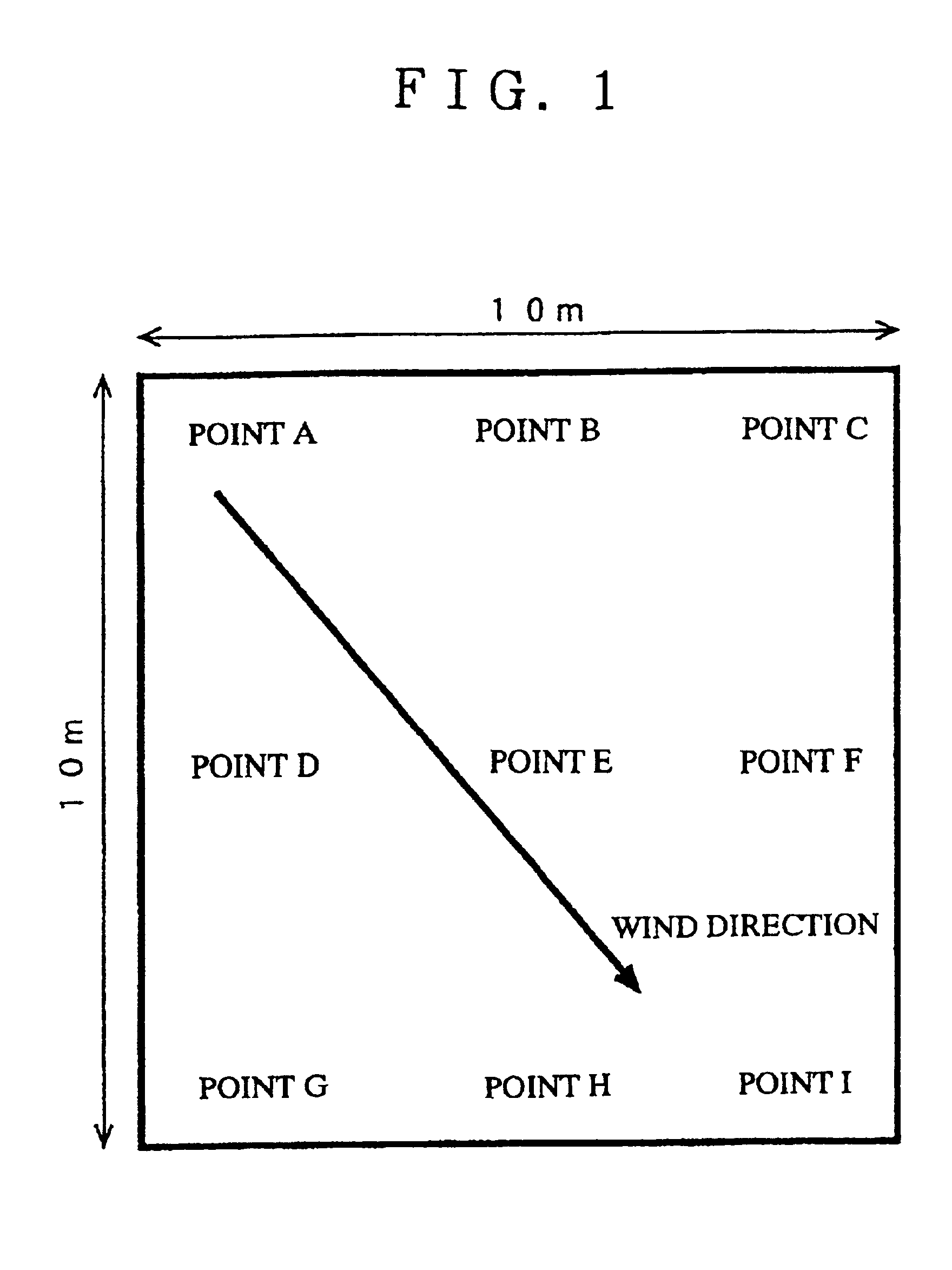

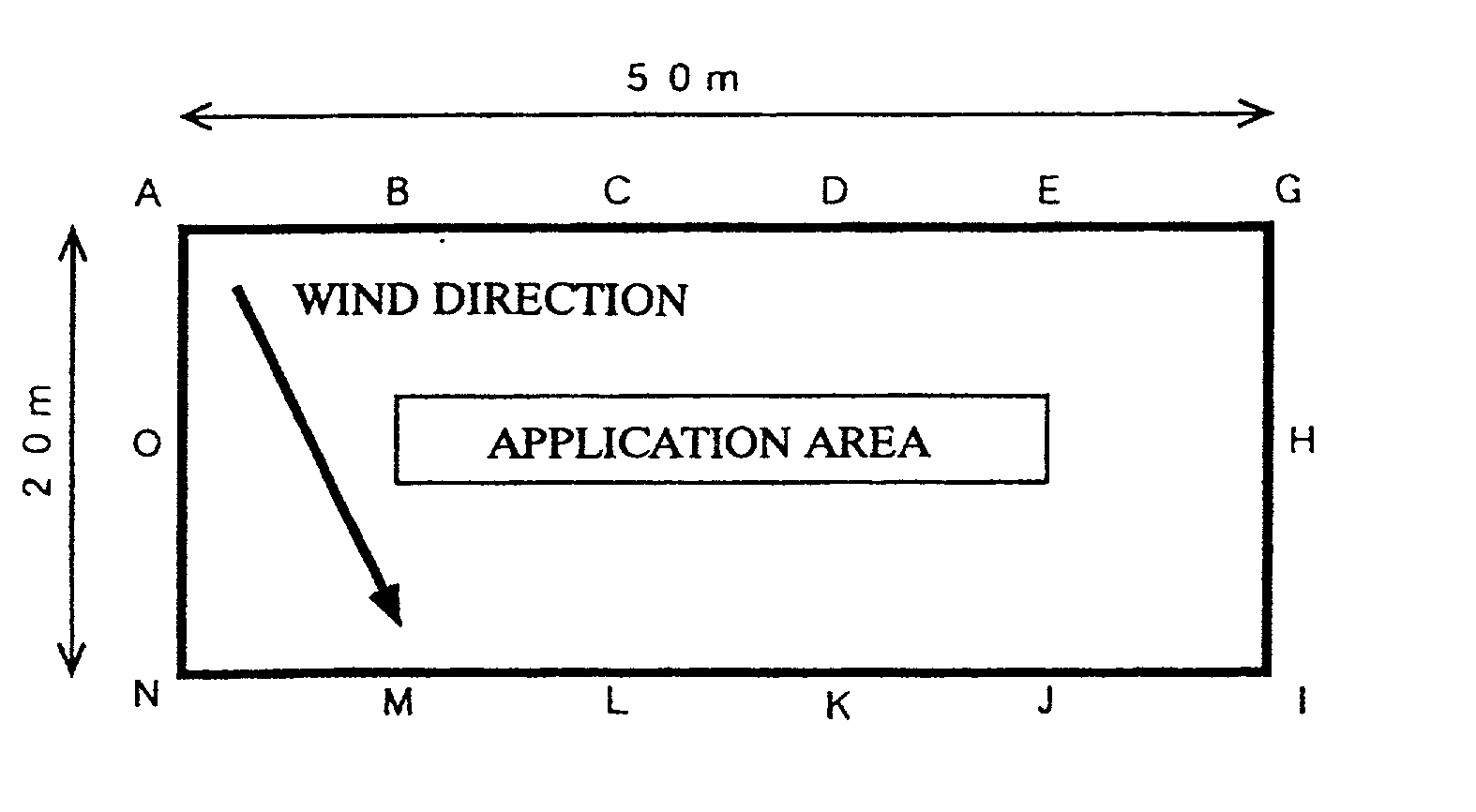

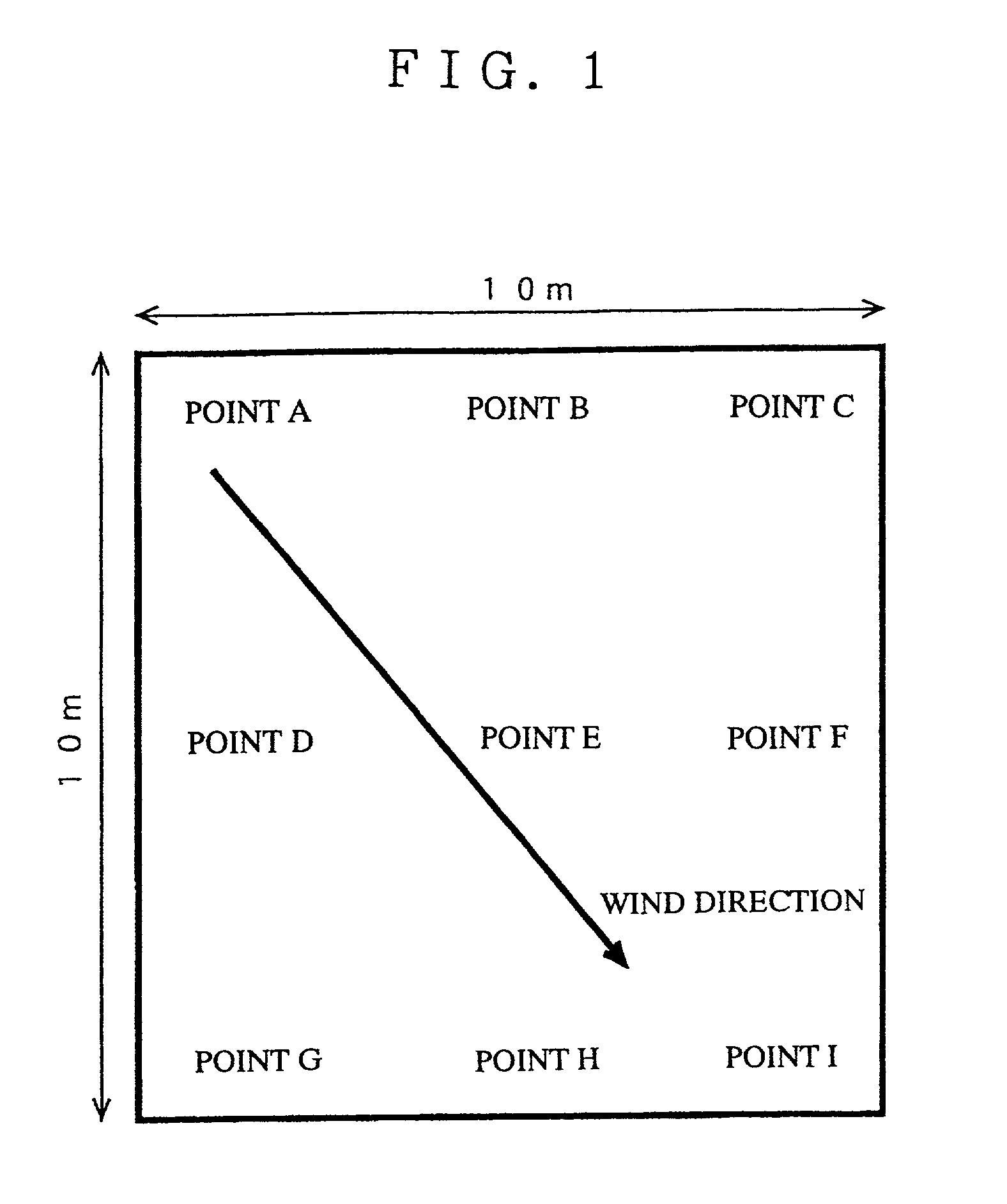

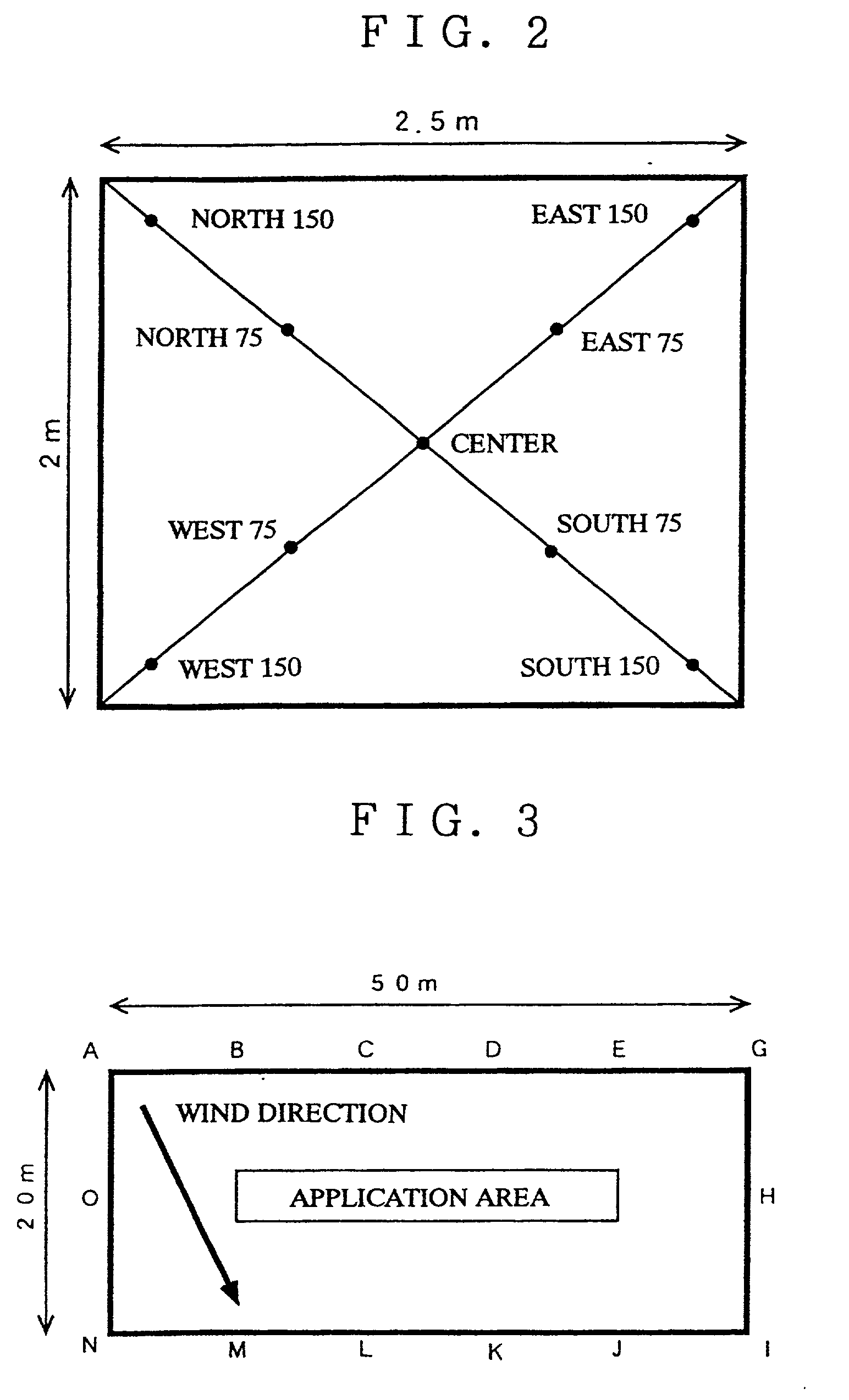

Solid agricultural chemicals composition, preparation thereof and the method for scattering the same

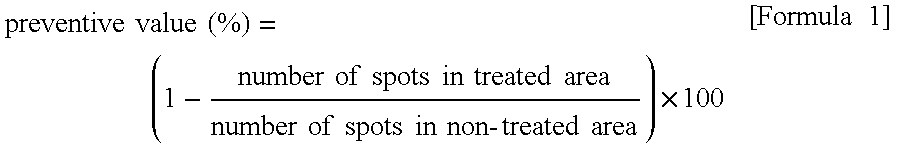

InactiveUS6797674B2High in oil absorbencyEasy to powderBiocideDrug compositionsFiberHigh concentration

An object of the present invention is to provide a solid agricultural chemicals composition which is excellent in environmental safety, has no disadvantages of powdering and seeping out of an agrochemically active ingredient while containing the agrochemically active ingredient in high concentration and is excellent in residual-effect of the agriculturally active ingredient; a solid agricultural chemicals composition comprising a fragment of a fibre crop having high oil absorbency and a liquid agrochemically active ingredient at room temperature or liquid matter prepared by dissolving or dispersing an agrochemically active ingredient in a liquid solvent; and a method of producing the solid agricultural chemicals composition comprising the steps of impregnating a liquid agrochemically active ingredient at room temperature or liquid matter prepared by dissolving or dispersing the agrochemically active ingredient into a fragment of a fibre crop having high oil absorbency, and making it into a shape of powder, granule, or tablet.

Owner:KUMIAI CHEM IND CO LTD

Environment friendly aldehyde-free odourless building glue

InactiveCN101705064AImprove frost resistanceIncrease storage capacityNon-macromolecular adhesive additivesUnsaturated alcohol polymer adhesivesPolyvinyl alcoholPreservative

The invention discloses an environmental friendly aldehyde-free odourless building glue which relates to a building glue. The building glue is prepared from 60%-80% of polyving akohol, 65%-80% of phosphoric acid, 2%-5% of urea, sodium hydroxide, 0.5%-1% of sodium polyacrylate, 0.1% of antiseptic and water up to 100%. The polyving akohol is esterified with the phosphoric acid under the catalysis of the urea for the first time, wherein the phosphoric acid is an inorganic polyprotic acid and can esterify with the hydroxyl of the polyving akohol, and the added urea can improve the freezing resistance and the storage performance of the glue. The building glue has no color or no odor, excellent transparent consistence, long storage time, no gelation at low temperature and strong adhesion stress; and the building glue can be used by mixing with white cement, double-flying powder, chalk powder and the like and has the advantages of easy construction, no powder falling or no skin curling.

Owner:童国松

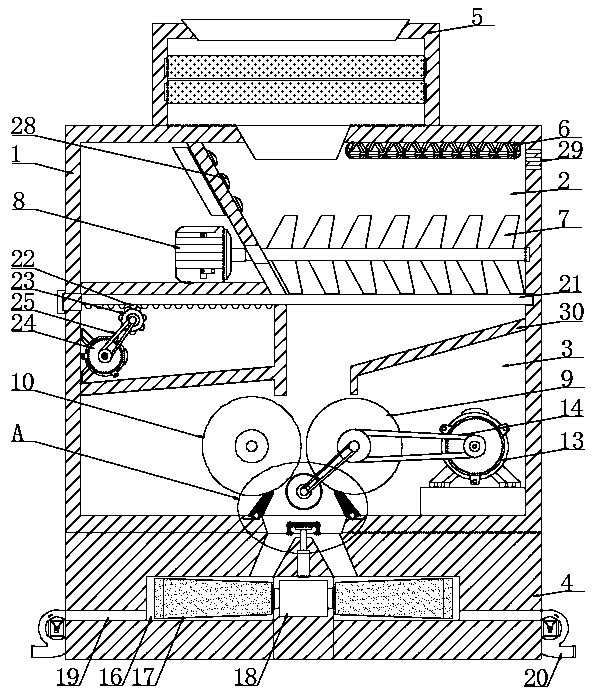

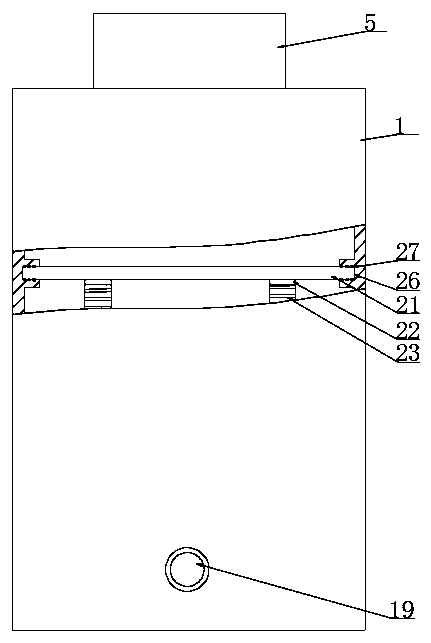

Equipment and method for separating irregular powder from spherical metal powder

ActiveCN107127157ATo achieve the separation effectEasy to observe the separationSievingGas current separationSuction forceMetal powder

Disclosed is equipment for separating irregular powder from spherical metal powder. A powder feeding tank body and a material tank body are arranged in a U-shaped tank. The material tank body is connected with a collector in the U-shaped tank. A net is arranged in the collector. The right end of the collector communicates with a powder blowing pipeline. The powder blowing pipeline is connected with an air duct. A net is arranged in the interior, on the right side of the U-shaped tank, of the powder blowing pipeline. The powder feeding tank is connected with the powder blowing pipeline. A draught fan is arranged in the powder blowing pipeline. A hinge valve is connected in the connecting position of the powder blowing pipeline and the air duct. A draught fan is arranged in the air duct. The air duct communicates with a top pipe opening of the collector. A separation method comprises the following steps that (1), screen nets are arranged, and the powder is located between the air duct screen net and the screen net at the bottom of the powder blowing pipeline; (2), samples enter from the powder feeding tank to the bottom of the powder blowing pipeline; (3), the draught fans are adjusted, and powder particles are layered in the powder blowing pipeline; (4), suction force of the collector is controlled by the hinge valve; and (5), after separating, the uniform and fine spherical metal powder is obtained in the material tank. The removal rate of sample separation at a time can reach 70%, and the irregular powder can be effectively separated from the spherical metal powder.

Owner:SINO EURO MATERIALS TECH OF XIAN CO LTD

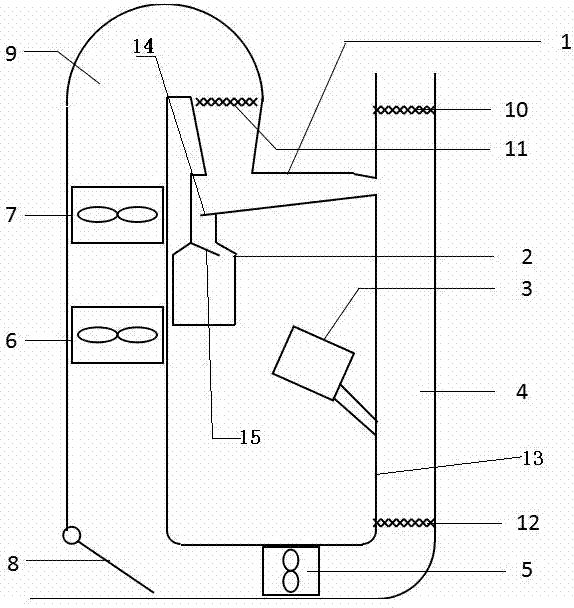

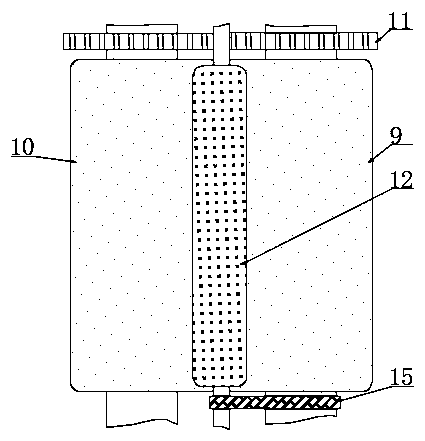

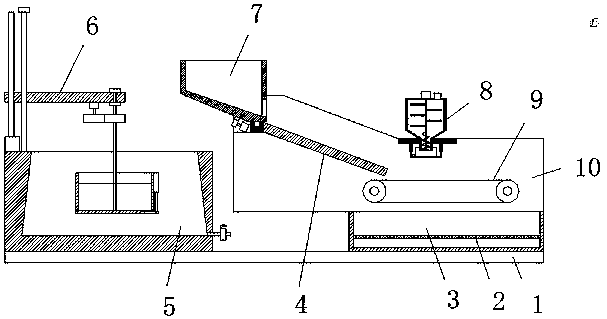

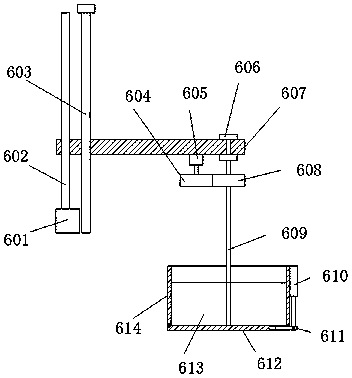

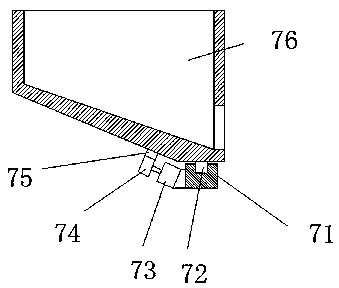

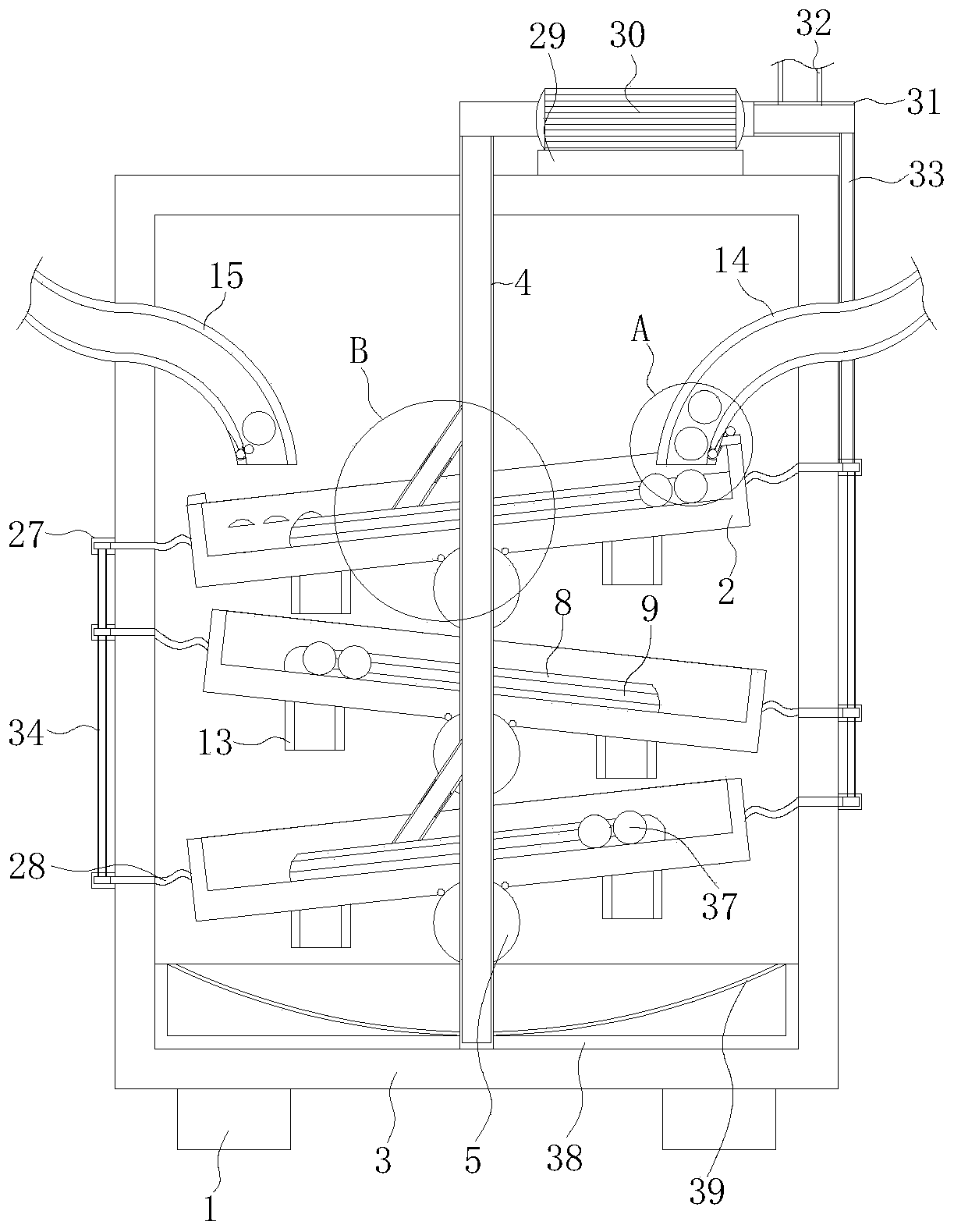

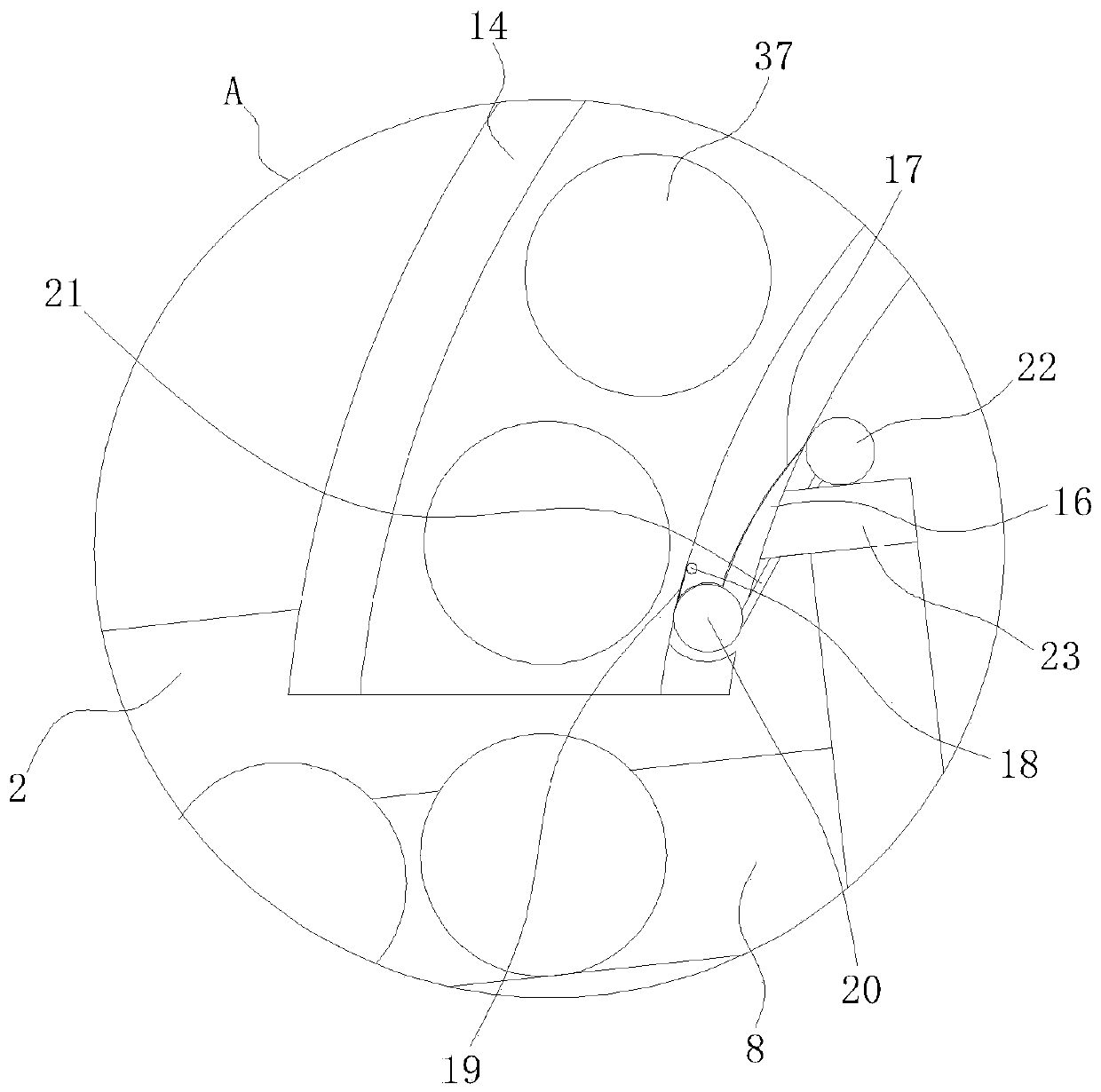

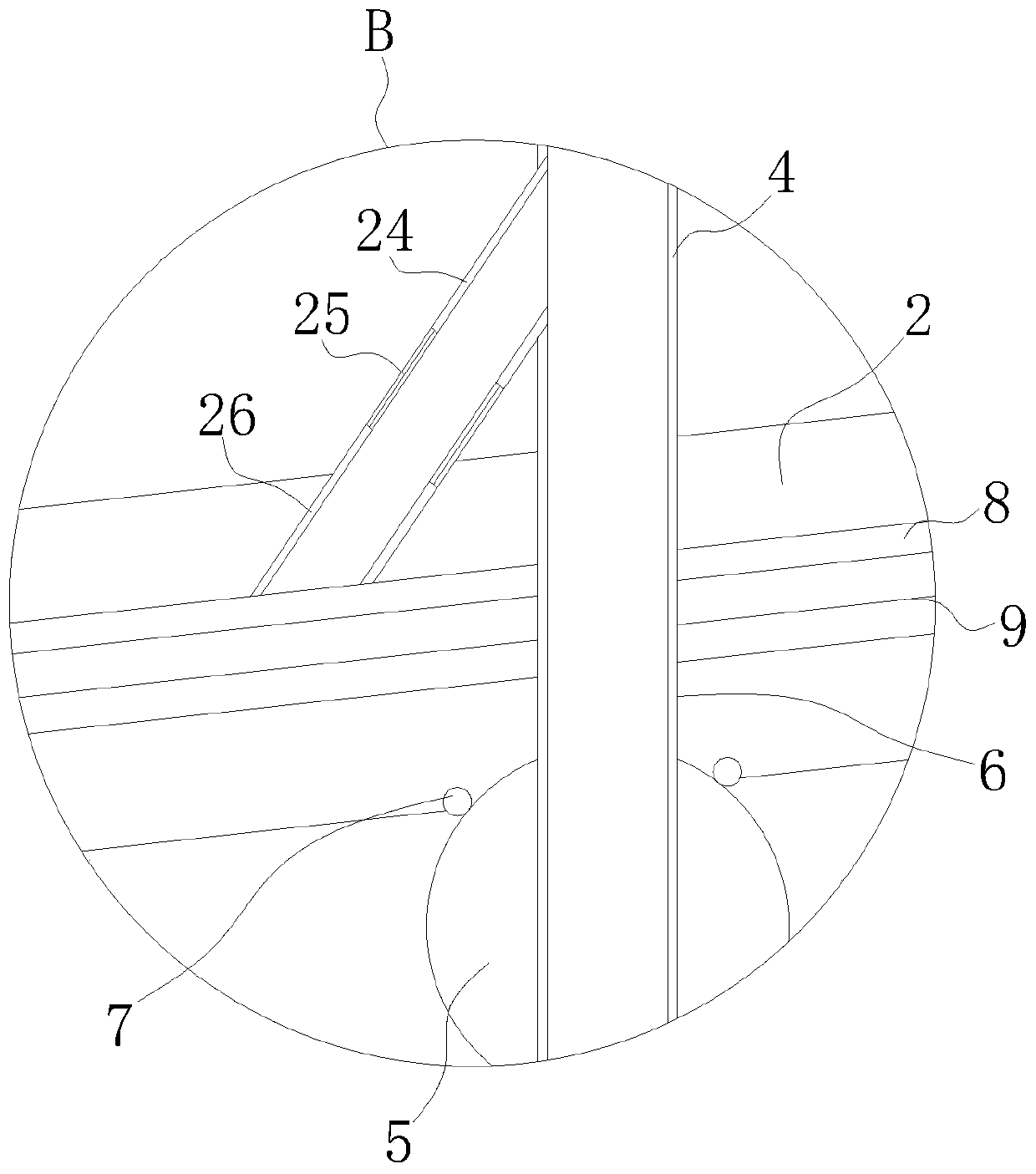

Special medical food and food material crushing equipment

InactiveCN110152857AReduce moistureReduce adhesionDrying machines with non-progressive movementsGrain treatmentsFood materialEngineering

The invention discloses special medical food and food material crushing equipment and in particular relates to the field of food preparation. The special medical food and food material crushing equipment comprises a box body. A drying chamber, a crushing chamber and a substrate are arranged in the box body, the drying chamber and the crushing chamber are separately arranged on the top and bottom of the crushing chamber, a crusher is arranged on the top of the box body, a feed inlet is formed in the top of the drying chamber, and the feed inlet is matched with the output end of the crusher. Thespecial medical food and food material crushing equipment crushes a food material into small pieces through the crusher and dries the food material in the drying chamber to reduce water for the convenience of powdering. The dried crushed material enters into the crushing chamber, and a second motor rotates, so that a driving grinding roller and a driven grinding roller move in opposite directionsto extrude and grind the food material into cakes. The cake food material is crushed into particles through a slitting knife roll, the particles then enter into a grinding drum, and an output shaft of a third motor is in transmission connection to a grinding roller to grind the food material into powder, so that the crushing efficiency is improved. An induced draft fan extracts the power from a discharge pipe, so that large-scaled production is achieved.

Owner:RIZHAO POLYTECHNIC

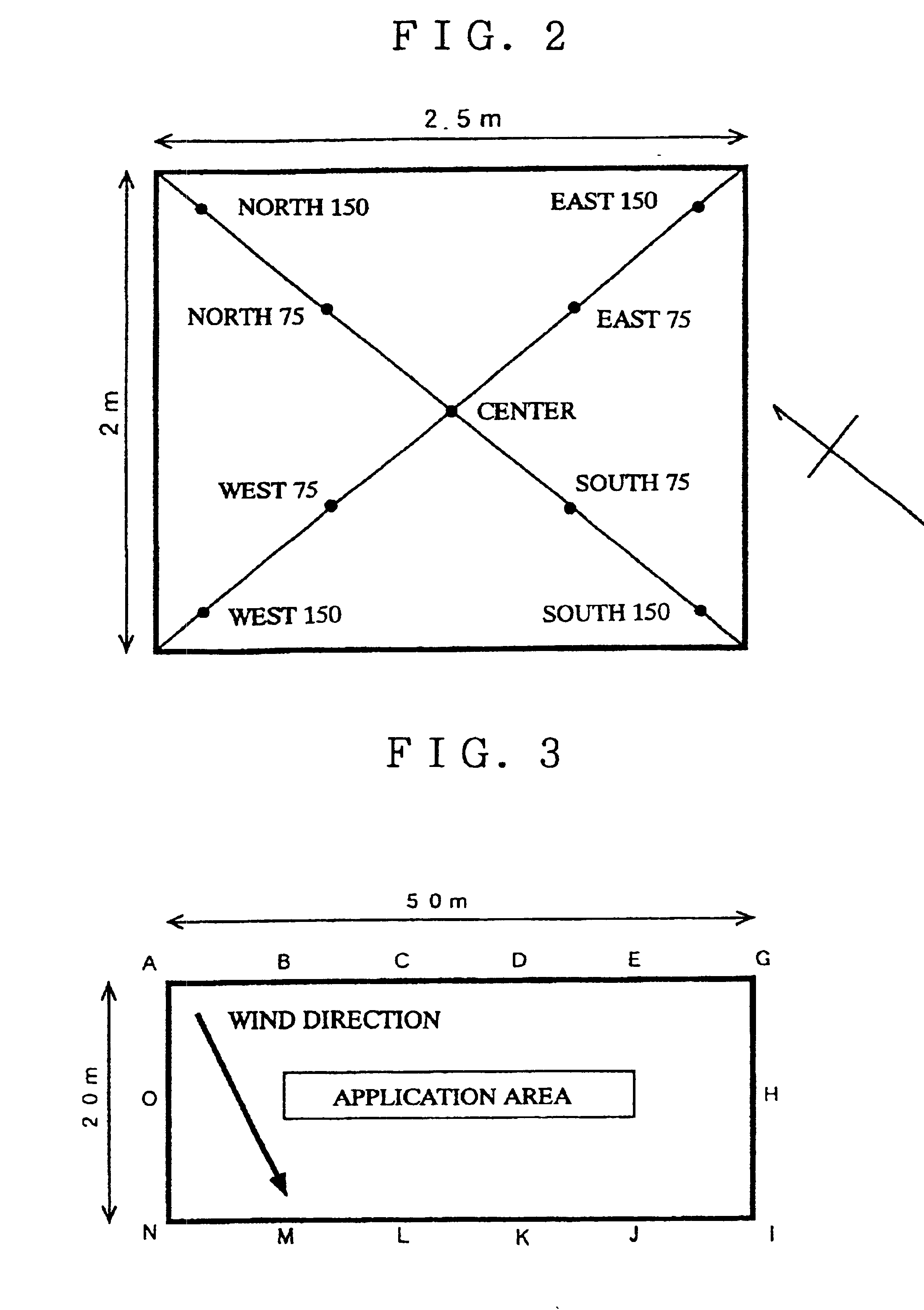

Solid agricultural chemicals composition, preparation thereof and the method for scattering the same

InactiveUS20020155955A1Promote degradationSatisfactory qualityBiocideDrug compositionsSolventPesticide

An object of the present invention is to provide a solid agricultural chemicals composition which is excellent in environmental safety, has no disadvantages of powdering and seeping out of an agrochemically active ingredient while containing the agrochemically active ingredient in high concentration and is excellent in residual-effect of the agriculturally active ingredient; a solid agricultural chemicals composition comprising a fragment of a fibre crop having high oil absorbency and a liquid agrochemically active ingredient at room temperature or liquid matter prepared by dissolving or dispersing an agrochemically active ingredient in a liquid solvent; and a method of producing the solid agricultural chemicals composition comprising the steps of impregnating a liquid agrochemically active ingredient at room temperature or liquid matter prepared by dissolving or dispersing the agrochemically active ingredient into a fragment of a fibre crop having high oil absorbency, and making it into a shape of powder, granule, or tablet.

Owner:KUMIAI CHEM IND CO LTD

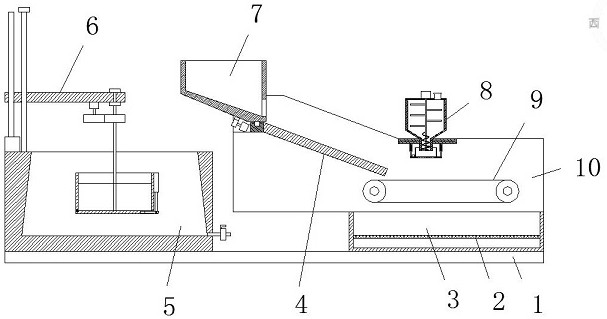

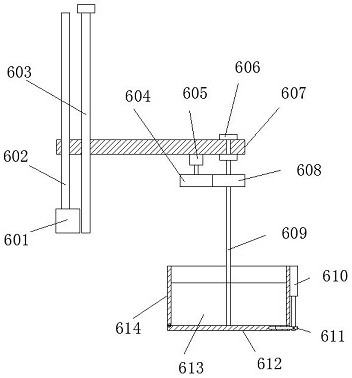

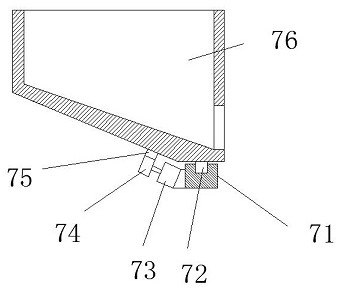

Composite potato chip production line

ActiveCN110432297ARealize oil throwing operationPrevent proliferationNon-rotating vibration suppressionBaked articles handlingProduction lineChipped potatoes

The invention discloses a composite potato chip production line. The production line comprises a bottom plate, a recovery box and an oil collecting box are mounted at the top of the bottom plate, an oil throwing device is mounted at the top of the oil collecting box, a first screen is fixed in the recovery box, baffles are fixed at two ends of the top of the recovery box, a guide plate, a conveying belt device and a powder scattering device are mounted between the two baffles, a discharging device is mounted at the top of the guide plate, the powder scattering device is located right above a conveying belt device, and the conveying belt device is located right above the recovery box. Due to adoption of centrifugal oil removal, the production line is more thorough and higher in efficiency than a traditional standing oil removal method; potato chips can be spread uniformly and coated with powder conveniently, a vibrator vibrates to discharge powder, the scattering uniformity is guaranteed, and the effect is very good; and the quality of the product is increased, the taste is better, and production line is convenient to operate and suitable to be promoted in enterprises.

Owner:汕头市华兴机械厂有限公司

Powdery shrinkage-reducing polycarboxylic acid water reducing agent and preparation method thereof

The invention discloses a powdery shrinkage-reducing type polycarboxylic acid water reducing agent and a preparation method thereof. The powdery shrinkage-reducing type polycarboxylic acid water reducing agent is prepared by introducing a hydrophobically modified polyether chain, a rigid group and ester bond bridged small molecular alcohol into a grafted copolymer to prepare a shrinkage-reducing type polycarboxylic acid water reducing agent mother solution, and then introducing a calcium-magnesium expanding agent as a separant to spray-dry the mother solution. The prepared powder is low in mixing amount, good in dispersing performance and excellent in shrinkage reducing effect, unification of water reducing and shrinkage reducing is achieved, and the powder is good in flowability, free ofcaking, good in storage stability and suitable for various dry-mixed mortars.

Owner:JIANGSU SOBUTE NEW MATERIALS +2

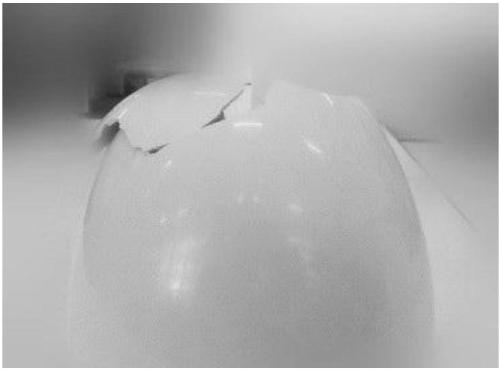

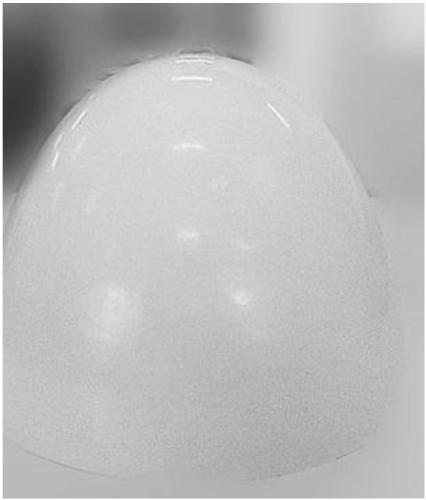

Improved toy shell material and preparation method thereof

The invention discloses an improved toy shell material. The improved toy shell material is prepared from a component A and a component B, and the weight ratio of the component A to the component B is1:(0.8-1.2), wherein the component a comprises the following components in percentage by mass: 18-22% of ethylene vinyl acetate (EVA), 2-4% of zinc stearate and 74-80% of calcium carbonate, and the component B comprises the following components in percentage by mass: 58-62% of calcium carbonate, 12-18% of a lubricant and 20-30% of EVA. The invention further discloses a preparation method of the improved toy shell material. The toy shell material can be easily cracked by pushing, a packaged finished product is not easily cracked in a transportation process, sharp points or edges are avoided after the shell material is broken, and thus children are prevented from being scratched.

Owner:PACIFIC INDAL ZHONGSHAN

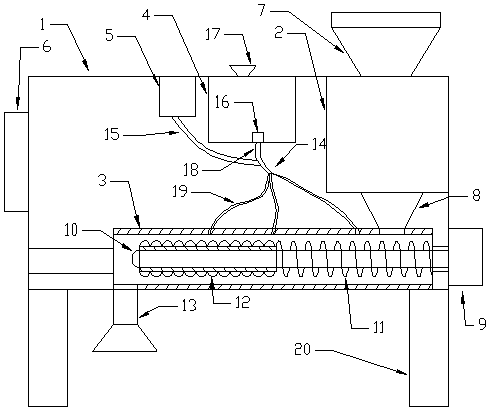

Novel efficient corn flour milling machine

InactiveCN108855528AFully groundedImprove grinding efficiencyDrying gas arrangementsCleaning using liquidsSpiral bladeWater storage tank

The invention discloses a novel efficient corn flour milling machine. The flour milling machine comprises a machine body, a bin arranged in the machine body, a powder milling bin arranged at the bottom of the machine body, a water storage tank, an air blower and a controller, wherein the water storage tank and the air blower are arranged in the machine body, and the controller is arranged on the machine body. A feeding hopper is arranged on the top of the bin. A discharging hopper is arranged at the bottom of the bin. A rotation motor is arranged at one end of the powder milling bin. A grinding shaft is connected to the output end of the rotation motor. A spiral blade is arranged at the front section of the grinding shaft, and the rear section of the grinding shaft is provided with a grinding roller. A powder outlet is formed in the bottom of the other end of the powder milling bin. The water storage tank communicates with the powder milling bin through a connecting pipe. The air blower communicates with the connecting pipe through an air pipe. By means of the novel efficient corn flour milling machine, corn can be sufficiently pulverized and ground, the corn powder milling effectis good, and efficiency is high; and meanwhile, the powder milling bin can be cleaned and blown dry, pollution and influences on next-time powder milling from residues of corn kernels are avoided, andhigh practical significance is achieved.

Owner:SICHUAN XIONGJIAN IND

Coarse food grain tea bubble preparing equipment based on heat conduction

The invention provides coarse food grain tea bubble preparing equipment based on heat conduction. The coarse food grain tea bubble preparing equipment comprises supporting legs, coarse food grain teabubbles and a plurality of powder rolling trays, wherein a powder rolling tank is fixedly connected to the surfaces of supporting legs; supporting hollow steel pipes are fixedly connected to the innerwall of the powder rolling tank; a plurality of disk rolling balls are fixedly connected to the surfaces of the supporting hollow steel pipes; penetrating holes are formed in the surface of each powder rolling tray; a plurality of disk rolling balls are embedded in the inner wall of each penetrating hole. The invention relates to the field of coarse food grain tea bubbles. According to the coarsefood grain tea bubble preparing equipment based on heat conduction disclosed by the invention, through circular wind sucking and wind blowing of a sucking and blowing fan, the recycling of tea powderis convenient; gravity is utilized to enable the whole rolling device to be in continuous circulating operation, so that energy is saved, and the working efficiency is improved; the working temperature in the powder rolling tank is in thermostatic control through heat condition, so that the problems that when powder rolling is performed by conventional coarse food grain tea bubble preparing equipment, the situation that the powder rolling is not uniform is easy to generate, the working efficiency is low, and during continuous working, the energy consumption of the equipment is high are effectively solved.

Owner:广东玺瑞健康产业科技有限公司

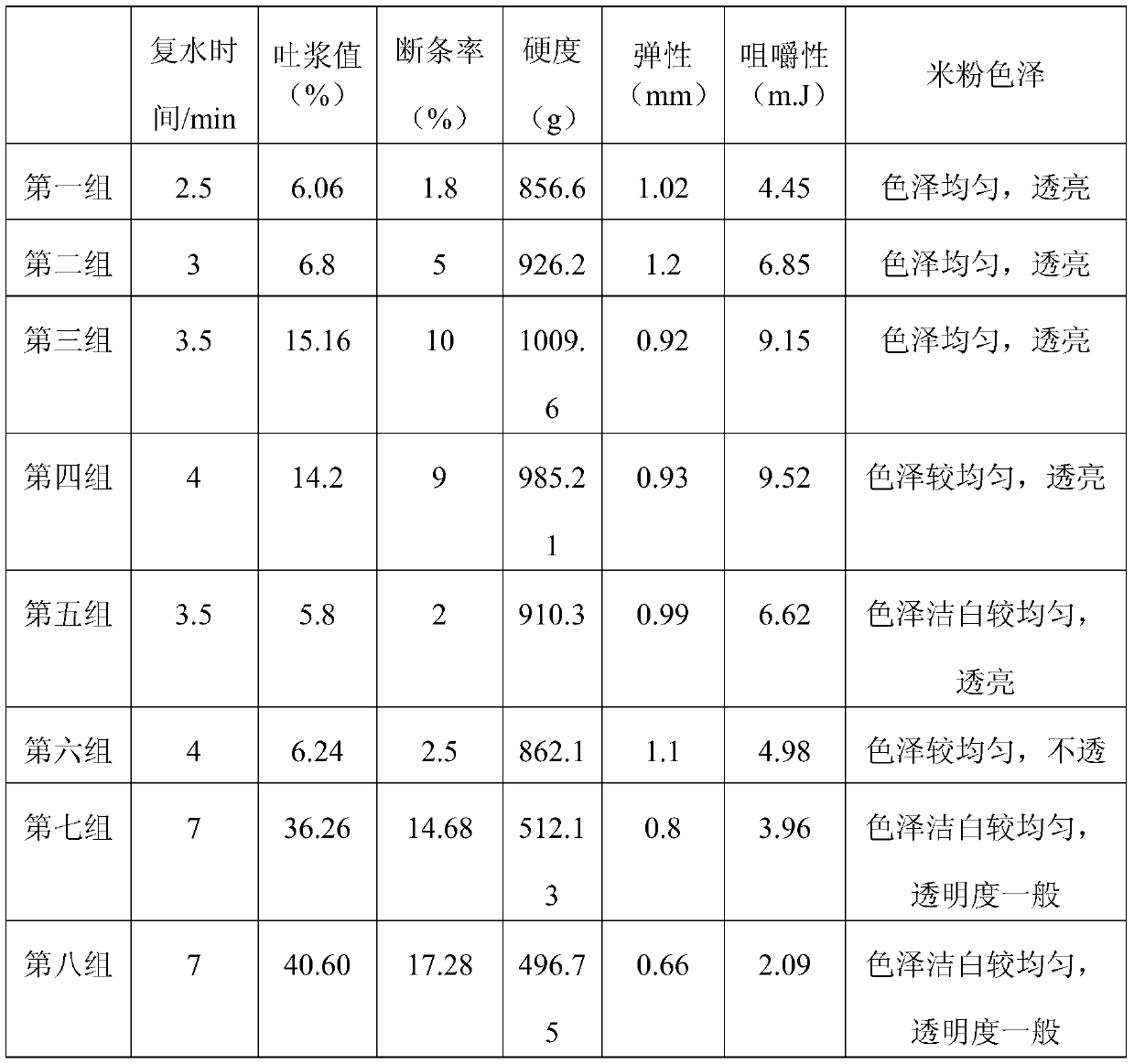

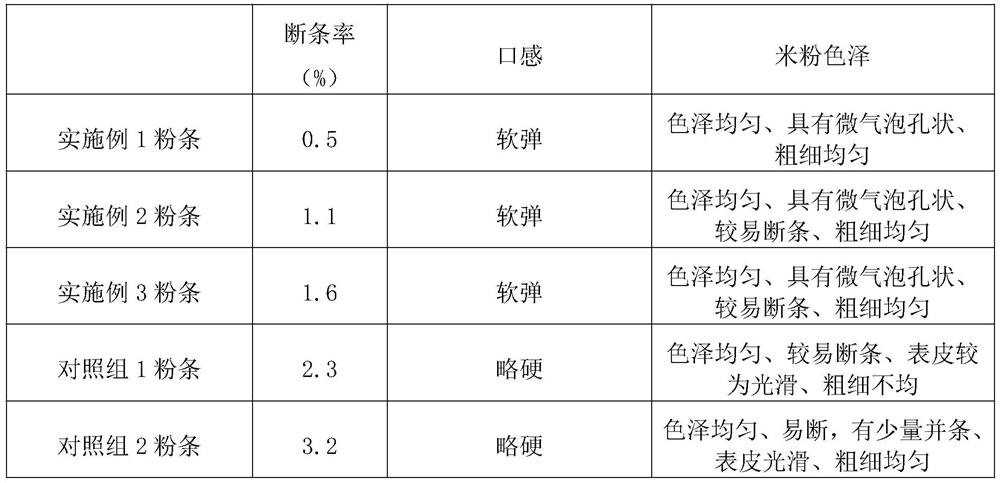

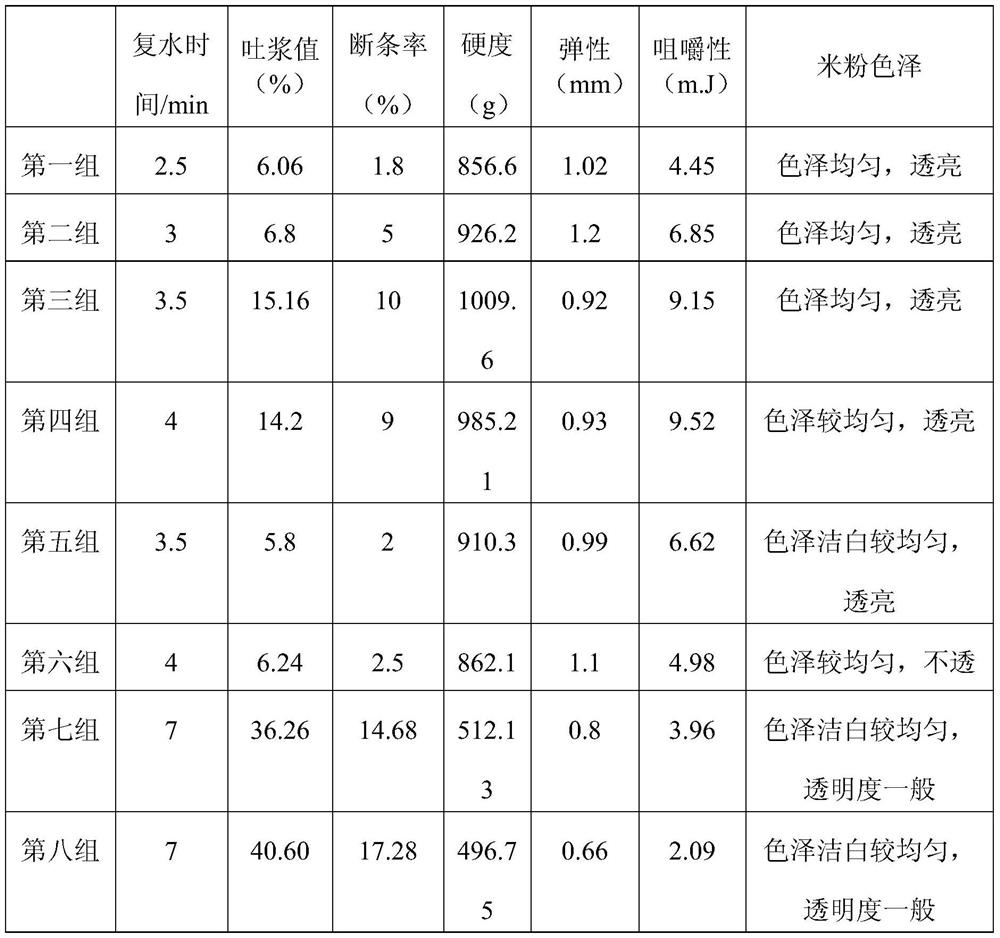

Method for processing semi-dry instant rice noodles

ActiveCN110037240ALow viscosityReduced Strength and HardnessFood ingredient as emulsifierSteamingMoisture

The invention provides a method for processing semi-dry instant rice noodles, and relates to the technical field of food processing. The method comprises the following steps: (1) raw material preparation; (2) fermentation; (3) pulping; (4) mixing; (5) enzymolysis; (6) primary steaming; (7) extrusion; (8) optimization; (9) secondary steaming; (10) cooling; and (11) drying. According to the semi-dryinstant rice noodles, the moisture content is controlled to be 14-16 percent through material proportion regulation and control, amylase optimizing treatment with twice fermentation, finished productmoisture control and the like, and the rice noodles can be taken when being soaked with boiling water at 80-100 DEG C for 2-5 minutes, the reconstitution properties are remained after long-time storage, and the problems of retrogradation, poor reconstitution properties of starch can be overcome.

Owner:GUANGXI ZHUANG AUTONOMOUS REGION ACAD OF AGRI SCI

Brewing type prepared dry rice noodles and preparation method thereof

PendingCN113575839AImprove qualityIncrease amylose contentFood ingredientsFood shapingFood safetyFood technology

The invention belongs to the technical field of food, and particularly relates to brewing type prepared dry rice noodles and a preparation method thereof, and the preparation method comprises the following steps: (1) preparing of raw materials; (2) soaking; (3) grinding; (4) blending; (5) extruding, curing, forming and cooling; (6) aging; and (7) drying. By regulating and controlling the material ratio, the performance of the modified cassava starch, extrusion and curing forming parameters and the like, the processed brewing type prepared dry rice noodles have uniform micro-bubble holes, are easy to brew and tasty, are rich in rice flavor and clear in soup, are not broken after being placed for a long time, can keep the state of being just brewed, and meet the requirements of DBS 45 / 051-2018 Food Safety Local Standard Dried Rice noodles.

Owner:广西农垦明阳淀粉发展有限公司

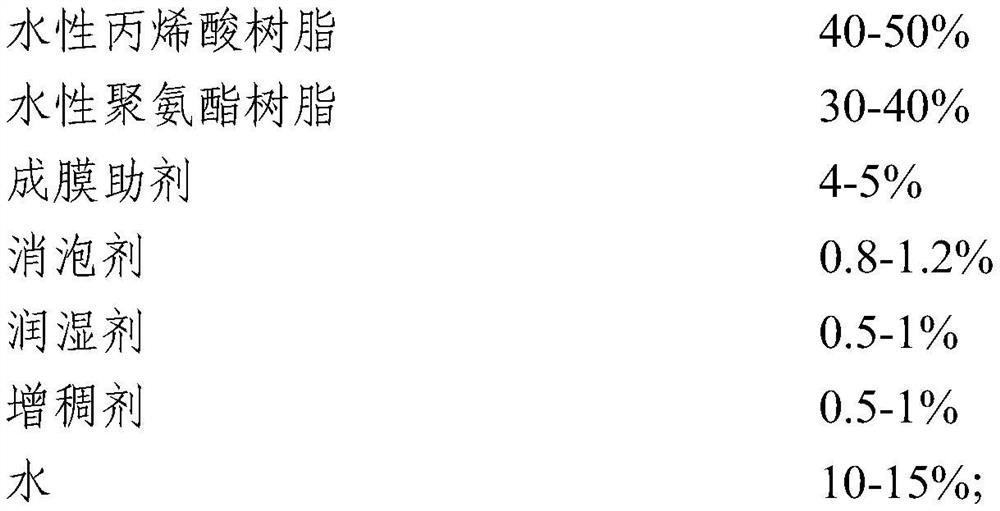

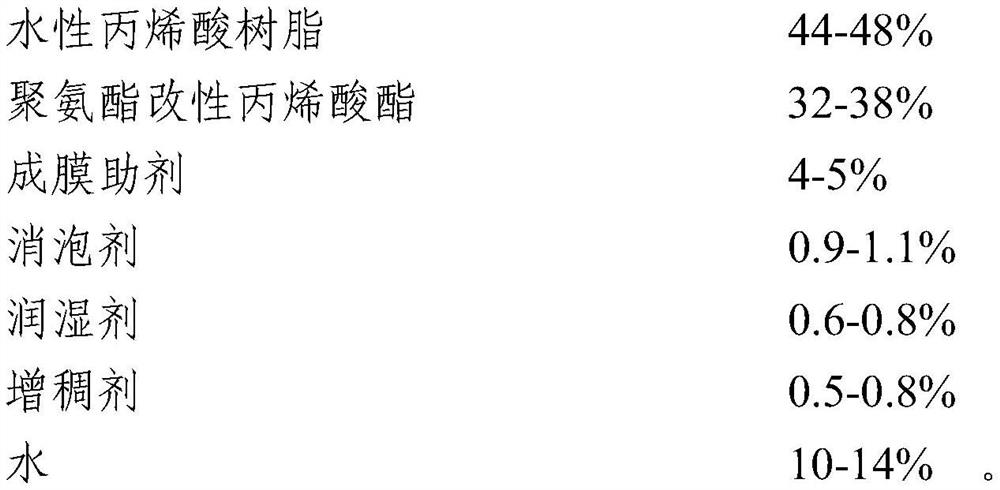

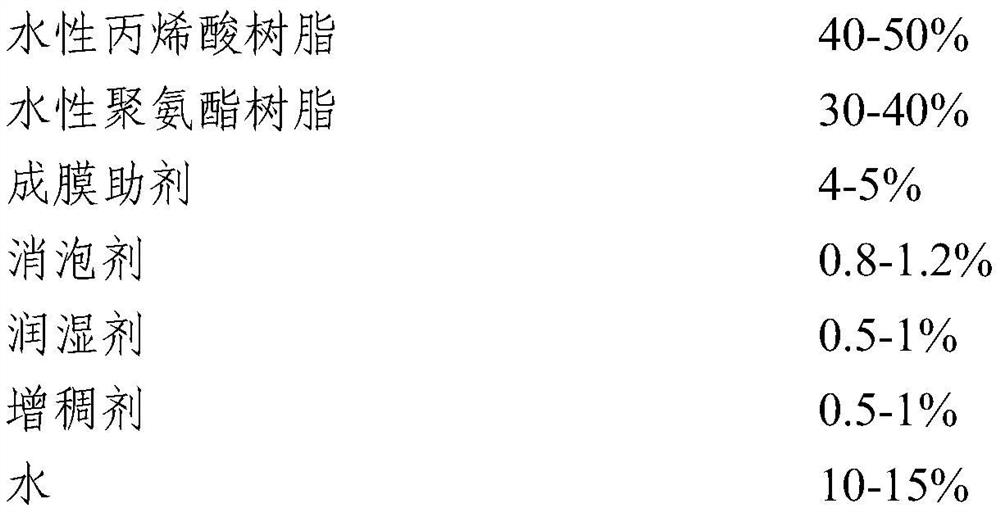

Water-based woodware clear primer and preparation method thereof

PendingCN114213918AHigh transparencyGood sandingPolyurea/polyurethane coatingsFilm resistanceAcrylic resin

The invention provides a water-based wood clear primer and a preparation method thereof. The clear primer comprises the following components in percentage by weight: 40-50% of water-based acrylic resin, 30-40% of water-based polyurethane resin, 4-5% of a coalescing agent, 0.8-1.2% of a defoaming agent, 0.5-1% of a wetting agent, 0.5-1% of a thickening agent and 10-15% of water. The water-based woodware clear primer coating provided by the invention has the advantages of excellent polishing property, good powder discharge, no adhesion to abrasive paper and excellent transparency, the paint film resistance is tested according to GB / T 23999-2009 and completely reaches the national standard, the water resistance can reach the first-grade standard, the water-based woodware clear primer coating basically has no abnormity, and the clear primer coating can be re-coated without polishing after being dried for 2-3 hours under the normal temperature condition, so that the water-based woodware clear primer coating has the advantages of environmental protection, environmental protection and the like. Recoating transparency and adhesive force are not affected, manpower and material resources of a furniture factory are greatly saved, and working efficiency is improved.

Owner:濮阳展辰新材料有限公司

Aqueous woodware solid color paint and preparation method thereof

InactiveCN110256932AImprove wettabilityHigh degree of bindingAntifouling/underwater paintsPaints with biocidesCross-linkEmulsion

The invention discloses an aqueous woodware solid color paint and a preparation method thereof, wherein the raw materials comprise, by weight, 1.00-10.00% of pure water, 1.00-3.00% of a pigment regulating agent, 20.00-40.00% of a filler, 40.00-70.00% of an emulsion A, 1.00-6.00% of a film forming aid, 0.10-0.50% of a substrate wetting agent, 0.10-0.50% of a defoamer, and 0.10-0.50% of a rheological auxiliary agent. According to the present invention, by using the self-cross-linking core-shell double-technology emulsion as the main raw material, the aqueous woodware solid color paint has good wettability on wood plates, and has high bonding degree with wood in the application in coating materials; and due to the unique structure design, the double-technology acrylic emulsion has good film forming performance, such that the paint film and the solvent type primer coat are densely combined so as to achieve good adhesion.

Owner:广东千叶松化工有限公司

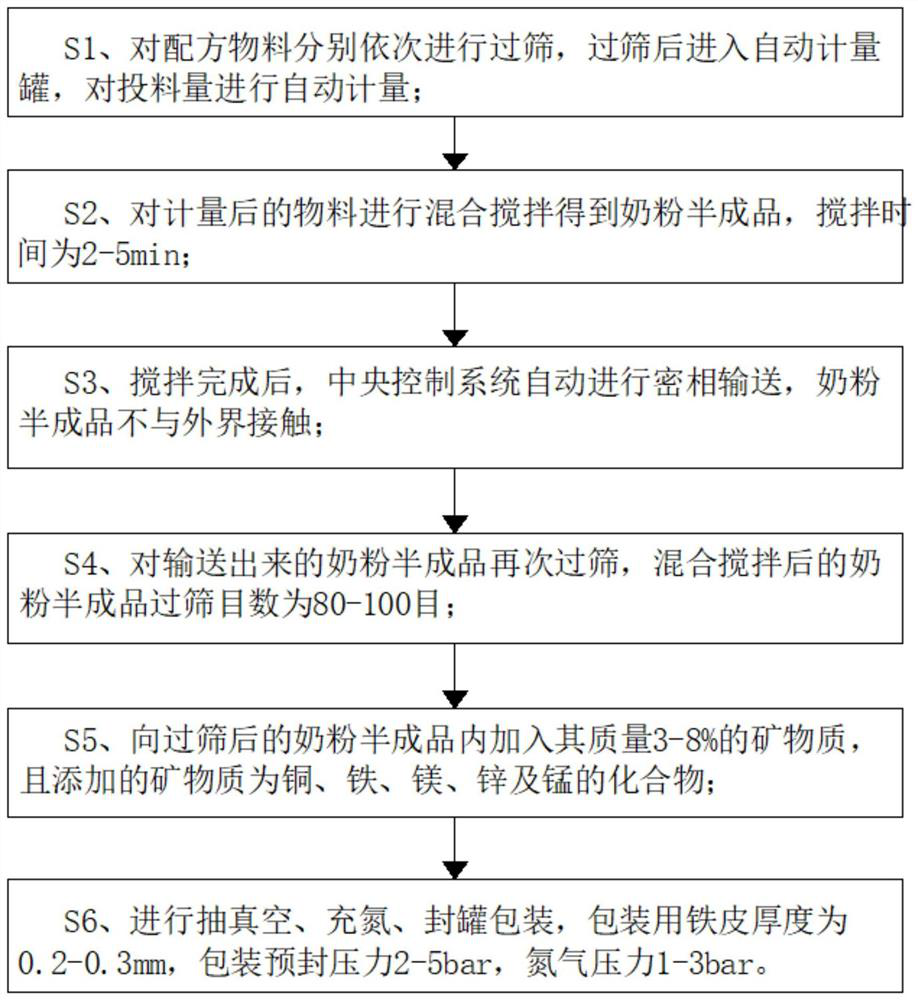

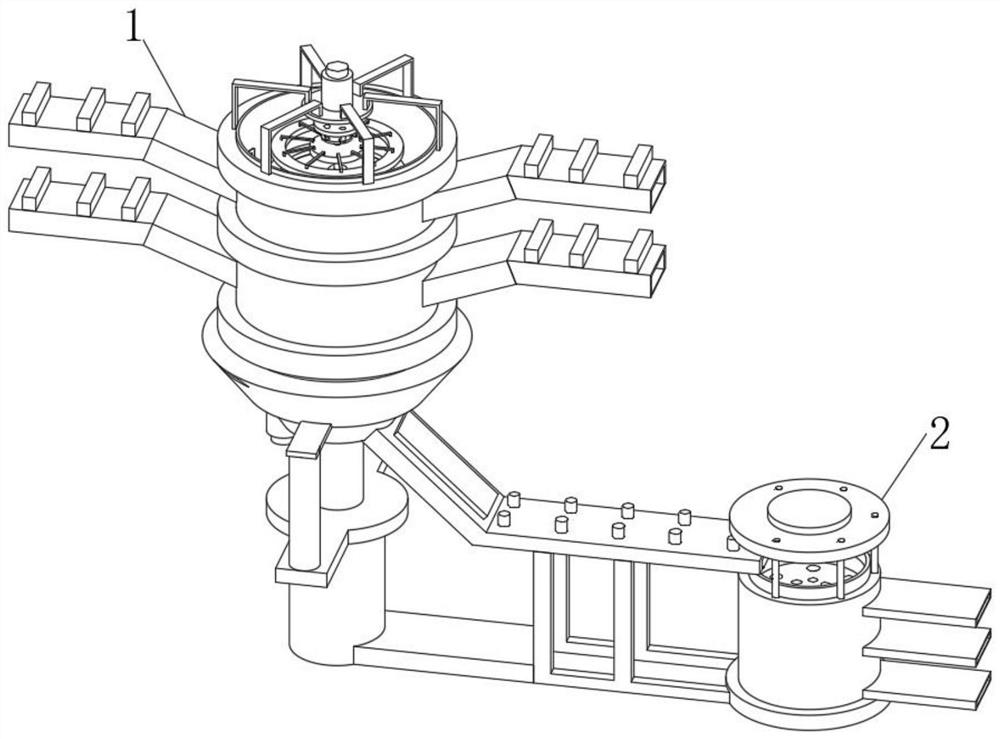

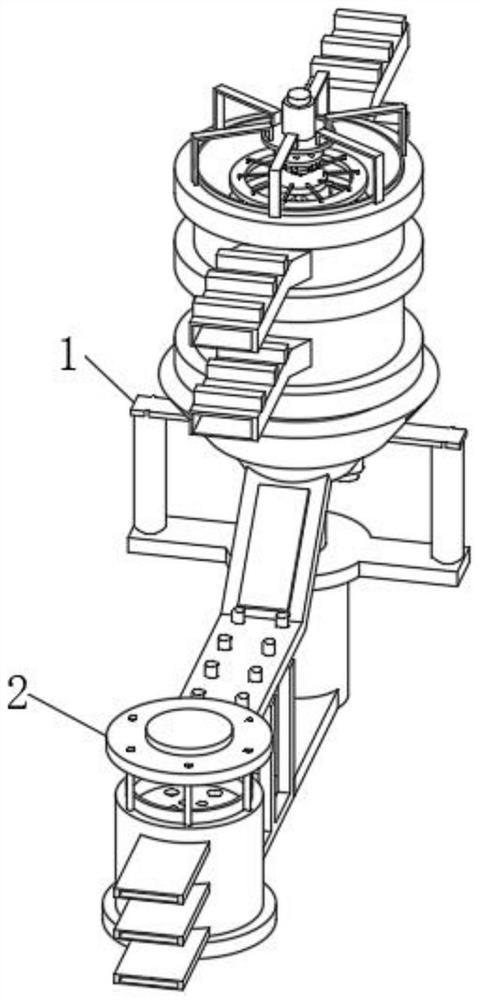

Linolenic acid formula goat milk powder and production device and method thereof

PendingCN114711300AGet Connected WorkRealize blendingSievingFood processingProcess engineeringVitamin

The invention relates to the technical field of goat milk powder production equipment, in particular to linolenic acid formula goat milk powder and a production device and method thereof.The production method comprises the following steps that formula materials are screened in sequence and then enter an automatic metering tank, and the feeding amount is automatically metered; mixing and stirring the metered materials to obtain a milk powder semi-finished product; after stirring is completed, dense-phase conveying is conducted; sieving the conveyed semi-finished milk powder again; adding mineral substances into the sieved milk powder semi-finished product; vacuumizing, filling nitrogen, sealing cans and packaging; the production device comprises a production structure and a screening structure, and the side end position of the production structure communicates with the screening structure. The nutritional ingredients of the goat milk are reserved, and the formula milk powder with scientific compatibility is formed by adding the desalted whey powder, the linoleic acid, the vitamins and other nutrient substances, so that the human body can comprehensively obtain the nutrient substances; meanwhile, powdering of the goat milk product is achieved, and the goat milk product is convenient to store, transport and eat at any time.

Owner:郑州悦牛企业管理咨询有限公司

A compound potato chips production line

ActiveCN110432297BRealize oil throwing operationPrevent proliferationNon-rotating vibration suppressionBaked articles handlingChipped potatoesProduction line

Owner:汕头市华兴机械厂有限公司

Flash metal powder coating and preparation method thereof

ActiveCN101955720BImprove flatnessIntense metallic glitter effectPowdery paintsEpoxy resin coatingsWaxMetal powder

The invention provides a glittery metallic powder coating and a preparation method thereof, which can solve the problems that the metallic glittery effect is undesirable, and the coat is easy to wear away and distributed unevenly existing in the prior art. The glittery metallic powder coating comprises the following components in percentage by weight: 50 to 70 percent of transparent powder, 25 to 45 percent of dark and light covering power, 2.0 to 5.0 percent of coarse aluminum silver powder, 0.05 to 0.5 percent of fine aluminum silver powder, 0.1 to 1 percent of wax powder, 0.1 to 1 percent of defoaming agent, and 0.05 to 0.5 percent of fluidity improver. The invention also provides a method for preparing the glittery metallic powder coating. The glittery metallic powder coating of the invention has the advantages that: the leveling can be improved; the surface of the coat has a strong metallic glittery effect, and the coat is easy to wear away and uniform in color so as to give people a fashionable and beautiful feeling and show a high-grade decoration effect, therefore, the glittery metallic powder coating is very suitable for high-grade decoration field; and meanwhile, the production cost of the glittery metallic powder coating is not high.

Owner:HAIER GRP CORP +1

A kind of processing method of semi-dry brewing rice noodles

ActiveCN110037240BLow gelatinization temperatureGood gelatinization temperatureFood ingredient as emulsifierAmylaseEnzymatic hydrolysis

Owner:GUANGXI ZHUANG AUTONOMOUS REGION ACAD OF AGRI SCI

A harmless resource treatment method for medical waste

ActiveCN110014027BEasily brokenEfficient dehydration effectSolid waste disposalIron pentacarbonylMethyl palmoxirate

The invention discloses a harmless recycling treatment method of medical waste, comprising the following steps: (1) mixing the medical waste with calcium oxide, drying at 120-140°C, and crushing to 100-200 mesh; 2) The pulverized material in step 1, corroded calcined zeolite, iron pentacarbonyl, methylphosphoramide, cement clinker, cementing material, mixed uniformly, shaped and solidified; the corroded calcined zeolite is soaked in concentrated hydrochloric acid for 10- After 20 minutes, it is obtained by calcining at 300-400°C and grinding; (3) calcining the cured material obtained in step (2) at a high temperature of 600-800°C. The invention adopts corrosion-calcined zeolite, iron pentacarbonyl and methylphosphoramide as reinforcement system, synergistically improving the compressive strength and crack resistance of the product.

Owner:长沙汇洋环保技术股份有限公司

Emulsifier for powdered emulsified explosive and its prepn process

InactiveCN1259290CImprove stabilityGood storage stabilityNon-explosive/non-thermic compositionsAlcoholEmulsion explosive

Owner:CHINA PETROLEUM & CHEM CORP +1

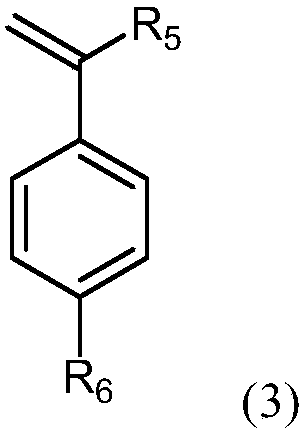

Application and preparation method of powdered styrene butadiene rubber friction material

InactiveCN114479133AEasy to powderHigh powder rateFriction liningActuatorsComposite materialPolymer chemistry

The invention discloses an application and a preparation method of a powdered styrene-butadiene rubber friction material. The preparation method comprises the following steps: sequentially adding water and styrene-butadiene latex into a polymerization kettle, stirring, heating, adding an oxidizing agent, carrying out a cross-linking reaction to obtain surface cross-linked styrene-butadiene latex, dispersing kaolin into ammonia water, adding a surface modifier, heating in a water bath in the stirring process, and carrying out heat preservation to obtain the powdered styrene-butadiene rubber friction material. The preparation method comprises the following steps: adding cross-linked styrene-butadiene latex into a stirred product, premixing in a high-speed stirrer, uniformly mixing, adding a coating agent to form a pulverization system, stirring in a common stirrer at a constant temperature, adding a flocculating agent, and strongly stirring in the high-speed stirrer, so that the pulverization system is subjected to pulverization, coagulation and co-precipitation. According to the application and the preparation method of the powdered styrene-butadiene rubber friction material, the powdered rubber is ideally dispersed in the friction material, the phenomenon of partial damage is not easy to occur when the friction material bears high-speed friction, the powdered rubber is easy to pulverize, the powder forming rate is high, the mechanical property is better, the long-time deformation is obviously reduced, and the tensile strength is also improved.

Owner:任丘市华创新型防水材料有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com