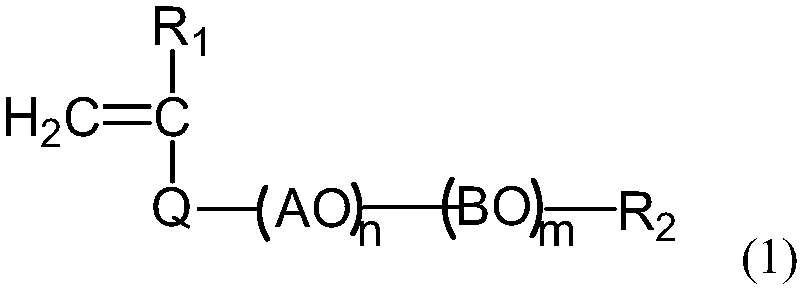

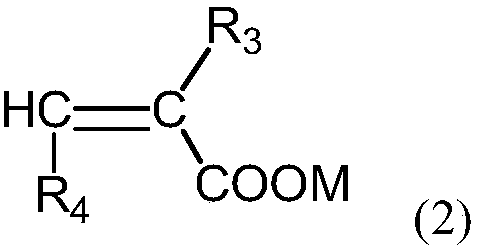

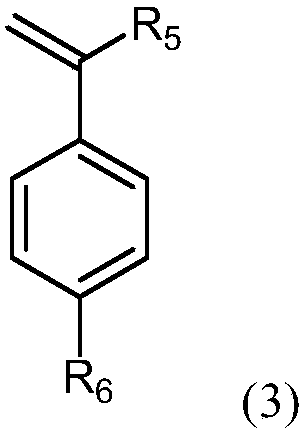

Powdery shrinkage-reducing polycarboxylic acid water reducing agent and preparation method thereof

A technology of water reducer and polycarboxylate, which is applied in the field of powder shrinkage reducing polycarboxylate water reducer and its preparation, and can solve the problems of powder affecting concrete strength, no dispersion performance, large dosage, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation Embodiment 1

[0069] In a glass reactor equipped with a thermometer, a stirrer, a dropping funnel, and a nitrogen inlet tube, the reaction vessel was purged with nitrogen while stirring, and the temperature was raised to 60°C, and 413.7g (0.7mol) of a-4 and 120g of water were dissolved At the end, 50.4g (0.7mol) b-1, 75.6g (0.35mol) d-1, 2.78g mercaptoethanol and 100g water are configured as drop solution I, and 16.8g (0.14mol) c-1 and 100g water are configured as Solution II, 16.68g L-ascorbic acid and 80g water were prepared as solution III, 27.82g hydrogen peroxide was added to the bottoming water, solutions I and II were added dropwise at a constant speed for 5.5 hours, solution III was added dropwise at a constant speed for 5.75 hours, after the addition was completed, keep warm for 4 hours, Then lower the temperature and neutralize the discharged material to obtain a polymer solution with a concentration of 60%. The weight average molecular weight of the obtained polymer is 11800, whic...

preparation Embodiment 2

[0072]In a glass reactor equipped with a thermometer, a stirrer, a dropping funnel, and a nitrogen inlet tube, the reaction vessel was purged with nitrogen while stirring, and the temperature was raised to 40°C, and 307.4g (0.2mol) of a-3 and 150g of water were dissolved At the end, 46.4g (0.4mol) b-3, 77g (0.14mol) d-3, 9.03g mercaptopropionic acid and 150g water are configured as drop solution I, and 20.6g (0.1mol) c-1 and 60g water are configured as Solution II, 16.68g of Diaobai powder and 120g of water were prepared as solution III, 13.54g of hydrogen peroxide was added to the base water, solutions I and II were added dropwise at a constant speed for 3 hours, solution III was added dropwise at a constant speed for 3.5 hours, after the addition was completed, keep warm for 3 hours, and then Lower the temperature and neutralize the discharged material to obtain a polymer solution with a concentration of 50%. The weight average molecular weight of the obtained polymer is 2360...

preparation Embodiment 3

[0075] In a glass reactor equipped with a thermometer, a stirrer, a dropping funnel and a nitrogen gas inlet tube, the reaction vessel was purged with nitrogen gas while stirring, and the temperature was raised to 25°C, and 307.4g (0.2mol) a-2 and 250g water At the bottom, 21.6g (0.3mol) b-1, 16.5g (0.06mol) d-3, 11.17g thioglycolic acid and 200g water are configured as drop solution I, and 16.52g (0.07mol) c-3 is drop solution II , 2.23g of Diaobai powder and 130g of water were prepared as solution III, 5.59g of hydrogen peroxide was added to the base water, and solutions I and II were added dropwise for 4 hours at variable speeds (40% for the first 1h, and 60% for the next 3h), and solution III was dropped at a constant speed Add for 4.5 hours, after the dropwise addition, keep warm for 2 hours, then cool down and neutralize the material to obtain a polymer solution with a concentration of 40%, and the weight average molecular weight of the obtained polymer is 37500, which is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com