Linolenic acid formula goat milk powder and production device and method thereof

A production device and technology for goat milk powder, which are applied in chemical instruments and methods, mixers with rotary stirring devices, transportation and packaging, etc., can solve unfavorable production work, unfavorable industrialization production work, and inconvenient screening production work. and other problems to achieve the effect of improving production quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

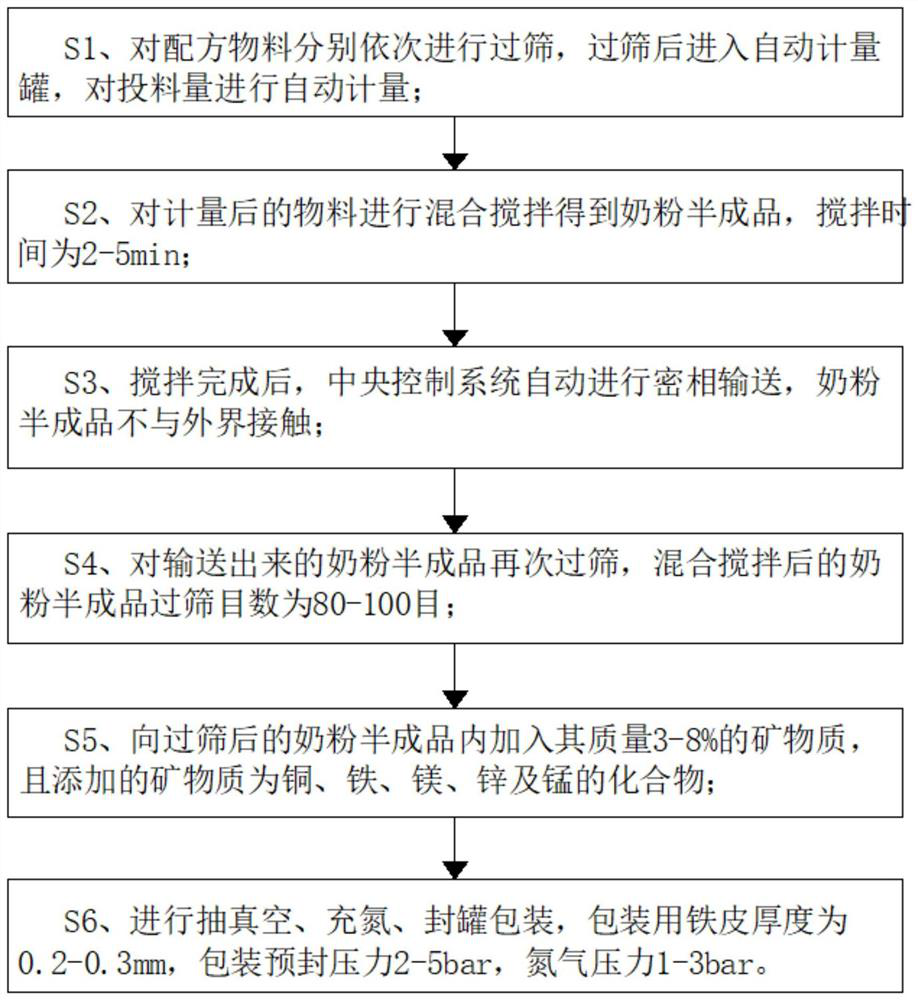

[0058] A linolenic acid formula goat milk powder, see figure 1 , its preparation process comprises the following steps:

[0059] S1. Screen the formula materials in turn, and then enter the automatic metering tank after the screening, and automatically measure the feeding amount;

[0060] S2, mixing and stirring the measured materials to obtain semi-finished milk powder, and the stirring time is 2min;

[0061] S3. After the stirring is completed, the central control system will automatically carry out dense phase conveying, and the semi-finished milk powder will not be in contact with the outside world;

[0062] S4, sieve the milk powder semi-finished product conveyed out again, and the sieving mesh number of the milk powder semi-finished product after mixing and stirring is 80 meshes;

[0063] S5. Add 4% minerals by mass to the sieved milk powder semi-finished product, and the added minerals are compounds of copper, iron, magnesium, zinc and manganese, wherein copper is pro...

Embodiment 2

[0067] A linolenic acid formula goat milk powder, see figure 1 , its preparation process comprises the following steps:

[0068] S1. Screen the formula materials in turn, and then enter the automatic metering tank after the screening, and automatically measure the feeding amount;

[0069] S2, mixing and stirring the measured materials to obtain semi-finished milk powder, and the stirring time is 4min;

[0070] S3. After the stirring is completed, the central control system will automatically carry out dense phase conveying, and the semi-finished milk powder will not be in contact with the outside world;

[0071] S4, sieve the milk powder semi-finished product conveyed out again, and the sieving mesh number of the milk powder semi-finished product after mixing and stirring is 85 meshes;

[0072] S5. Add 6% minerals by mass to the sieved milk powder semi-finished product, and the added minerals are compounds of copper, iron, magnesium, zinc and manganese, copper is provided by...

Embodiment 3

[0076] A linolenic acid formula goat milk powder, see figure 1 , its preparation process comprises the following steps:

[0077] S1. Screen the formula materials in turn, and then enter the automatic metering tank after the screening, and automatically measure the feeding amount;

[0078] S2, mixing and stirring the measured materials to obtain semi-finished milk powder, and the stirring time is 2-5min;

[0079] S3. After the stirring is completed, the central control system will automatically carry out dense phase conveying, and the semi-finished milk powder will not be in contact with the outside world;

[0080] S4, sieve the milk powder semi-finished product conveyed out again, and the sieving mesh number of the milk powder semi-finished product after mixing and stirring is 100 meshes;

[0081] S5. Add 8% minerals by mass to the sieved milk powder semi-finished product, and the added minerals are compounds of copper, iron, magnesium, zinc and manganese, copper is provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com