A processing method and processing device of a selenium-rich functional solid beverage

A solid beverage and processing device technology, which is applied in the direction of protein-containing food ingredients, lighting and heating equipment, non-progressive dryers, etc., can solve the problems of affecting taste and nutritional supplementation, easy loss of nutrients, and decline in beverage taste. Achieve the effect of improving frying performance, improving mixing performance and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

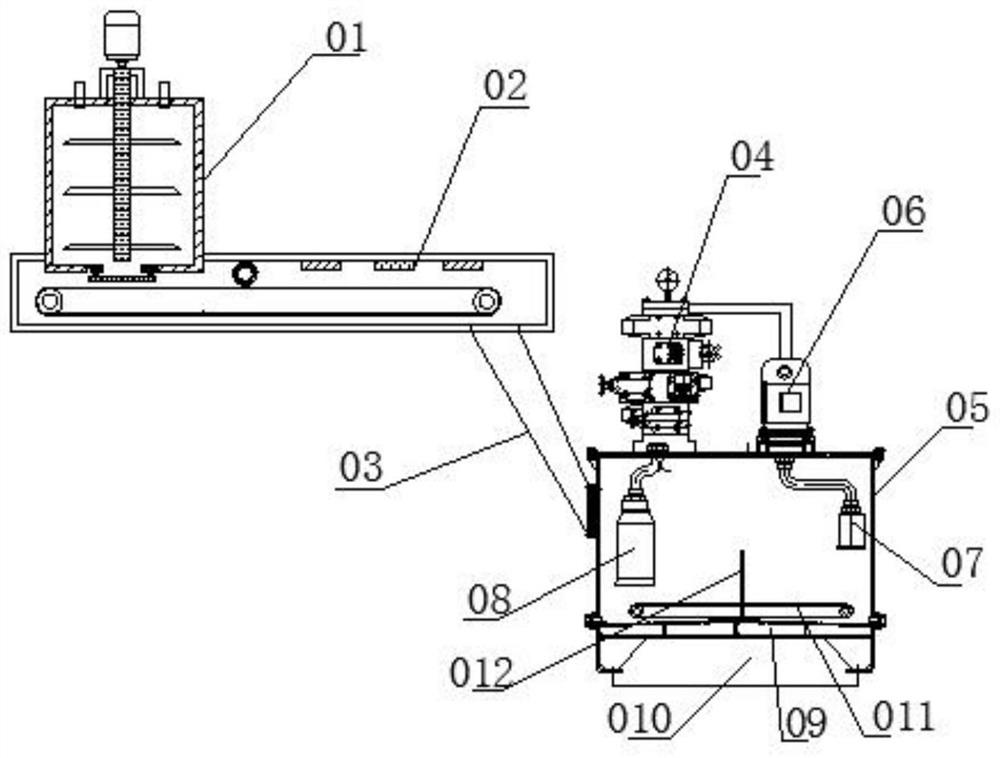

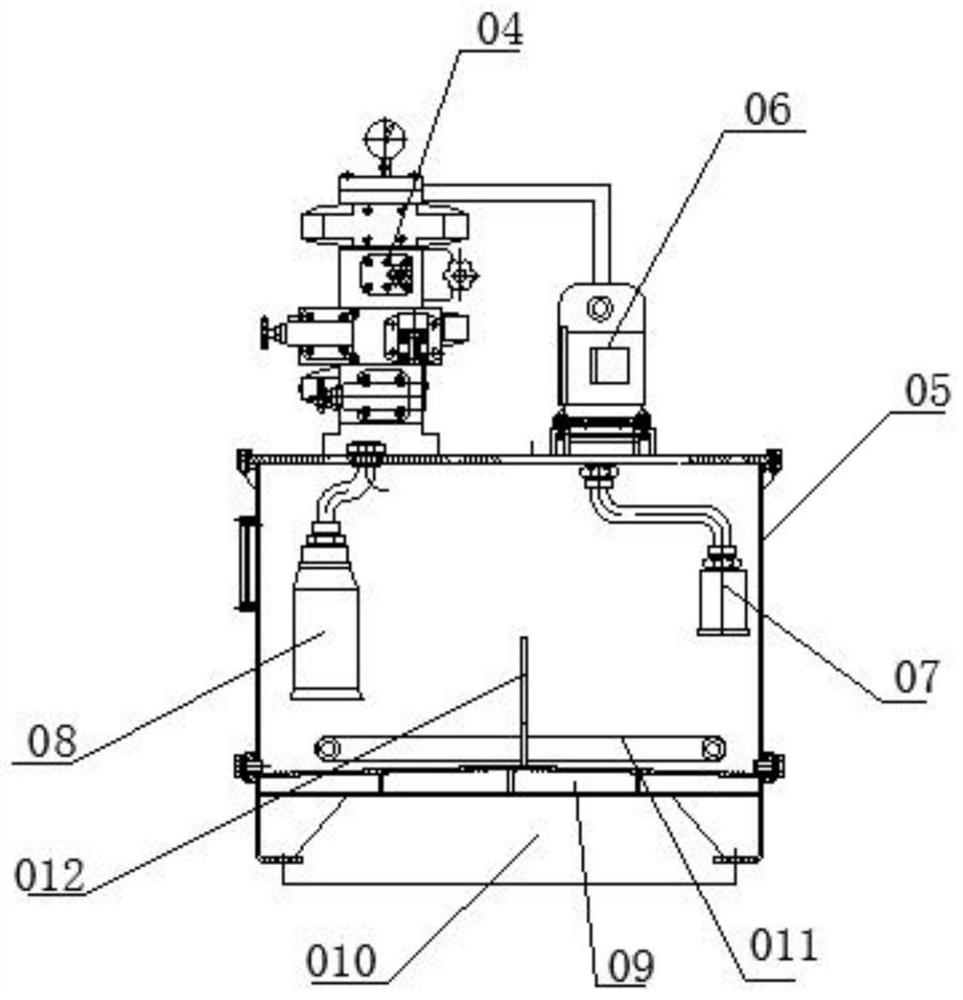

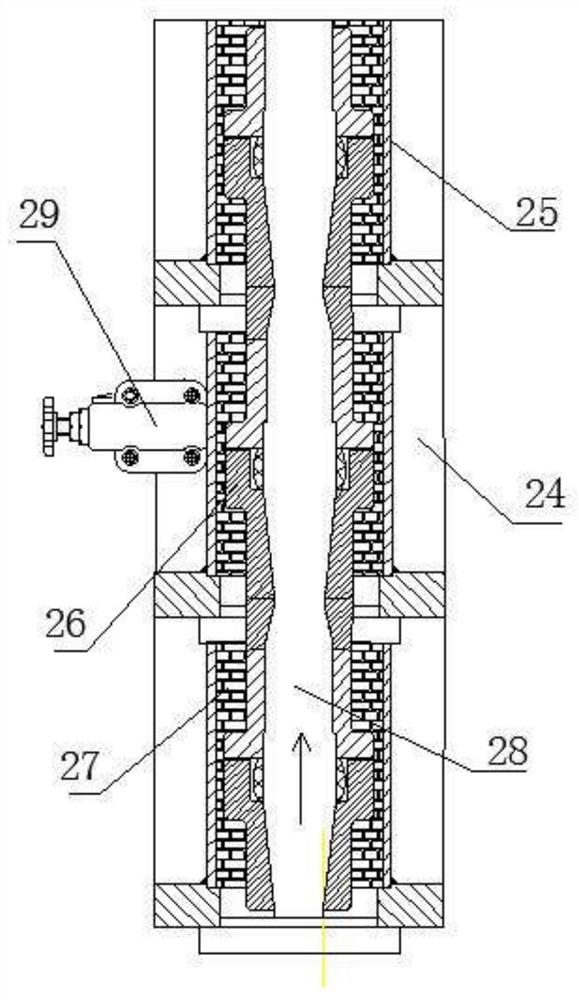

[0031] see Figure 1~6 , in an embodiment of the present invention, a selenium-rich functional solid beverage processing device includes a powder mixing mechanism 01, a disinfection and delivery mechanism 02, and a frying treatment mechanism, wherein the output end of the powder mixing mechanism 01 Connected to the disinfection and delivery mechanism 02, the output end of the disinfection and delivery mechanism is connected to the frying treatment mechanism using a delivery pipe 03; it is characterized in that the frying treatment mechanism includes a heat treatment box 05 and a drying Circulation pipe assembly 04; both ends of the drying circulation pipe assembly extend into both sides of the interior of the heat treatment box, the bottom of the heat treatment box 05 is provided with a heating seat 010, and the interior of the drying circulation pipe assembly is also provided with a heating Assemblies, the heating assembly and the heating seat are constructed so that the temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com