Emulsifier for powdered emulsified explosive and its prepn process

A technology of powdery emulsion explosives and emulsifiers, which is applied to non-explosive/non-thermal agent components, explosives, offensive equipment, etc., and can solve the problems of being unsuitable for the production of powdery emulsion explosives, suitable for powdery emulsion explosives, and soft emulsion matrix , to achieve good storage stability, improve storage stability, and smooth emulsification conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

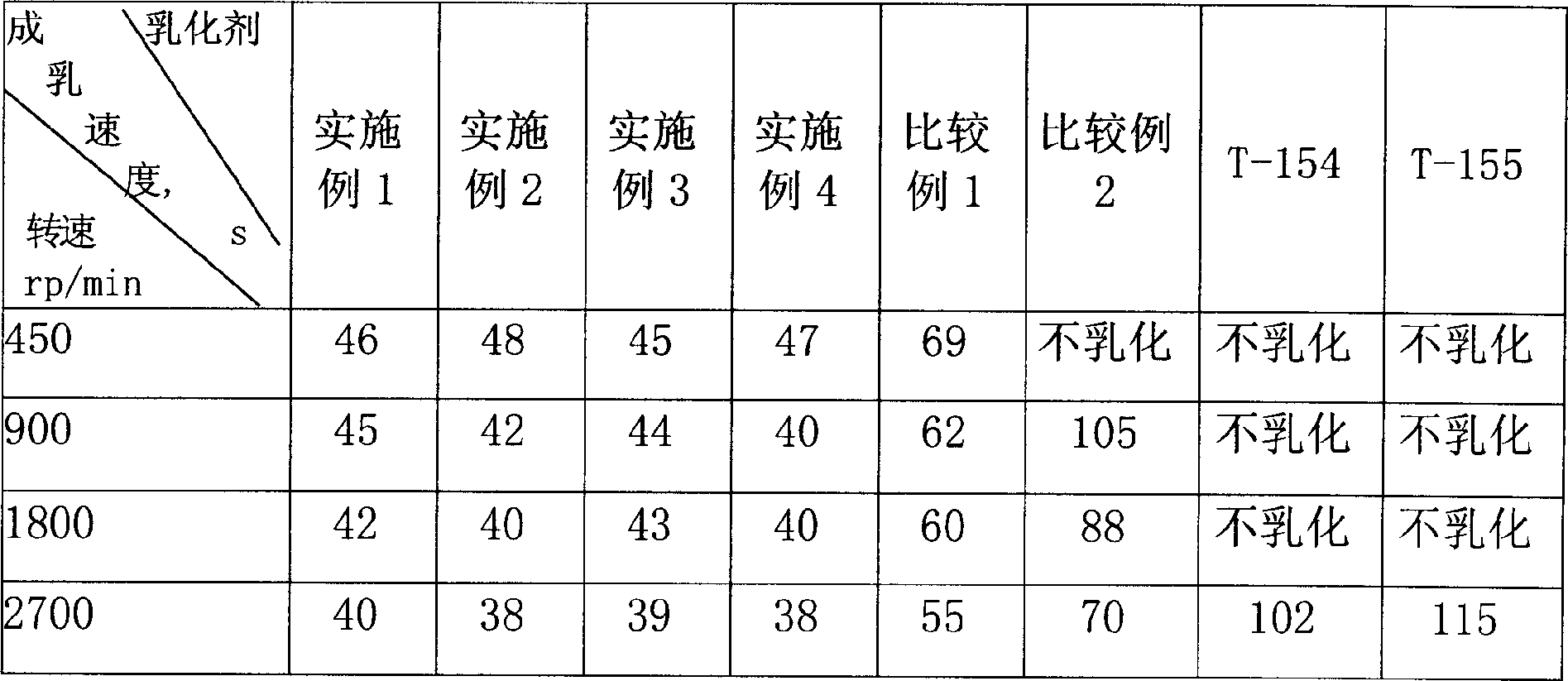

Examples

Embodiment 1

[0019] Add 160g of polyisobutylene (Mn=1000) and 14g of maleic anhydride into the reaction kettle, heat to 110°C, start stirring and feed chlorine gas, slowly heat up to 200°C within 3 hours, stop feeding chlorine gas at the same time, and continue stirring After 1 hour, the prepared polyisobutylene maleic anhydride (alkenic anhydride) was used for the next reaction. Take 100g of alkene anhydride, 0.3g of monoethanolamine, 1.5g of diethanolamine and 1.2g of triethanolamine, add 0.5g of 30w% NaOH solution, and react for 4 hours at a temperature of 190°C and a pressure of -0.02MPa.

Embodiment 2

[0021] Prepare 100g of alkene anhydride according to the method of Example 1, add 4.5g of monoethanolamine, 6.0g of diethanolamine and 4.5g of triethanolamine, and add 1.0g of KOH solution with a concentration of 20w%, and react at a temperature of 150°C and a pressure of -0.04MPa. 6 hours.

Embodiment 3

[0023] Prepare 100g of alkene anhydride according to the method in Example 1, add 18g of monoethanolamine, 9g of diethanolamine and 3.0g of triethanolamine, and add 1.5g of KOH solution with a concentration of 20w%, and react for 1 hour at a temperature of 220°C and a pressure of -0.08MPa .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com