Water-based woodware clear primer and preparation method thereof

A technology for clear primer and woodware, applied in the field of coatings, can solve the problems of labor efficiency, labor, and easy generation of heat, saving manpower and material resources, shortening drying time, and improving work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

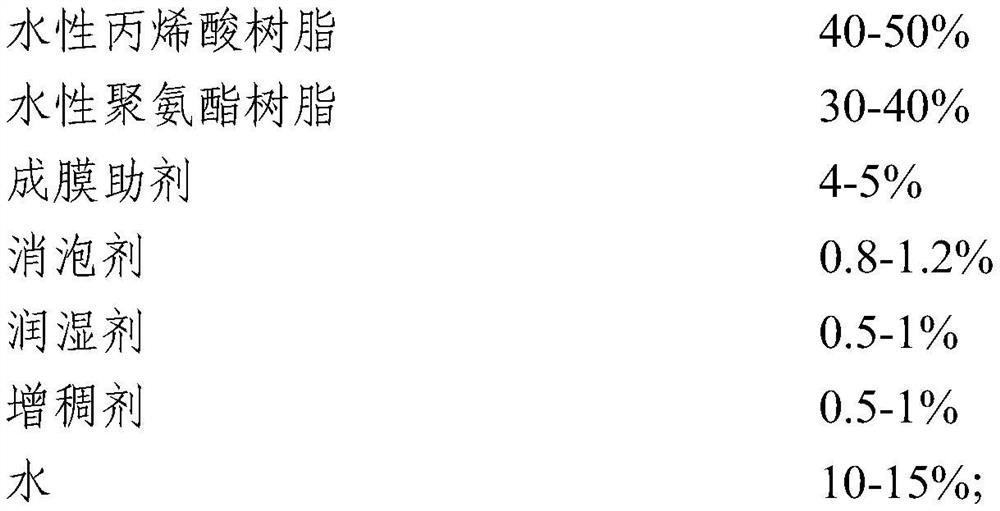

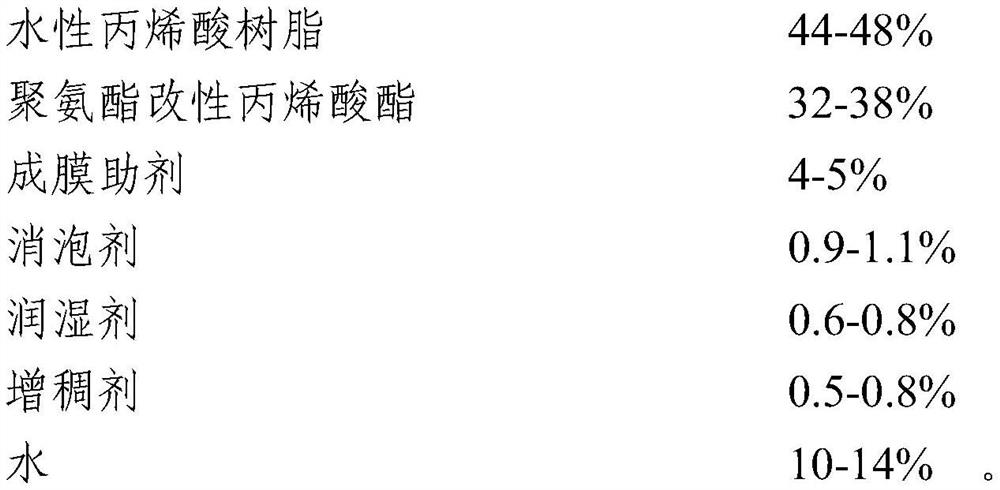

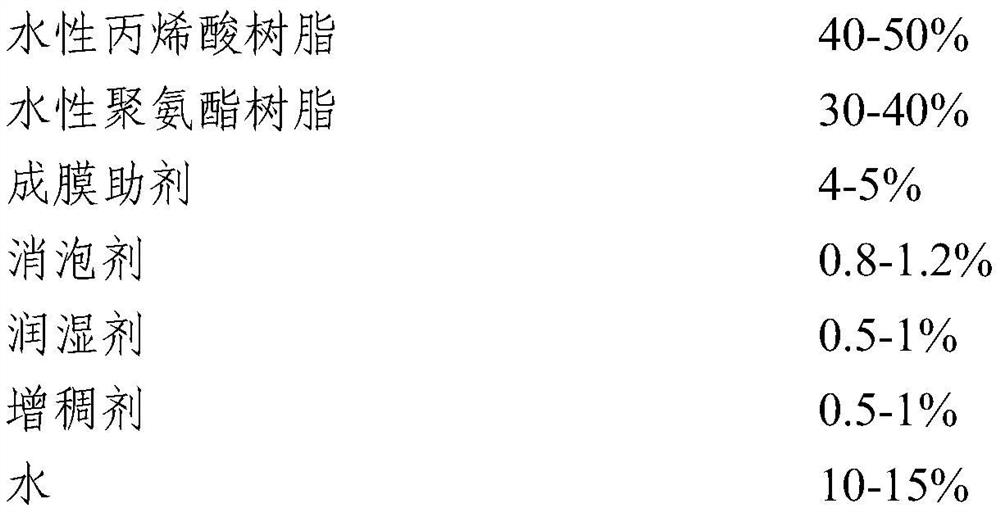

Method used

Image

Examples

Embodiment 1

[0030] Example 1 Preparation of aqueous wood cleaner

[0031] This embodiment provides a water-based wood cleaped paint coating comprising a component (total weight percent): 50% of the aqueous acrylic resin; polyurethane modified acrylate I 30%; defoaming 0.5%; wetting agent 0.8%; 4% film forming aid; thickener 0.5%; margin is water.

[0032] The preparation method includes the following steps: First, each component is referred to, then a well-known water-based aqueous acrylic resin and a polyurethane modified acrylate are mixed, 700 ~ 900 rpm medium speed is 5 to 10 min, sequentially add defoaming agent, moisturizing Wet agent, film formation auxiliary, 1000 to 1200 rpm high speed dispersed 15 to 25 min to no shrinkage, and finally added thickeners and water, 700 ~ 900 rpm medium speed dispersed to standard viscosity 75 to 80 ku / 25 ° C.

Embodiment 2

[0033] Example 2 Preparation of aqueous wood cleaner

[0034] This embodiment provides a water-based wood cleaped paint coating comprising a component (total weight percent): 100% weight of the aqueous acrylic resin; polyurethane modified acrylate I 20%; defoaming 0.5%; wetting agent 0.8%; 4% film forming aid; thickener 0.5%; margin is water.

Embodiment 3

[0035] Example 3 Preparation of aqueous wood cleaner

[0036] This embodiment provides a water-based wood cleaped coating comprising a component (total weight percentage of 100%): 40% of the aqueous acrylic resin; polyurethane modified acrylate I 40%; defoaming 0.5%; wetting agent 0.8%; film forming aid 3%; thickener 0.5%; margin is water.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com