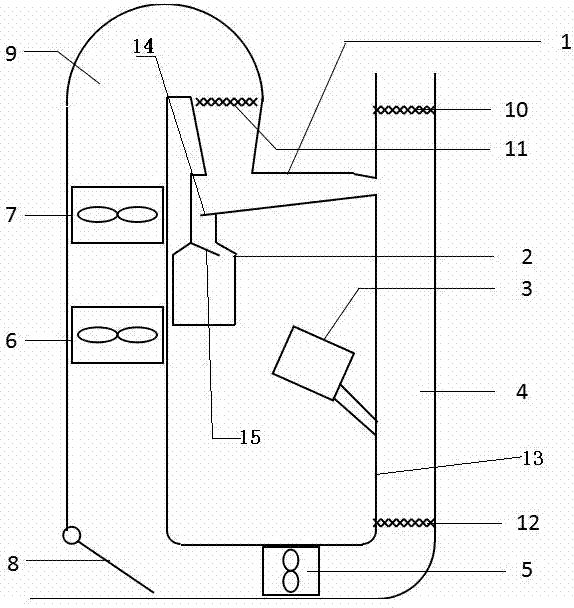

Equipment and method for separating irregular powder from spherical metal powder

A technology of metal powder and special-shaped powder, which is applied in the field of equipment for separating special-shaped powder from spherical metal powder, to achieve the effect of uniformity and quality improvement, and easy powder removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Take the 45-106 spherical titanium powder sample mixed with 30wt.% of <180μm-sized gravel as the sample to be tested, install 325 mesh screens on the upper and lower sides of the powder blowing pipeline and the air duct, and put the sample into the powder blowing pipeline of the equipment. The power of the fan is controlled at 100w, and the hinge is opened by 50%. The mass fraction of <180μm gravel in the collector is 3wt.%, and the separated sample is tested again to sieve the mass fraction of gravel <0.5wt.%. Up to 90%, to achieve good results.

Embodiment 2

[0042] Take the 106-180 size spherical titanium powder sample as the sample to be tested, and the proportion of non-spherical powder in the original sample is 1.51%. Install 200 mesh screens on the upper and lower sides of the powder blowing pipeline and the air duct respectively, and put the sample into the powder blowing tube On the road, the power of the fan is controlled at 130w, the hinge is opened by 30%, and the proportion of special-shaped powder obtained in the collector is 0.43%. The one-time removal rate reaches 72%, achieving a good separation effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com