Special medical food and food material crushing equipment

A crushing equipment and medical technology, applied in lighting and heating equipment, food science, non-progressive dryers, etc., can solve the problems of incomplete crushing of food powder, easy adhesion to the inner wall of the machine, inconvenience of mechanized production, etc., to achieve convenience The effect of carrying food materials, improving grinding efficiency, and refining food powder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

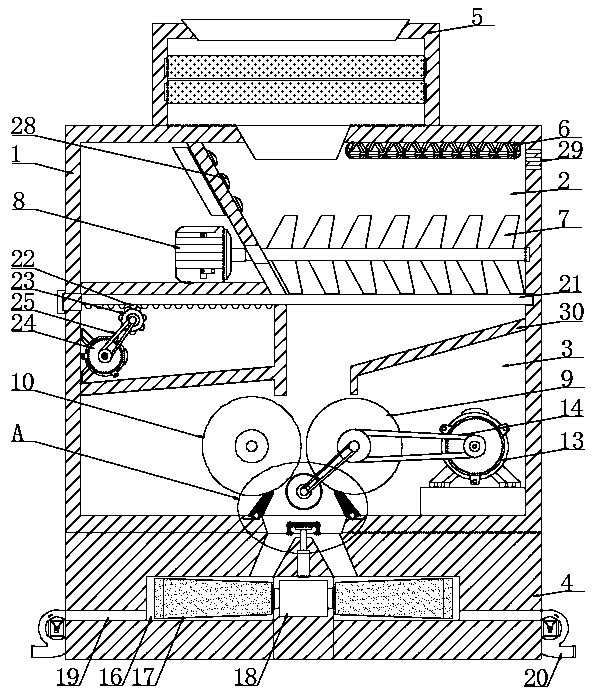

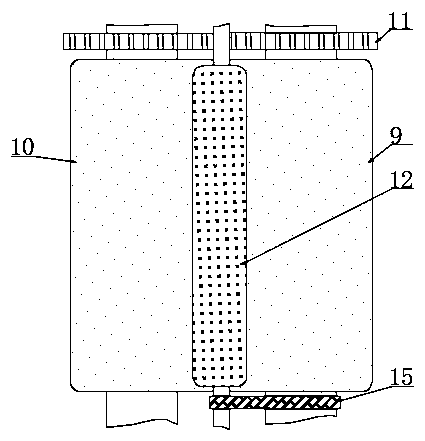

[0026] according to Figure 1-4 A kind of equipment for crushing food and ingredients for special medical use is shown, which includes a box body 1, inside of which is provided a drying chamber 2, a crushing chamber 3 and a base 4, and the drying chamber 2 and the crushing chamber 3 are respectively Set on the top and bottom of the crushing chamber 3, the top of the box 1 is provided with a crusher 5, and the top of the drying chamber 2 is provided with a feed port, and the feed port matches the output end of the crusher 5. An electromagnetic heater 6 is provided on the top of the inside of the drying chamber 2, a stirrer frame 7 runs through the drying chamber 2, and a first motor 8 is provided at one end of the stirrer frame 7, and the drying chamber 2 is connected to the pulverizing There is a closing device between the chambers 3, and the crushing chamber 3 is provided with a driving roller 9 and a driven roller 10 that match each other, and one end of the driving roller 9...

Embodiment 2

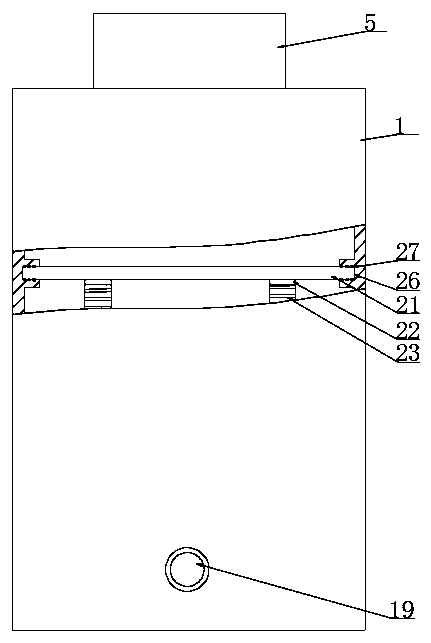

[0029] according to Figure 1-2As shown in a special medical food and material crushing equipment, the closing device includes a bearing slide 21, the bottom of the bearing slide 21 is provided with a rack 22, and the bottom of the rack 22 is meshed with a second gear 23. The inner wall of the box body 1 is fixedly connected with a fourth motor 24, the third transmission belt 25 is arranged between the output shaft of the fourth motor 24 and the second gear 23, the inner wall of the box body 1 is provided with a chute 26, and the slide plate and The chute 26 is matched, and the connection between the chute 26 and the bearing slide 21 is provided with a roller 27. The bearing slide 21 matches the chute 26, and the roller 27 facilitates the bearing slide 21 to slide. The fourth motor 24 passes through the third The transmission belt 25 is connected to the second gear 23, and the second gear 23 meshes with the rack 22 to make the load slide 21 slide, thereby controlling the openi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com