Method for processing semi-dry instant rice noodles

A processing method and semi-dry technology, applied in the direction of food ingredients as emulsifiers, food science, etc., can solve the problems of long-term storage, and achieve the effects of preventing aging, shortening rehydration time, and reducing strength and hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

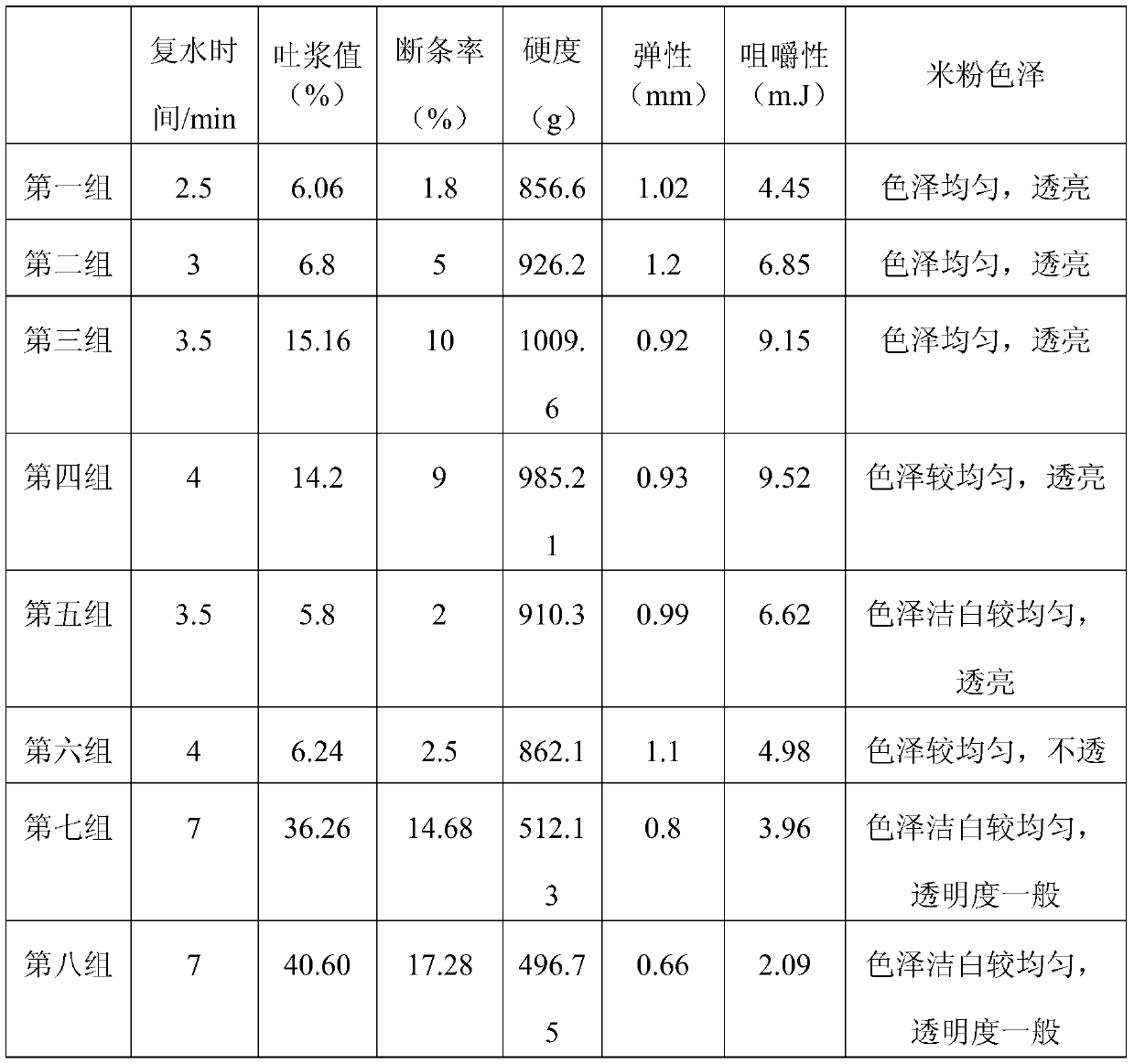

Examples

Embodiment 1

[0036] Present embodiment provides a kind of processing method of semi-dry type brewing rice flour, comprises the following steps:

[0037] (1) Preparation of raw materials: Take the following raw materials by weight for subsequent use: 50 parts of rice, 10 parts of starch mixture, 10 parts of miscellaneous grain mixture and 0.3 part of distilled glyceryl monostearate; wherein, the rice is according to the mass ratio of Early indica rice and late indica rice mixed in a ratio of 3:1; wherein, the starch mixture is obtained by the following method: mixing potato starch, corn starch, and wheat starch in a mass ratio of 2:2:1 to obtain the starch mixture Wherein, the modified potato starch is acetate modified starch; the miscellaneous grain mixture is obtained by the following method: the whole potato powder, the whole tapioca powder, the whole taro powder and the whole sweet potato powder are mixed according to the mass ratio of 2:1:1:1 , milling, so that the fineness of the mixe...

Embodiment 2

[0049] Present embodiment provides a kind of processing method of semi-dry type brewing rice flour, comprises the following steps:

[0050] (1) Preparation of raw materials: Take the following raw materials by weight for subsequent use: 70 parts of rice, 15 parts of starch mixture, 20 parts of miscellaneous grain mixture and 0.4 part of distilled glyceryl monostearate; wherein, the rice is according to the mass ratio of Early indica rice and late indica rice mixed in a ratio of 3:1; wherein, the starch mixture is obtained by the following methods: 1) dissolving potato starch in distilled water to prepare 42% starch milk, and placing the starch milk at a constant temperature of 50°C In a water bath, add 1% cross-linking agent, after reacting for 15 minutes, adjust the pH to 8.2; then add acetic anhydride accounting for 9% of the weight of potato starch at 27°C, keep the pH value of the solution constant during the reaction, and the reaction ends Finally, adjust the pH of the so...

Embodiment 3

[0062] Present embodiment provides a kind of processing method of semi-dry type brewing rice flour, comprises the following steps:

[0063] (1) Preparation of raw materials: Take the following raw materials by weight for subsequent use: 100 parts of rice, 30 parts of starch mixture, 50 parts of miscellaneous grain mixture and 0.5 part of distilled glyceryl monostearate; wherein, the rice is Early indica rice and late indica rice mixed in a ratio of 5:1; wherein, the starch mixture is obtained by the following methods: 1) dissolving potato starch in distilled water to prepare 45% starch milk, and placing the starch milk at a constant temperature of 55°C In a water bath, add 1.5% cross-linking agent, after reacting for 20 minutes, adjust the pH to 8.5; then add 10% acetic anhydride accounting for the weight of potato starch at 30°C, keep the pH value of the solution constant during the reaction, and the reaction ends Finally, adjust the pH of the solution to be 7.0, then wash an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com