Process for making vermicelli without alums

A processing method and technology of vermicelli, applied in the direction of food science, etc., can solve unfavorable health problems, achieve the effect of easy powdering, increasing somersaults, and beneficial to human health

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

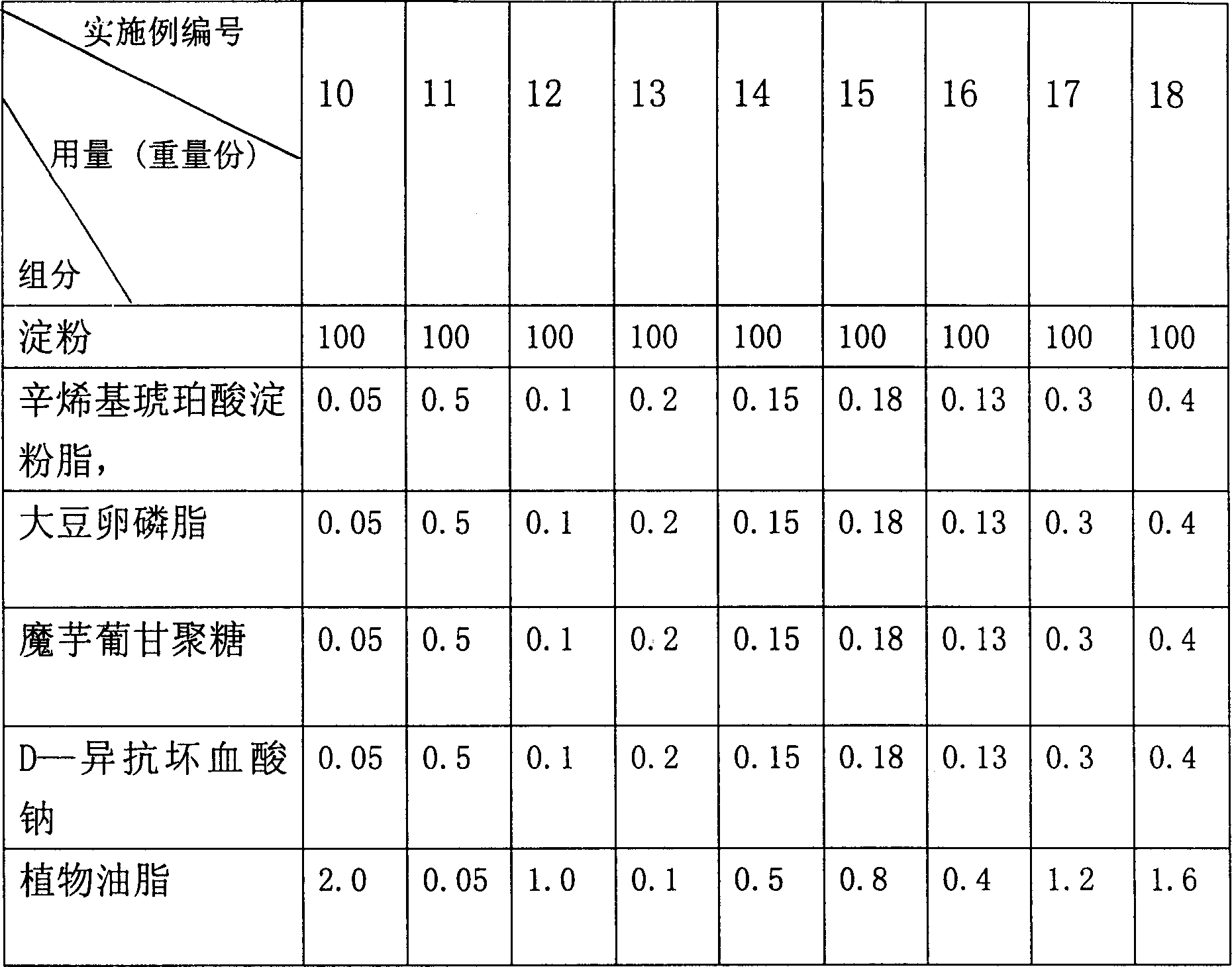

Examples

Embodiment 1

[0027] Embodiment 1: potato,

[0028] A kind of processing method of alum-free vermicelli (sheet), mainly is made up of following steps:

[0029] a, combined powder: by 100 parts (weight) of starch, 0.05 part of octenyl succinic acid starch lipid, 0.05 part of soybean lecithin, 0.02 part of konjac glucomannan, 0.02 part of D-isoascorbate (sodium D-iso-Vc) Parts, soybean oil, peanut oil, palm oil, rapeseed oil or other edible vegetable oils (such as: sesame oil, sunflower oil, olive oil, etc.) or a mixture of two or more 2.0 parts, the proportion of water Take the amount separately, mix and stir evenly:

[0030] b. Aging and forming: the mixed mixture is processed into vermicelli or powder by a vermicelli machine or manually;

[0031] c. Cutting: Cut the cured vermicelli or powder into 30---1000 mm length;

[0032] d. Weighing and subpackaging: the cut vermicelli or powder pieces are weighed at 50-300 grams per portion, and then put into forming drying bowls or boxes respect...

Embodiment 2

[0037] A kind of processing method of alum-free vermicelli (sheet), mainly is made up of following steps:

[0038] a, combined powder: by 100 parts (weight) of starch, 0.5 part of octenyl succinic acid starch lipid, 0.5 part of soybean lecithin, 0.05 part of konjac glucomannan, 0.02 part of D-sodium erythorbate, soybean oil, peanut oil, Palm oil, rapeseed oil or other edible vegetable oils (such as: sesame oil, sunflower oil, olive oil, etc.) or a mixture of two or more than 0.05 part, the appropriate amount of water is taken separately, mix and stir evenly ;

[0039] b. Aging and forming: the mixed mixture is processed into vermicelli or powder by a vermicelli machine or manually;

[0040] c. Cutting: Cut the cured vermicelli or powder into 30-1000 mm length;

[0041] d. Weighing and subpackaging: the cut vermicelli or powder pieces are weighed at 50-300 grams per portion, and then put into forming drying bowls or boxes respectively;

[0042] E, dry: dry the vermicelli or ...

Embodiment 3

[0046] A kind of processing method of alum-free vermicelli (sheet), mainly is made up of following steps:

[0047] a, combined powder: by 100 parts (weight) of starch, 0.1 part of octenyl succinic acid starch lipid, 0.1 part of soybean lecithin, 0.1 part of konjac glucomannan, 0.1 part of D-sodium isoascorbate (D-iso-Vc sodium) Parts, soybean oil, peanut oil, palm oil, rapeseed oil or other edible vegetable oils (such as: sesame oil, sunflower oil, olive oil, etc.) one or a mixture of two or more 1.0 parts, the proportion of an appropriate amount of water Take the amount separately, mix and stir evenly;

[0048] b. Aging and forming: the mixed mixture is processed into vermicelli or powder by a vermicelli machine or manually;

[0049] c. Cutting: Cut the cured vermicelli or powder into 30-1000 mm length;

[0050] d. Weighing and subpackaging: the cut vermicelli or powder pieces are weighed at 50-300 grams per portion, and then put into forming drying bowls or boxes respectiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com