Automatic zincification device and control method thereof

A driving device and automatic technology, applied in coating, metal material coating process, hot-dip galvanizing process, etc., can solve the problem of insufficient precision in improving the stability of zinc addition, poor precision in zinc addition and temperature control, and harsh working environment And other problems, to achieve the effect of fully automatic control, improve precision, and avoid splashing of zinc liquid

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

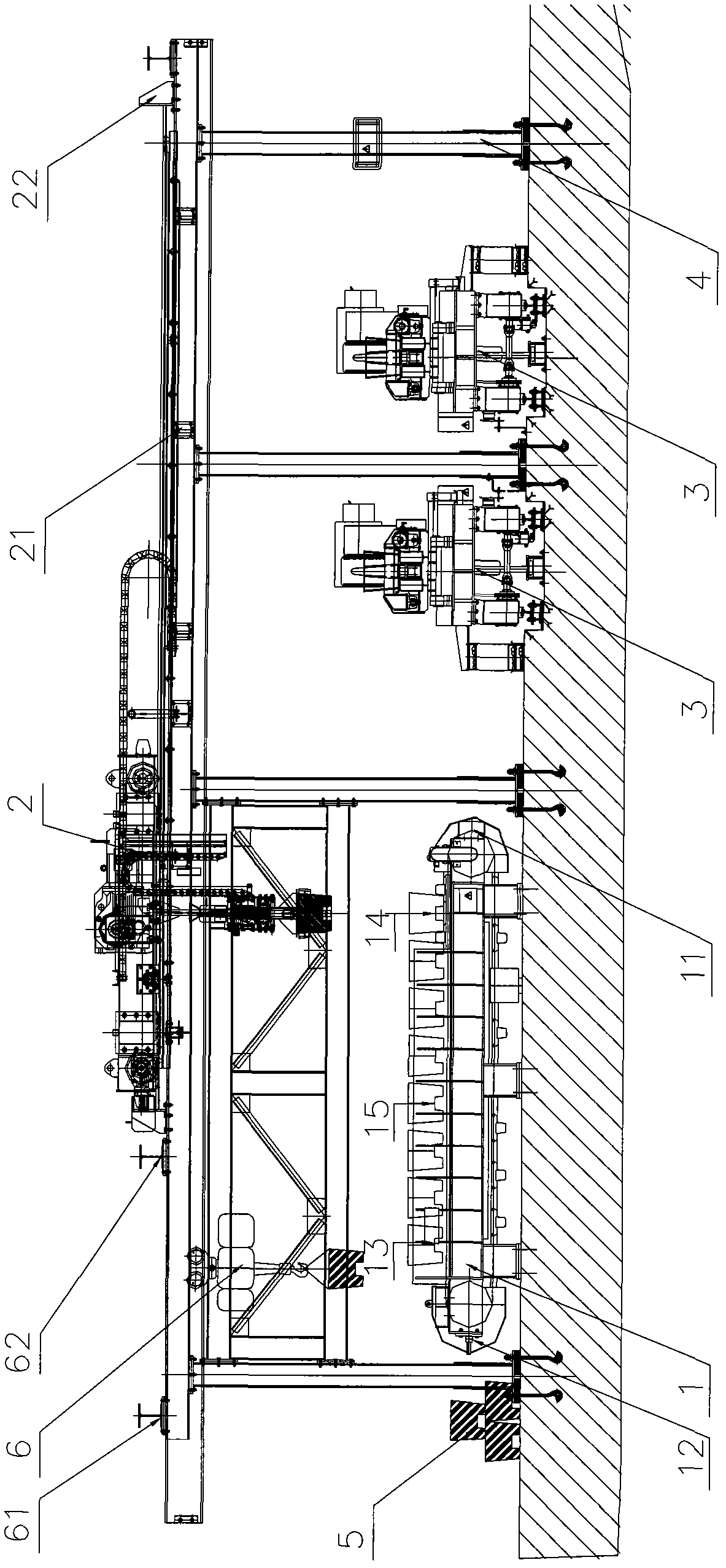

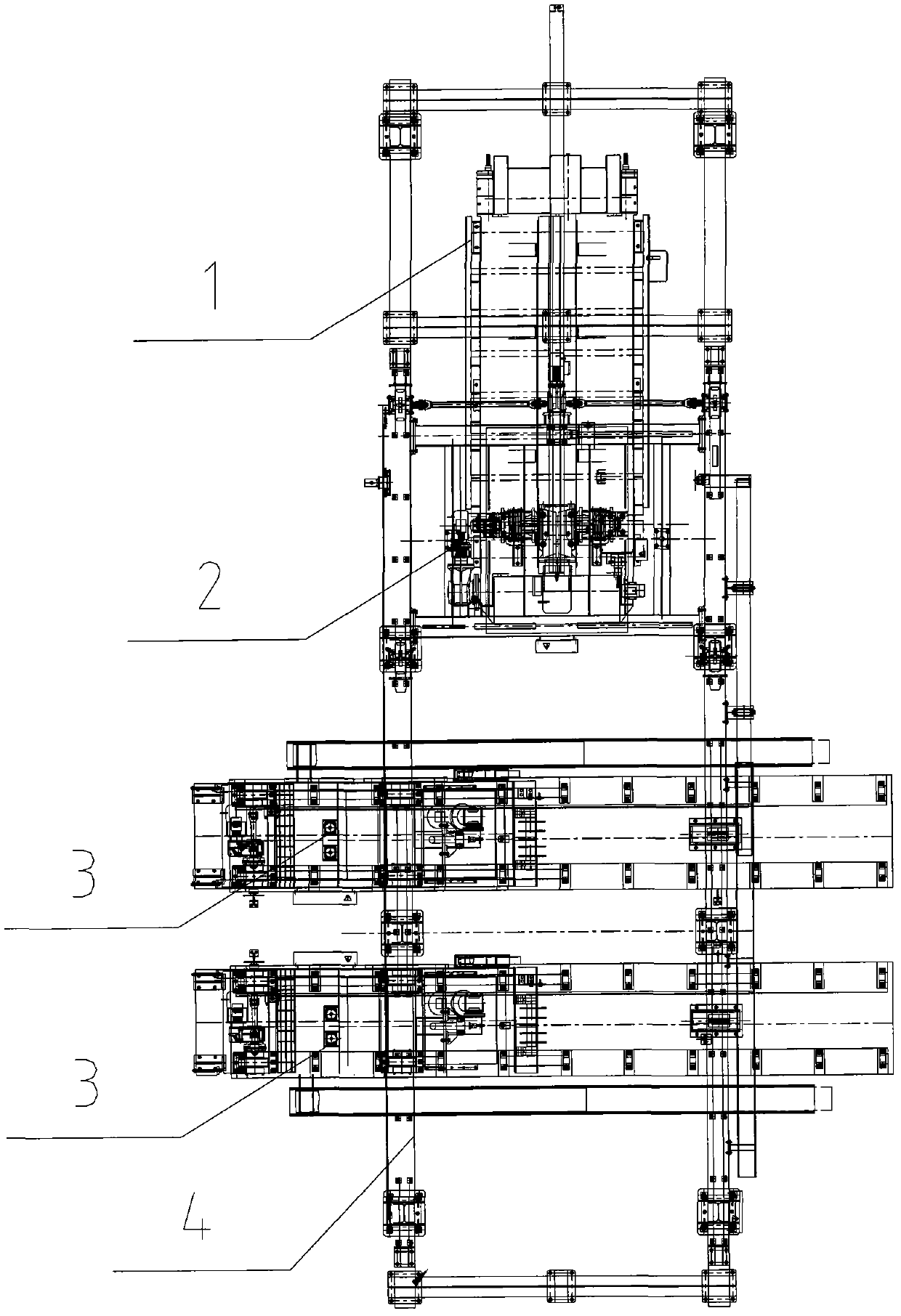

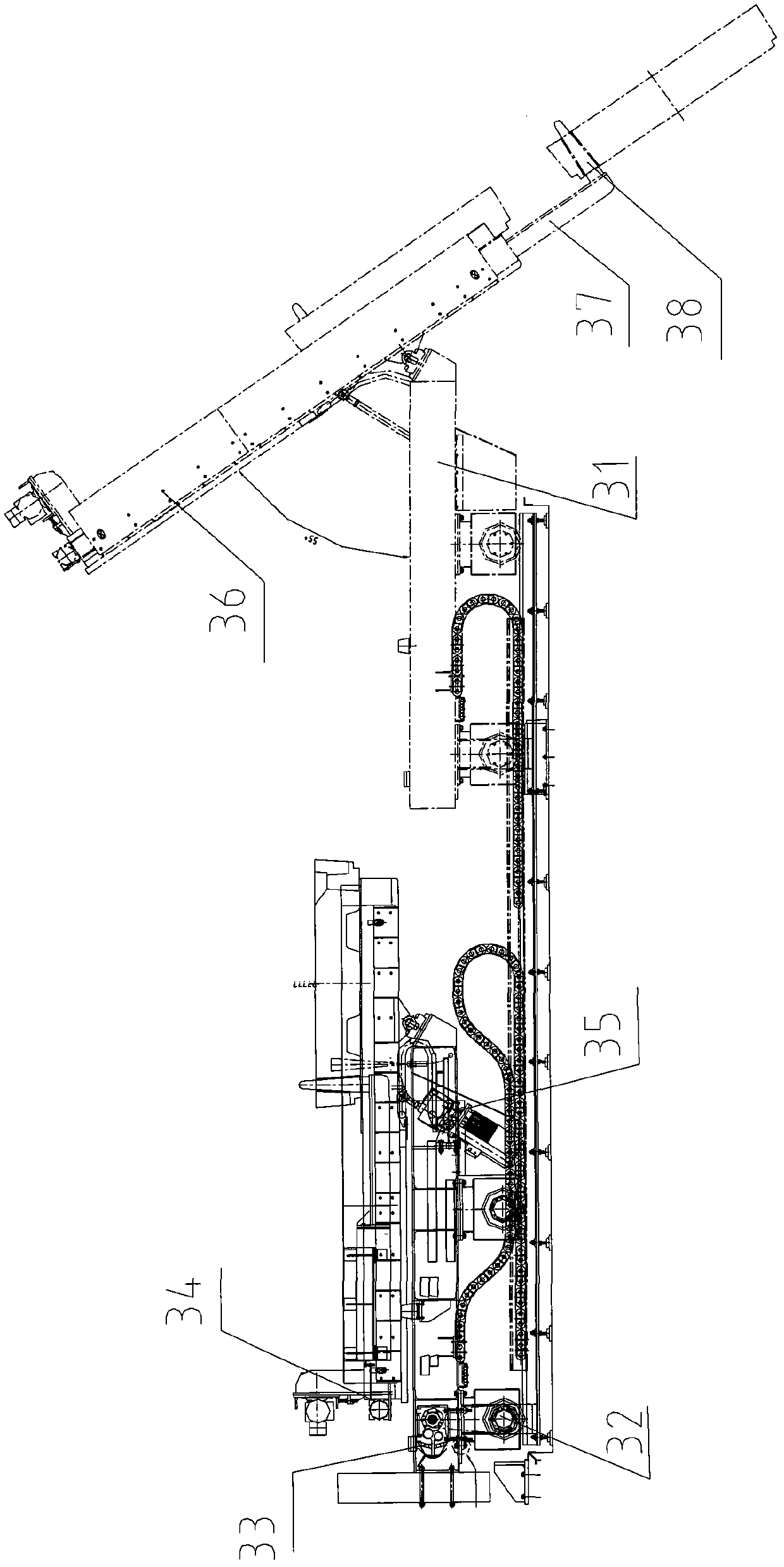

[0047] like figure 1 and figure 2As shown, the automatic zinc adding device includes: the control PLC as the general control element of the whole automatic zinc adding device; the support 4 includes several columns and horizontally arranged tracks; the manipulator device 2 is located on the horizontal track of the support 4, and the manipulator Device 2 includes: a walking trolley and a manipulator fixedly connected thereto, the walking trolley is electrically connected to the control PLC, and accepts the control of the control PLC to walk along a horizontal track, and the walking limit position of the walking trolley is determined by the first limit switch 21 and the second limit switch respectively. The switch 22 detects and transmits to the control PLC; the manipulator is electrically connected to the control PLC, accepts the control of the control PLC to grip the zinc ingot, and moves vertically up and down. The upper sensor and the lower sensor on the manipulator device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com