Display device and source electrode driver thereof

A source driver and display device technology, applied in static indicators, instruments, etc., can solve problems such as increased operating temperature and burnout of parts, and achieve the effect of avoiding burnout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

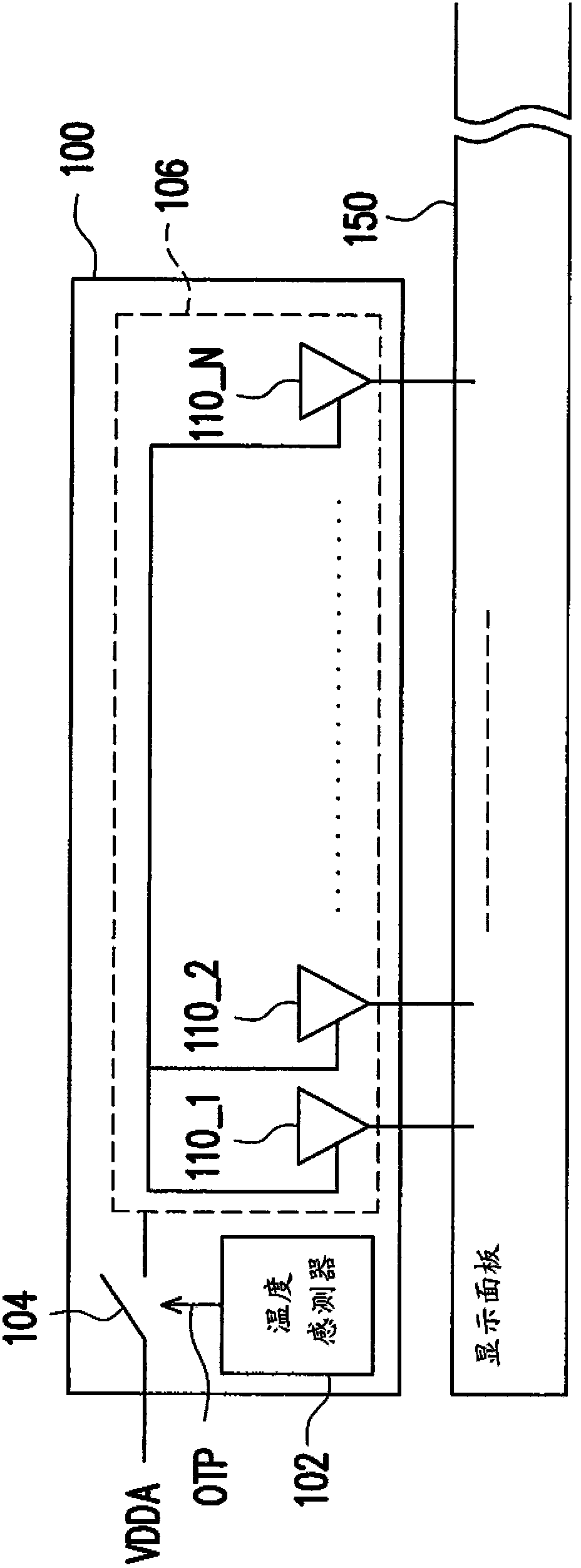

[0035] figure 1 A schematic diagram of the source driver 100 according to the first embodiment of the present invention is shown. Please refer to figure 1 , the source driver 100 includes a temperature sensor 102 , a power switch 104 and a core circuit 106 , and the core circuit 106 includes driving voltage generating circuits 110_1 - 110_N for driving the display panel 150 . The power switch 104 is coupled to the transmission path of the core circuit 106 receiving the operating power VDDA.

[0036] In this implementation, the temperature sensor 102 detects the operating temperature of the source driver 100 to obtain the operating temperature. The temperature sensor 102 also performs a comparison operation between the working temperature and the first preset temperature, so as to generate the over-temperature protection activation signal OTP according to the comparison result. To put it simply, when the temperature sensor 102 finds that the operating temperature is higher t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com