High-order supermode direction coupling waveguide detector with symmetric horizontal directions

A directional coupling, horizontal direction technology, used in optical waveguides, light guides, optics and other directions, can solve the problems of weak propagation direction, large coupling loss, difficult processing, etc., to improve the responsivity and photocurrent, reduce local overheating, Avoid burnout effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

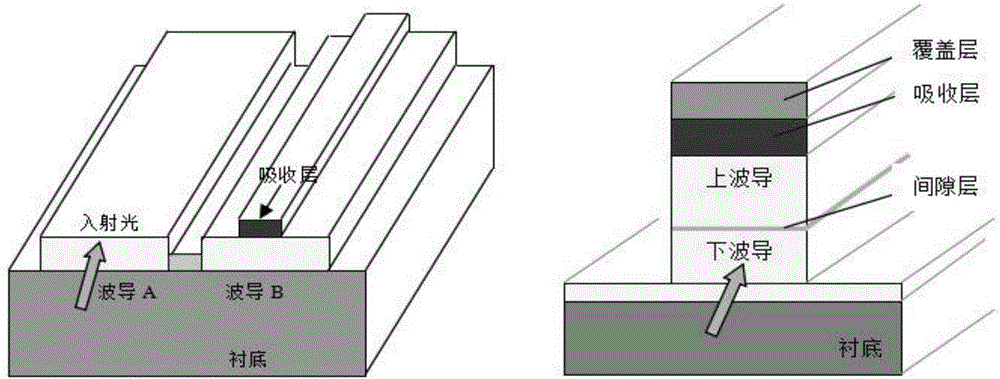

[0044] In the embodiment of the present invention, the working wavelength of the waveguide detector is 1.55 μm, the material of the substrate layer 1 is InP, the material of the waveguide layer 2 is InGaAsP, the material of the absorption layer 3 is InGaAs, and the material of the cover layer 4 is InP.

[0045] First, some basic theoretical parameters are listed. The refractive index of the material used in the waveguide detector is shown in Table 1, and the thickness of each layer is shown in Table 2, wherein the widths of the left waveguide 21, the middle waveguide 22 and the right waveguide 23 are is 5 μm, and the total width of the waveguide layer 2 is 15 μm. The thickness of the covering transition layer 6 is 0.5 μm.

[0046] Table 1

[0047] waveguide material Refractive index InP 3.14 InGaAsP 3.3 InGaAs 3.56-0.1i

[0048] Table 2

[0049] layer waveguide layer Absorbent layer Overlay thickness 5μm 0.12μm 0....

Embodiment 2

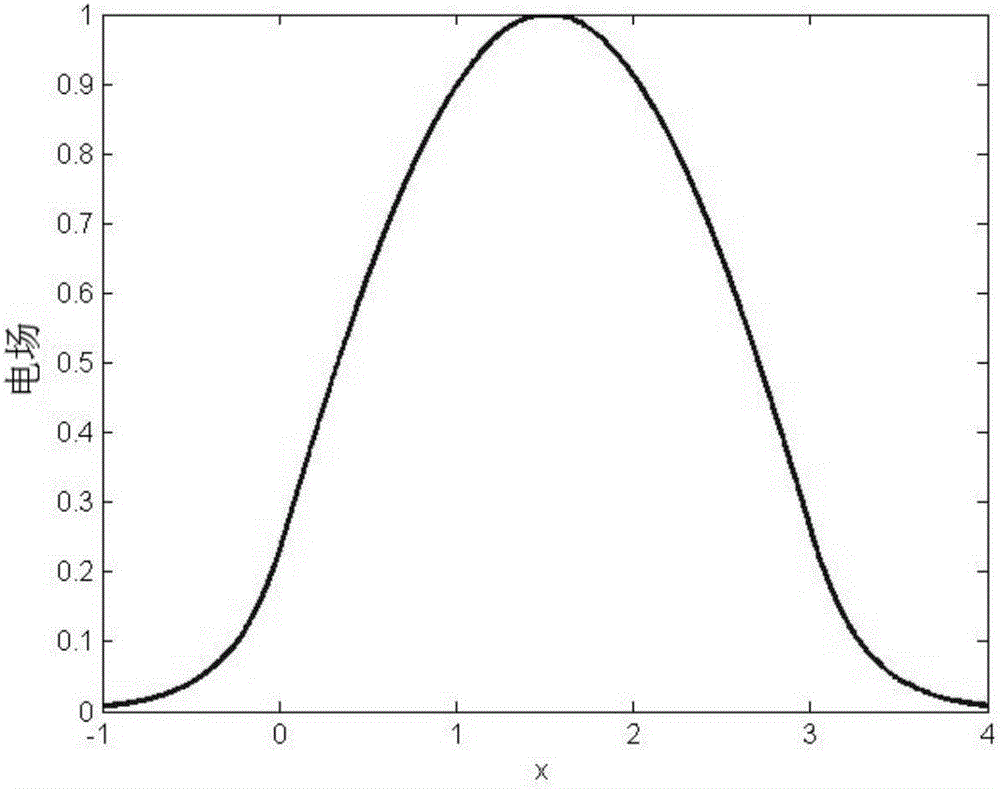

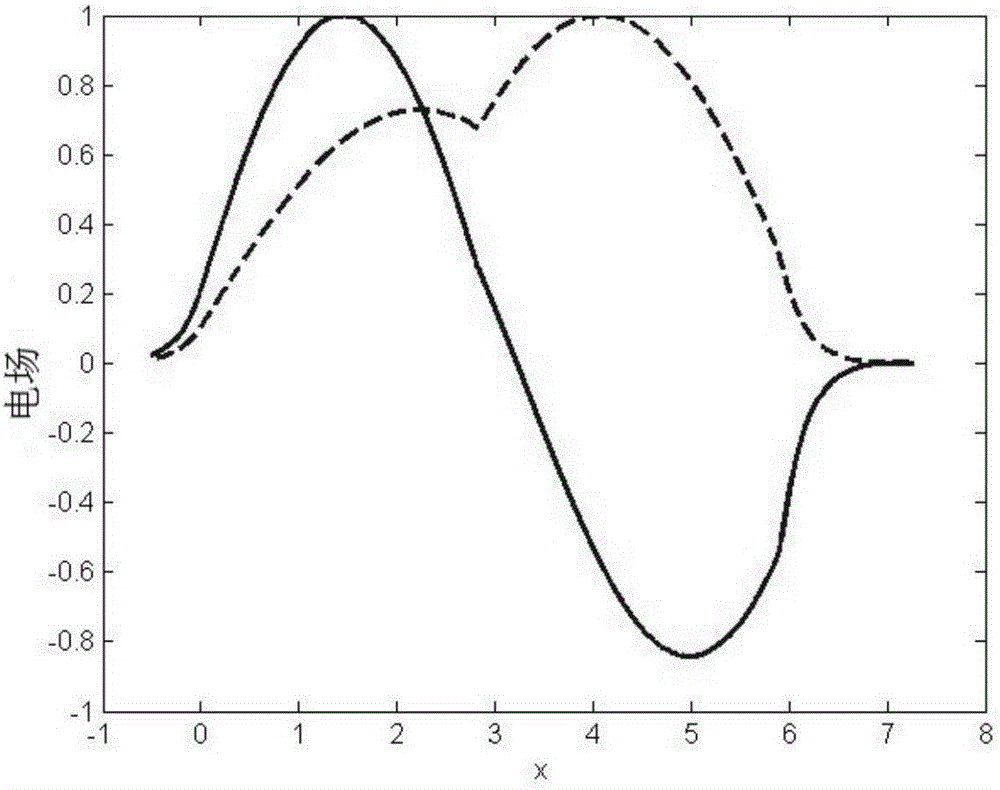

[0055] The above structural parameters are numerically simulated by using BeamPROP software, and the input light adopts Gaussian beam. For a horizontally symmetrical high-order supermode direction-coupled waveguide detector, the input light is irradiated on the end face in the middle of the waveguide layer 2 . The obtained waveguide refractive index distribution diagram and the simulation result diagram are as follows: Figure 8 and Figure 9 shown.

[0056] exist Figure 9 In the simulation result figure, the left box diagram represents the change of the optical field distribution along the z direction inside the horizontally symmetric high-order supermode direction-coupled waveguide detector. The block diagram on the right is the change diagram of optical power. When the waveguide length is 0, the first curve on the left is the change of the total power in the waveguide, the second curve is the change of power in the middle waveguide 22, and the third curve is the change ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com