Shell for filling gelatinized solid-liquid phase mixed fuel with stirring function

A mixed fuel, solid-liquid phase technology, used in nuclear power generation, ammunition testing, greenhouse gas reduction, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

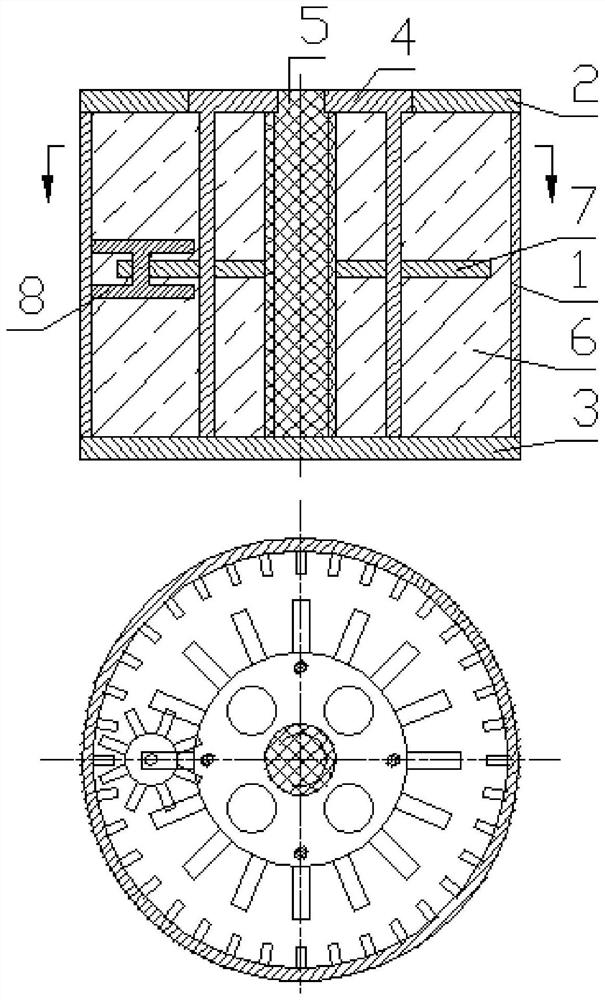

[0059] Such as figure 1 As shown, this embodiment provides a gelled solid-liquid phase mixed fuel shell with a stirring function, including an upper end cover 2 , a lower end cover 3 , and a gelled solid-liquid phase mixed fuel 6 . It is characterized in that it also includes a housing 1, a support frame 4, a throwing device 5, an axially moving stirring plate 7, and a circularly moving stirring plate 8;

[0060] The housing 1 is a first cylindrical body, the first cylindrical body of the housing 1 is a rotating body, the upper end surface of the first cylindrical body of the housing 1 is the first upper concentric annular surface, and the first circular surface of the housing 1 The lower end surface of the cylinder body is the first lower end concentric annular surface, the inner side surface of the first cylinder of the housing 1 is the first inner cylindrical surface, and thirty-six first vertical cylinders are connected to the first inner cylindrical surface of the housing...

Embodiment 2

[0104] Such as figure 1 As shown, this embodiment provides a gelled solid-liquid phase mixed fuel shell with a stirring function, including an upper end cover 2 , a lower end cover 3 , and a gelled solid-liquid phase mixed fuel 6 . It is characterized in that it also includes a housing 1, a support frame 4, a throwing device 5, an axially moving stirring plate 7, and a circularly moving stirring plate 8;

[0105] The housing 1 is a first cylindrical body, the first cylindrical body of the housing 1 is a rotating body, the upper end surface of the first cylindrical body of the housing 1 is the first upper concentric annular surface, and the first circular surface of the housing 1 The lower end surface of the cylinder body is the first lower end concentric annular surface, the inner side surface of the first cylinder of the housing 1 is the first inner cylindrical surface, and thirty-six first vertical cylinders are connected to the first inner cylindrical surface of the housing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com