A warhead shell with improved filling ratio based on laser coaxiality measuring instrument

A technology of coaxiality measurement and loading ratio, applied in explosives, offensive equipment, explosives processing equipment, etc., can solve problems such as explosion, reduction of fuel loading, combustion, etc., to ensure safety and avoid the risk of burning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

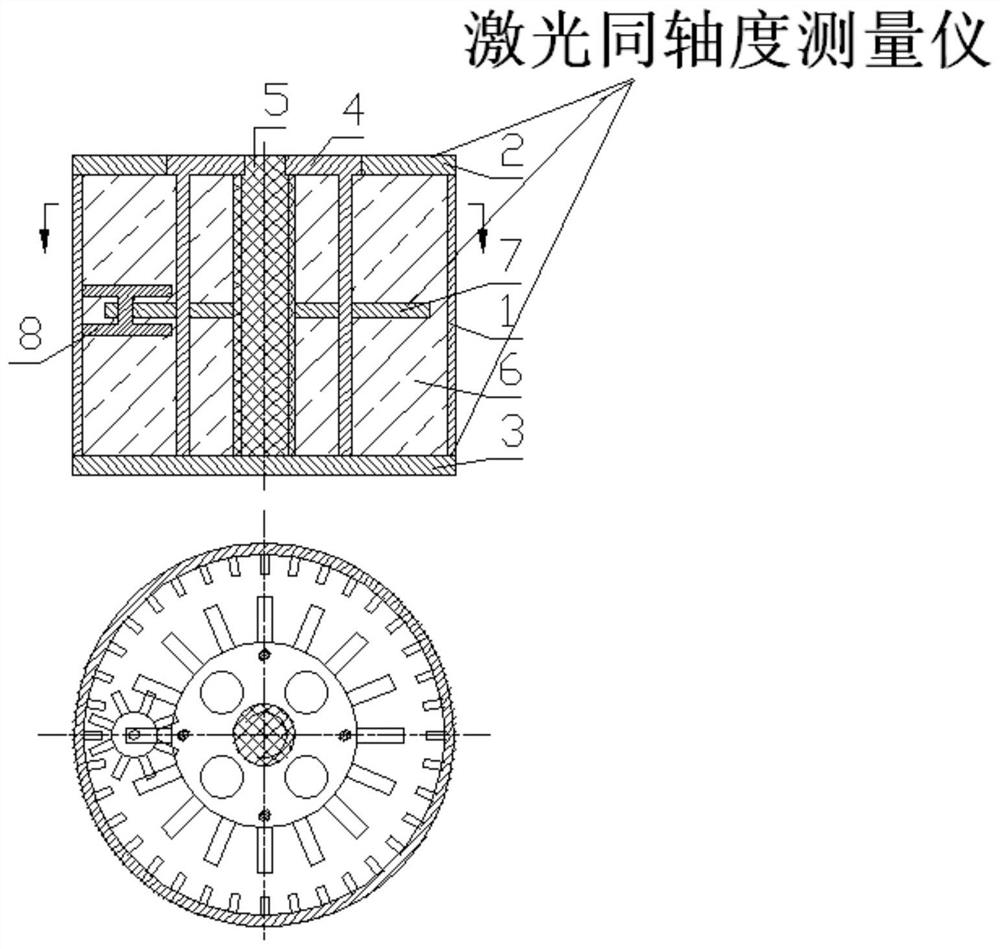

[0059] Such as figure 1 As shown, the present embodiment provides a warhead casing based on a laser coaxiality measuring instrument to increase the filling ratio, including an upper end cover 2 , a lower end cover 3 , and a gelled solid-liquid mixed fuel 6 . It is characterized in that it also includes a housing 1, a support frame 4, a throwing device 5, an axially moving stirring plate 7, a circularly moving stirring plate 8, and a laser coaxiality measuring instrument; the laser coaxiality measuring instrument is used for testing The axial coaxiality data of the upper end cover (2), the lower end cover (3) and the axially moving stirring plate (7), and the maximum axial deviation is not greater than 0.8 degrees;

[0060] The housing 1 is a first cylindrical body, the first cylindrical body of the housing 1 is a rotating body, the upper end surface of the first cylindrical body of the housing 1 is the first upper concentric annular surface, and the first circular surface of t...

Embodiment 2

[0104] Such as figure 1 As shown, the present embodiment provides a warhead casing based on a laser coaxiality measuring instrument to increase the filling ratio, including an upper end cover 2 , a lower end cover 3 , and a gelled solid-liquid mixed fuel 6 . It is characterized in that it also includes a housing 1, a support frame 4, a throwing device 5, an axially moving stirring plate 7, a circularly moving stirring plate 8, and a laser coaxiality measuring instrument; the laser coaxiality measuring instrument is used for testing The axial coaxiality data of the upper end cover (2), the lower end cover (3) and the axially moving stirring plate (7), and the maximum axial deviation is not greater than 0.8 degrees;

[0105] The housing 1 is a first cylindrical body, the first cylindrical body of the housing 1 is a rotating body, the upper end surface of the first cylindrical body of the housing 1 is the first upper concentric annular surface, and the first circular surface of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com