Fluid anti-gravity flowing device driven by air cushion

A mobile device and anti-gravity technology, applied to offensive equipment, ammunition, weapon accessories, etc., can solve problems such as explosion and combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

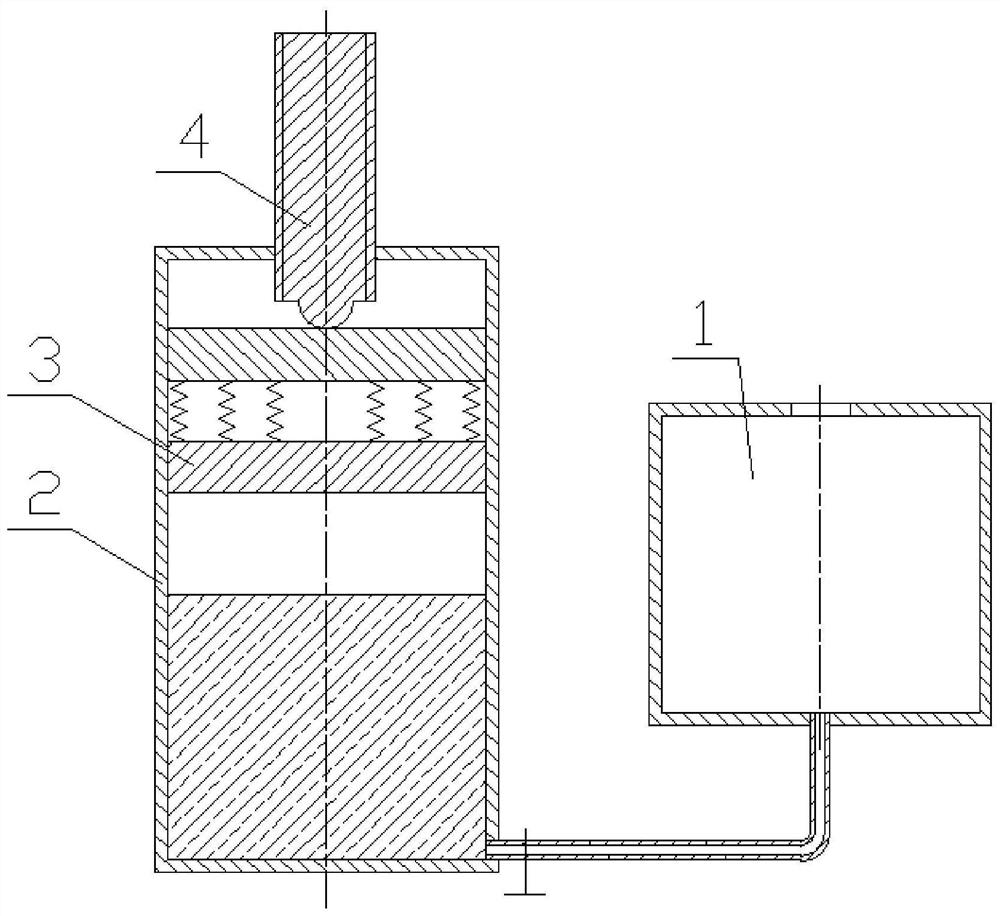

[0038] Such as figure 1 As shown, this embodiment provides a fluid anti-gravity flow device driven by an air cushion. It includes a body detonation warhead 1, and is characterized in that it also includes a pressure vessel 2, a buffer layer 3, and a threaded push rod 4;

[0039] The shape of the body detonation warhead 1 is a first hollow cylinder, the first hollow cylinder of the body detonation warhead 1 is a rotating body, and the first hollow cylinder of the body detonation warhead 1 is from top to bottom It is composed of a first upper circular plate, a first cylindrical body, and a first lower circular plate. The center of the first upper circular plate of the body detonation warhead 1 has a first upper circular hole. The center of the lower end circular plate has a first lower end circular hole;

[0040] The body detonation warhead 1 is the shell of the body detonation warhead, and the inner cavity of the body detonation warhead 1 is filled with a gelled solid-liquid ...

Embodiment 2

[0067] The difference between embodiment 2 and embodiment 1 is:

[0068] In this embodiment, the initial distance between the lower end surface of the third lower cylinder of the buffer layer 3 and the upper liquid surface of the gelled solid-liquid phase mixed fuel in the inner cavity of the pressure vessel 2 is 260 mm;

[0069] In this embodiment, the stiffness coefficient of the third spring of the single buffer layer 3 is 16N / cm;

[0070] In this embodiment, the inner diameter of the second conduit of the pressure vessel 2 is 2.7cm;

[0071] Process ten identical body detonation warhead shells, five of which are filled with solid-liquid mixed fuel by the original method. After filling, CT scanning is performed, and the bubble diameters in the solid-liquid mixed fuel in five shells are found The size of the air bubbles is more than 1cm, and the bubbles of this size have affected the subsequent use of the body detonation warhead; the other five use this plan to fill the sol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Elastic coefficient | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com