Airing bed used for solid fermentation of food

A solid-state fermentation and air-drying technology, which is applied to solid-phase fermentation bioreactors, specific-purpose bioreactor/fermenter, bioreactor/fermenter combinations, etc., can solve the problems of high labor intensity, low production efficiency, Avoid burns and other problems, to avoid the risk of personnel burns, facilitate control, and prevent pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

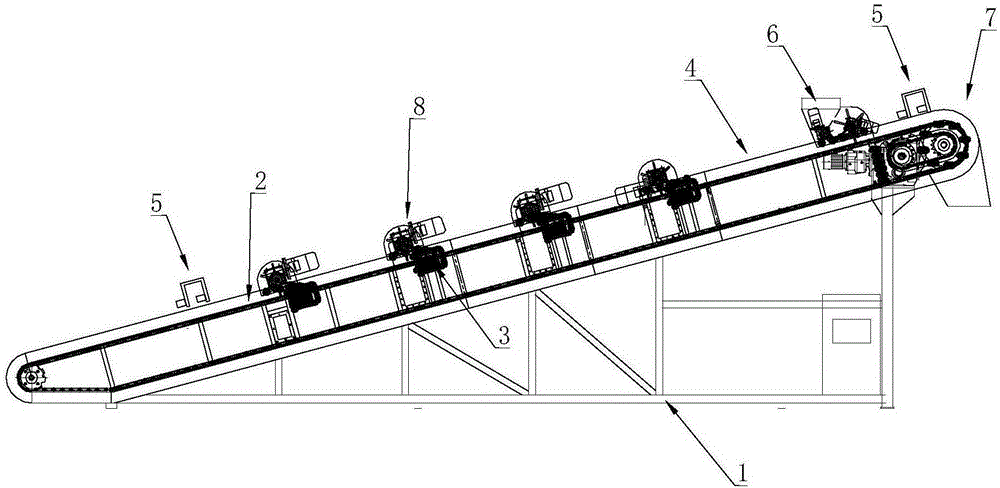

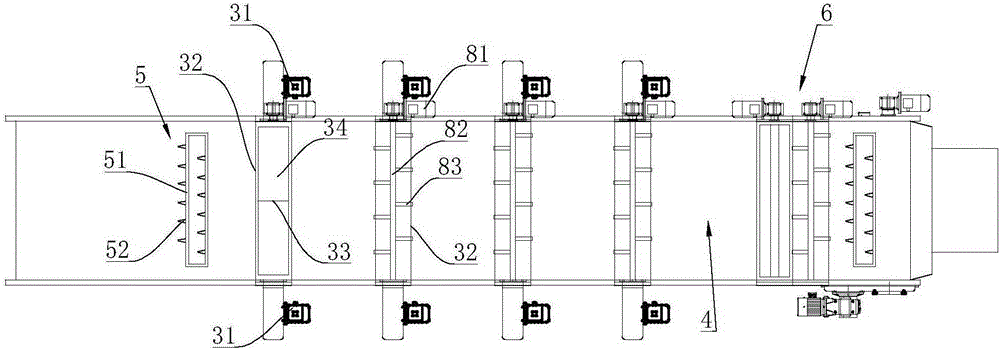

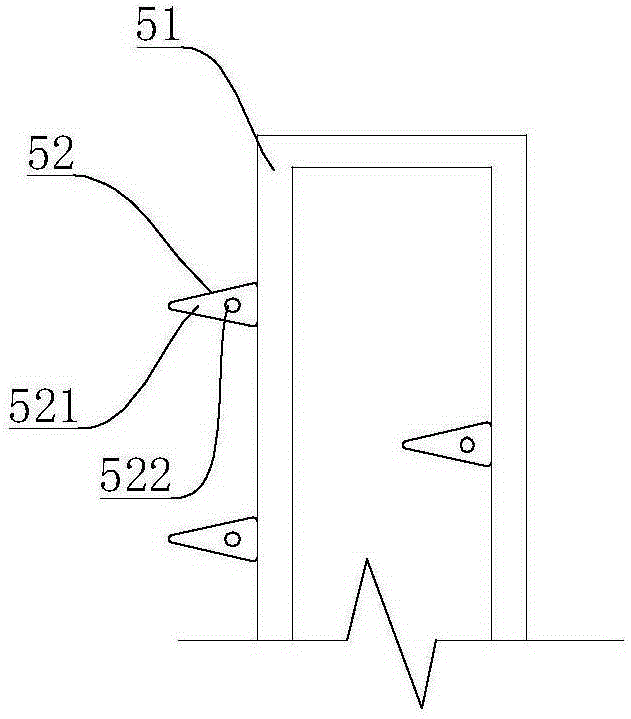

[0024] The drying bed for solid-state fermentation of food includes a support frame 1, and the support frame 1 is provided with a conveyor belt 2 in a closed-loop layout and a drive mechanism 7 for driving the conveyor belt 2 to run, and also includes at least one set of mutually cooperating The air supply system 3 and the material turning system 8, the air supply system 3 includes a fan 31 and an air supply box 32 connected to each other, the air supply box 32 is arranged below the conveying mesh belt 2, and the top of the air supply box 32 is provided with An air outlet 34 , the air outlet 34 points to the conveying mesh belt 2 , and the turning area of the material turning system 8 is located on the upper surface area of the conveying mesh belt 2 directed by the air outlet 34 .

[0025] Drying bed of the present invention can be used for solid-state ferment...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com