Cartridge for a mixer faucet, faucet comprising a cartridge of this type, and thermostatic assembly to be fitted together with this cartridge

A mixer and thermostatic element technology, applied in instruments, valve details, multi-port valves, etc., can solve problems such as increased space requirements, and achieve the effect of avoiding burns

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

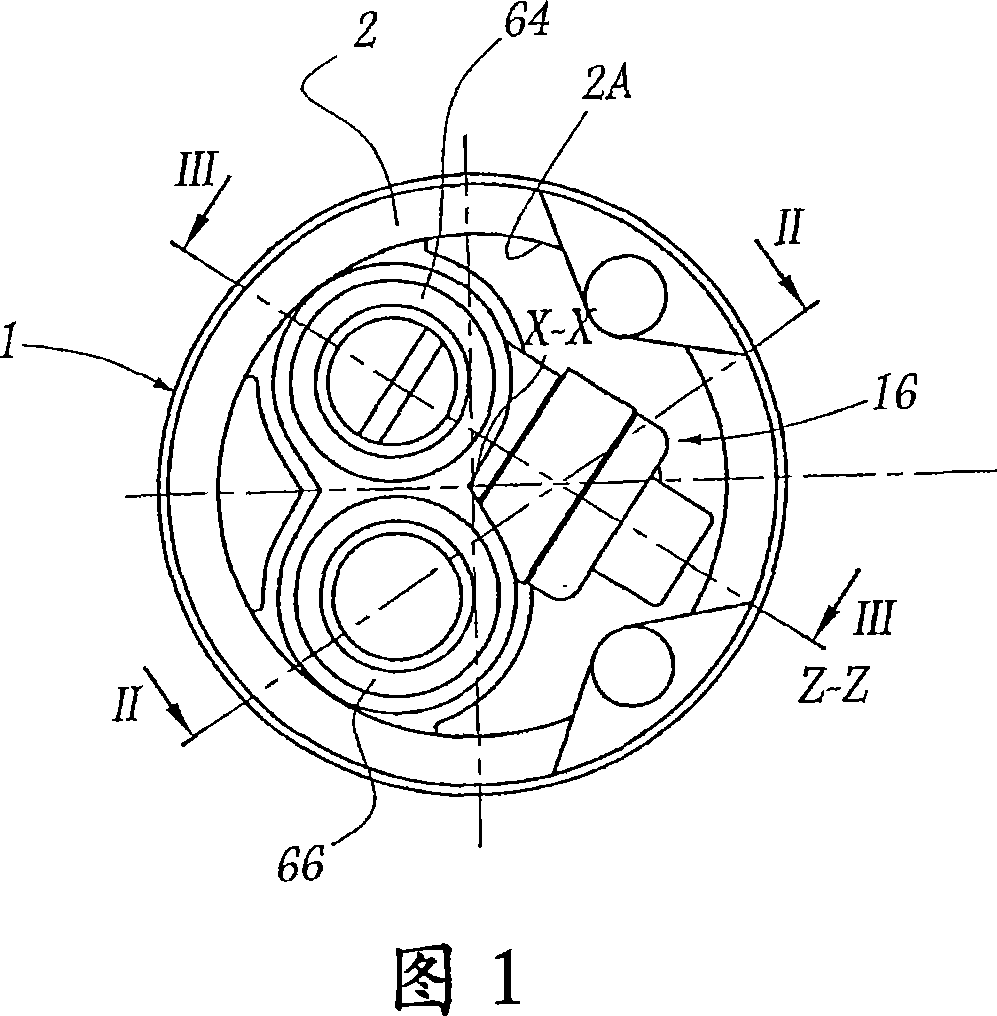

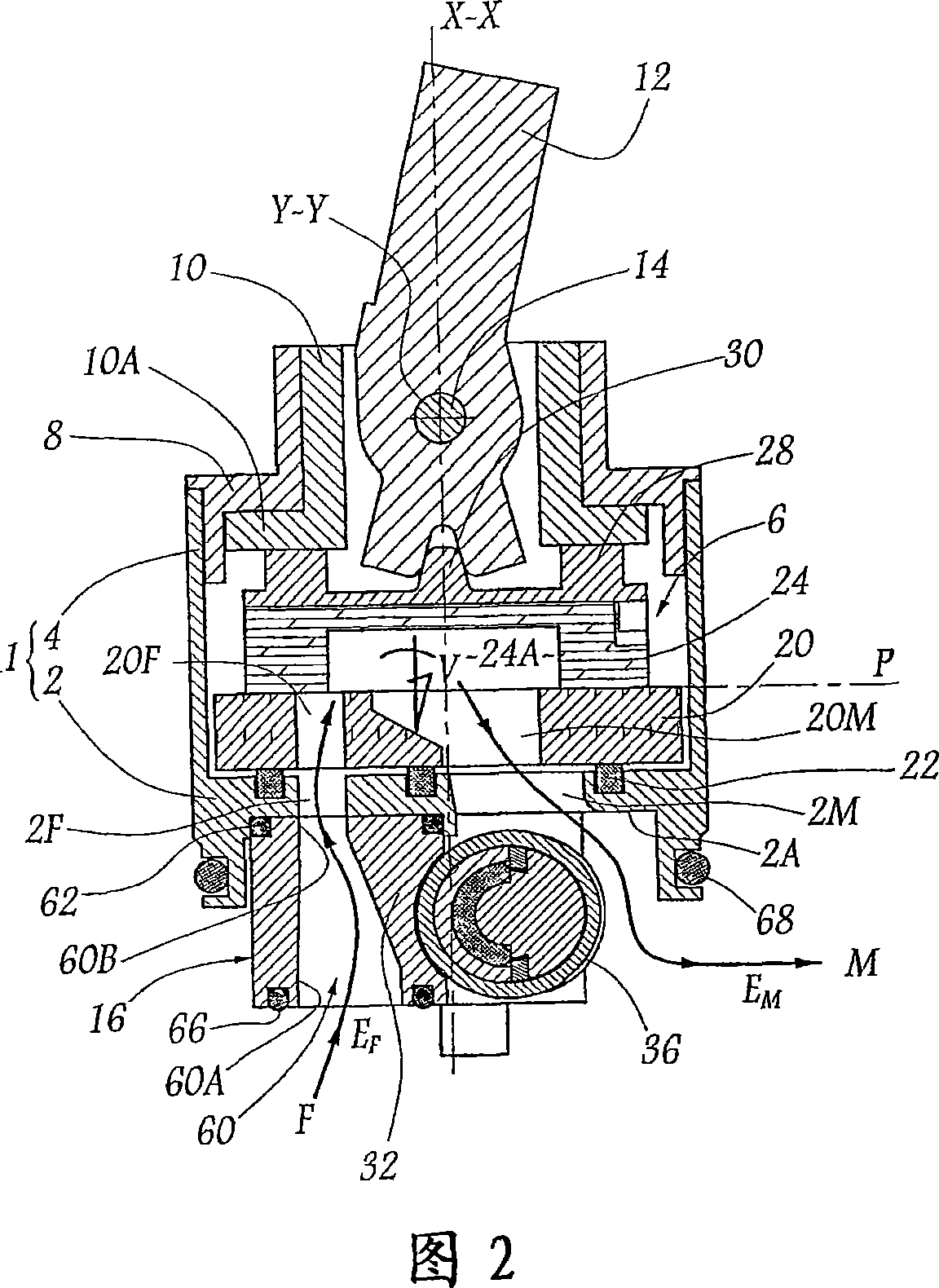

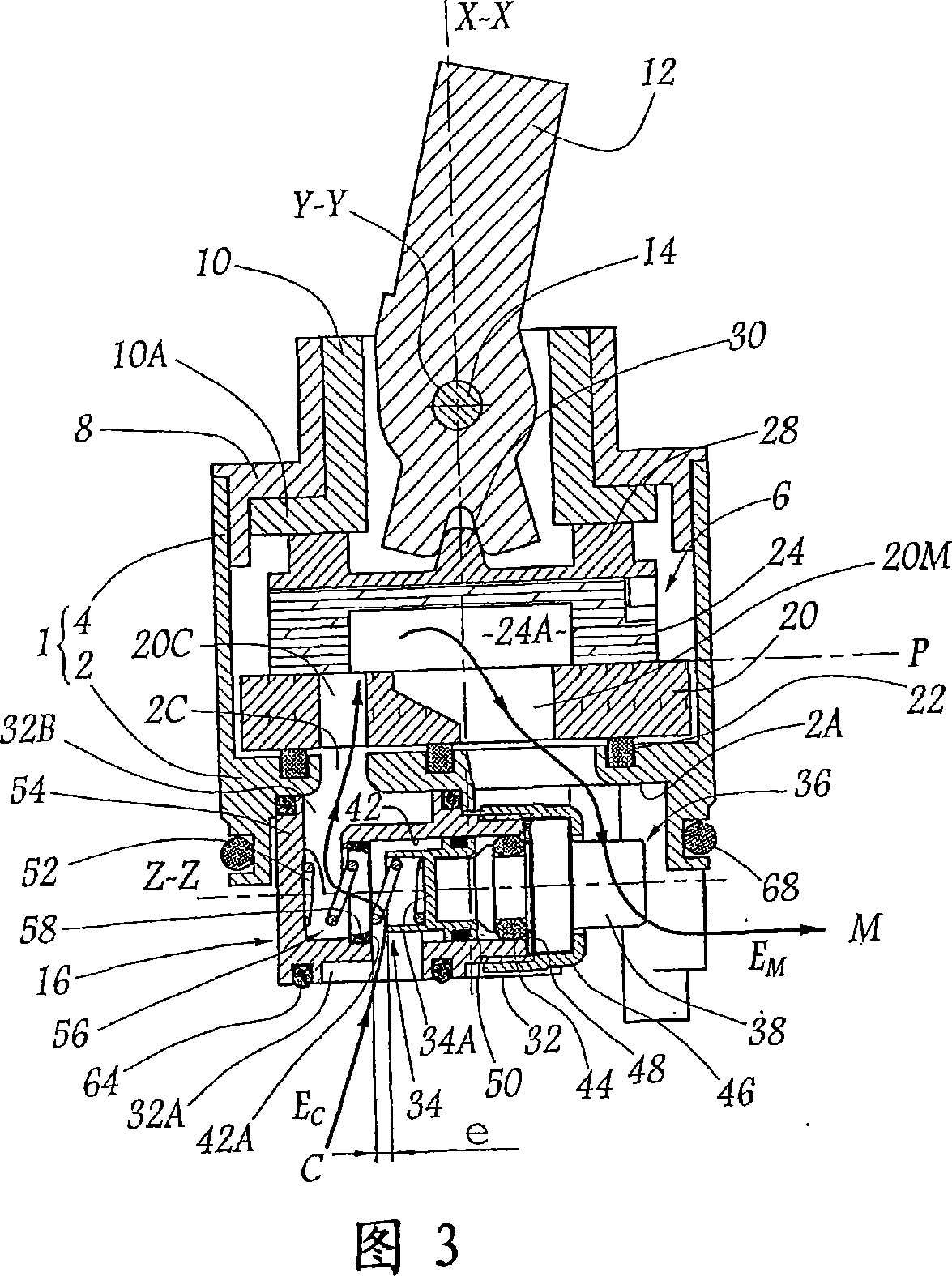

[0032] Figures 1 to 4 show a mixer tap cartridge designed to be fitted to a water supply tap, especially for domestic appliances. For convenience, the later part of this specification defines the term "upper" to refer to the upper part of Fig. 2 to Fig. 4, and the term "lower" to refer to its relative direction.

[0033] The spool comprises a rigid body 1 forming a housing, having a substantially cylindrical outer surface with axis X-X. The housing comprises a lower base 2 above which extends a tubular skirt 4 centered on the axis X-X. This defines an interior space 6 delimited at the bottom by the base 2 and at the top by a cover 8 fixedly attached to the upper end of the skirt 4 , for example by clips. The cover 8 has a central opening in which is guided a sleeve 10 fitted with a collar 10A pressed against the lower face of the cover 8 so that the sleeve 10 can rotate about the axis X-X relative to the fixed cover. This rotation is limited by a stop system (not shown) over...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com