Horizontal type heat conduction oil heating furnace and method thereof

A heat transfer oil and heating furnace technology, applied in the field of boilers, can solve the problems of insufficient combustion, waste of resources, unevenness, etc., and achieve the effects of solving insufficient combustion, improving heating efficiency, and burning thoroughly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

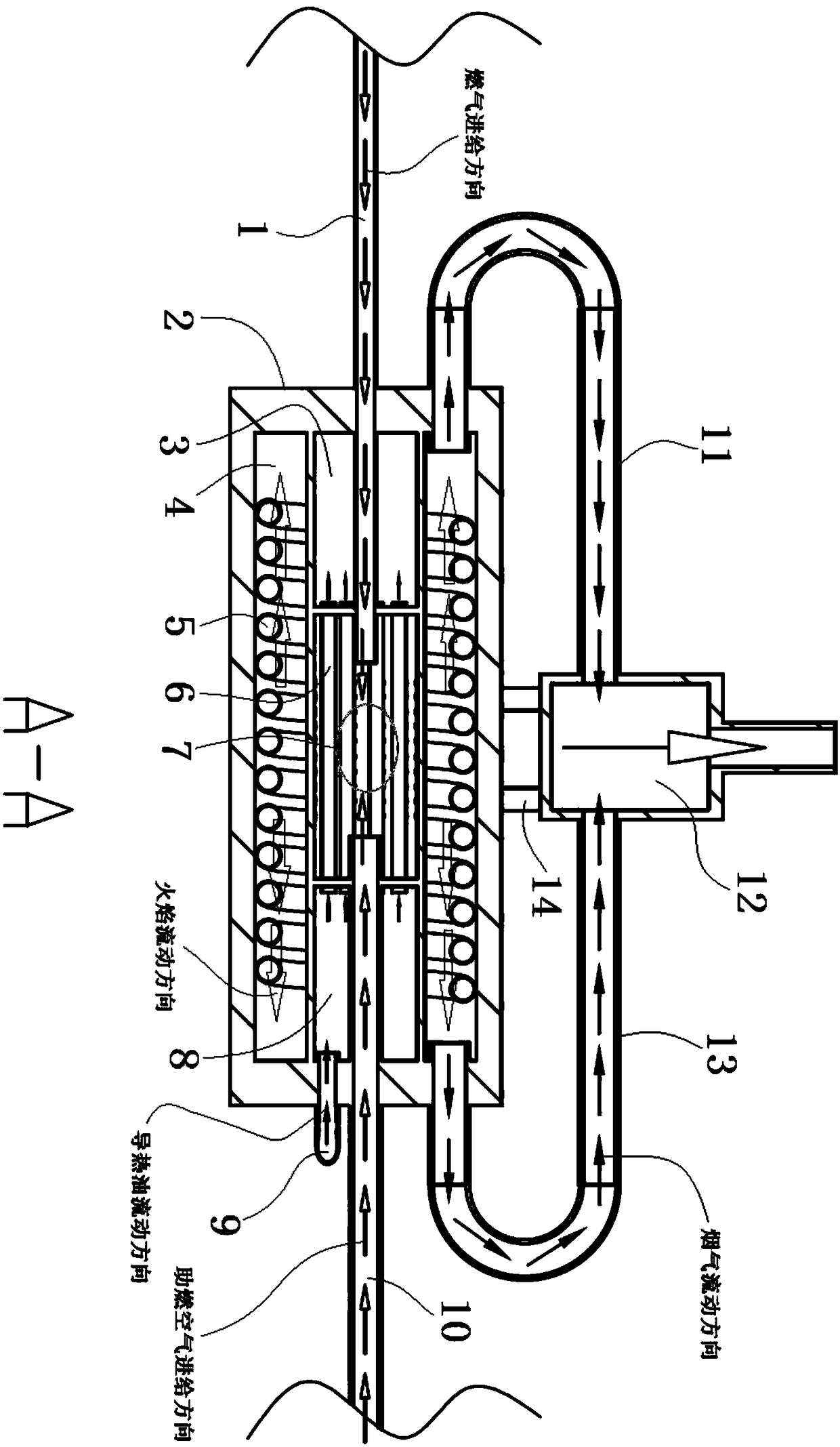

[0028] The present invention will be further described below in conjunction with the accompanying drawings.

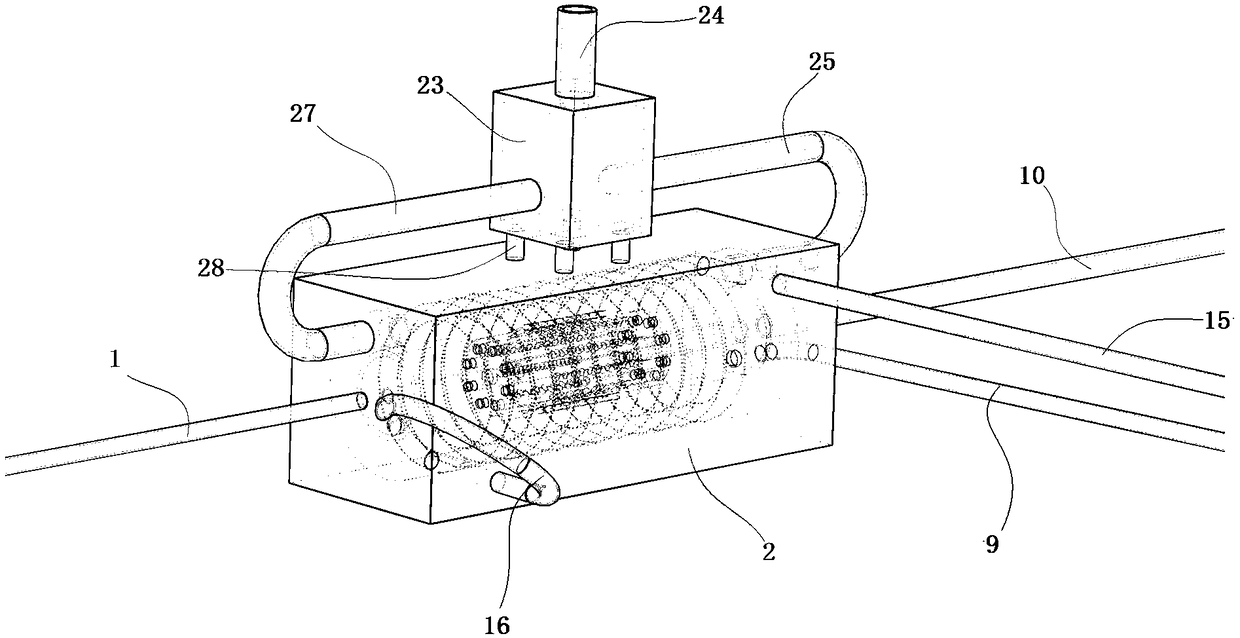

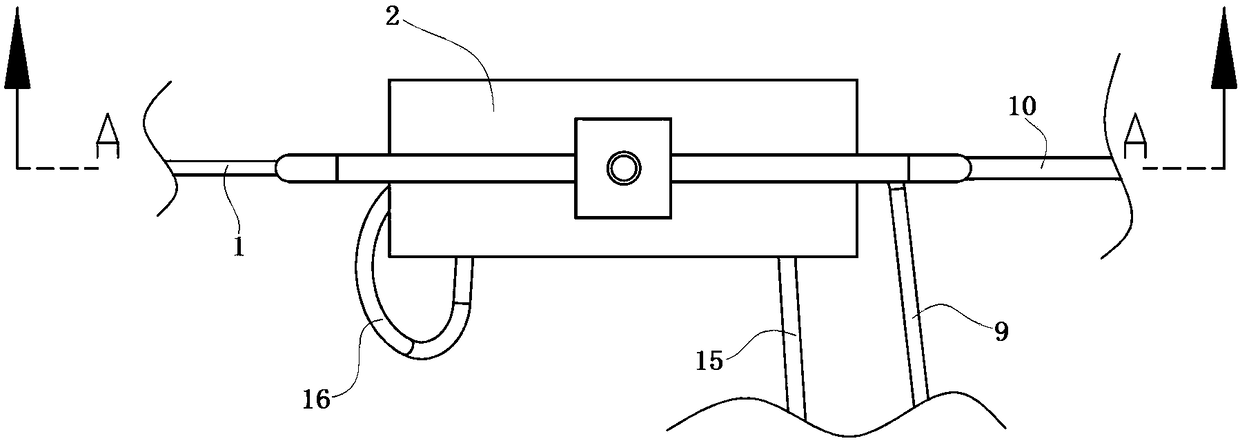

[0029] as attached Figures 1 to 6 A horizontal heat-conducting oil heating furnace shown includes a horizontal furnace body 2, a left smoke guide pipe 27, a right smoke guide pipe 25, a smoke collecting box 23 and a total smoke exhaust pipe 24;

[0030] The smoke collecting box 23 is supported and arranged above the outer wall of the horizontal furnace body 2 by several box supports 28, and the smoke collecting box 23 is centrally arranged on the upper side of the horizontal furnace body 2, and the central setting is to make the The flue gas in the left smoke guide pipe 27 and the right smoke guide pipe 25 are subjected to the same resistance along the course in the process of advancing, which improves the uniformity of the flame expanding to both sides in the secondary combustion chamber 4; the left smoke guide pipe 27 The smoke inlet end leads to the left smoke dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com