Printed circuit board

A printed circuit board, one-sided technology, applied in the direction of printed circuit, printed circuit, printed circuit components, etc., can solve the problems of high product scrap rate, complex heat dissipation process and inconvenient maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

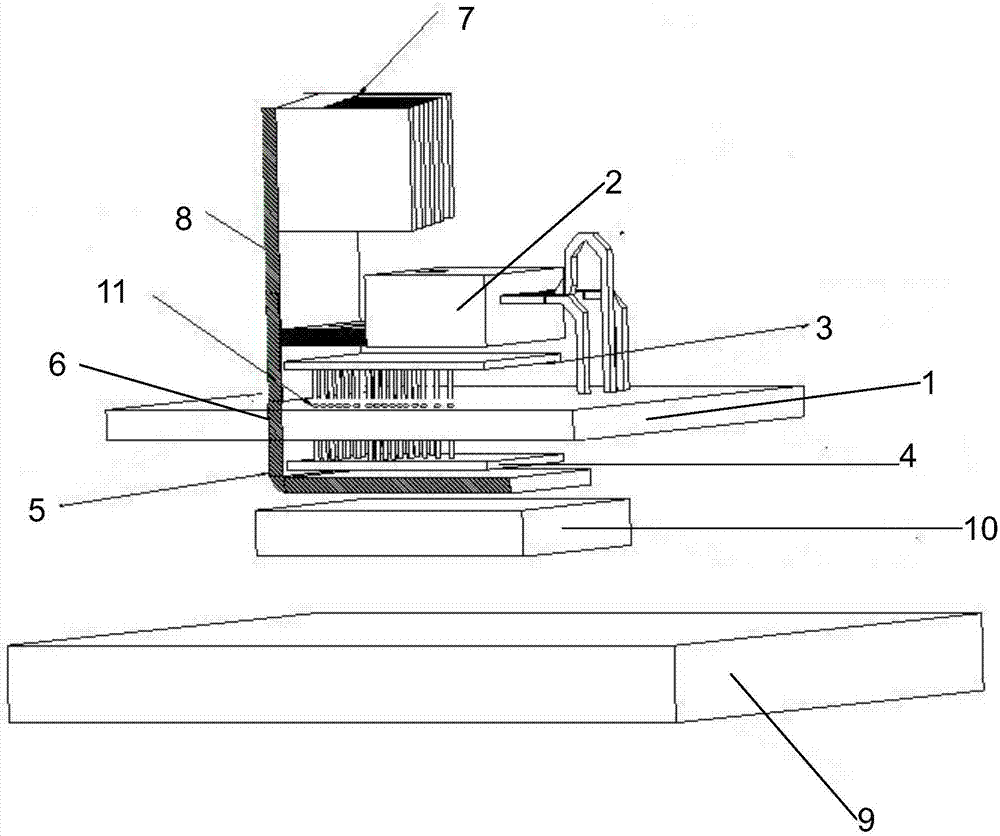

[0017] Such as figure 1 As shown, a printed circuit board includes a PCB board 1 and a power electronic component 2 mounted on one side of the PCB board 1 that generates heat during operation. The power electronic component 2 is such as a transistor, and the area of the PCB board 1 corresponding to the power electronic component 2 A plurality of via holes 11 are provided inside, and a solder paste 3 is provided between the power electronic component 2 and the PCB board 1, and the solder paste 3 penetrates into the other side of the PCB board 1 through the plurality of via holes 11 and forms a solder paste layer on the other side 4. The solder paste layer 4 on the other side of the PCB board 1 is also provided with metal heat sink strips 5 such as copper strips that are in contact with the solder paste layer 4, and the PCB board 1 is also provided with metal heat sink strips 5 insertion holes 6 After bending, the metal heat sink strip 5 passes through the PCB board 1 through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com