High-performance three-dimensional carbon nanotube composite negative electrode material, preparation method therefor and application thereof

A carbon nanotube composite and negative electrode material technology, applied in the direction of nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problem that the volume effect of high-capacity active materials cannot be effectively improved, and the active materials are not uniform Dispersion, low charge transfer efficiency and other issues, to achieve the effect of good industrialization prospects, improved cycle performance, and convenient industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

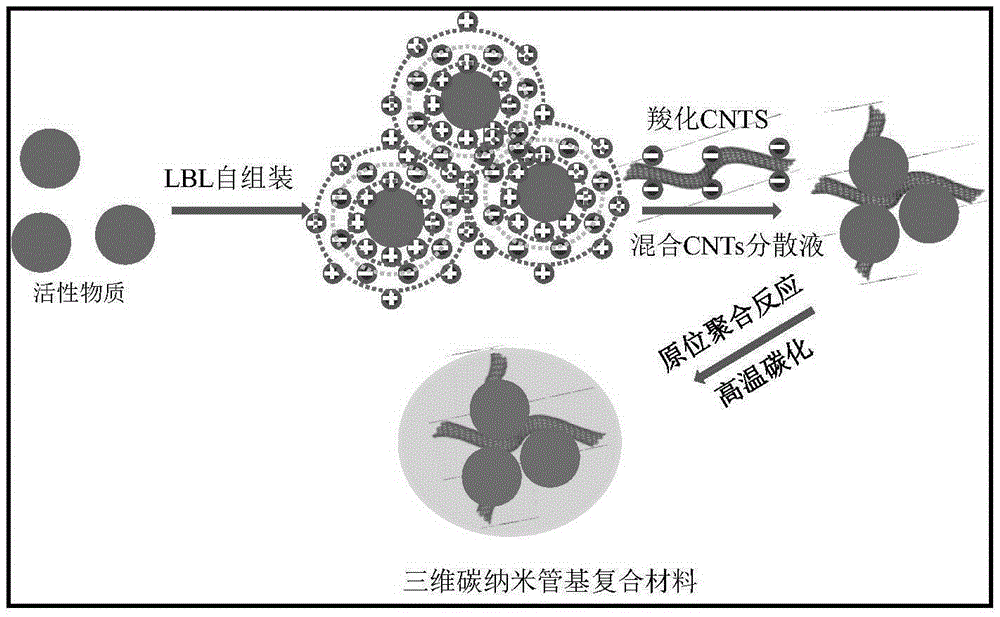

Method used

Image

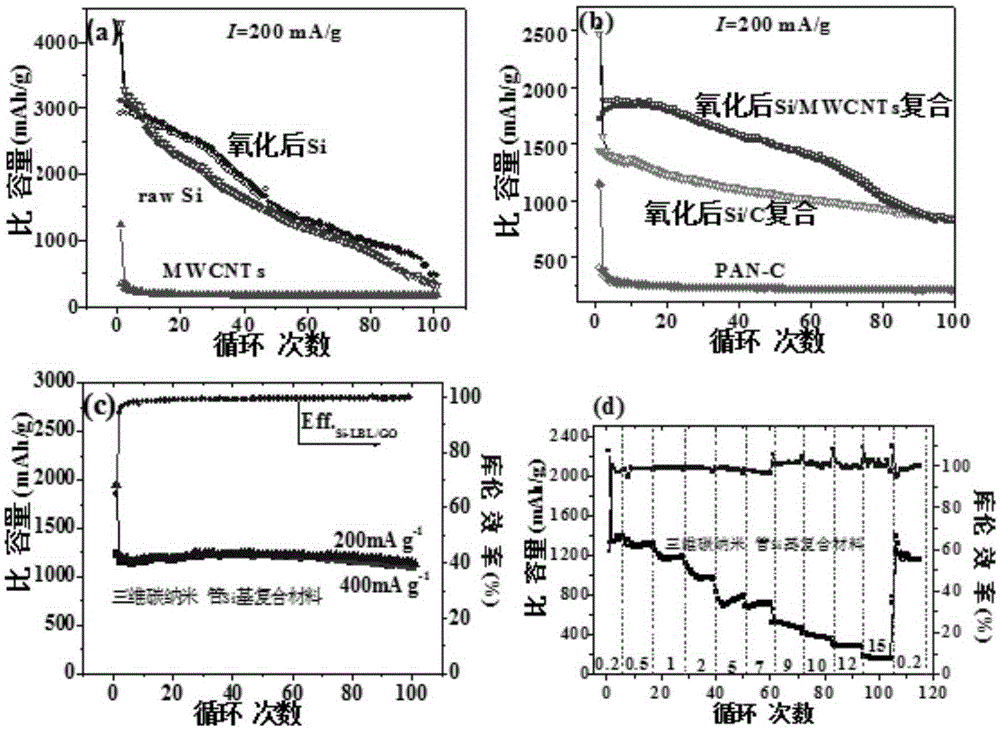

Examples

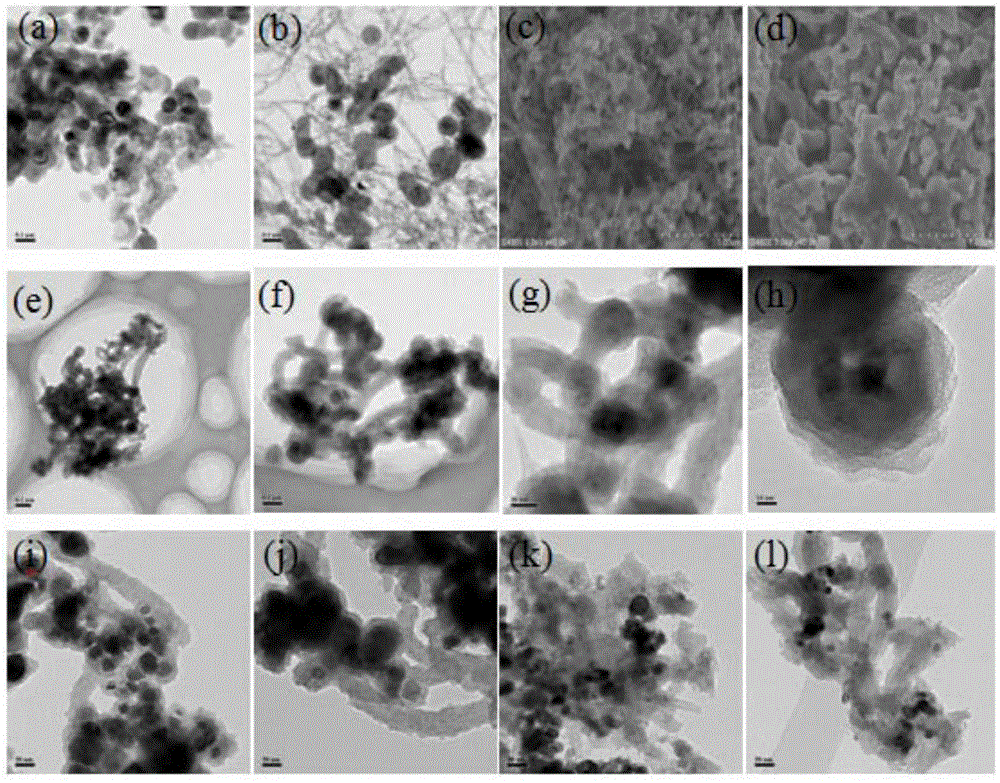

Embodiment 1

[0035] 1) Prepare two 200mL aqueous solutions containing 1wt.%PDDA and 0.2M NaCl, and disperse them uniformly by ultrasonic dispersion for 10 minutes; The surface oxidized Si powder (particle size 100-200nm) was sequentially modified by PDDA-PSS-PDDA, filtered, vacuum-dried at 70°C for 2 hours, ground after drying, and stored with labels;

[0036] 2) Take 0.1g of the above-mentioned modified Si powder and redisperse it in 200mL deionized water, and disperse it ultrasonically for 2 hours to make it evenly dispersed;

[0037] 3) Add 0.02g of carboxylated carbon nanotubes into 200mL of deionized water, and ultrasonically disperse for 2 hours to uniformly disperse the carboxylated carbon nanotubes;

[0038] 4) In the case of high-speed stirring, take the above-mentioned modified Si powder solution and pour it into the dispersion of carboxylated carbon nanotubes, continue to stir for 2 hours and then let it stand, use a separatory funnel to take out the carboxylated carbon nanotube...

Embodiment 2

[0041] 1) Prepare two 200mL aqueous solutions containing 1wt.%PDDA and 0.2M NaCl, and disperse them uniformly by ultrasonic dispersion for 10 minutes; Sintered SnO 2 Nanoparticles (50nm) were sequentially modified by PDDA-PSS-PDDA, filtered, and vacuum-dried at 70°C for 2h. Grind after drying, mark and store;

[0042] 2) Take the above modified SnO 2 Re-disperse 0.2g of nanoparticles in 200mL of deionized water, and ultrasonically disperse for 2 hours to make them uniformly dispersed;

[0043] 3) Add 0.02g of carboxylated carbon nanotubes into 200mL of deionized water, and ultrasonically disperse for 2 hours to uniformly disperse the carboxylated carbon nanotubes;

[0044] 4) In the case of high-speed stirring, take the above modified SnO 2 Pour the nanoparticle solution into the dispersion of carboxylated carbon nanotubes, continue to stir for 2 hours and then let it stand, use a separatory funnel to take out the carboxylated carbon nanotubes / active substance suspension i...

Embodiment 3

[0047] 1) Prepare two 200mL aqueous solutions containing 1wt.%PDDA and 0.2M NaCl, and disperse them uniformly by ultrasonic dispersion for 10 minutes; Sintered ZnFe 2 o 4 Nanoparticles (about 50nm) were sequentially modified by PDDA-PSS-PDDA treatment, filtered, and vacuum-dried at 70°C for 2h. Grind after drying, mark and store;

[0048] 2) Take the above modified 0.1gZnFe 2 o 4 Nanoparticles were redispersed in 200mL deionized water, and ultrasonically dispersed for 2 hours to make them uniformly dispersed;

[0049] 3) Add 0.01g of carboxylated carbon nanotubes into 200mL of deionized water, and ultrasonically disperse for 2 hours to uniformly disperse the carboxylated carbon nanotubes;

[0050] 4) In the case of high-speed stirring, take the above-mentioned modified 0.1gZnFe 2 o 4 Pour the nanoparticle solution into the dispersion of carbon nanotubes, continue to stir for 2 hours, then let it stand still, use a separatory funnel to take out the carbon nanotube / active...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com