Ionic liquid modified carbine, preparation method for same and application thereof

An ionic liquid and modified technology, which is applied in the field of solar cells, can solve the problems of low efficiency, low conductivity, and limited filling rate of sensitized solar cells, and achieve cost reduction and operation process, simple preparation method, and good stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

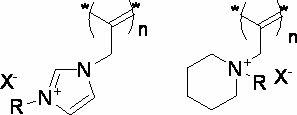

[0022] Embodiment 1: the preparation of piperidine derivatives:

[0023] In a 100 mL round-bottomed flask, mix 8.6 g (0.1 mol) of piperidine with 100 mL of anhydrous tetrahydrofuran, and mix 11.9 g (0.1 mol) of propyne bromide under vigorous stirring. The reaction was stirred for 48 h and filtered to obtain a slightly yellow product. Then the solvent was removed by rotary evaporation, and 9 g of slightly yellow liquid was obtained, yield: 71%.

Embodiment 2

[0024] Example 2: Preparation of imidazole derivatives

[0025] In a 250 mL round-bottomed flask, mix 13.6 g (0.2 mol) imidazole with 100 mL of anhydrous tetrahydrofuran, and mix 24 g (0.2 mol) propyne bromide under vigorous stirring. The reaction was stirred for 48 h and filtered to obtain a slightly yellow product. Then the solvent was removed by rotary evaporation, and 15 g of slightly yellow liquid was obtained, yield: 70%.

Embodiment 3

[0026] Embodiment 3: preparation based on the polyyne of imidazole ionic liquid modification:

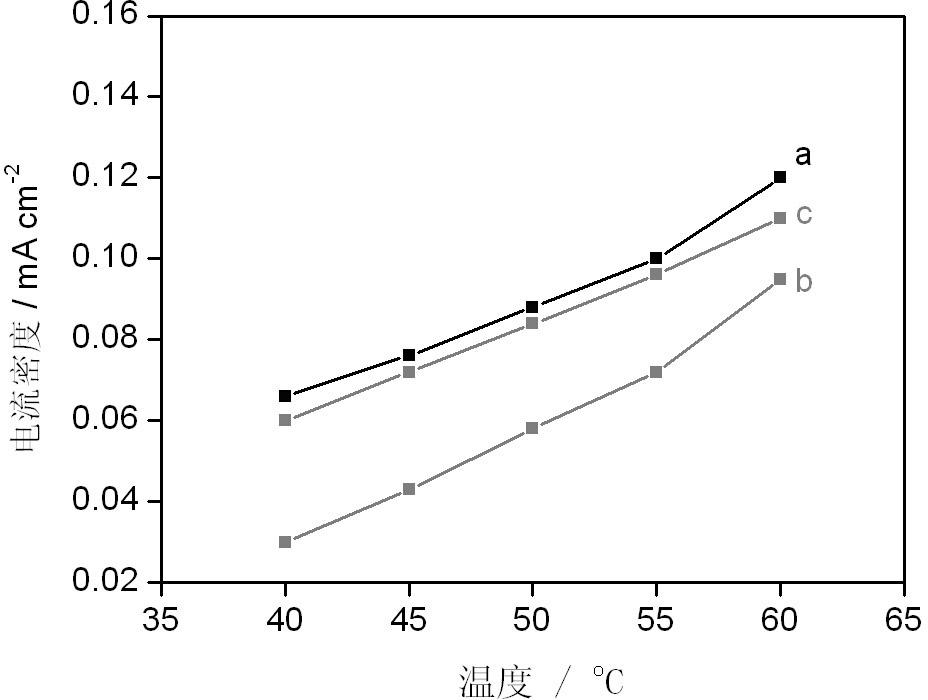

[0027] In a 50 mL round-bottomed flask, mix (2 g, 0.019 mol) imidazole and methyl iodide (4.5 g, 0.03 mol), then add 5-30 mL of methanol, at 0-100 o The reaction was stirred at C for 24-72 h, and filtered to obtain 2.9 g of slightly yellow product. The conductivity is 40 S / cm, ( figure 1 a).

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com