Lithium ion battery cathode and preparation method thereof

A lithium-ion battery and negative electrode technology, applied in the field of lithium-ion battery negative electrode and its preparation, can solve the problems that are not conducive to the lightweight and practical application of batteries, the poor conductivity of MOFs materials, and the reduction of the proportion of active materials, etc., to achieve light weight and conductive performance Good, high specific capacity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

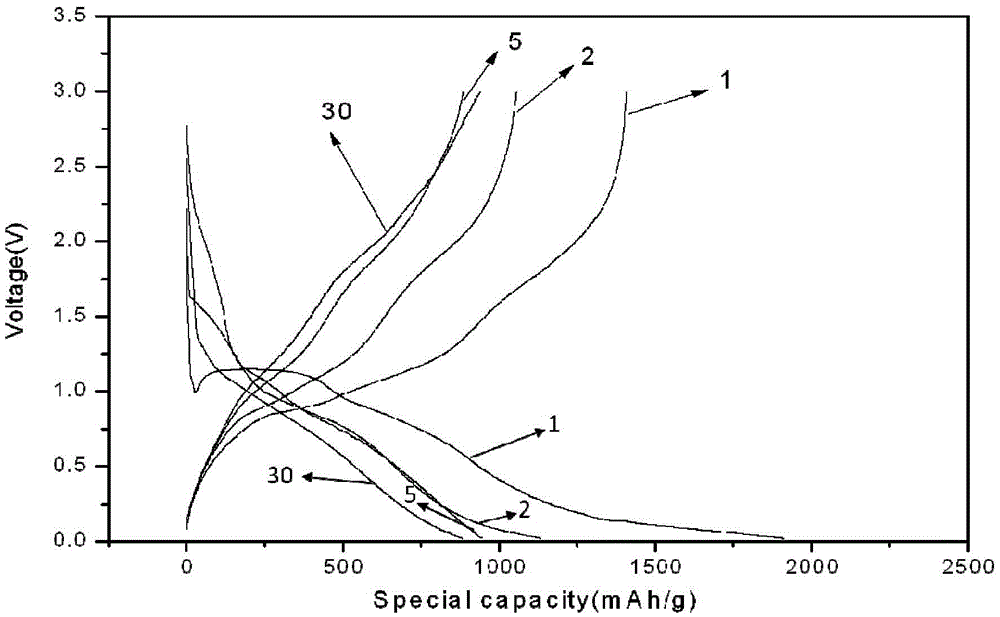

Examples

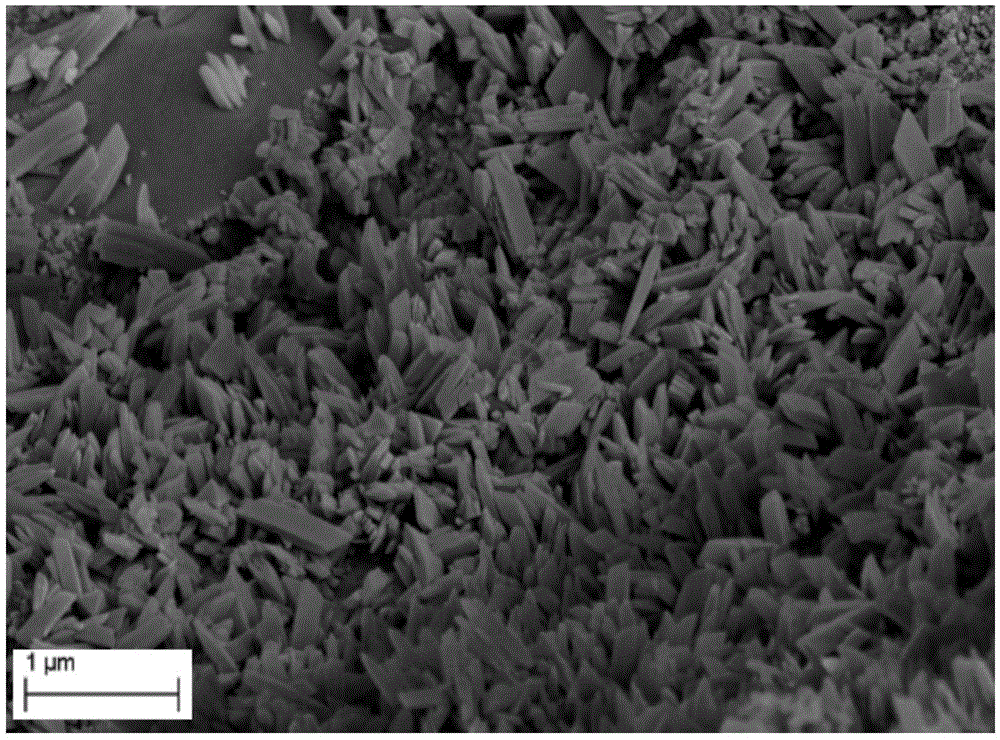

Embodiment 1

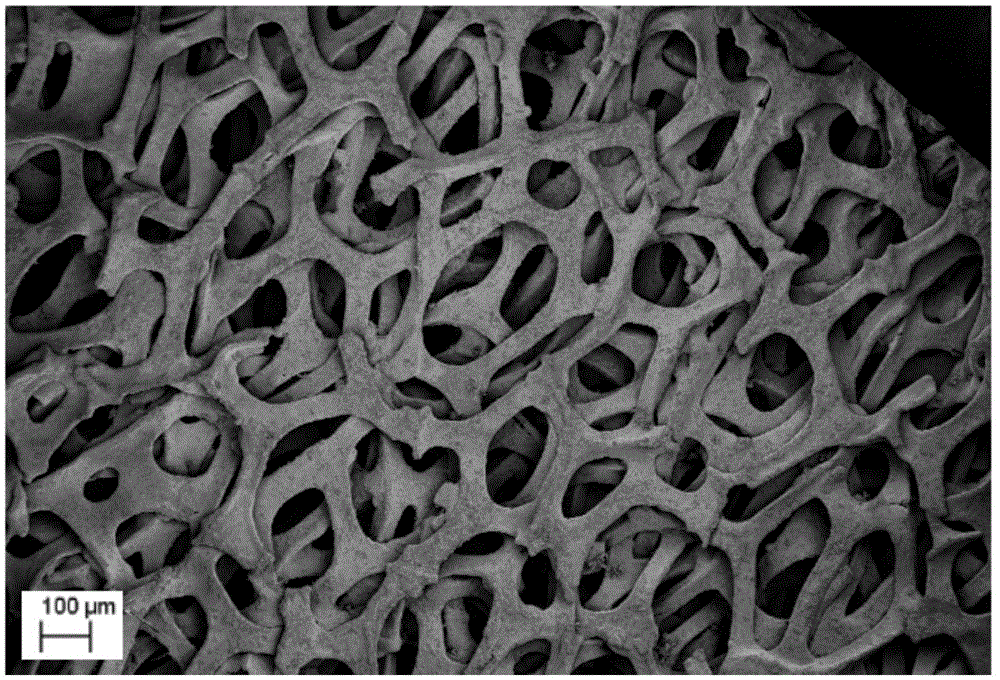

[0031] (1) Pretreatment foamed copper sheet: use a rolling machine to compact the foamed copper substrate with a porosity of 95-98% under a pressure of 10 MPa, then wash the foamed copper sheet with hydrochloric acid, and then wash the foamed copper sheet with absolute ethanol slices, placed in a protective atmosphere, dried at 60°C, and set aside;

[0032] (2) Measure 30ml of N, N-dimethylformamide, 20ml of absolute ethanol and 10ml of distilled water (volume ratio 3:2:1) at room temperature, and record it as solvent; weigh 0.105g of terephthalamide at room temperature Formic acid, 0.375g cobalt nitrate hexahydrate (molar ratio is 1: 2), recorded as the active reaction substance; and the solvent and the active reaction substance were added successively in a stainless steel hydrothermal reaction kettle with polytetrafluoroethylene lining, and stirred for 1h;

[0033] (3) Perforate the pretreated foamed copper sheet, and immerse it in the stainless steel hydrothermal reaction k...

Embodiment 2

[0036] (1) Pretreatment foamed copper sheet: use a rolling machine to compact the foamed copper substrate with a porosity of 95-98% under a pressure of 10 MPa, then wash the foamed copper sheet with hydrochloric acid, and then wash the foamed copper sheet with absolute ethanol slices, placed in a protective atmosphere, dried at 60°C, and set aside;

[0037] (2) Measure 30ml of N,N-dimethylformamide, 10ml of absolute ethanol and 10ml of distilled water (volume ratio 3:1:1) at room temperature, and record it as solvent; weigh 0.105g of terephthalamide at room temperature Formic acid, 0.375g cobalt nitrate hexahydrate (molar ratio is 1: 2), recorded as the active reaction substance; and the solvent and the active reaction substance were added successively in a stainless steel hydrothermal reaction kettle with polytetrafluoroethylene lining, and stirred for 1h;

[0038] (3) Perforate the pretreated foamed copper sheet, and immerse it in the stainless steel hydrothermal reaction ke...

Embodiment 3

[0041] (1) Pretreatment foamed copper sheet: use a rolling machine to compact the foamed copper substrate with a porosity of 95-98% under a pressure of 10 MPa, then wash the foamed copper sheet with hydrochloric acid, and then wash the foamed copper sheet with absolute ethanol slices, placed in a protective atmosphere, dried at 60°C, and set aside;

[0042] (2) Measure 30ml of N, N-dimethylformamide, 20ml of absolute ethanol and 20ml of distilled water (volume ratio 3:2:2) at room temperature, and record it as solvent; weigh 0.105g of terephthalamide at room temperature Formic acid, 0.375g cobalt nitrate hexahydrate (molar ratio is 1: 2), recorded as the active reaction substance; and the solvent and the active reaction substance were added successively in a stainless steel hydrothermal reaction kettle with polytetrafluoroethylene lining, and stirred for 1h;

[0043](3) Perforate the pretreated foamed copper sheet, and immerse it in the stainless steel hydrothermal reaction ke...

PUM

| Property | Measurement | Unit |

|---|---|---|

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com