Method for preparing chloropropylene oxide from biomass glycerol

A technology of epichlorohydrin and biomass, which is applied in the field of preparing epichlorohydrin from biomass glycerol, can solve the problems of high cost of epichlorohydrin preparation and insufficient utilization of raw materials, achieve good industrialization prospects, increase environmental and economic Benefits and less by-products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

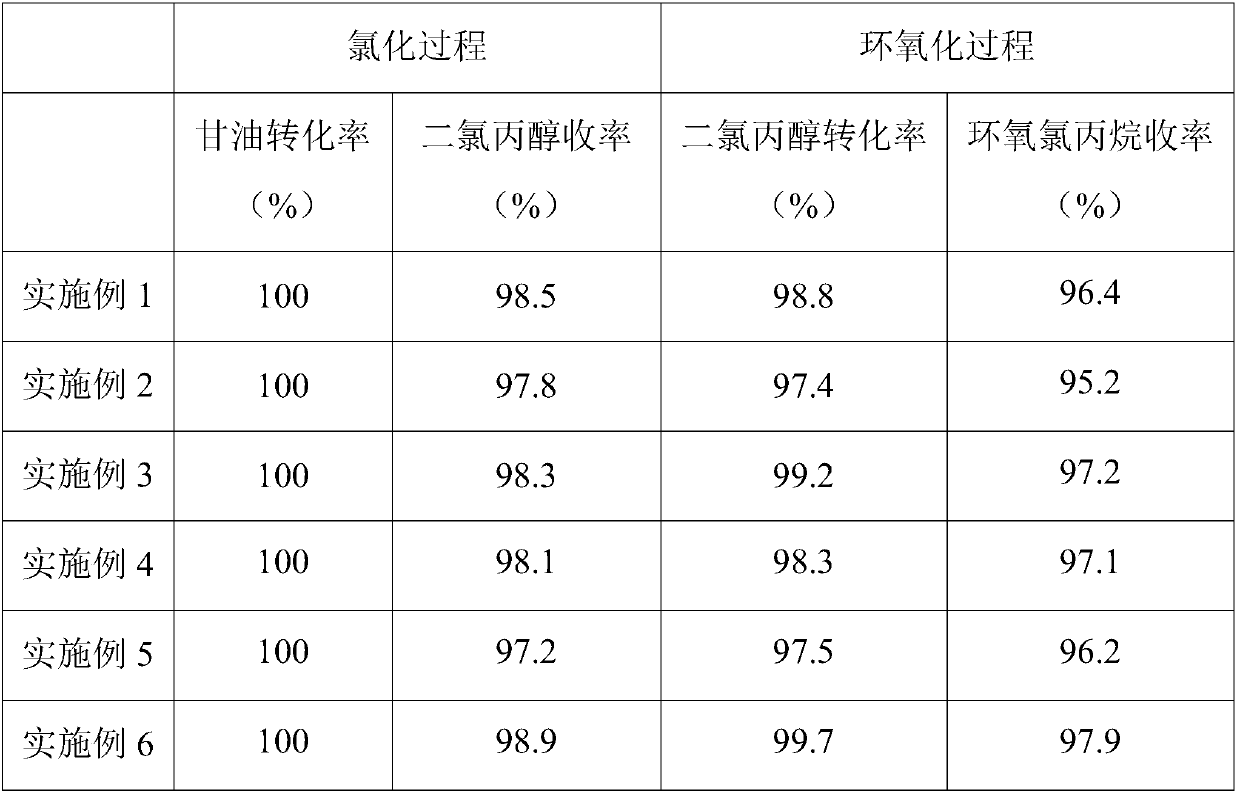

Examples

Embodiment 1

[0023] (1) Mix 1kg of glycerin and 25g of propionic acid, heat to 115°C and keep it warm, pass hydrogen chloride gas into the system at a flow rate of 300mL / min; bubbling for 72 hours, and absorb the tail gas with lye;

[0024] (2) After the material obtained in step (1) is cooled to room temperature, it is transferred to another reactor, heated to 30°C, and then 1.12L of 10mol / L KOH solution is added to continue the reaction for 30min;

[0025] (3) After the reaction in step (2) is completed, the solid is removed by filtration to obtain an epichlorohydrin solution.

Embodiment 2

[0027] (1) Mix 1kg of glycerin and 35g of acetic acid, heat to 140°C and keep it warm, feed hydrogen chloride gas into the system at a flow rate of 300mL / min; bubbling reaction for 48h, tail gas is absorbed with lye;

[0028] (2) After the material obtained in step (1) is cooled to room temperature, it is transferred to another reactor, heated to 30°C, and then 1.27L of 8mol / L KOH solution is added to continue the reaction for 30min;

[0029] (3) After the reaction in step (2) is completed, the solid is removed by filtration to obtain an epichlorohydrin solution.

Embodiment 3

[0031] (1) Mix 1kg of glycerin and 50g of acetic acid and heat it to 90°C and keep it warm, then pass hydrogen chloride gas into the system at a flow rate of 300mL / min; bubbling for 72 hours, and absorb the tail gas with lye;

[0032] (2) After the material obtained in step (1) is cooled to room temperature, it is transferred to another reactor, heated to 60°C, and then 1.09L of 6mol / L KOH solution is added to continue the reaction for 30min;

[0033] (3) After the reaction in step (2) is completed, the solid is removed by filtration to obtain an epichlorohydrin solution.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com