Integrated production method and device for plant fiber mattress

A plant fiber and production device technology, which is applied to mattresses, spring mattresses, stuffed mattresses, etc., can solve problems such as unsatisfactory effects, large stacking labor, and irregular stacking.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

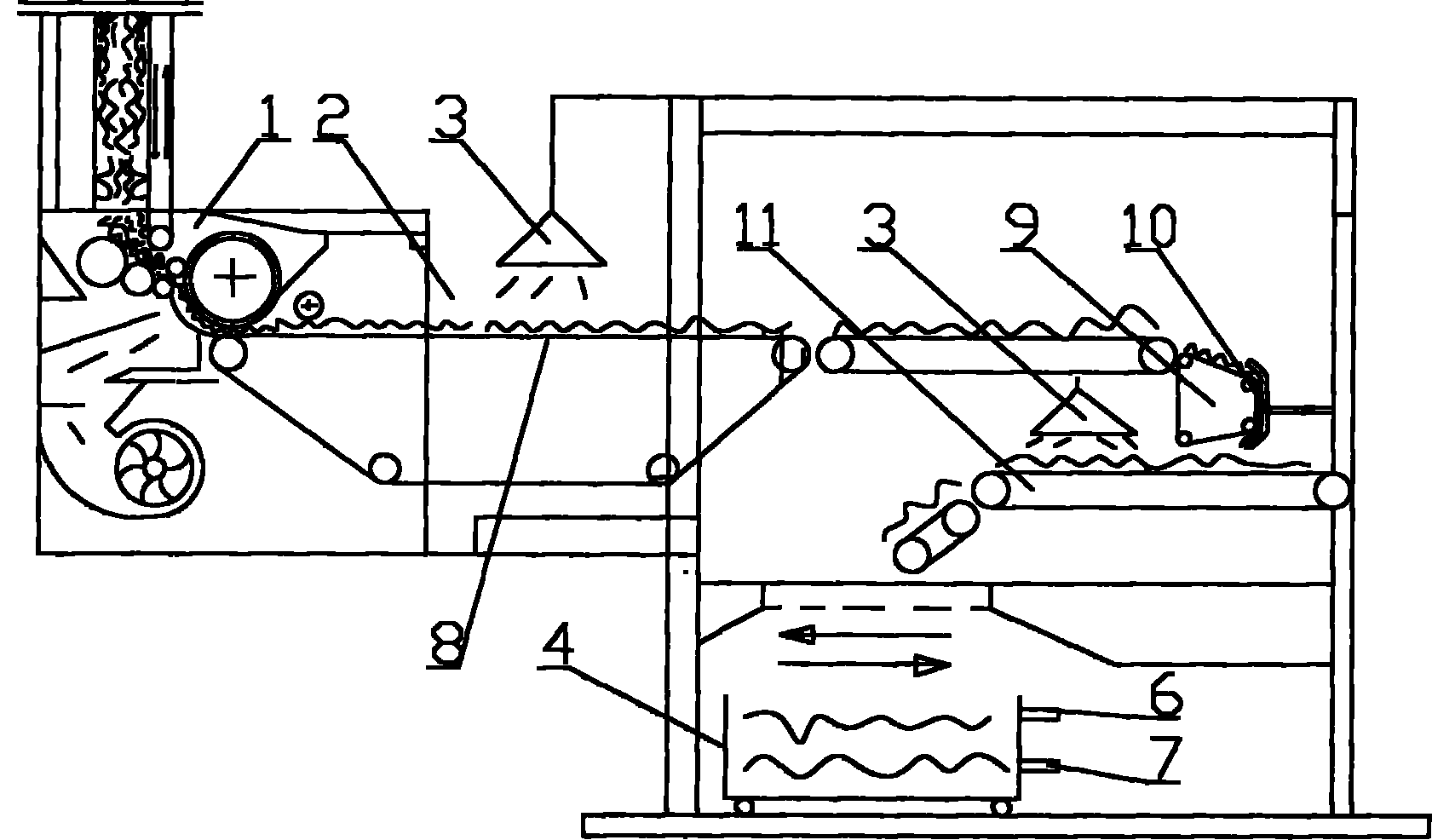

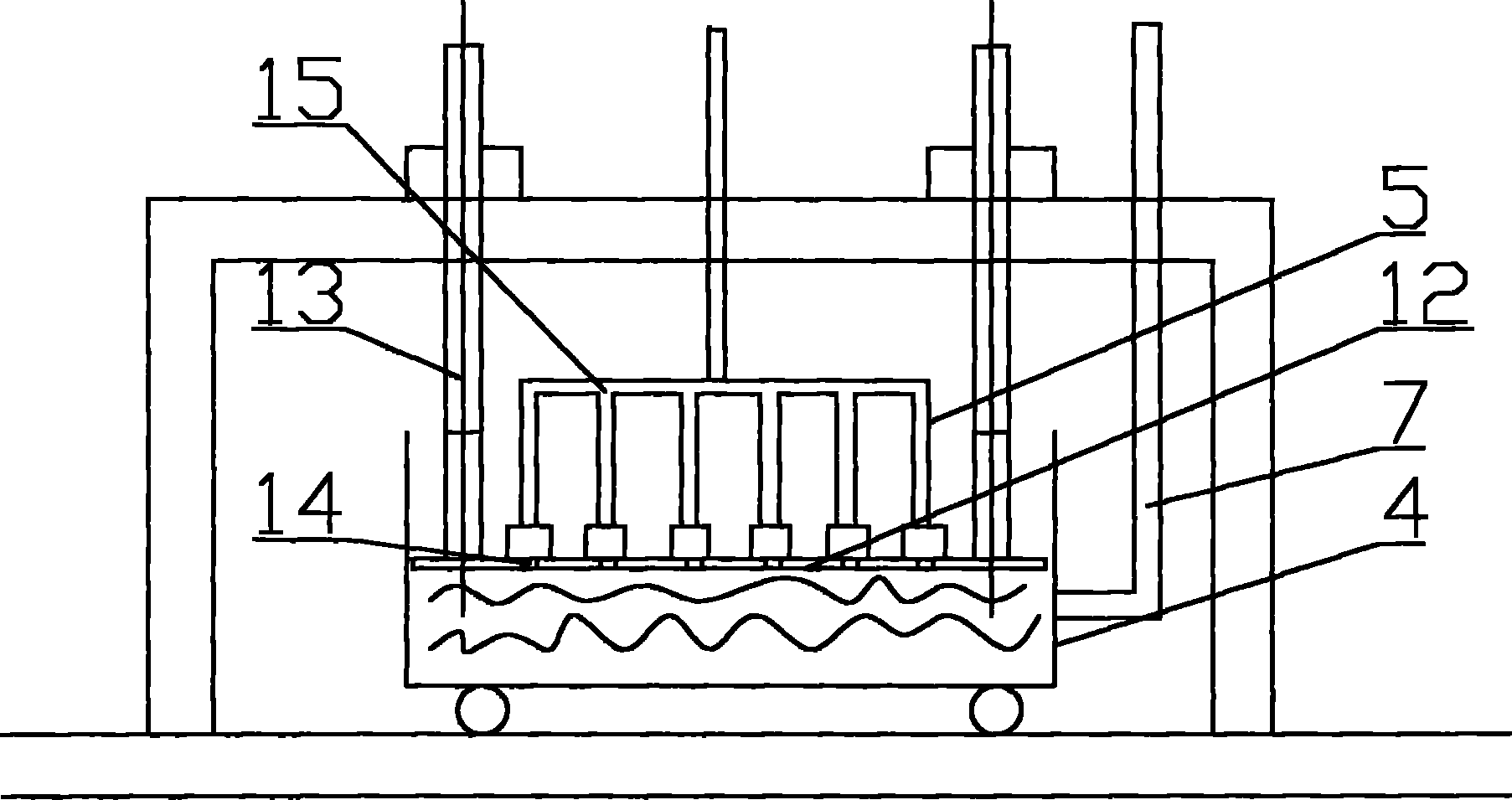

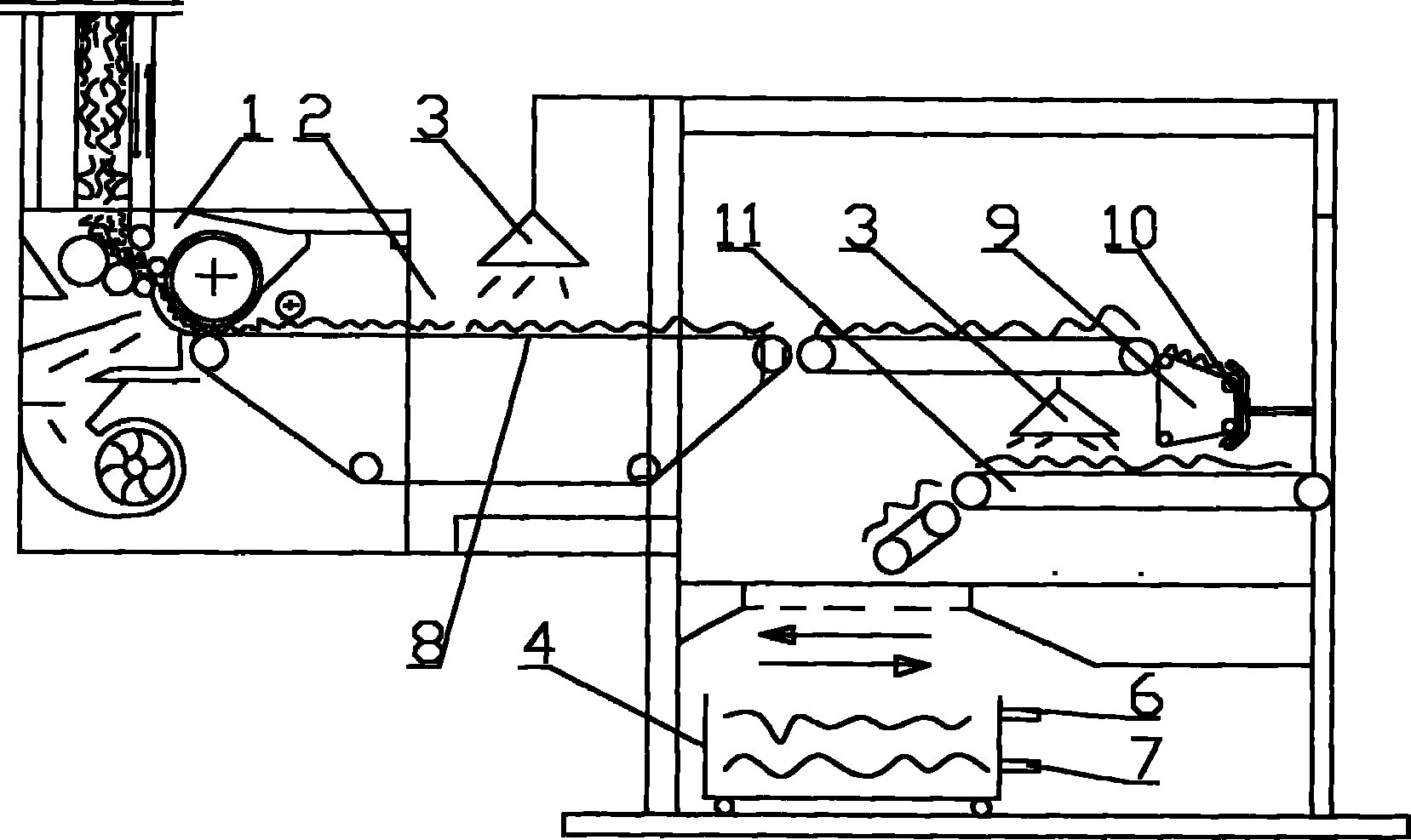

[0015] Embodiments of the present invention: as figure 1 Shown, adopt existing plant fiber elastic sheet material flaking machine 1, flaking machine 1 connects sheet material overturning conveyer belt 2, glue spraying machine 3 is installed on sheet material overturning conveyer belt 2, sheet material overturning conveyer belt 2 will After the elastic sheet is turned over, the glue sprayer 3 sprays glue on both sides, and a mold 4 is installed at the end of the sheet turning conveyor belt 2. The size of the mold 4 is designed according to the size of the mattress, and a heat press 5 is installed above the mold 4. Hot air inlet 6 and outlet 7 are arranged on 4, and the sheets in the mold 4 are hot-pressed and shaped.

[0016] The used sheet turning conveyor belt 2 includes the first conveyor belt 8, the first conveyor belt 8 is connected to the turning pulley 9 and the turning baffle 10, the elastic sheet is turned over 180 degrees, and the second conveyor belt 11 is connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com