Automatic stacking control system of bulk cargo wharf stacker

A technology of control system and stacker, which is applied in the field of automatic stacking control system of stacker, can solve problems that are not conducive to the occupational health and safety of workers, achieve good economic and practical value, good effect, and improve the effect of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

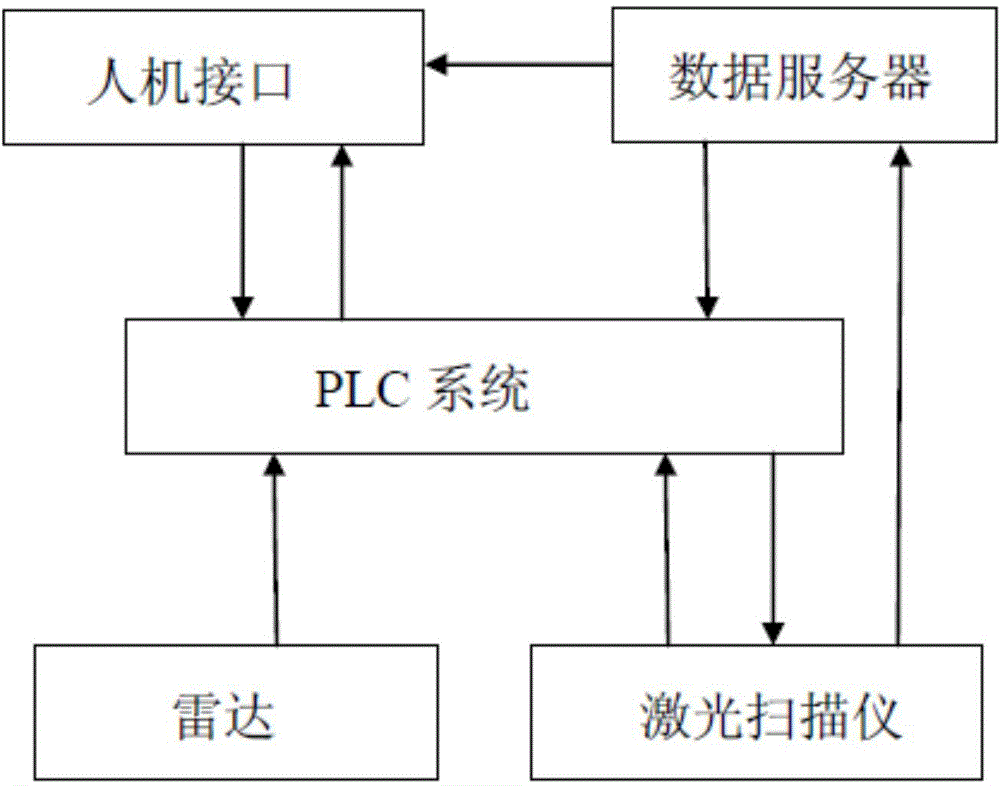

[0010] like figure 1 As shown, the automatic stacking control system of the stacker at the bulk cargo terminal includes a PLC system, a radar, a laser scanner, a data server, and a man-machine interface. The PLC system is bidirectionally connected to the man-machine interface, and the output of the radar It is connected with the PLC system, the laser scanner is bidirectionally connected with the PLC system, the output of the laser scanner is connected with the data server, and the output of the data server is respectively connected with the man-machine interface and the PLC system connection.

[0011] The laser scanner is connected with the PLC system through OPC.

[0012] The radar is installed on the front end of the cantilever of the stacker to measure the height of the coal stacking type in the yard; the laser scanner is used to scan the information dat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com