A preparation process of polycarbonate-ether polyol and oil-resistant and low-temperature resistant polyurethane elastomer

A polyether polyol and preparation technology, applied in the preparation of polycarbonate-ether polyol, oil-resistant and low-temperature resistant polyurethane elastomer field, can solve the problems of poor low-temperature resistance and oil resistance, improve low-temperature resistance and ensure regularity properties, excellent reactivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

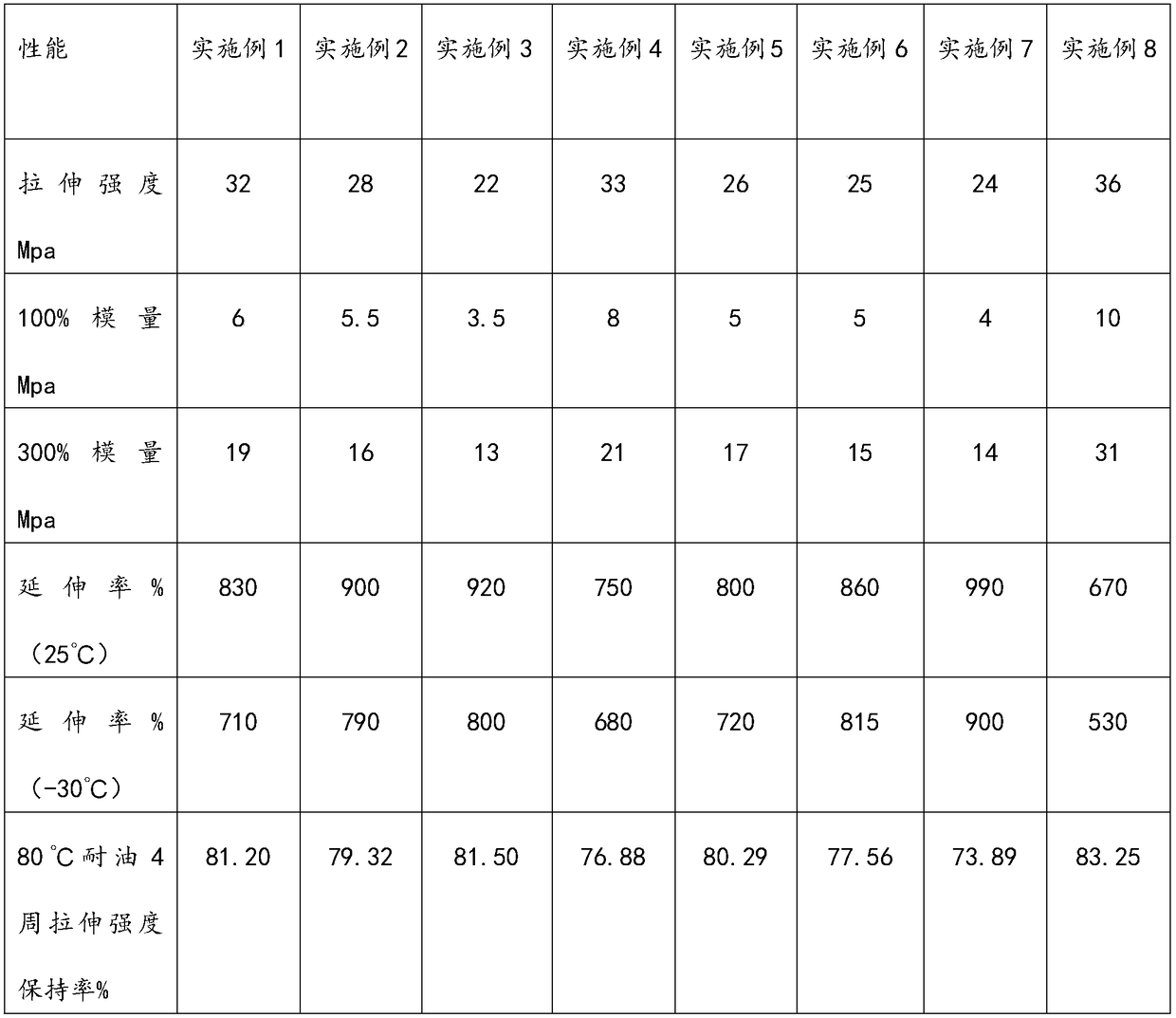

Examples

Embodiment 1

[0030] A kind of preparation technology of polycarbonate-ether polyol, comprises the steps:

[0031] 1) Add 315.78g of 1,4-butanediol, 525.60g of PTMG-600 and 1.01g of catalyst tetrabutyl titanate into a reactor equipped with a rectification device, and then start stirring and raise the temperature to At 90°C, use a peristaltic pump to continuously add a total of 493.36 g of dimethyl carbonate to the reaction system, and keep the temperature at 90°C for 1 hour during the continuous addition process;

[0032] 2) Then raise the temperature to 180°C within 4 hours, during which the temperature at the top of the rectification column is controlled not to exceed 65°C. After constant temperature reaction for 1 hour, add 3.15g of 1,4-butanediol to the reaction system, and stir for 1 hour;

[0033] 3) Afterwards, carry out de-end grouping and hydroxyl end-capping. When no distillate in the reaction system is evaporated, start the vacuum device, evacuate to -0.09Mpa, reduce the temperat...

Embodiment 2

[0039] A kind of preparation technology of polycarbonate-ether polyol, comprises the steps:

[0040] 1) Add 248.68g of 1,4-butanediol, 709.56g of PTMG-600 and 1.25g of catalyst tetrabutyl titanate into the reactor equipped with a rectification device, and then start stirring and raise the temperature to At 90°C, use a peristaltic pump to continuously add a total of 443.71 g of dimethyl carbonate to the reaction system, and keep the temperature at 90°C for 1 hour during the continuous addition process;

[0041] 2) Then raise the temperature to 160°C within 4 hours, during which the temperature at the top of the rectification column is controlled not to exceed 65°C. After constant temperature reaction for 1 hour, add 2.48g of 1,4-butanediol to the reaction system, and stir for 1 hour;

[0042] 3) Afterwards, carry out de-end grouping and hydroxyl end-capping. When no distillate in the reaction system is evaporated, start the vacuum device, evacuate to -0.09Mpa, reduce the temper...

Embodiment 3

[0048] A kind of preparation technology of polycarbonate-ether polyol, comprises the steps:

[0049] 1) Add 204.97g of 1,5-pentanediol, 787.20g of PEG-600 and 1.26g of catalyst tetrabutyl titanate into a reactor equipped with a rectification device, and then start stirring and heat up to 90°C; use a peristaltic pump to continuously add a total of 369.52 g of dimethyl carbonate to the reaction system, and control the temperature at 90°C for 1 hour during the continuous addition process;

[0050] 2) Then raise the temperature to 180°C within 4 hours, during which the temperature at the top of the rectification column is controlled not to exceed 65°C. After constant temperature reaction for 1 hour, add 1.80g of 1,4-butanediol to the reaction system, and stir for 1 hour;

[0051] 3) Finally, carry out de-end grouping and hydroxyl end-capping. When there is no distillate in the reaction system, start the vacuum device, evacuate to -0.085Mpa, reduce the temperature and discharge the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com